TIFATECH HTCLW User manual

S21-037

Coffee Machine Control Board

HTCLW

Instruction Manual

S21-037

PREFACE

Thank you for purchasing our HTCLW, Control board for the Coffee machine.

This manual contains instructions for the mounting, functions, operations, and

notes when operating the HTCLW. To ensure safe and correct use, thoroughly

read and understand this manual before using this product.

To prevent accidents arising from the misuse of this product, please ensure the

operator receives this manual.

HAZARD INTENSITY LEVELS

The level of risk and importance of the notification is determined by the

following definitions. Always observe the warnings to ensure safety and prevent

potential injury and product damage.

Important:

Alerts against unsafe practices. Observe Important notifications to

prevent possible minor personal injury or damage to the board.

Warning:

Indicates a potentially hazardous situation that, if the Warning is

ignored, could result in injury or death.

Note:

Gives additional information which may be helpful for the proper

operation of the board.

S21-037

WARNINGS:

Note: TIFATECH Co., Ltd declines all responsibility for damage to

persons or property resulting from failure to follow the instructions and warning

listed below when installing and using this board.

Ensure every part of the machine including actuators and sensors is working

properly before replacing the new control board.

Ensure that the power supply voltage does not fluctuate by more than 6%.

Before mounting or removing the control board, disconnect it from the power

supply and wait a while for it to cool down.

Do not remove any original electrical part of the board.

Repairing, cleaning, or parts replacement should only be performed by

TIFATECH or other qualified service personnel.

Children should never be allowed to play with the board.

This board is intended to only use for the espresso coffee machine control

board. Do not use it for any other purpose.

PRECAUTIONS

Installation precautions

Read thoroughly the following conditions before installing the HTCLW board

to the coffee machine.

The mounting location must be:

No flammable, explosive gases

No exposure to water.

An ambient temperature of 0 to 70°C that does not change rapidly, and

no icing.

An ambient non-condensing humidity of 35 to 85 %RH.

Operation and Maintenance Precautions

S21-037

Do not touch live terminals. This may cause an electrical shock or

problems in operation.

Ensure the board surface is completely dry before powering.

Periodic cleaning will reduce the risk of damaging the board.

S21-037

*** CONTENTS ***

I. GENERAL ......................................................................................................... 1

1. Introduction......................................................................................................1

II. TECHNICAL SPECIFICATIONS ................................................................... 2

1. Dimensions (mm) ............................................................................................. 2

2. Specifications ...................................................................................................2

III. WIRING............................................................................................................. 3

IV. PROGRAMMING AND USE ........................................................................... 5

1. Programming standard dose..............................................................................5

2. Coffee dispensing .............................................................................................6

3. Automatic group cleaning................................................................................. 6

4. Pre-infusion......................................................................................................6

5. Filling...............................................................................................................6

6. Setting of operational parameters......................................................................7

Temperature setting.......................................................................................7

Other parameters setting................................................................................8

V. ERROR DETECTION AND TROUBLESHOOTING.................................. 10

1

S21-037

I. GENERAL

1. Introduction

This manual contains important instructions regarding the safe intended use of

the machine.

If any damaged or loss to this manual, request a copy from the TIFATECH

manufacturer.

Important: Please note the following conditions for your machine to function

properly:

Only machines with temperature control function can use this control board

This board must be used along with our accompanied display HTCLS-LT

for optimal performance and also the proper operation.

Additionally, we provide the PBL-22F0B button, which is exclusive to our

business. Tests showed that it is durable and suitable to use with this board.

Note: Please adhere to the wiring guidelines below if you use different

button items to ensure proper functionality.

2

S21-037

II. TECHNICAL SPECIFICATIONS

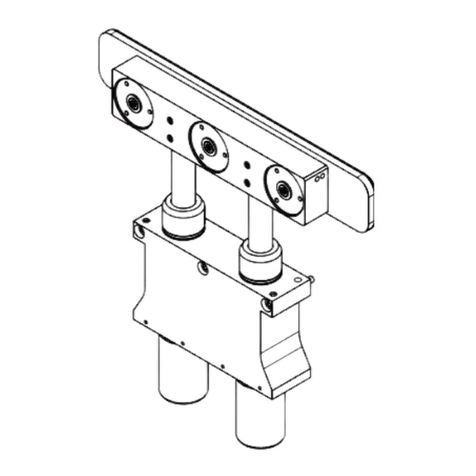

1. Dimensions (mm)

2. Specifications

Power supply: 230V AC 50/60Hz

Actuator voltage: 230V AC

Button and LED nominal voltage: 12V

HTCLW control board

HTCLS-LT display

3

S21-037

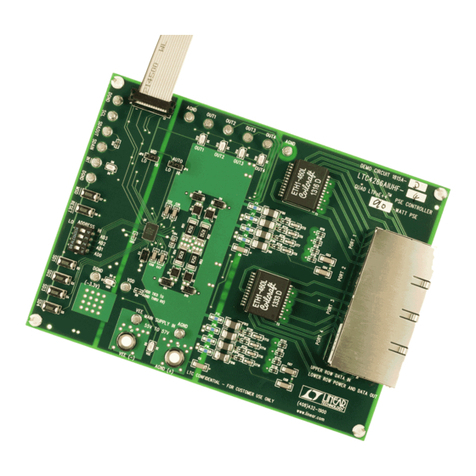

III. WIRING

(1) V12

(2) 2ShotLED

(3) GND

(4) 2ShotBtn

(5) V12

(6) 1ShotLED

(7) GND

(8) 1ShotButton

((17) V5

(9) V12

(10) SettingLED

(11) GND

(12) SettingBtn

(13) WL1

(14) GND

(15) GND

(16) WL2

(18) OUT

(19) OUT

(20) DISPLAY

(1) AC(L)

(1) AC(L)

(3) AC(N)

(4) Filling

(5) Group

(6) Pump

(7) Heat

(8) Unused

(9) K-

(10) K+

4

S21-037

Important:

Any mistake in connecting actuators will affect the normal operation of the

coffee machine, and even cause damage.

