Thwaites Mach 443 Assembly instructions

Tier II: Issue 4

T0473

Mach 443, Mach 444, Mach 474,

Mach 475

Operator’s

Instruction

Manual

3 - 4.5 Tonne (Hydrostatic)

Mach 475 - 3 Tonne Hi-SwivelMach 474 - 3.5 Tonne Powerswivel

Introduction

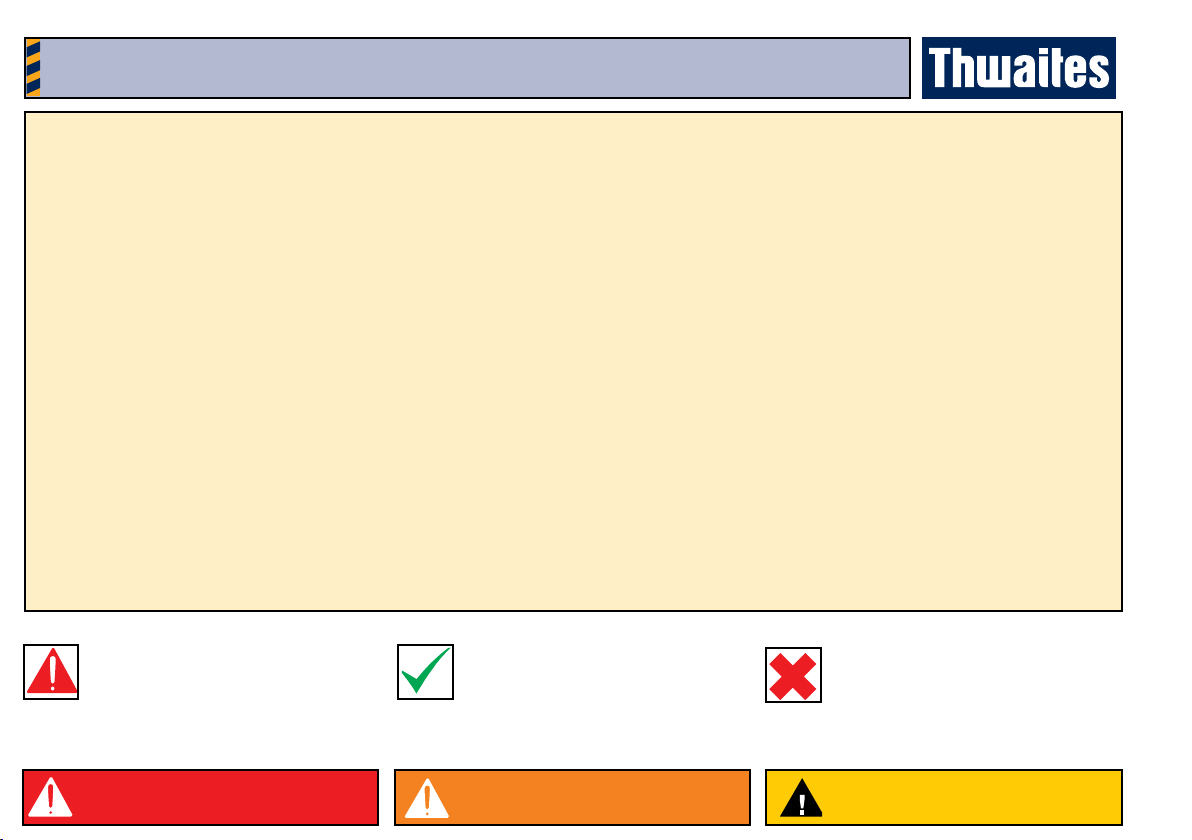

Safety Symbols

• Attention!

• Be alert!

• Your safety is involved!

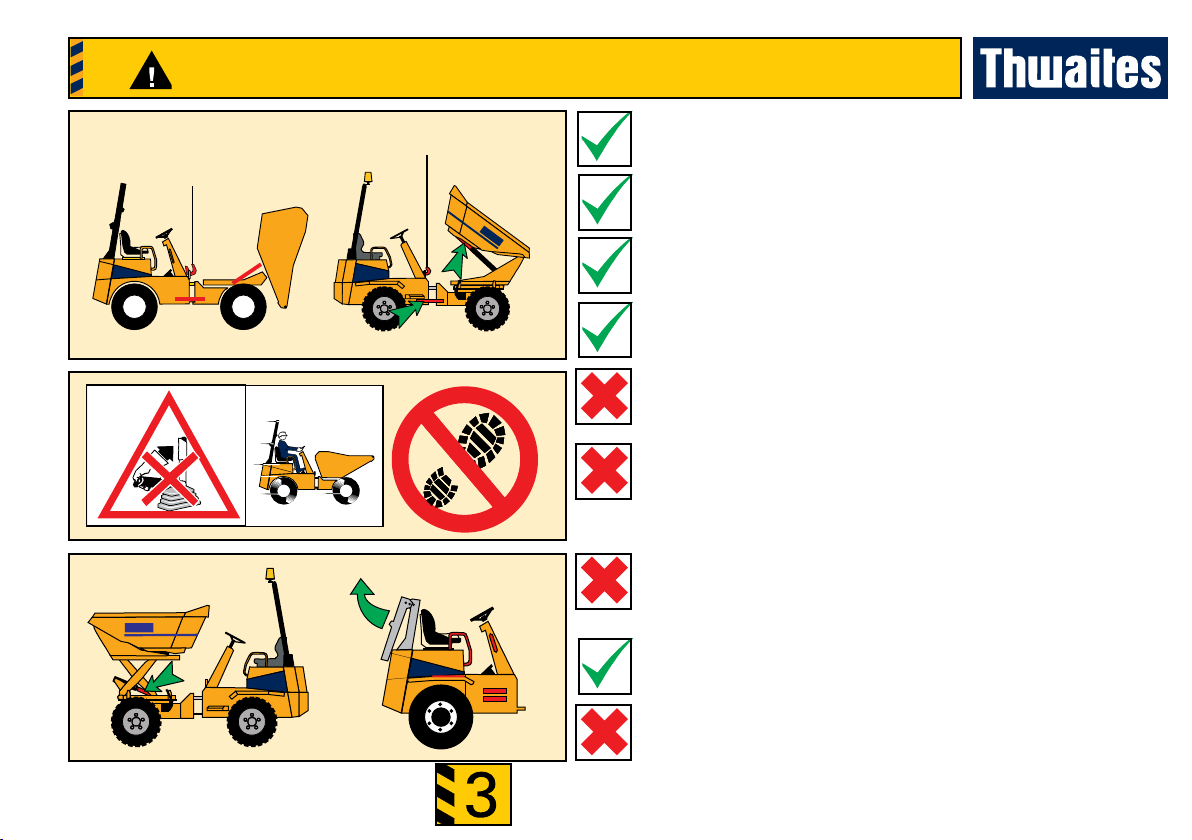

• Correct action • Incorrect action/procedure

which should NOT be carried

out

CAUTION

WARNING

DANGER

Signal words:

Signal words are used on the machine and within this manual to identify levels of hazard seriousness:

Thwaites Limited puts Safety First

It is the policy of Thwaites Limited to promote safety in the

operation of its machines and to create a general awareness of

site safety and safe working practices for the operators of its

machines.

This Operator’s Instruction Manual is intended for both new

and experienced machine operators. It should remain with

the machine at all times. All operators should be aware of its

location and contents.

It is important that all operators are fully trained and familiar

with the machine and that they have read and understood the

information contained within this book before they attempt

to operate in the site conditions for which the machine was

designed.

This book details practices and operations which Thwaites

Limited recommends. DO NOT operate this machine in ways

other than those detailed within this book.

This machine is designed for customary construction site

operations, and the transportation of bulk materials commonly

carried on such sites; that is their ‘intended use’. Under certain

controlled conditions the dumper may be used for towing

wheeled loads.

Due to the varied nature of the operation of site dumpers and

the absence of an agreed test standard, any gures quoted

by Thwaites in relation to vibration values and exposure are

for reference purposes only. It is the responsibility of the

employer to assess vibration exposure based on the actual site

conditions, and operating practices, at the point of use.

Hand Arm Vibration - The daily exposure Action/Limit Values

of between 2.5 - 5.0m/s2 (A8) are unlikely to be exceeded in an

eight-hour reference period.

Whole Body Vibration - The daily exposure can only be

accurately determined at the point of use. This exposure must

be managed in respect of the Action/Limit Values of 0.5 and

1.15 m/s2 (A8) respectively.

Employers should not rely solely on published vibration

gures when undertaking risk assessments. Depending on the

site conditions, cycle times may need to be adjusted in order

to reduce operator exposure levels.

Vibration values based on typical duty cycles are available

on request from Thwaites. These may be used for reference

purposes only.

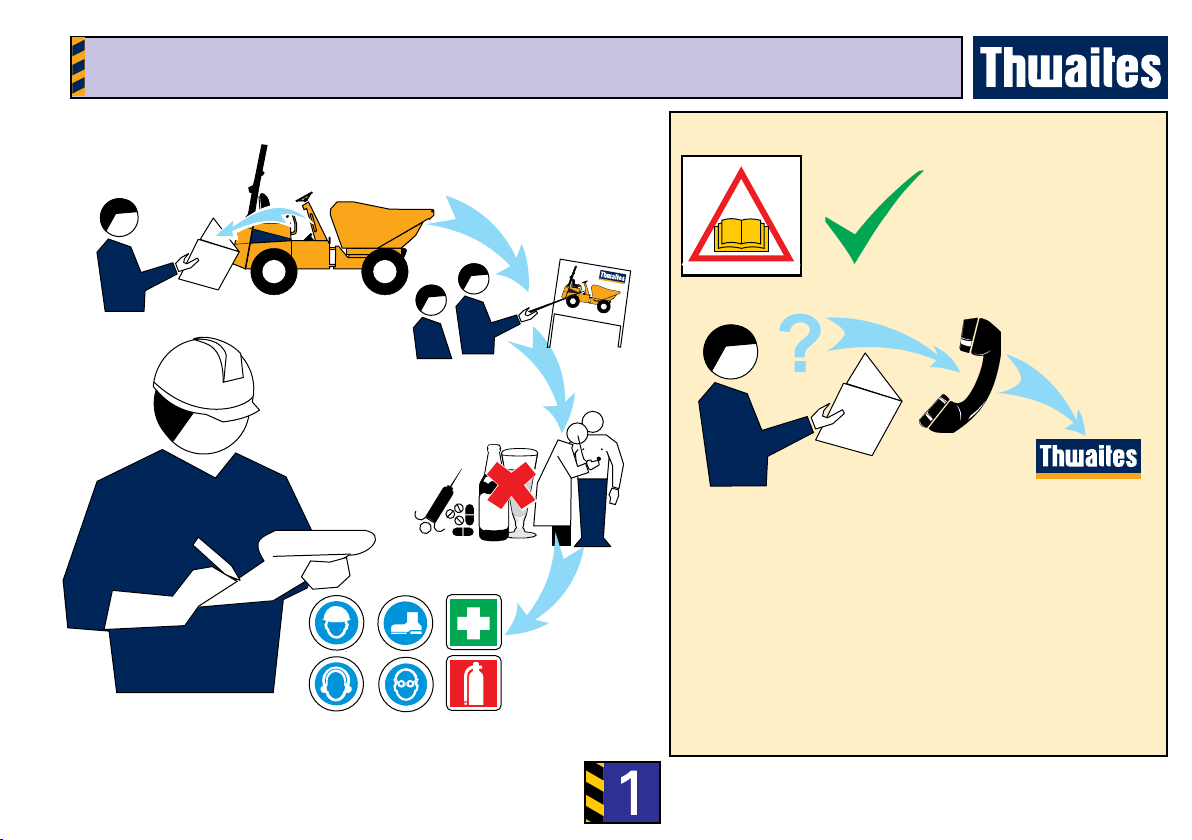

1

Complete Checks in Section Before Starting The Engine

1 Contact your Thwaites dealer in case of further

questions

2 Learn to operate this machine

3 Ensure you are t to operate

4 Wear correct safety clothing and ensure that safety

equipment is available

Before operating this machine

Distributor

Read this manual

1

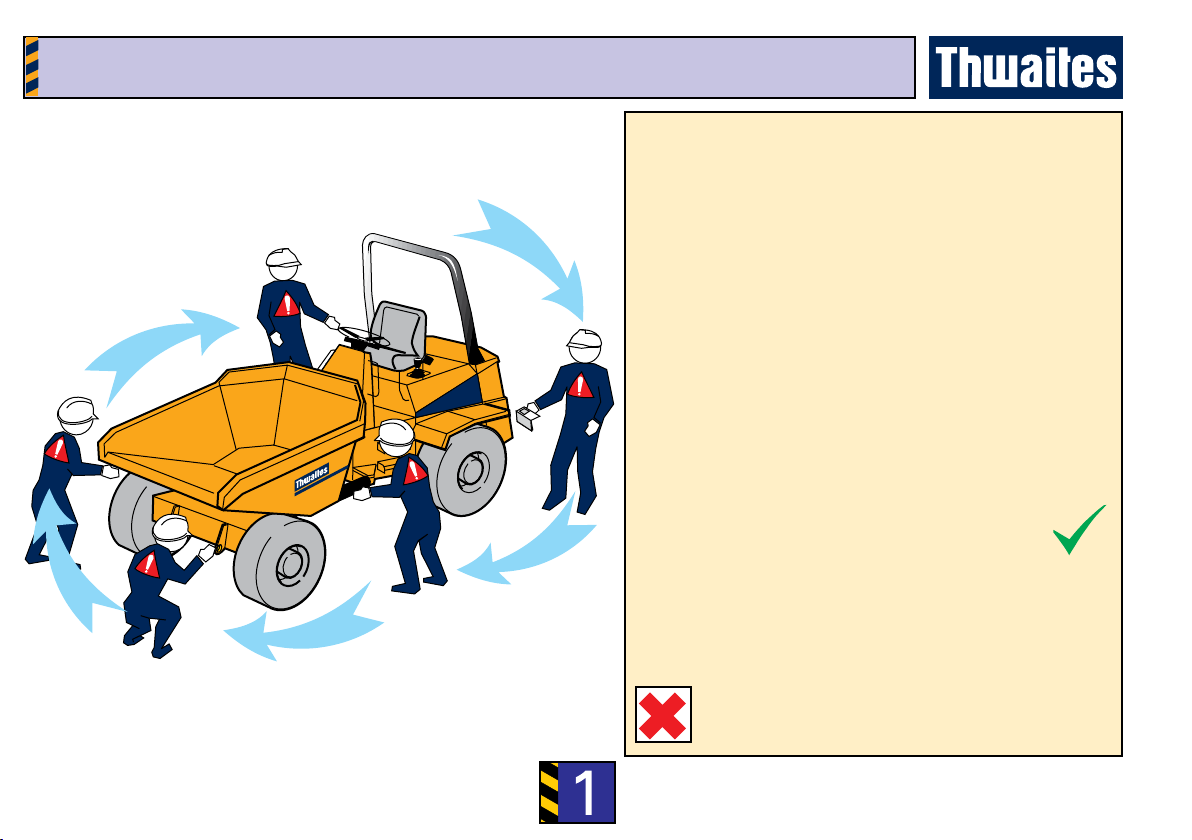

Complete Checks in Section Before Starting The Engine

Walk Around The Machine

Visually check the machine

1 Are the chassis lock and the skip lock disengaged?

2 Are the controls, crush zone and hydraulic rams

clean, and clear of debris?

3 Is the Roll-Over Protective frame (ROPS frame)

secure, fully upright and undamaged?

4 Is the seatbelt anchorage secure and serviceable?

5 Are the covers and mudguards secure?

6 Are the hoses free from uid leaks?

7 Are all safety decals legible?

8 Are the tyres free of cuts or splits?

9 Are all bolts tight and in position?

10 Are the steering wheel and the steering column

undamaged?

11 Have the daily maintenance tasks been

performed? (See rear cover)

Report all faults immediately.

Before operating this machine

DO NOT OPERATE THE MACHINE UNTIL

ALL FAULTS HAVE BEEN RECTIFIED.

1

Complete Checks in Section Before Starting The Engine

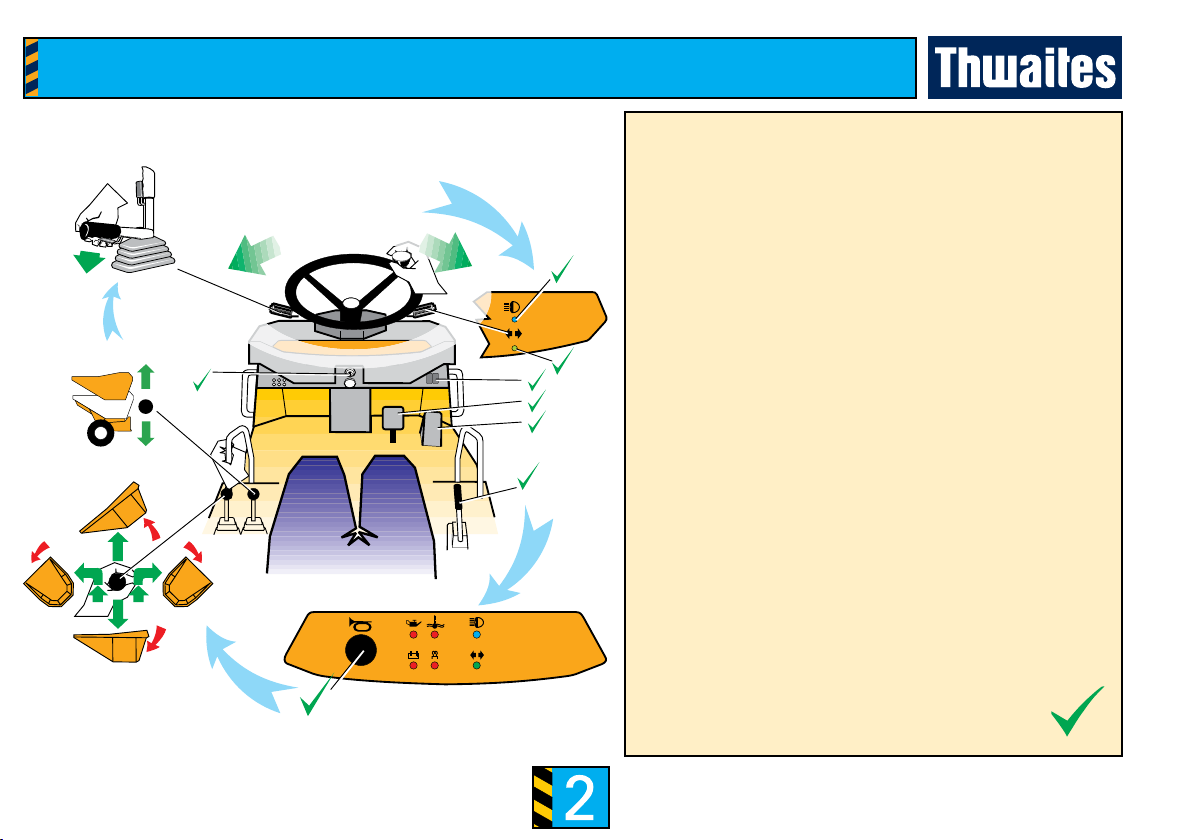

Mount the machine and check the controls

1 Use the grabrails and foot steps provided to

manoevre into seating position. Face the machine

at all times when mounting and dismounting

2 Is the engine cover secure and locked?

3 Adjust the seat position for comfort and easy

access to controls

4 Fasten the seatbelt. Adjust accordingly for safety

and comfort

5 Is the hand brake ON?

6 Set the transmission to neutral

7 Does the foot brake feel rm?

8 Do not operate the machine without understanding

all its controls as described in the following pages

WARNING

Seatbelt MUST BE WORN when operating machines

tted with a ROPS frame.

Before operating this machine

1

Complete Checks in Section Before Starting The Engine

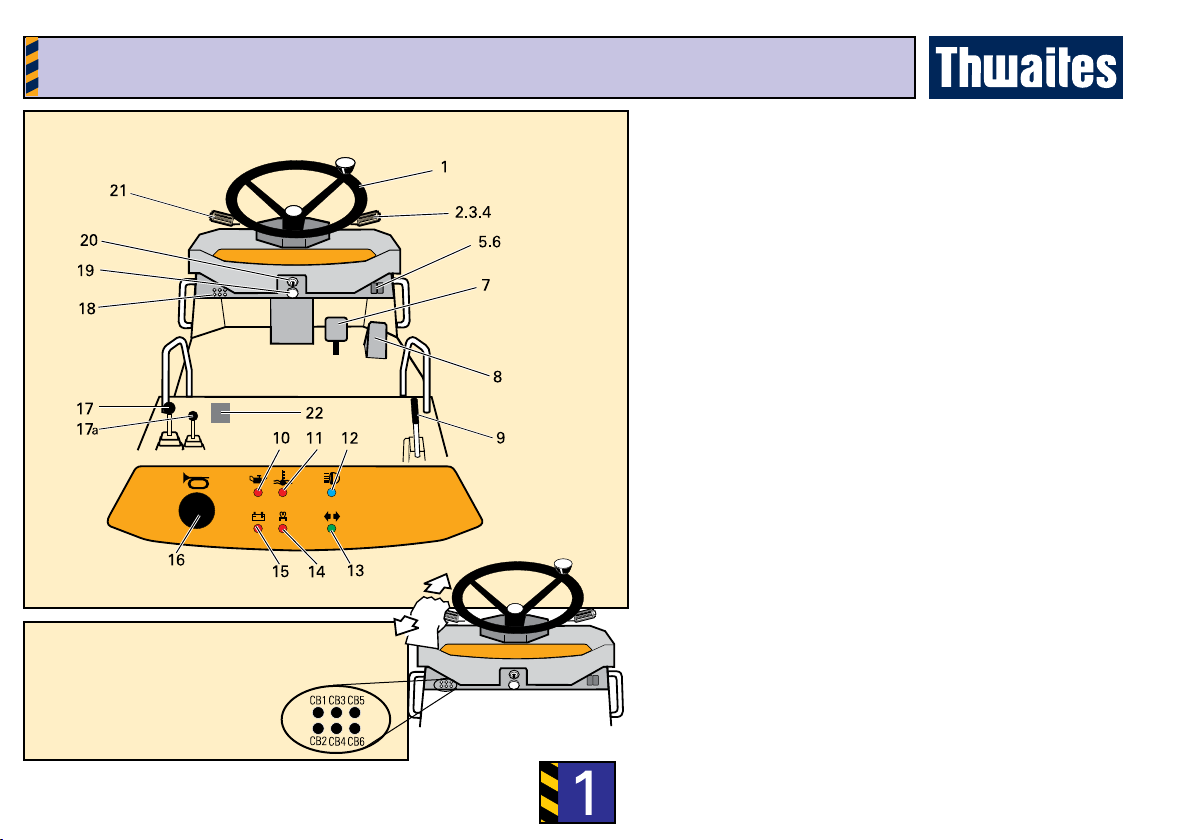

Control locations & functions

1 Steering wheel.

2 Direction lever -

forward = left turn - back = right turn.

3 Lights - twist 1 = sidelights ON - twist 2 =

Dipped headlights ON

4 Up = ash. Down = main beam

5 Hazard warning light switch

6 Beacon switch*

7 Foot brake pedal/inching

8 Throttle pedal

9 Hand brake lever

10 Engine oil pressure warning light

11 Water temperature warning light

12 Headlamp main beam pilot light

13 Direction indicator pilot light

14 Heat/start pilot light

15 Battery charging warning light

16 Horn push

17 Skip-tip and Skip-rotate lever

17a Skip-raise lever (Hi-Swivel only)

18 Circuit breakers (push to reset)

19 Warning buzzer

20 Ignition switch

21 Forward/Reverse/High/Low Speed Lever (FNR

lever)

22 Maxi fuse (under engine cover)

CB1 Fuel/direction solenoids

CB2 Instrumentation/warning

CB3 Lights

CB4 Flash

CB5 L/H sidelights

CB6 R/H sidelights

Layout of controls

1

Complete Checks in Section Before Starting The Engine

7

8

Control Functions – in depth

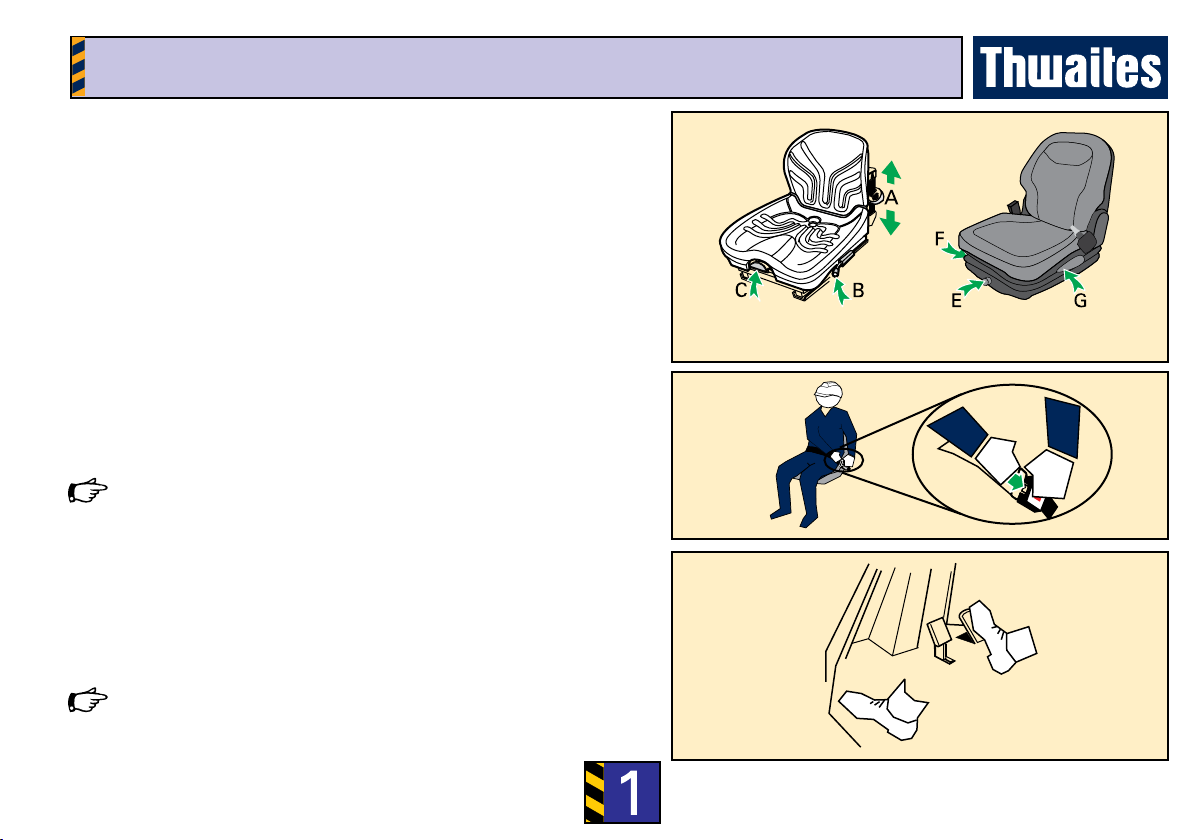

Seatbelt (if tted)

• Adjust length of belt when seated on machine

• Press buckle blade into buckle lock

• Pull belt webbing through buckle blade to remove slack

Seatbelt should not be worn loose. It should pass comfortably across the

hips and not the abdomen.

Throttle pedal – right foot

• Apply pressure to increase speed

• Release pressure from the pedal to reduce speed

Foot brake pedal+inching pedal – right foot

• Push down on the pedal to slow/stop the machine.

Use left foot when inching is required.

Push down while pressing throttle pedal (8) with right foot and release to

move machine.

Seat adjustment

Type 1:

A – Push down to set driver weight (seat empty)

Push fully down and release to reset (seat empty)

B – Lift to slide seat assembly forwards/backwards

C – Lift to slide cushion forward and set backrest

Type 2:

E – Turn knob to set driver weight

F – Lift to slide seat assembly forwards/backwards

G – Lift handle to adjust backrest Type 1 Type 2

1

Complete Checks in Section Before Starting The Engine

Hand brake lever – right hand

When the machine is stationary (or in an emergency):

• Pull up to apply

• Pull catch and lower to release

An audible warning device is fitted to your machine. This will sound when

the hand brake is engaged and the engine is running.

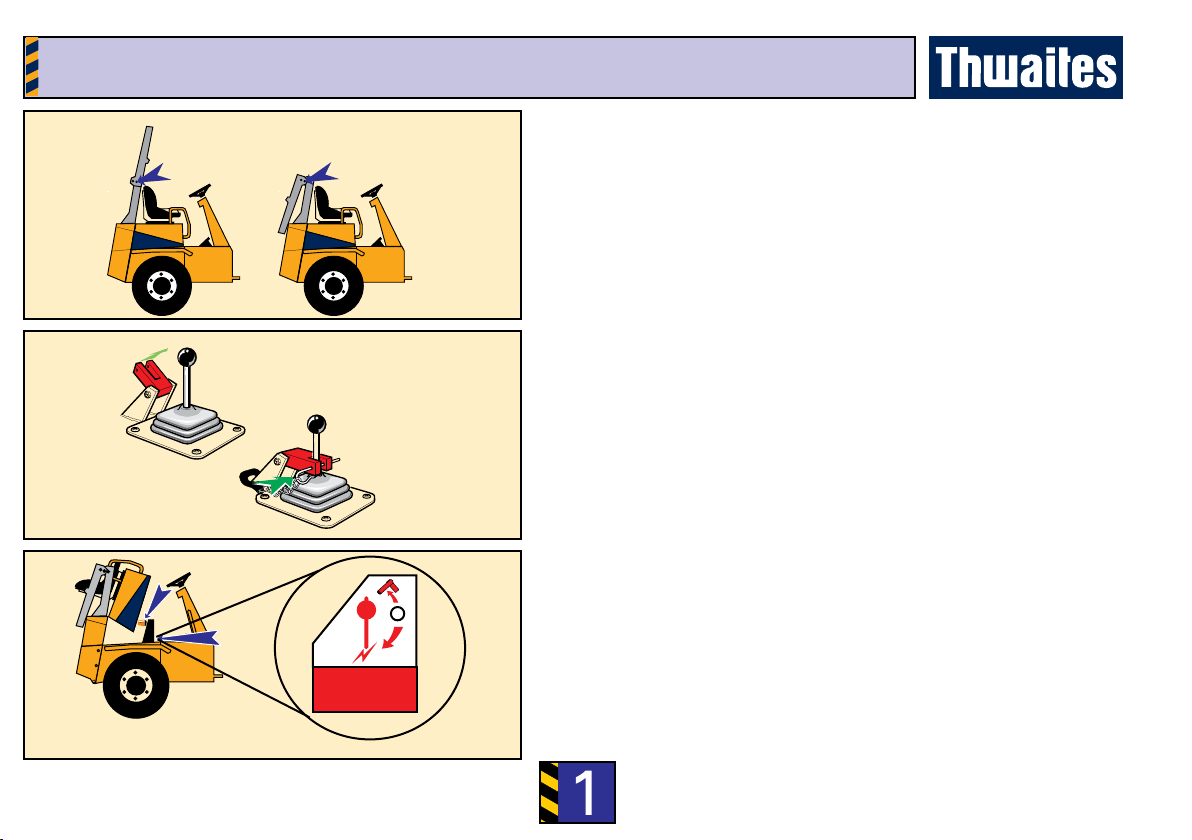

FNR/High and low speed lever – left hand

• Push forwards to travel in a forward direction

• Lever centred = neutral.

• Pull back to travel in a reverse direction

Twist lever anti-clockwise (2) for HIGH speed travel

Twist lever clockwise (1) for LOW speed travel

Opening and closing the engine cover

• Insert ignition key and turn anti-clockwise to unlock

• Pull handle to release and raise cover

• Lower cover, secure and lock before driving

Control Functions – in depth

1

Complete Checks in Section Before Starting The Engine

Steering wheel – both hands

• Turn the wheel clockwise to turn machine to right

• Turn the wheel anti-clockwise to turn machine to left

Ensure the non-steering hand is on the engine cover grabrail when using the

spinner knob for low-speed single-handed steering.

Control Functions – in depth

Skip-Rotate lever (Powerswivel and Hi-Swivel models) – left hand

• Tip skip 100 mm (4”) to disengage pivot centring lock

Rotate skip, fully lowered to centre to automatically engage centring lock.

• Push lever to the right to rotate skip to right

• Push lever to the left to rotate skip to left

• An increased engine speed will reduce cycle times

Movement of the skip is disabled if the steering wheel is moved (priority

steering).

Skip-raise lever (Hi-Swivel model) – left hand

• push forward to raise skip

• push backwards to lower skip

1

Complete Checks in Section Before Starting The Engine

Lowering and raising the folding ROPS frame

• Remove linch pins and withdraw frame lock pins

• Lower frame and insert lock pins and linch pins in new position

• Reverse the procedure to raise the frame

• Ensure all pins are secure before driving

Beacon stowage

• Unplug and remove beacon

• Secure beacon on bracket provided beneath bonnet

Battery isolator (Beneath engine cover)

• Turn key anti-clockwise to isolate the battery power supply

Control Functions – in depth

Skip-tip lever lock (if tted)

• Place yoke over tipping lever and secure with linch pin to lock

• Fold back the yoke and secure using linch pin when not in use

2

Complete Checks In Section Before Loading The Machine

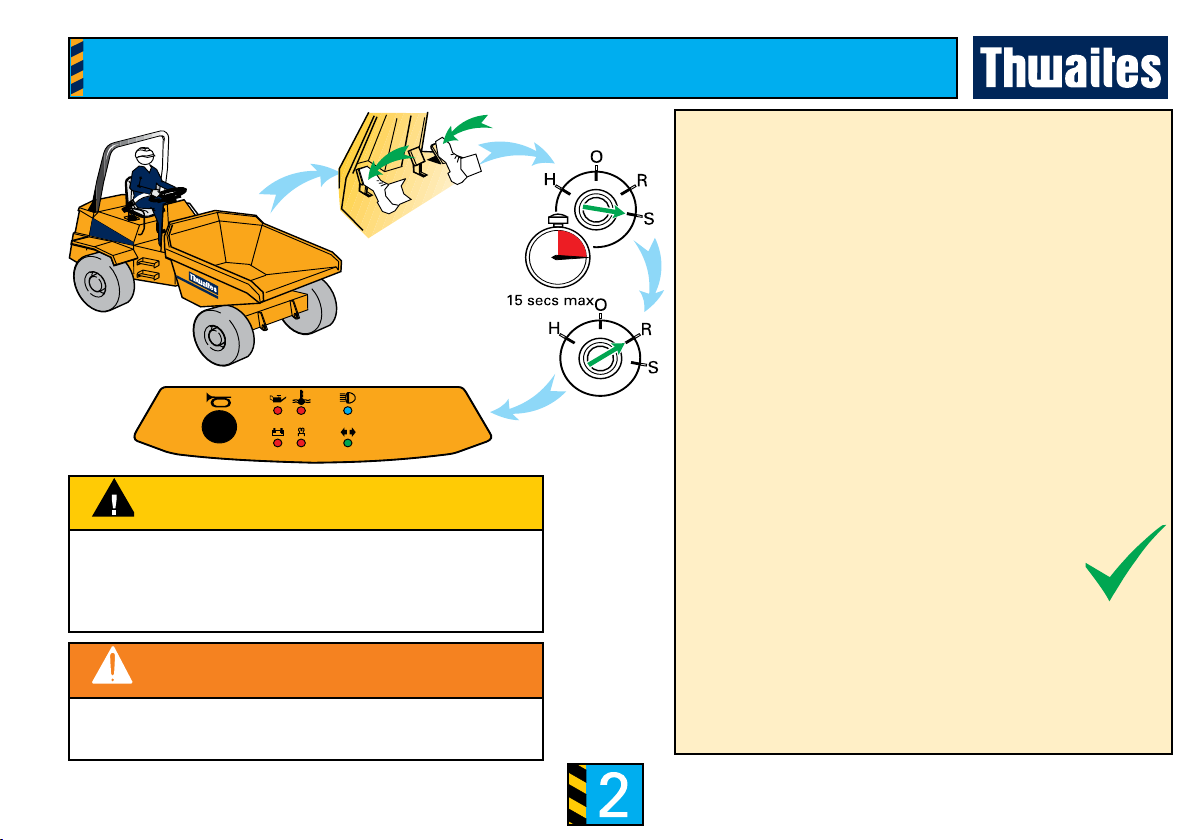

How to START and STOP the engine

CAUTION

• Do not use unauthorised starting aids

• Do not tow or bump start

• If a panel light remains on switch off engine (key to

‘O’) and investigate the problem.

WARNING

Do not start the engine unless you are sitting in the

driver’s seat.

To start the engine

• Set FNR lever to neutral

• Depress accelerator pedal fully and turn the key

clockwise to the start position ‘S’

All panel lights self-test (illuminate) and should extinguish

on start-up.

• Allow the engine to turn for 15 seconds max.

If the engine does not start within 15 seconds, return key

to position ‘O’ and wait 30 seconds before turning to ‘S’

again.

• When the engine res, release key.

(The key will spring back to ‘Run’ position ‘R’).

• Reduce accelerator pedal pressure to prevent over-

revving.

Cold start aid

Turn key to position ‘H’. When panel light extinguishes

start engine (as above).

To Stop The Engine

• Turn key to position ‘O’.

2

Complete Checks In Section Before Loading The Machine

Function Checks - Engine ON

Brakes

• Does the foot brake feel rm?

• Does the hand brake keep the machine stationary

when applied?

Steering

• Rotate the steering wheel clockwise and anti-clockwise

Electrics

• Does the horn sound?

• Does the reverse alarm sound? (Optional).

• Does the beacon ash? (Optional)

• Do all the lights function correctly?

* Side

* Main

* Stop

* Indicators

* Hazards

Skip-tip and skip-rotate lever

• Tip and return skip

• Rotate skip clockwise and anti-clockwise

Skip-raise lever (Hi-Swivel model)

• Raise and lower skip

Preliminary checks

2

Complete Checks In Section Before Loading The Machine

Moving from rest and stopping

• Select forward or reverse

• Select low ratio

• Release hand brake

• Slowly depress accelerator and move away

• Hold steering wheel with both hands

• Remove foot from accelerator pedal

• Brake gently to a halt using foot brake

• Apply hand brake when stationary

Changing speed/direction

• Select high ratio

• The machine must be stationary and the hand brake

must be engaged before changing direction (forward/

reverse).

After operating - park safely

• Always leave skip empty when not in use

• Ensure machine is on rm level ground

• Apply hand brake

• Engage neutral (FNR lever)

• Hydraulic system at rest in a safe condition

• Stop engine and remove key

• Lock engine cover

Driving procedure and safe parking

CAUTION

• Novice operators should always start with forward motion

on clear, level ground

• A low gear should always be selected when a driver is

unfamiliar with machine type

3

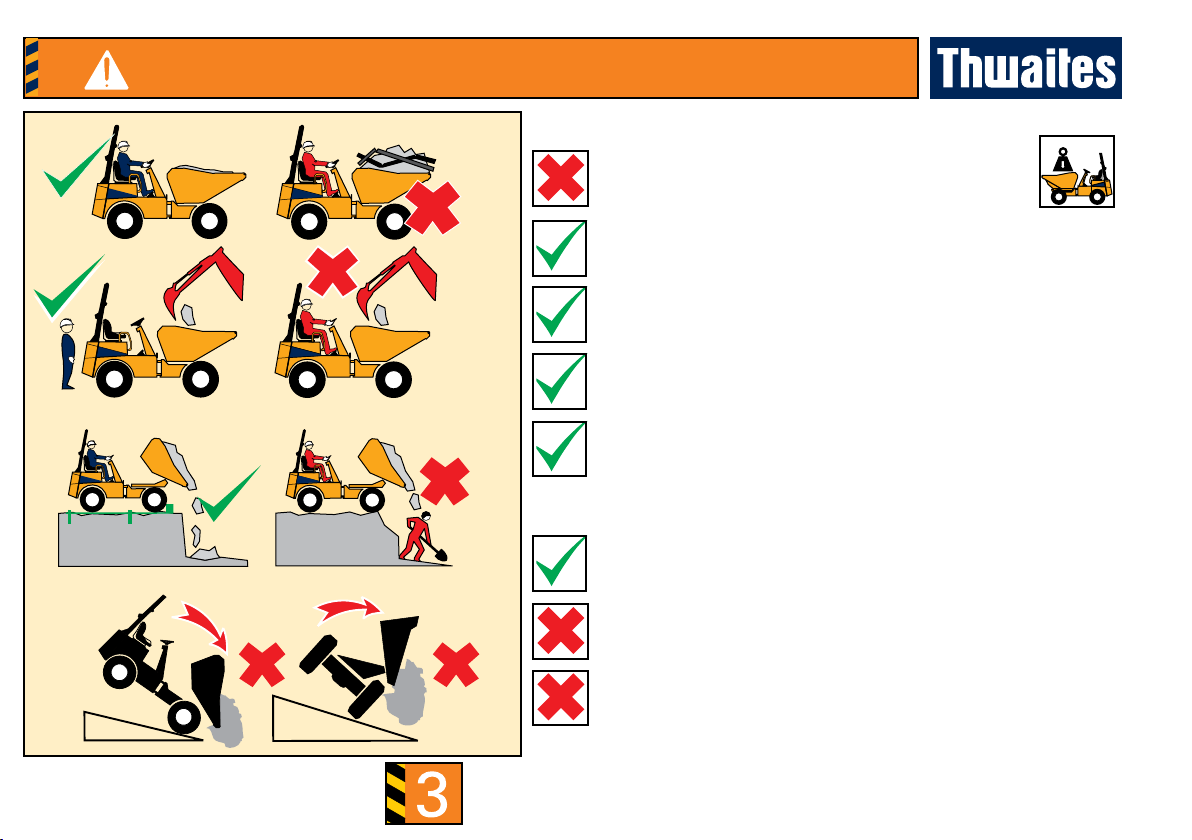

Attention! Section Correct and Incorrect Working Practices

DANGER IMMEDIATE HAZARDS WHICH WILL RESULT IN SEVERE PERSONAL

INJURY OR DEATH

Powerswivel and Hi-Swivel WORKING ON GRADIENTS

DO NOT exceed maximum stated gradients

DO NOT turn across gradients

DO NOT brake suddenly in wet, muddy, icy conditions or when

operating on loose surfaces

DO NOT run downhill with controls in neutral

Travel straight up, down or along a gradient

Keep speed to a minimum and use the foot brake to reduce speed

when travelling down gradients

Always position swivel skip in central lock

Always engage hand brake when stopped on sloping ground to

prevent movement, and, in addition, chock wheels securely when

leaving the machine unattended

DO NOT operate raise mechanism on sloping ground

(Hi swivel model only) - check spirit-level indicator

3

Attention! Section Correct and Incorrect Working Practices

DANGER IMMEDIATE HAZARDS WHICH WILL RESULT IN SEVERE PERSONAL

INJURY OR DEATH

VISIBILITY

Check ahead and behind machine before operation

CRUSH ZONE

Stay clear of articulation area when the engine is running.

WORKING UNDER A RAISED SKIP

Lock skip safety prop during maintenance

Be aware of low-visibility areas when operating

Before operating, sound the horn to warn people in the

immediate area

Never work under an un-propped skip

When using skip safety prop engage skip-tip lever lock

(if tted)

Never operate the machine’s controls when standing on either

side of machine

3

Attention! Section Correct and Incorrect Working Practices

WARNING HAZARDS OR UNSAFE PRACTICES WHICH COULD RESULT IN SEVERE

PERSONAL INJURY OR DEATH

LOADING THE MACHINE

DO NOT exceed machine’s rated capacity

UNLOADING THE MACHINE

Use STOPBOARDS and SUPPORT walls on trenches

Apply hand brake, set transmission to NEUTRAL, turn engine

OFF, disembark the machine and STAND CLEAR

Clear debris from controls

Ensure SAFE STABLE LOW load which allows good visibility.

