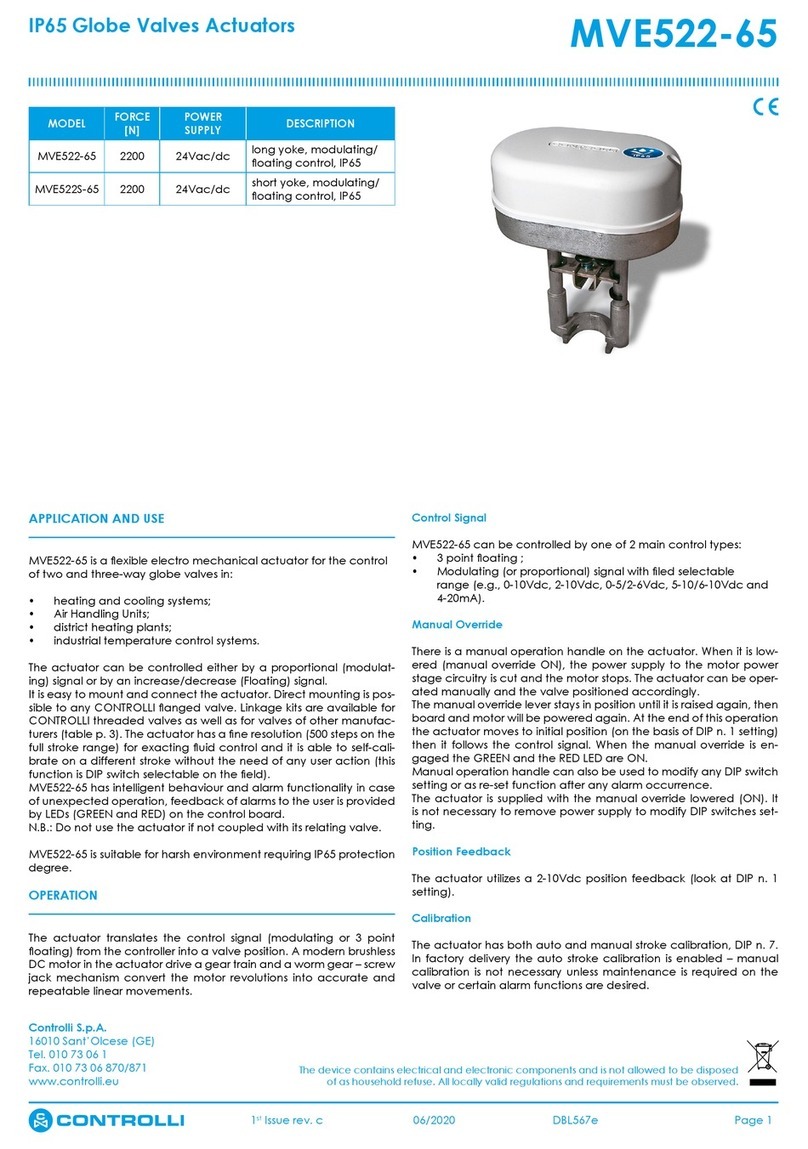

Automatic control systems for:

air conditioning/heating/industrial thermal process.

ISO 9001

The performances stated in this sheet can be modified without any prior notice due to design improvements

