TIGA TITAN 20 B Instruction manual

Workshop

manual

Titan

2008-2012

Edition Manual Chapter Page

2008-10-17 Workshop Manual, Stiga Titan 1 General instructions 1

1 General instructions

Contents in this chapter

General

This Workshop Manual is intended for Stiga Titan models 2008. The article numbers and

product names are designated in the table under “Technical specification” at page 21.

This Manual do not cover repair instructions for the motors. Regarding motors, contact the

respective representative in the actual country.

This Manual and its specifications are valid for machines in their original design. In case of

modified or changed machine, the manual accordance is limited.

The manual is divided in the following chapters:

Chapter 1 is this chapter

Chapter 2 Chassis

Chapter 3 Steering

Chapter 4 Hydraulic system

Chapter 5 Belts

Chapter 6 Control Wires

Chapter 7 Electrical system

1.3.2 Extended guarantee ............ 4

1.3.3 Component guarantee,

chassis................................. 4

1.3.4 Exeptions ............................. 4

1.3.5 Conditions for validity of the war-

ranties .................................. 4

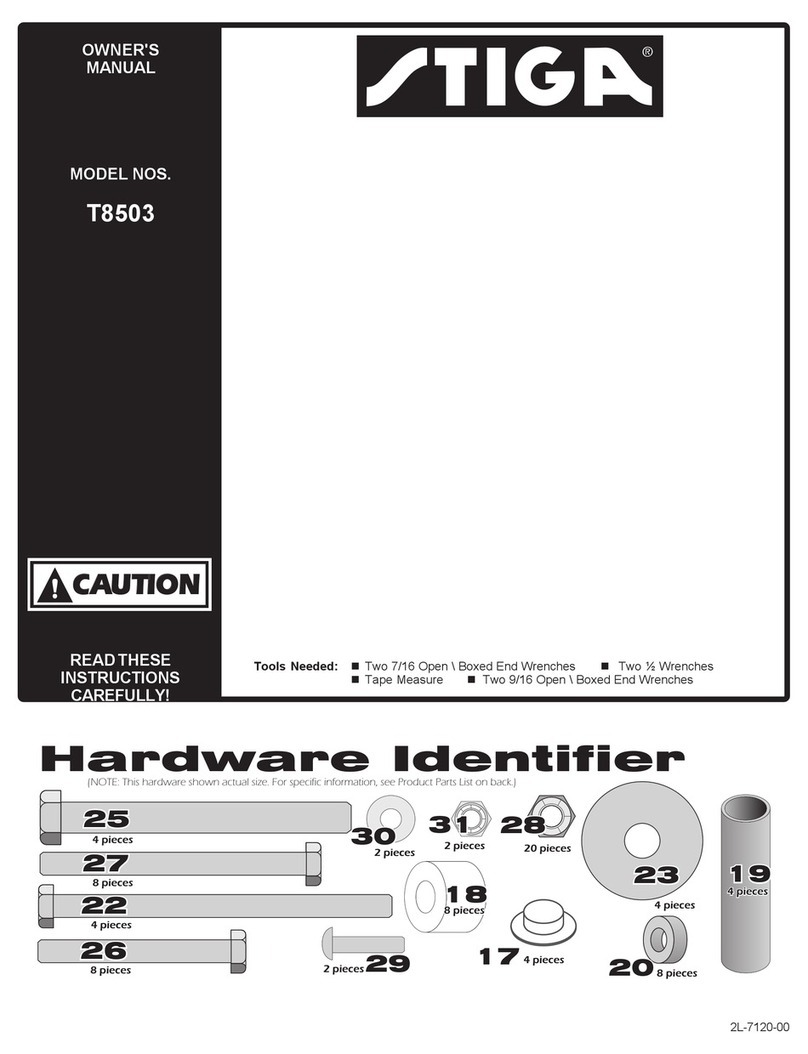

1.4 Unpacking and assembly....... 5

1.4.1 Unpacking............................ 5

1.4.2 Battery ................................. 6

1.4.3 Assembly ............................. 7

1.4.4 Final checks......................... 9

1.5 Service ..................................... 11

1.6 Technical specifications ........ 12

1.6.1 General tightening torque .... 14

1.7 Instructions for use ................ 14

1.1 Introduction................................2

1.1.1 Responsibility declaration.......2

1.1.2 How this manual is used ........2

1.1.3 Abbreviations..........................2

1.2 Safety Precautions ....................2

1.2.1 Symbols and general

warnings .................................3

1.2.2 Warm parts.............................3

1.2.3 Moving parts...........................3

1.2.4 Lifting and blocking up............3

1.2.5 Cleanliness.............................3

1.2.6 Tightening torque ...................3

1.2.7 Sharp edges ...........................3

1.2.8 Replacement parts .................3

1.2.9 Inspection ...............................3

1.3 Guarantee...................................4

1.3.1 Guarantee period ...................4

Edition Manual Chapter Page

2008-10-17 Workshop Manual, Stiga Titan 1 General instructions 2

1.1 Introduction

1.1.1 Responsibility declaration

In spite of the great care we have taken there may be errors in this publication.

The author cannot be made liable for incorrect or missing information.

GGP SE reserves the right to regularly change product specifications without prior notice.

All the information in this book is based on the information available at the time of

production. Illustrations and photographs may be arranged schematically, which implies

that one picture may cover several models and therefore not correspond exactly with all

models.

1.1.2 How this manual is used

To make this manual easy to understand we have divided the machine into its main

systems and components. These parts are now the different chapters in the book.

Each chapter is divided up into sections.

There is a quick-guide on the cover of this book, which refers to the different chapters. In

each chapter there is a detailed table of contents so that you can easily and quickly find

what you are looking for.

For example, if you are looking for information on the Accessory Lifter you will find this in

chapter 3, Chassis and Body. On the first page in chapter 3 there is a detailed table of

contents which refers to the correct section, in this case section 3.1.

Always check that you are reading the right chapter for your particular machine before

starting the repair work.

1.1.3 Abbreviations

The following abbreviation is used in this manual:

PTO Power Take Off

1.2 Safety Precautions

This manual has been written primarily for trained mechanics working in a well-equipped

workshop. Nevertheless, the manual contains such detailed information that it can also be

of use to owners who wish to carry out simple service and repairs on their machine.

A basic knowledge of repairs, tools and repair instructions is, however, always a

prerequisite for first-rate results.

A qualified mechanic should always be consulted if the owner does not have sufficient

knowledge to carry out repairs.

During the warranty period all service must be carried out by an Authorised Workshop for

the warranty to be valid.

The following basic points should be observed if the machine is to function perfectly:

• Follow the service schedule.

• Be on the alert for sudden vibrations or abnormal noise to avoid major breakdowns.

• Always use Genuine Spare Parts

• Follow the descriptions in this manual carefully. Do not take any short cuts.

Edition Manual Chapter Page

2008-10-17 Workshop Manual, Stiga Titan 1 General instructions 3

1.2.1 Symbols and general

warnings

Warning!

This symbol indicates a risk of

personal injury or damage if the

instructions are not followed.

Note!

This text indicates a risk of damage to

the material or risk of unnecessarily

complicated work if the instructions

are not followed.

1.2.2 Warm parts

Please observe that engine and exhaust

system picks up a lot of heat during use.

To avoid injuries, allow the machine to cool

before any kind of repairs are made to or

near parts of the engine or exhaust

system.

1.2.3 Moving parts

Always stop the engine and remove the

starter key before inspections or repairs

are carried out.

Always use extreme caution when testing

systems with moving parts to avoid

injuries.

Always use Genuine Spare Parts during

service work.

1.2.4 Lifting and blocking up

Before work under the machine, always

make sure that lifting devices and jack-

stands are approved for the weight.

Work safe!

1.2.5 Cleanliness

Clean the machine before starting repairs.

Dirt that penetrates into sensitive

components can seriously influence the

service life of the machine.

Special important is the cleanliness when

working with the hydraulic system. See

special warnings in that chapter.

1.2.6 Tightening torque

Unless otherwise stated the tightening

torque in the tables in the section

Technical specifications must be used for

the different sizes of screws. This does not

refer to self-tapping screws, which are

mainly used for the assembly of body

parts.

1.2.7 Sharp edges

Watch out for sharp edges, especially

when working with the mower deck. The

blades can be very sharp. Always wear

gloves when working with the blades.

1.2.8 Replacement parts

Always use Genuine Spare Parts during

service work.

1.2.9 Inspection

Each part dismantled in conjunction with

service work must be inspected.

Examine for: wear, cracks, out of

roundness, straightness, dents,

discolouring, abnormal noise and

jamming.

Edition Manual Chapter Page

2008-10-17 Workshop Manual, Stiga Titan 1 General instructions 4

1.3 Guarantee

1.3.1 Guarantee period

For consumer use: two years from date of

purchase.

For professional use: 200 hours or three

months, whichever comes first.

1.3.2 Extended guarantee

The guarantee period can be extended to

a maximum of 300 hours or 3 years from

the date of purchase provided that the

prescribed basic services have been

carried out at an authorised Stiga Service

workshop during the relevant guarantee

period. The services must be verified in the

service book.

1.3.3 Component guarantee,

chassis

Faults occurring in the machine’s bearing

in the articulated steering joint, as well as

the front and rear chassis, are covered by

a 10 year component guarantee from the

date of purchase

The guarantee is valid provided that the

prescribed basic services have been

carried out at an authorised service

workshop during the relevant guarantee

period. The services must be verified in the

service book.

1.3.4 Exeptions

The extended warranty does not cover

damage due to the following:

• Neglect by users to acquaint themselves

with accompanying documentation.

• Carelessness.

• Incorrect and non-permitted use or

assembly.

• The use of non-genuine spare parts.

• The use of accessories not supplied or

approved by the manufacturer.

Neither does the warranty cover:

• Wearing components such as blades,

belts, wheels,battery and cables.

• Normal wear.

• Engine and transmission. These are cov-

ered by the engine manufacturer’s war-

ranties, with separate terms and

conditions.

The purchaser is covered by the national

laws of each country. The rights to which

the purchaser is entitled with the support of

these laws are not restricted by this

warranty.

1.3.5 Conditions for validity of the

warranties

The fully completed warranty card must be

sent to Stiga´s subsidiary or distributor.

In the event of a claim, the service history

must be confirmed with a copy of the

service book.

Edition Manual Chapter Page

2008-10-17 Workshop Manual, Stiga Titan 1 General instructions 5

1.4 Unpacking and assembly

Every Stiga Titan has undergone an extensive

control programme before delivery. The

machines are delivered as completely

assembled as possible.

Thanks to this the assembly on delivery is rapid

and easy.

The correct and careful assembly of the

machine on delivery is a simple way of ensuring

satisfied customers!

Note!

The machine shall remain placed on the

pallet during the unpacking and

assembly.

1.4.1 Unpacking

Open up the crate and release the part as

follows:

1. Check the air pressure in the tyres. The

pressure is designated adjacent to the

actual wheel.

The air pressure in the tyres is of critical

importance for the performance and

handling of the machine. The correct air

pressure for mowing is 0.9 bar in all tyres.

When using the machine with other

implements, see the respective implement

manual regarding the tyre pressure.

However, the maximum permitted

pressure is always 1,3 bar.

Too high pressure in the tyres leads to that

the machine drives poor due to:

• A small surface in contact to the ground.

• Hard tyre = less flexibility = self cleaning char-

acteristic deteriorate.

2. Remove the following parts from the

package and put them on the floor.

• The seat and, if applicable, the neck rest.

• The steering wheel.

• The plastic bag, containing owners manuals,

information video and assembly screws.

Too high pressure Correct pressure

Edition Manual Chapter Page

2008-10-17 Workshop Manual, Stiga Titan 1 General instructions 6

1.4.2 Battery

The battery is a closed type which means that

water or electrolyte cannot be topped up.

The battery charge level is read at the indicator

eye on top of the battery. The charge level can

also be read by a voltameter, where the

following values are valid:

12,7 V Fully charged

12,4 V Half charged

12,0 V Empty, no current

Warnings!

Do not wear rings, metallic bracelet,

chain round the neck or similar metal

objects when working with the

battery. It can cause short-circuit,

burns and fire.

The battery must be fully charged

before being used for the first time.

The battery must always be stored

fully charged. If the battery is stored

while discharged, serious damage will

occur.

If the cables are disconnected/

connected in the wrong order, there is

a risk of a short-circuit and damage to

the battery.

If the cables are interchanged, the

generator and the battery will be

damaged.

The engine must never be driven with

the battery disconnected. There is a

risk of serious damage to the

generator and the electrical system.

Installation of battery

See also the respective installation manual,

delivered with the machine.

After the battery is charged, remove the motor

casing and install it in the machine. Connect first

the red cable to plus (+) and then the black cable

to minus (-).

Charging with the engine

The battery can be charged using the en-

gine’s generator as follows:

1. Install the battery in the machine as

shown below.

2. Place the machine outdoors or install

an extraction device for the exhaust

fumes.

3. Start the engine according to the

instructions in the user guide.

4. Allow the engine to run continuously

for 45 minutes.

5. Stop the engine. The battery will now

be fully charged.

Charging using battery charger

The battery is allowed to be charged with

max 4 A. At higher charging currents, the

battery will be damaged.

Edition Manual Chapter Page

2008-10-17 Workshop Manual, Stiga Titan 1 General instructions 7

1.4.3 Assembly

The assembly procedure shall take place in a

clean, well illuminated and dry place.

Assemble the machine as follows:

Assembly of steering wheel

The machine is delivered without the steering

wheel with its rod disassembled. Assemble as

follows:

1. Install the steering column jacket on the

steering column

2. Check that the holes coincide.

3. Secure by knocking in the tension pin fully.

Use a counterhold.

Also make sure that the logo on the steering

wheel is in the correct position.

Edition Manual Chapter Page

2008-10-17 Workshop Manual, Stiga Titan 1 General instructions 8

Assembly of seat

Install the seat as follows:

1. Place the seat in place and assemble the

two front screws with nuts. Don´t tight yet.

2. Assemble the two rear screws with nuts.

3. Tigheten the four screws.

Assembly of headrest

Install the headrest as follows:

1. Hold the headrest in place and assemble

the two screws .

2. Tigheten the screws.

x2

Edition Manual Chapter Page

2008-10-17 Workshop Manual, Stiga Titan 1 General instructions 9

1.4.4 Final checks

Actions before starting

Carry out the following before starting the

machine:

• Check/top up with fuel.

• Check the engine oil level.

• Check the coolant level.

• Check to make sure that the air filter indicator

has not been tripped.

• Check that the water separator’s and fuel fil-

ter’s taps are open.

• Check that the water separator does not con-

tain water. Drain if necessary.

• Check the oil level in the hydraulic tank. See

“3.5.8” in instructions of use.

• Carry out safety checks.

• Check that the disengagement lever is in the

inner position. See “3.4.19”.

Test driving

Drive the machine for a few minutes. Test all

the functions. Pay special attention to the

safety functions, see next page. If the machine

is to be delivered with mower deck or other

accessories, fit these before test driving the

machine.v

Edition Manual Chapter Page

2008-10-17 Workshop Manual, Stiga Titan 1 General instructions 10

General safety checks

Electric safety check

Object Result

Fuel lines and connections. No leak.

Power cables. All insulation intact.

No mechanical damage.

Exhaust system. No leakage in the connections.

All screws tightened.

Hydraulic hoses. No leakage. No damage.

Drive the machine forwards/

backwards and release the

drive/service brake pedal.

The machine should stop.

Test driving. No unusual vibrations.

No unusual noise.

Status Action Result

The clutch-brake pedal not

depressed.

PTO not activated.

Attempt to start. The engine

should not start.

The clutch-brake pedal not

depressed.

PTO activated.

Attempt to start. The engine

should not start.

Engine running. PTO activated. The operator

leaves the seat.