DO NOT tip skip if load is sticking

DO NOT discharge load when working on sloping ground

Reduce payload if materials being carried are not free owing

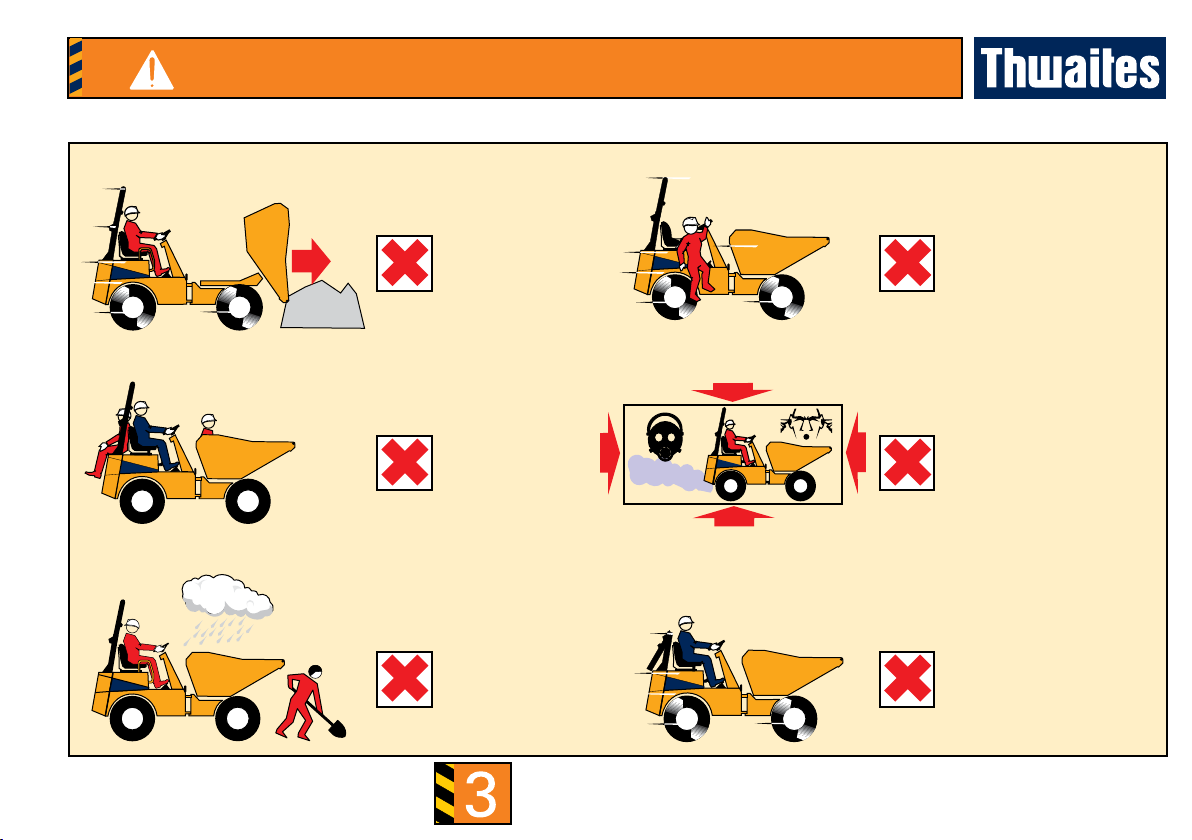

3WARNING HAZARDS OR UNSAFE PRACTICES WHICH COULD RESULT IN SEVERE

PERSONAL INJURY OR DEATH

Attention! Section Correct and Incorrect Working Practices

DRIVING

NEVER dismount from a

moving machine

Site hazards to

avoid: adverse

weather conditions;

icy surfaces; people

DO NOT drive with

the skip tipped

(bulldozing)

DO NOT carry

passengers

Avoid conned work

areas - exhaust fumes

and noise can be a

hazard

DO NOT operate with the

ROPS frame folded

3

Attention! Section Correct and Incorrect Working Practices

WARNING HAZARDS OR UNSAFE PRACTICES WHICH COULD RESULT IN SEVERE

PERSONAL INJURY OR DEATH

TOWING A TRAILER

Place ballast load in skip. This load should be a minimum of

25% of the machine’s rated payload

The gross weight to be towed plus the ballast load MUST

NOT exceed rated payload of machine

DO NOT exceed maximum tow bar pull or vertical load

Towing must not be carried out on sloping ground

Always use a Thwaites-approved towing pin

TRANSPORTATION

Reverse machine slowly onto a suitable trailer

DO NOT drive the machine forwards when loading

1 Apply hand brake

2 Stop engine

3 Chock wheels (To prevent movement)

4 Engage chassis locking bar

5 Secure to trailer

6 Ensure legal load (Height/weight)

3

Attention! Section Correct and Incorrect Working Practices

CAUTION HAZARDS OR UNSAFE PRACTICES WHICH COULD RESULT IN MINOR

PERSONAL INJURY OR PRODUCT OR PROPERTY DAMAGE

Hi-Swivel

USING A CRANE TO LIFT THE MACHINE

Tip skip fully forward

Place the locking channel over the tipping ram-rod, then reset

the skip until it is impeded by the channel

Engage chassis locking bar

Lift using centre eye provided

HAND BRAKE

DO NOT apply hand brake if the machine is moving (except in

an emergency)

SLOPING SURFACES

DO NOT step on the rear mudguards’ sloping surfaces

SCISSOR LIFT (HI-SWIVEL MODEL ONLY)

In order to secure the skip in a raised position, place the locking

channel over the lifting-ram rod

Powerswivel

HINGED ROPS

Use grab handles, tread grips (if tted) and steps when

standing on the machine to lower the ROPS frame

Avoid wet surfaces

3

Attention! Section Correct and Incorrect Working Practices

CAUTION HAZARDS OR UNSAFE PRACTICES WHICH COULD RESULT IN MINOR

PERSONAL INJURY OR PRODUCT OR PROPERTY DAMAGE

1

2

CAUTION - MACHINE RECOVERY

In order to tow the machine, the high-pressure circuit at the

hydrostatic pump must be opened.

To open the pump, follow this procedure:

At the left side of the pump below the oor plate there is one high-

pressure control valve at the top, and another at the bottom.

To activate the hydrostatic transmission bypass:

• release lock nut (2);

• screw in grub screw (1) until ush with top of nut (2);

• tighten nut (2).

• Reverse procedure prior to machine being placed back into

service.

TOWING THE MACHINE

• The maximum towing speed of 2 km/h should not be exceeded.

• The towing distance should not exceed 1 km.

This manual suits for next models

3

Table of contents

Other Thwaites Tractor manuals