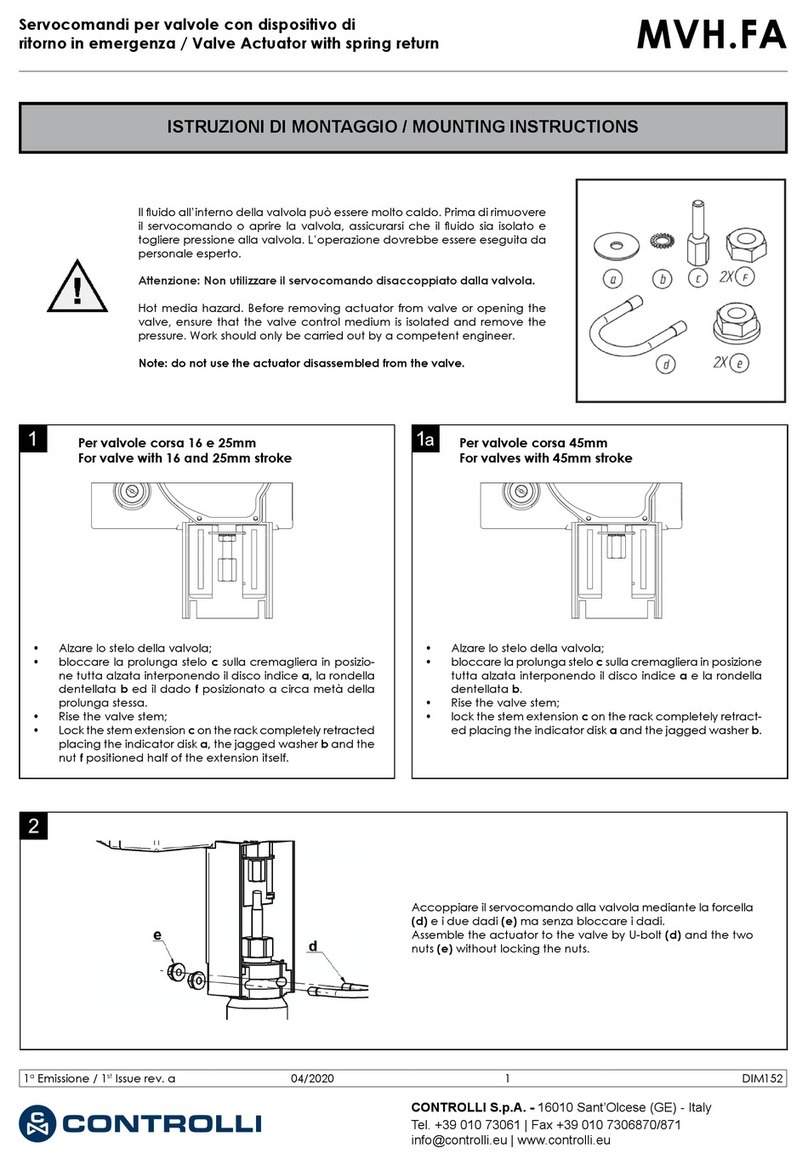

ACTUATOR STROKE CALIBRATION (only for MVH36/56)

- Loosen the locking screws located on the cover and put it off.

- Using a screwdriver, turn counter-clockwise the right potentiometer and clockwise the left one up to their mechanical stop.

- Acting on the manual knob, as shown in fig. 5, bring the indicator disk to both stroke ends and position the related adjustable

indicators.

ELECTRICAL CONNECTIONS

Perform the connections in compliance with existing rules and using max 2,5 mm2cross section wires.

Follow the instructions by using wire terminals on power supply wires in order to prevent accidental contacts between cables at

different voltages in case of wrong installation. On the power supply line install a protection device compliant to existing rules with

a 125 mA intervention threshold and a minimum 3 mm contact opening. The device is not supplied with the product.

MVH26/46 MVH36/36A/36C/56

N3009

Neutral- Supply in N

Supply phase in Y1 (joint up)

Supply phase in Y2 (joint down)

Supply 24 V ~ + 10%

(1) For MVH36 model, connect the potentiometer central of the controller (165 Ohm) to Y terminal, the extremities to M and V+

terminals.

(2) The joint moves downwards when the jumper on SW3 is inA position and the control signal increases.

(3)Connect the position indicator with input current to S3 (or S2) and S1 terminals. Connect the position indicator with input voltage

to S3 (or S2) and M (max 2 mA) terminals. With joint up between M (S1) and S2 minimum voltage value; between M (S1) and

S3 maximum current (voltage) value.

(4) When the actuator is in upper position, the potentiometer has 0 Ohm between W3 and W2 and 1000 Ohm between W2 and

W1 and a variation of 22.2 Ohm for each mm. of stroke.

Supply

control

W1 Auxiliary

W2 Central potentiometer MVH

W3 26/46 (4)

L1 Phase

L2 Neutral

M Common

V+ +15V output (1)

Y Control signal (2)

S3 0...10V or 0..200uA

S2 10...0V or 200...0uA (3)

S1 Analogue common

1st Issue rev. e 01/12 4 DIM156e