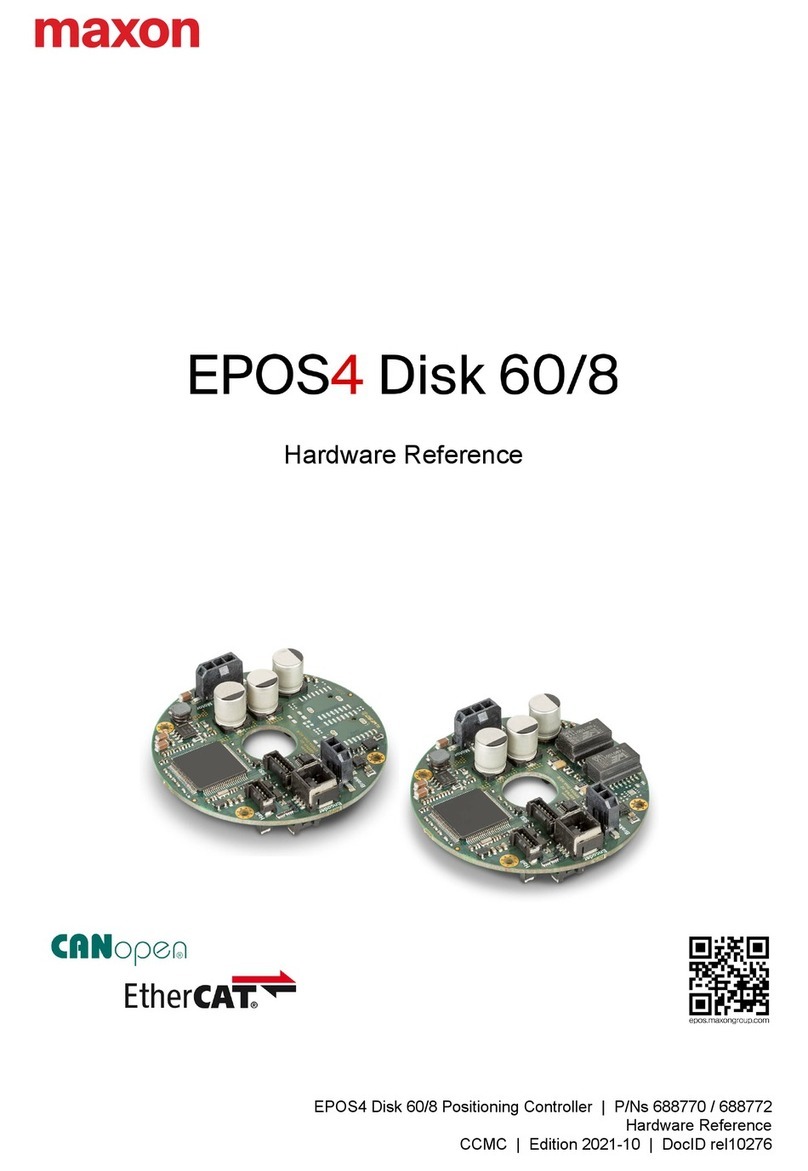

Maxon 297115-01 User manual

Other Maxon Controllers manuals

Maxon

Maxon EPOS 50/5 Application guide

Maxon

Maxon EPOS4 50/5 Application guide

Maxon

Maxon ESCON 36/2 DC Application guide

Maxon

Maxon EP0S4 Disk 60/12 Application guide

Maxon

Maxon EPOS4 Use and care manual

Maxon

Maxon ESCON Module 50/8 Application guide

Maxon

Maxon PARVALUX SC 50/15 Application guide

Maxon

Maxon EPOS4 Application guide

Maxon

Maxon EPOS4 Application guide

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions