Please retain instructions for future reference

CAUTION:

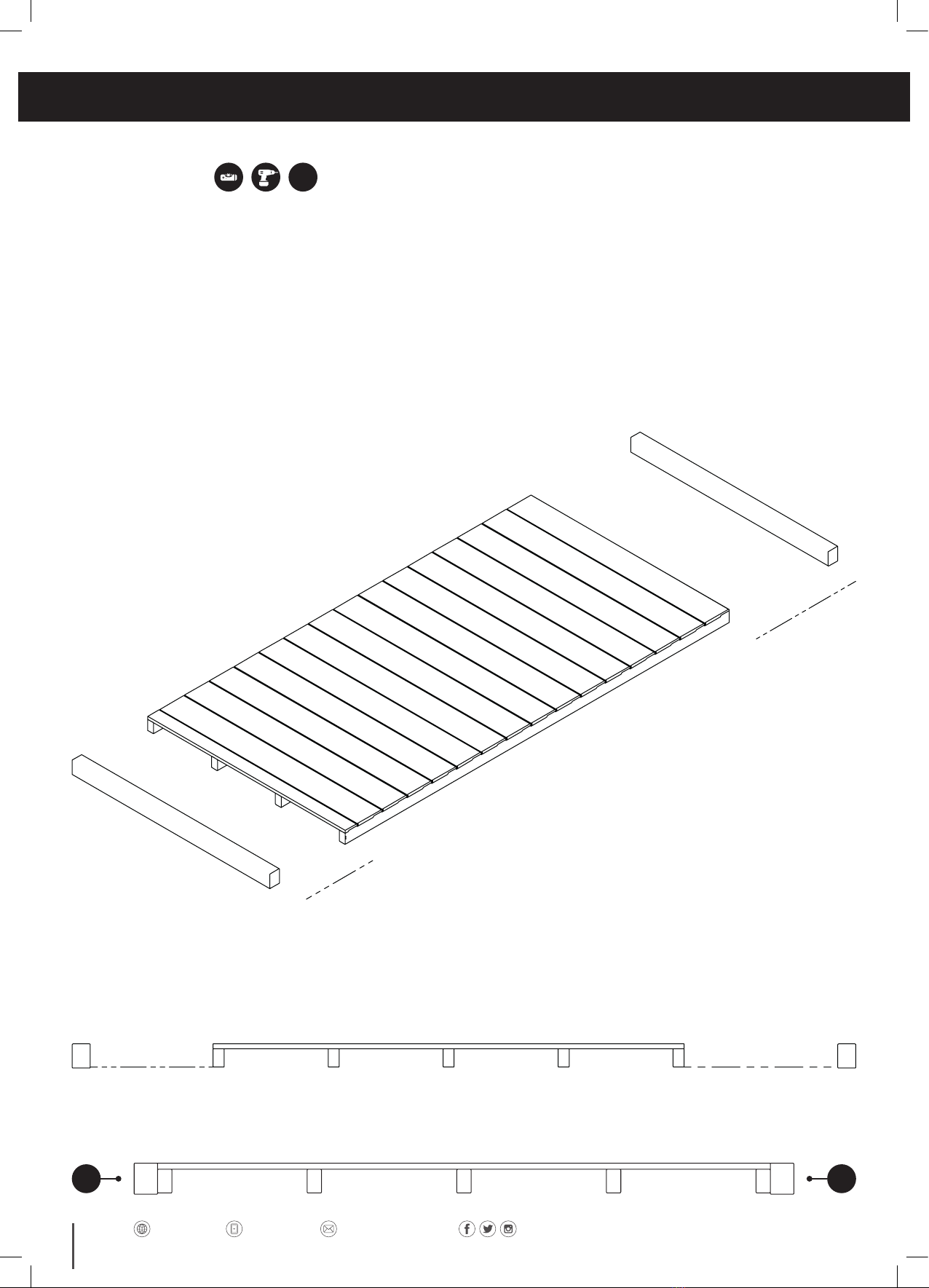

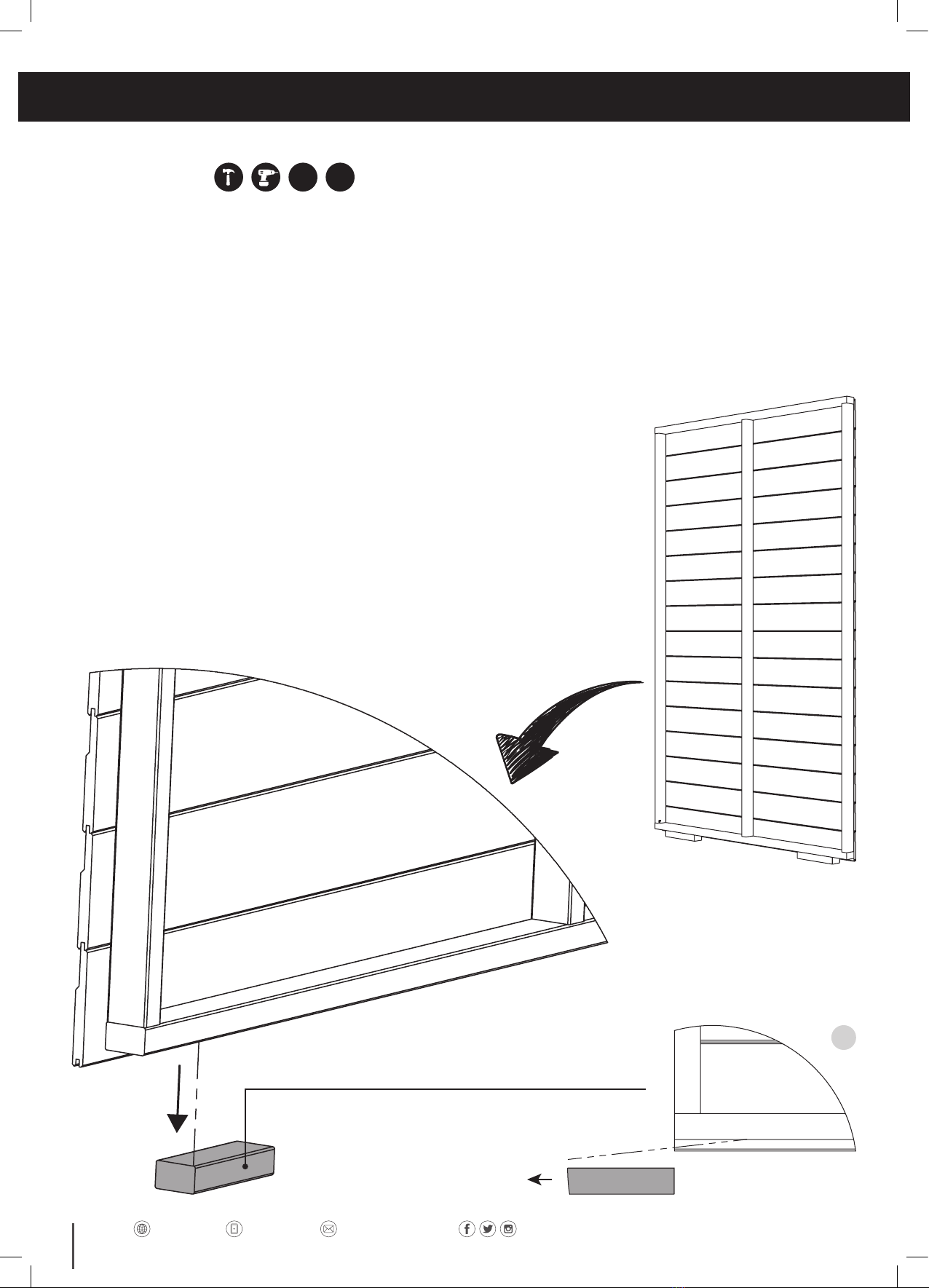

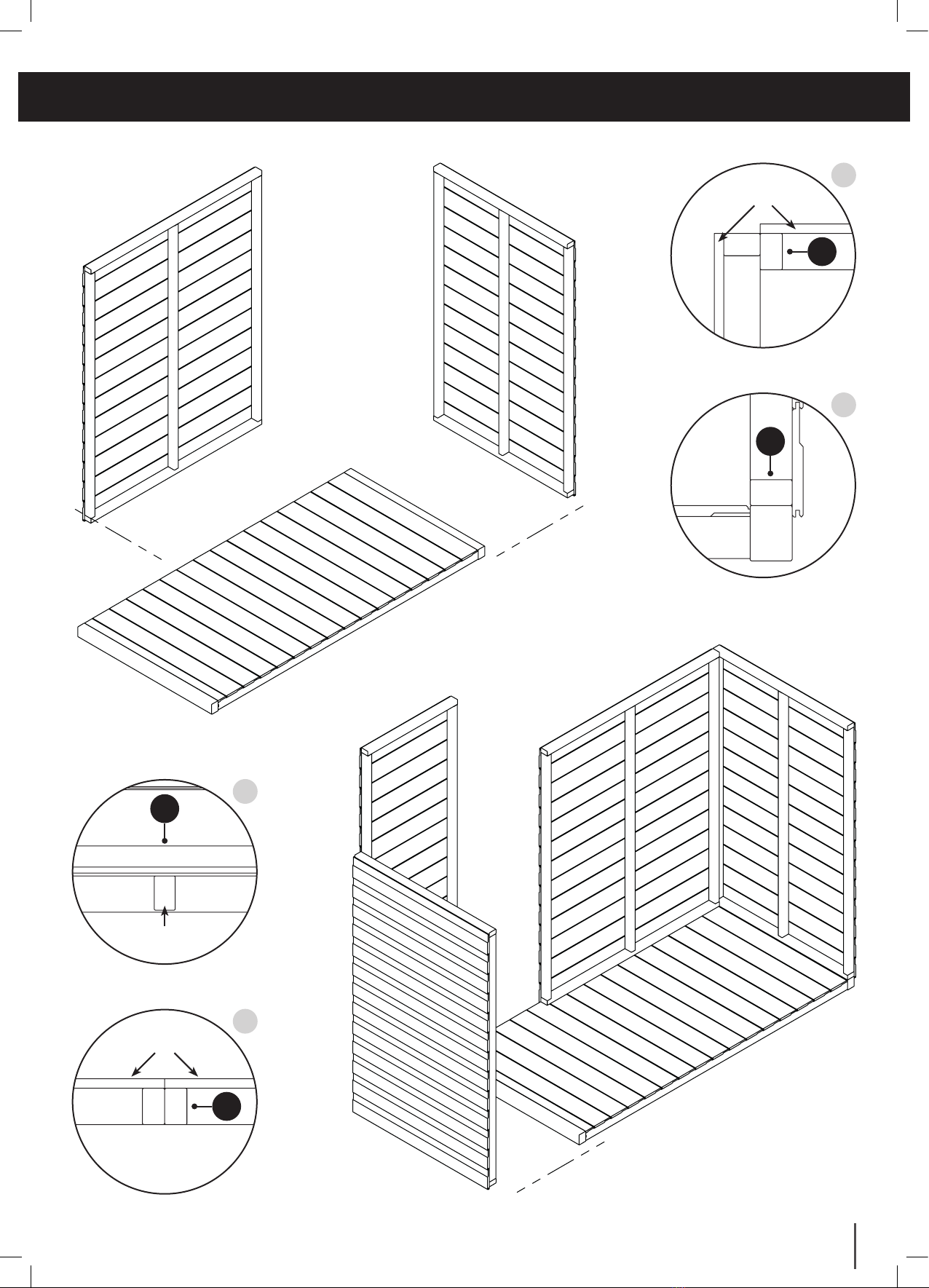

All buildings should be erected

by two competent adults.

CAUTION:

It is advisable to wear gloves

during building installation.

Whilst all products manufactured are made to the highest standards of Safety and in the case of childrens products independently tested to

EN71 level, we cannot accept responsibility for your safety whilst erecting or using this product.

* TigerSkin®Water Based Treatment:

The unique formula of our TigerSkin® pre-treatment provides a reassuring layer of protection for your shed or summer

house. Each panel is carefully dipped and dried to provide maximum coverage, and ensure that your building will have

protection from the moment it arrives and is assembled. A water repellent formula which is harmless to plants, not only

does it help to shield the timber, it also gives it a warm tone that looks great on your property. Once erected, your building

should be treated regularly.

MADE IN THE UK SINCE 1913.

We have been making our high quality, great

value sheds here in Britain for decades.

03

ROOF COVERING OPTIONS

All Tiger buildings are designed to use TigerFelt® high grade poly-backed durable mineral roong felt. If you have

chosen a different roof covering option – such as EPDM rubberised roof covering or Shed Shingles, please see

their separate roong instructions available on their product pages at tigersheds.com.

MAINTENANCE

To validate your guarantee and ensure longevity of the product, it is ESSENTIAL that your building is treated with

a suitable wood preserver or paint either BEFORE or AFTER assembly, both internally and externally. For the

continued protection for unpainted areas of your garden building we recommend maintaining your timber treat-

ment with TigerSkin®preserver. This solvent based wood treatment will penetrate deep into the wood giving

years of protection against the weather and also enhance timber grain with a rich long lasting protection. A water

repellent formula which is harmless to plants when dry, it is available in a wide range of colours to refresh the look

and feel of your garden building. Discover more at tigersheds.com.