Đầu nối

Mô tả

2ShotLED

2 Shot espresso LED input

2ShotBtn

2 Shot espresso button input

1ShotLED

1 Shot espresso LED input

1ShotBtn

1 Shot espresso button input

SettingLED

Setting LED input

SettingBtn

Setting button input

V12

12V output

GND

Ground

WL1

Water level probe of boiler

WL2

Water level probe of tank

V5

5V output

OUT

Water flow meter

DISPLAY

Display input

AC(L), AC(N)

Power supply

Filling

Filling solenoid input

Group

Group solenoid input

Display cable input

5

S21-037

Pump

Pump input

Heat

Heating element input

K-, K+

Type K thermocouple

IV. PROGRAMMING AND USE

Three buttons are integrated into this control board and each serves a particular

purpose. The 1 Shot and 2 Shot espresso buttons allow for automatic coffee delivery,

while the Stop button is for continuous coffee brewing.

1. Programming standard dose

Please follow the instructions below for programming coffee dosage for drink

buttons.

Step 1: Press and hold the 1 Shot espresso button or 2 Shot espresso

buttons for 3 seconds to start to program on that one. Siren sounds

and the selected button begin flashing.

Step 2: Press the Stop button to dispense coffee and press it again when

reaching the desired coffee dose. The Stop button light is on while dispensing.

Step 3: Press and hold the programmed button for 3 seconds to save its new dose

and finish the setting process.

6

S21-037

Repeat the procedure above for programming on the remaining button.

2. Coffee dispensing

Press the Stop button once to start the coffee brewing process, then

press it again to stop

Press the 1 shot espresso button or 2 shot espresso button

to dispense a preset coffee dose that is previously programmed.

3. Automatic group cleaning

It’s feasible to automate the group cleaning procedure by step below:

Press and hold the 2 shot espresso button for at least 5 seconds until the

siren stops sounding and the machine starts to discharge water.

The cleaning time and period can be modified by the user (page 9).

4. Pre-infusion

To enable the pre-infusion mode, press and hold the button for 3

seconds until the siren sounds.

Do similarly the step above to disable it

Note: The coffee dose on buttons needs to be reprogrammed for it to work

correctly.

5. Filling

When the boiler is in an out-of-water state for more than 2.7 seconds, the pump

and filling valve will automatically open to fill up the boiler. The siren sounds

continuous until the boiler’s water level is enough.

After being full of water for 2.7 seconds, the filling process will automatically

stop.

7

S21-037

Note: The water source should always be available for filling operation.

6. Setting of operational parameters

In addition to the core functions, a machine’s operational parameters can be changed

to improve the user experience.

Button

Name

Replace function

1 shot espresso

Increase (+)

2 shot espresso

Change/Confirm

Stop

Decrease (-)

Temperature setting

Press and hold the 1 shot espresso and 2 shot espresso

simultaneously for 3 seconds until the siren sound.

The display starts to alternate between two states like the illustration below.

Use the increase/decrease button to adjust the threshold temperature of the boiler

heating process.

8

S21-037

Temperature range:0 -120°C

Step: 1

Default: 114°C

Press and hold the Confirm button for 3 seconds to exit the setting process.

Other parameters setting

Press and hold the 2 shot espresso and the Stop button

simultaneously for 3 seconds until the siren sound. The 2 shot espresso light begins

to flash.

Use the Increase/Decrease button to adjust the parameter value.

Use Confirm/Change button to save your changes and move on to set a new

parameter.

Press and hold the Confirm button for 3 seconds to leave the setup

mode. All lights return to the off state.

9

S21-037

10

S21-037

Table of parameters explanation :

Parameter

Range

Step

Default

Description

P

0 - 100

1

0

Propotional coefficient

(Recommend: P = 0)

HYS

1 - 10

1

2

The smallest

temperature difference

required to activate the

heating element

ACT

1 - 10

1

7

Auto cleaning time

ACC

1 - 10

1

7

Period of the cleaning

process

SCF

1 - 5

1

3

Pre-infusion time

Unit: second

V. ERROR DETECTION AND TROUBLESHOOTING

Note: The following mistakes will result in thesiren sounding continuous and

the deactivation of all machine operations. When there is no error, the

machine will resume its normal operation.

11

S21-037

Error

code

Display

status

Cause

Purpose

Solution

Er1

Tank is out of

water

To protect

pump and

heating element

Supplement water for tank.

Check the water source.

Check the water level probe

(Just apply with the machine has

water tank)

Er2

Pump is

opened over

60 seconds

To protect

pump from

overworking

Restart the machine

If it's not user mistake, get in

touch with us for support.

Er3

Boiler

overheating

To avoid

harming the

components

inside

Turn off the machine at least 5

minutes

Er4

Thermocouple

connection

error

To protect the

heating element

Check the thermocouple

connection on board

Er5

Thermocouple

is broken

To protect the

heating element

Replace the new one or contact

us for support

TIFATECH Co., Ltd

Address: 14 Tran Tu Binh Street, Hoa Chau Ward, Hoa Vang District, Da

Nang City, Viet Nam

Email: tifatech.vn@gmail.com

Tel: +84(0)899.600.009

Website: https://tifatech.vn/

https://hardtech.vn/

Table of contents