PTO should dis-

engage.

Cruise control activated. The operator

leaves the seat.

Cruise control

should disengage.

Cruise control activated. Clutch-brake

pedal

depressed.

Cruise control

should disengage.

Control for implement lifter not

in floating position.

Attempt to

engage PTO.

PTO should not

be able to

engage.

Edition Manual Chapter Page

2008-10-17 Workshop Manual, Stiga Titan 1 General instructions 11

1.5 Service

Every new machine is delivered with a service book. Every service shall be documented

in the service book. This service book is part of the active post-market programme and

s

hall be kept in a safe place during the entire lifetime of the machine. Hand over the service

book if the machine is sold in 2:nd hand.

Service shall be carried out according to the table below, regarding items and intervals.

Service point

1st time Interval See paragraph

in instruc-

tions of use

Hours of opera-

tion/Calendar

months

Water separator,

check 50/- 6.4

Pre-filter, cleaning 6.4

Fuel filter, replace 400/- 6.5

Tyre pressure,

check, adjust 6.6

Engine oil, filter,

change 50/12 200/12 6.7

Hydraulic oil, filter,

change/clean 50/12 400/12 6.8

Wheel motors ,

change oil 50/12 200/12 6.9

Belt transmis-

sions, check 50 200/- 6.10

Cooling system,

clean 1000/12 6.11

Battery, check 50/- 6.12

Air filter, clean

pre-filter 6.13

Air filter, change

inner filter 6.13

Lubrication 6.14

Adjusting valves 1000/- 6.15

Grinding valves 2000/- 6.15

Edition Manual Chapter Page

2008-10-17 Workshop Manual, Stiga Titan 1 General instructions 12

1.6 Technical specifications

TITAN 20 B TITAN 26 B TITAN 26 H TITAN 26 HS

13-7421-21 13-7432-21 13-7434-21 13-7436-21

Machine type Multi purpose implement

carrier

Multi purpose implement

carrier

Multi purpose implement

carrier

Multi purpose implement

carrier

Measures MAX LxWxH (mm) 2300x1060x1950 2300x1060x1950 2300x1090x2000 2300x1090x2000

Height over R.O.P.S. 1950 1990 1990 1990

Height over seat 1300 1300 1500 1500

Wheelbase 1200 1200 1200 1200

Weight, without operator 600 kg 610 kg 620 kg 630 kg

Weight, max 900 kg 1100 kg 1100 kg 1100 kg

Weight distribution with driver Rear: 60%, Front: 40% Rear: 60%, Front: 40% Rear: 60%, Front: 40% Rear: 60%, Front: 40%

Weight distribution with driver, deck in

transport position

Rear: 30%, Front: 70% Rear: 30%, Front: 70% Rear: 30%, Front: 70% Rear: 30%, Front: 70%

Engine Yanmar 3TNV70-XMHS Yanmar 3TNV76-XMHS Yanmar 3TNV76-XMHS Yanmar 3TNV76-XMHS

Type Naturally aspirated,

watercooled, 4 stroke, 3

cylinder IDI diesel engine

Naturally aspirated,

watercooled, 4 stroke, 3

cylinder IDI diesel engine

Naturally aspirated,

watercooled, 4 stroke, 3

cylinder IDI diesel engine

Naturally aspirated,

watercooled, 4 stroke, 3

cylinder IDI diesel engine

Gross power @ 3600 rpm 17 kW, 23 Hp 22 kW, 30 Hp 22 kW, 30 Hp 22 kW, 30 Hp

Gross power @ 3000 rpm 15 kW, 20 Hp 19 kW, 26 Hp 19 kW, 26 Hp 19 kW, 26 Hp

Engines power rating, net ISO 3046/1 ISO 3046/1 ISO 3046/1 ISO 3046/1

Net power @ 3600 rpm 16 kW, 21 Hp 21 kW, 29 Hp 21 kW, 29 Hp 21 kW, 29 Hp

Net power @ 3000 rpm 14 kW, 19 Hp 18,5 kW, 25 Hp 18,5 kW, 25 Hp 18,5 kW, 25 Hp

High idle speed 3200 rpm 3200 rpm 3200 rpm 3200 rpm

Low idle speed 1250 rpm 1250 rpm 1250 rpm 1250 rpm

Bore 70 mm 76 mm 76 mm 76 mm

Stroke 74 mm 82 mm 82 mm 82 mm

Displacement 854 cc 1115 cc 1115 cc 1115 cc

Low temp specification -20°C -20°C -20°C -20°C

Low temp starting aid standard standard standard standard

Emission standard EU: N/A. US: EPA Tier 4 EU: Stage 3A (97/68/EC)

US: EPA Interim Tier 4

EU: Stage 3A (97/68/EC)

US: EPA Interim Tier 4

EU: Stage 3A (97/68/EC)

US: EPA Interim Tier 4

Specific fuel consumption @ rated net

output

294 g/KW-h 287 g/KW-h 287 g/KW-h 287 g/KW-h

Specific fuel consumption @ 75% output 302 g/KW-h

Specific fuel consumption @ 50% output 363 g/KW-h

Gradient, engine 25° (30° for 3 min) 25° (30° for 3 min) 25° (30° for 3 min) 25° (30° for 3 min)

Fuel system

Fuel pump mechanical mechanical mechanical mechanical

Fuel type Diesel (EN590:96) Diesel (EN590:96) Diesel (EN590:96) Diesel (EN590:96)

Alternative fuel Max 5% RME (EN24214) Max 5% RME (EN24214) Max 5% RME (EN24214) Max 5% RME (EN24214)

Water separator standard standard standard standard

Fuel filter type Paper element cartridge Paper element cartridge Paper element cartridge Paper element cartridge

Air cleaner

Type Dual filter, dry type Dual filter, dry type Dual filter, dry type Dual filter, dry type

Backpressure indicator Yes Yes Yes Yes

Extra large filter for extended cleaning

intervals

Yes Yes Yes Yes

Volumes

Fuel tank capacity ~40 L ~40 L ~40 L ~40 L

Engine coolant capacity ~4 L ~4 L ~4 L ~4 L

Engine oil capacity ~2,8 L ~3,4 L ~3,4 L ~3,4 L

Hydraulic system volume ~20 L ~20 L ~20 L ~20 L

Hydraulic system change volume ~17 L ~17 L ~17 L ~17 L

Reduction gear in wheel motors ~0,2 l / wheel 0,2 l / wheel 0,2 l / wheel 0,2 l / wheel

Basic machine data

Edition Manual Chapter Page

2008-10-17 Workshop Manual, Stiga Titan 1 General instructions 13

TITAN 20 B TITAN 26 B TITAN 26 H TITAN 26 HS

13-7421-21 13-7432-21 13-7434-21 13-7436-21

Hydraulic systems

Travel system, type Permanent 4x4, hydraulic

wheel motors

Permanent 4x4, hydraulic

wheel motors

Permanent 4x4, hydraulic

wheel motors

Permanent 4x4, hydraulic

wheel motors

Max travel speed 20 km / h 20 km / h 20 km / h 24 km / h

Wheel size front and rear 20x10.00x10 20x10.00x10 20x10.00x10 23x10.50x12

Travel pump 23,9cc variable axial

piston pump

23,9cc variable axial

piston pump

24,5cc variable axial

piston pump

24,5cc variable axial

piston pump

Travel pump version Shoeless type pistons Shoeless type pistons Shoe type pistons Shoe type pistons

Travel pump operating pressure 0-280 bar 0-280 bar 0-280 bar 0-280 bar

Travel pump, charge pump 4 cc inner rotor gear

pump

4 cc inner rotor gear

pump

4 cc inner rotor gear

pump

4 cc inner rotor gear

pump

Travel pump charge pump operating

pressure

2,9 bar 2,9 bar 2,9 bar 2,9 bar

Wheel motors 13 cc axial piston motor

w. gear reduction

13 cc axial piston motor

w. gear reduction

13 cc axial piston motor

w. gear reduction

13 cc axial piston motor

w. gear reduction

Wheel motors front max load 650 kg / pcs 650 kg / pcs 650 kg / pcs 650 kg / pcs

Wheel motors rear max load 650 kg / pcs 650 kg / pcs 650 kg / pcs 650 kg / pcs

Wheel motors, front Shoeless type pistons Shoeless type pistons Shoe type pistons Shoe type pistons

Wheel motors, rear Shoe type pistons Shoe type pistons Shoe type pistons Shoe type pistons

Auxiliary pump 4,2 cc gear pump 4,2 cc gear pump 4,2 cc gear pump 4,2 cc gear pump

Auxiliary pump operating pressure 125 bar 125 bar 125 bar 125 bar

Hydraulic oil cooling system Tube Tube Radiator Radiator

Hydraulic oil type 10W-30 10W-30 10W-30 10W-30

Reduction gear in wheel motors, oil type #90 or SAE 50 #90 or SAE 50 #90 or SAE 50 #90 or SAE 50

Power take off (PTO)

PTO type Belt Belt Hydraulic Hydraulic

PTO pump - - 14 cc gear pump 14 cc gear pump

PTO pump operating pressure - - 210 bar 210 bar

PTO pump max output - - 42 l/min 42 l/min

Frame and steering

Steering system Genuine articulated

steering

Genuine articulated

steering

Genuine articulated

steering

Genuine articulated

steering

Steering angle +/- 55° +/- 55° +/- 55° +/- 55°

Steering Fully hydraulic Hydraulic Hydraulic Hydraulic

Frame HD welded profile frame HD welded profile frame HD welded profile frame HD welded profile frame

Frame material Box sextion, 80x50x4

mm

Box sextion, 80x50x4

mm

Box sextion, 80x50x4

mm

Box sextion, 80x50x4

mm

Operator area

Seat type Pro high comfort Pro high comfort Pro high comfort Pro high comfort

Seat suspension adjustable Yes Yes Yes Yes

Seat position adjustable Yes Yes Yes Yes

Backrest position adjustable Yes Yes Yes Yes

Arm rest Yes Yes Yes Yes

Extended seat back - - Yes Yes

Speed control HST pedal HST pedal HST pedal HST pedal

Cruise control yes Yes Yes Yes

Low fuel warning - - Yes Yes

Head light Yes Yes Yes Yes

Hour meter Yes Yes Yes Yes

Seat heating, electrical Option Option Option Option

Safety

Roll over protection system (R.O.P.S) option option option option

Cabin - option option option

Cabin heating - option option option

Air conditioning - option option option

Implement interface

Implement attachment front no tools required no tools required no tools required no tools required

Lift capacity front 200 kg** 250 kg** 250 kg** 250 kg**

Side floating holder yes yes yes yes

Implement attachment rear no tools required no tools required no tools required no tools required

Load capacity rear 200 kg** 300 kg** 300 kg** 300 kg**

Load capacity top 80 kg** 100 kg** 100 kg** 100 kg**

Trailer weight, max 50-300 kg* 50-300 kg* 50-500 kg* 50-500 kg*

*Note: Vehicle combination total weight! **Note: Machine balance / weight distribution!

Edition Manual Chapter Page

2008-10-17 Workshop Manual, Stiga Titan 1 General instructions 14

1.6.1 General tightening torque

Unless otherwise stated, the following

tightening torque are applicable for screws and

nuts on the machine:

1.7 Instructions for use

Some procedures, e.g. changing motor oil,

motor filter and items in final checks etc., are

refered to the instruction for use, delivered with

the machine.

The instruction of use is written in 16 languages

and divided in two parts. The first part always

contains the languages SV, FI, DA, NO, DE,

EN, FR and NL.

Tightening torques

Thread Torque

M5 5 Nm

M6 9 Nm

M8 22 Nm

M10 45 Nm

Edition Manual Chapter Page

2008-10-23 Workshop Manual, Stiga Titan 2 Chassis and body 1

2 Chassis and body

Contents in this chapter

General

To facilitate the driving, handling of work equipment and to make it comfortable for the

driver, the machines are equipped with a various number of aid equipments. These

equipments can be hydraulic, electric or mechanic devices.

This chapter gives a brief description of the equipments and describes their repair and

replacements.

2.1 Description .................................2

2.2 Cruise control ............................3

2.2.1 Description..............................3

2.2.2 Disassembly ...........................3

2.2.3 Assembly ................................4

2.3 Cooler .........................................5

2.3.1 Description..............................5

2.3.2 Disassembly ...........................5

2.3.3 Assembly ................................6

2.3.4 Filling coolant..........................6

2.3.5 Lubrication chassis .................7

Edition Manual Chapter Page

2008-10-23 Workshop Manual, Stiga Titan 2 Chassis and body 2

2.1 Description

The chassis is built up on and around a

articulated frame with its articulation point in the

middle. This configuration imply that both the

front wheels and the rear wheels participate in

the turning actions and the rear wheels follow

the traces of the front wheels. This is a great

advantage in common and a requirement when

cutting around trees and corners. The rear

wheel will never pass a bend in an inner circle

and interfere with the obstruction.

This configuration also gives an optimal small

uncut circle, when driving with maximal turning.

The articulated frame is also articulating in the

vertical plane with ±6°. This makes it possible

for all the four wheels to press evenly against

the ground when the ground is bumpy.

To the chassis is also fitted control organs,

which conduct operator commands to the

actual device at the machine. I.e. wire and rod

between brake and pedal, throttle wire, etc.

Edition Manual Chapter Page

2008-10-23 Workshop Manual, Stiga Titan 2 Chassis and body 3

2.2 Cruise control

2.2.1 Description

The cruise control works as a temporary lock

for the speed lever at the hydraulic pump.

The electromagnet (A) is sliding along the

Brake plate (B). When the cruise control

engages, 12 V is connected to the

electromagnet (A) which locks in its actual

position against the brake plate (B). Such the

mechanics, drive pedal, linkage and hydraulic

pump lever are locked in position for desired

speed.

2.2.2 Disassembly

Disassemble the speed cruiser as follows:

1. Remove the upper and the right motor

hoods.

2. Disconnect the drive wire from the pump

lever by loosening the nut. Use a 10 mm

spanner. To lock the stud in the hole,

preventing it to rotate, press the wire end

upwards.

3. Disconnect the magnet cables.

4. Loosen the screw and nut, holding the lever

to the pump. Use two 13 mm spanners.

Remove the parts:

•Screw

•Nut

• Lever

• Distance

•Spring

• Magnet

A

B

Edition Manual Chapter Page

2008-10-23 Workshop Manual, Stiga Titan 2 Chassis and body 4

5. If necessary, loosen the brake bracket by

unscrewing the two nuts.

6. Loosen the drive wire from the brake

bracket.

2.2.3 Assembly

Assemble all parts in reverse order. See also

the figure.

If the drive wire has been removed from the

brake bracket, adjust the wire. See “2.4.5

Adjustment”.

Note!

Check that the megnet tab (D) fits in the

lever hole.

D

Edition Manual Chapter Page

2008-10-23 Workshop Manual, Stiga Titan 2 Chassis and body 5

2.3 Cooler

2.3.1 Description

The radiator is intended to keep the motor

temperature constant at the working

temperature during operation. It is therefore

important thet the coolant can flow freely

through the radiator.

2.3.2 Disassembly

Disassemble the radiator as follows:

1. Remove the motor hoods:

• Turn and remove the screws (A).

• Unhook the straps (B X 4).

• Lift up and remove the 4 hoods.

• Unscrew the 4 screws (C) and remove the

top hood.

The coolant is very hot direct after

use. Let the motor cool down before

draining the coolant.

2. Place a tray under the lower radiator hose

and loosen the hose from the radiator. The

hose clamp is accessible from the under

side.

3. Remove the radiator cap to let the air into

the system for easier draining.

4. Loosen the upper radiator hose and the

expansion tank hose from the radiator.

A

A

B

A

A

B

CC

This manual suits for next models

3

Table of contents

Other TIGA Lawn Mower manuals