Tiger Tigercub Crazy Cottage User manual

Other Tiger Garden House manuals

Tiger

Tiger TIGERFLEX Elysia User manual

Tiger

Tiger JAVAN User manual

Tiger

Tiger SHIPLAP APEX WINDOWLESS SHED User manual

Tiger

Tiger PRESSURE TREATED OCTAGONAL Configuration guide

Tiger

Tiger Aura User manual

Tiger

Tiger KIPLING LOG CABIN User manual

Tiger

Tiger SAMPI User manual

Tiger

Tiger MAYFLOWER SUMMERHOUSE User manual

Tiger

Tiger LOG STORE User manual

Tiger

Tiger Tigercub Magic Mansion User manual

Tiger

Tiger SIGMA TIG/INS48 User manual

Tiger

Tiger Caspian User manual

Tiger

Tiger TIGERFLEX ZORA User manual

Tiger

Tiger Lana User manual

Tiger

Tiger CORBETTI User manual

Tiger

Tiger TIGERFLEX TIG/INS39 User manual

Tiger

Tiger GARDEN STUDIO User manual

Tiger

Tiger TIGERCUB LUXURY LOUNGE User manual

Tiger

Tiger Tigercub Groovy Garage User manual

Tiger

Tiger KERR User manual

Popular Garden House manuals by other brands

Yardmaster

Yardmaster 66 ZGEY Assembly instructions

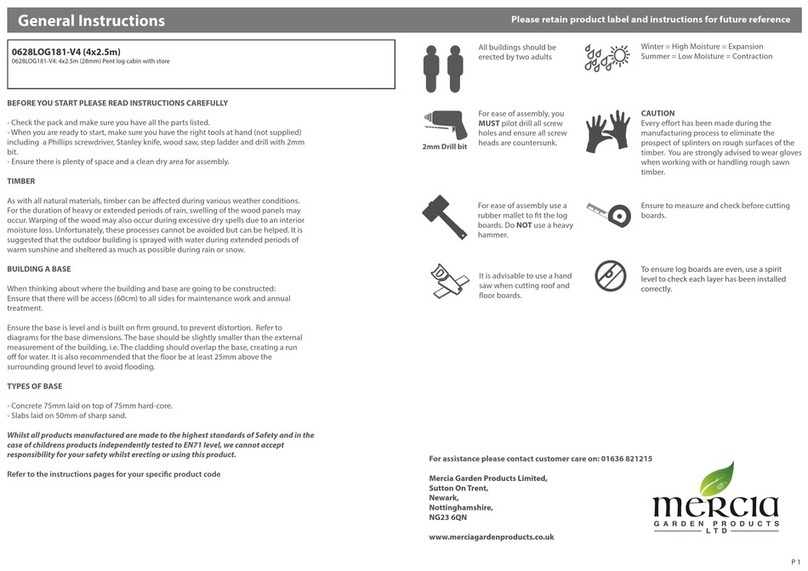

Mercia Garden Products

Mercia Garden Products 0628LOG181-V4 manual

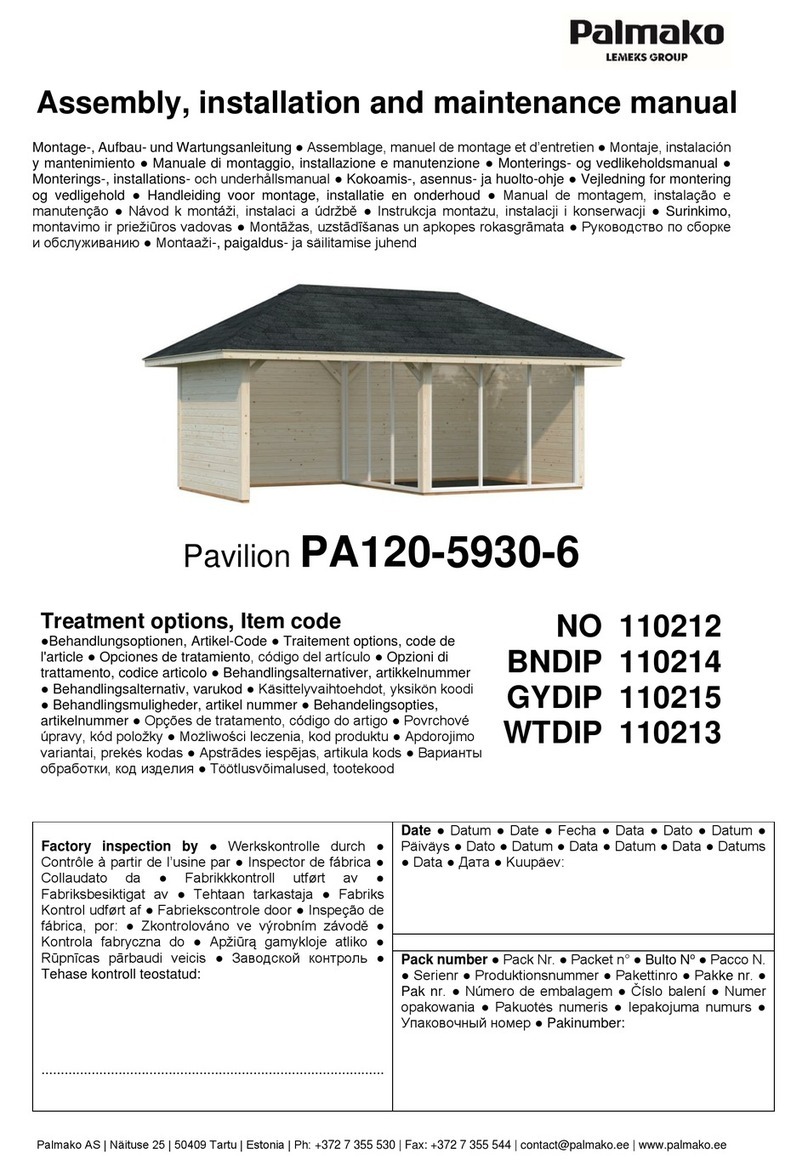

Lemeks

Lemeks Palmako PA120-5930-6 Assembly, installation and maintenance manual

Rion

Rion Hobby Gardener Assembly instructions

Select

Select ISAAC E9682 Assembly manual

Palmako

Palmako Saale installation manual

Palmako

Palmako Roger FR44-5953-2 installation manual

Lemeks

Lemeks Palmako Grace PM56-4529 Assembly, installation and maintenance manual

Mercia Garden Products

Mercia Garden Products 03WES0808-V1 General instructions

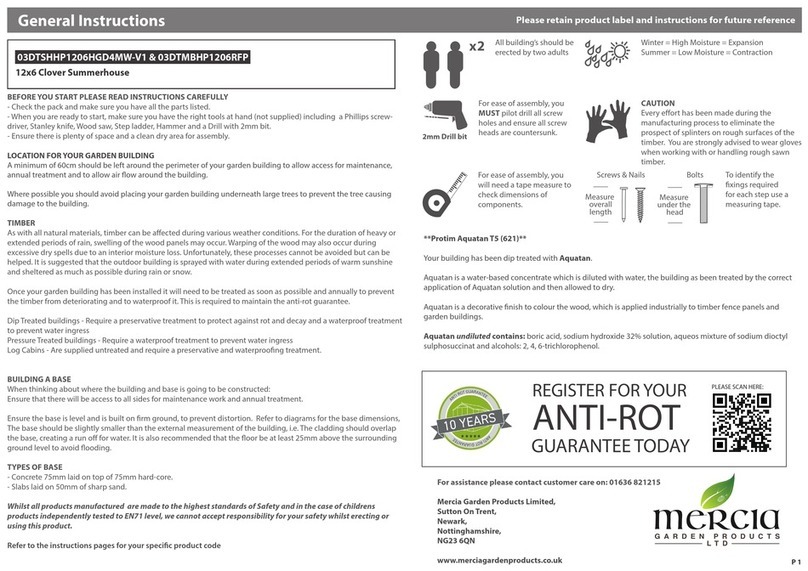

Mercia Garden Products

Mercia Garden Products 03DTSHHP1206HGD4MW-V1 General instructions

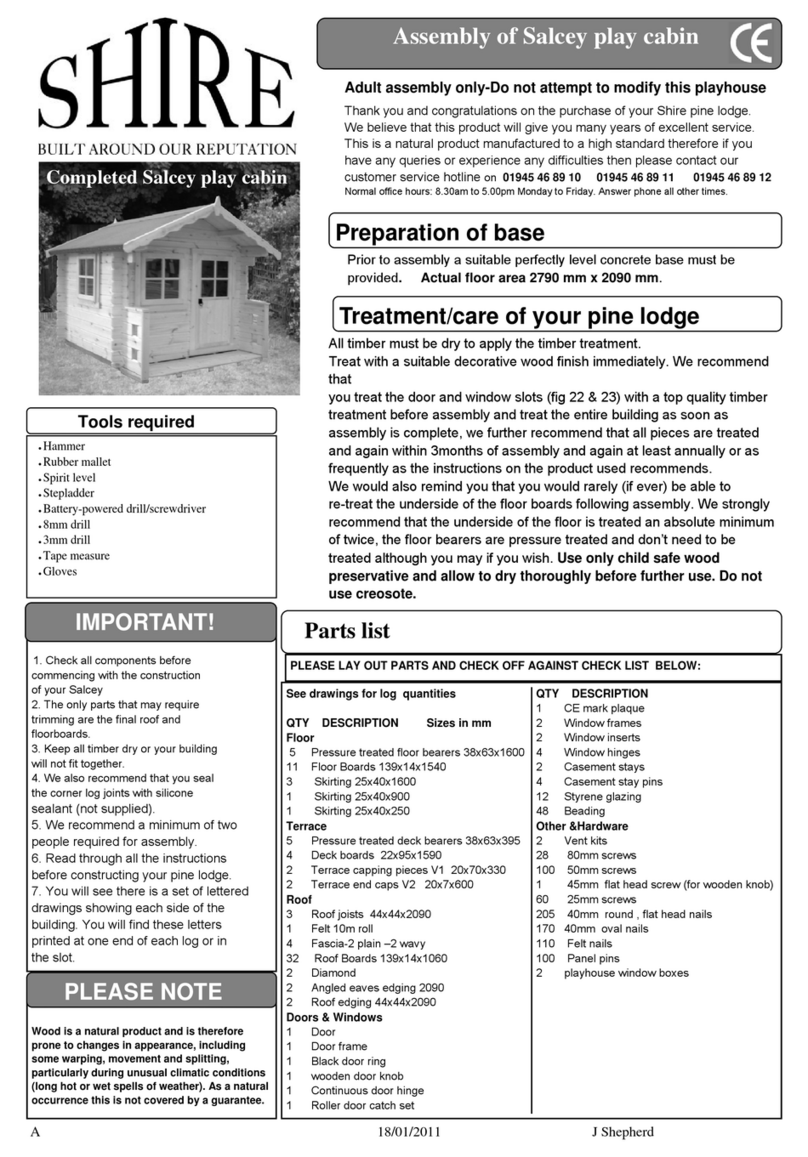

Shire

Shire Salcey Assembly

Pergola kits USA

Pergola kits USA PREMIUM VINYL PAVILION Assembly manual

G21

G21 Boston 882 manual

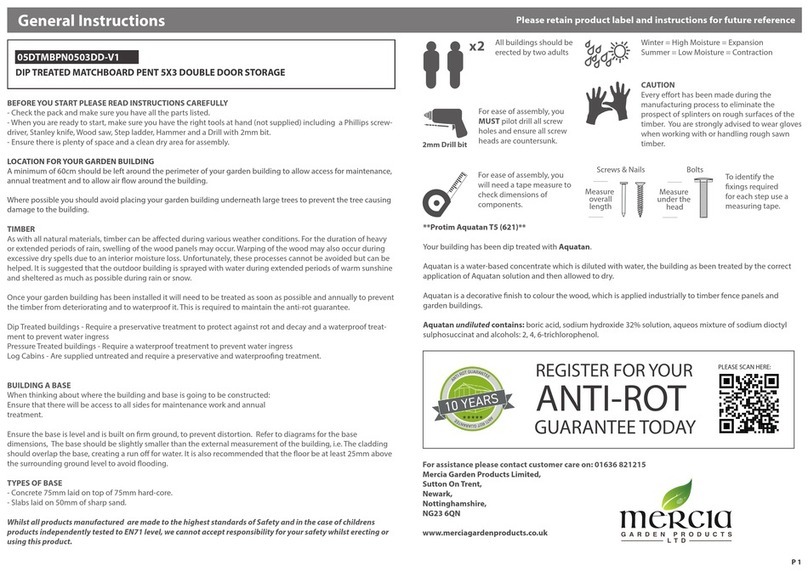

Mercia Garden Products

Mercia Garden Products 05DTMBPN0503DD-V1 Assembly instructions

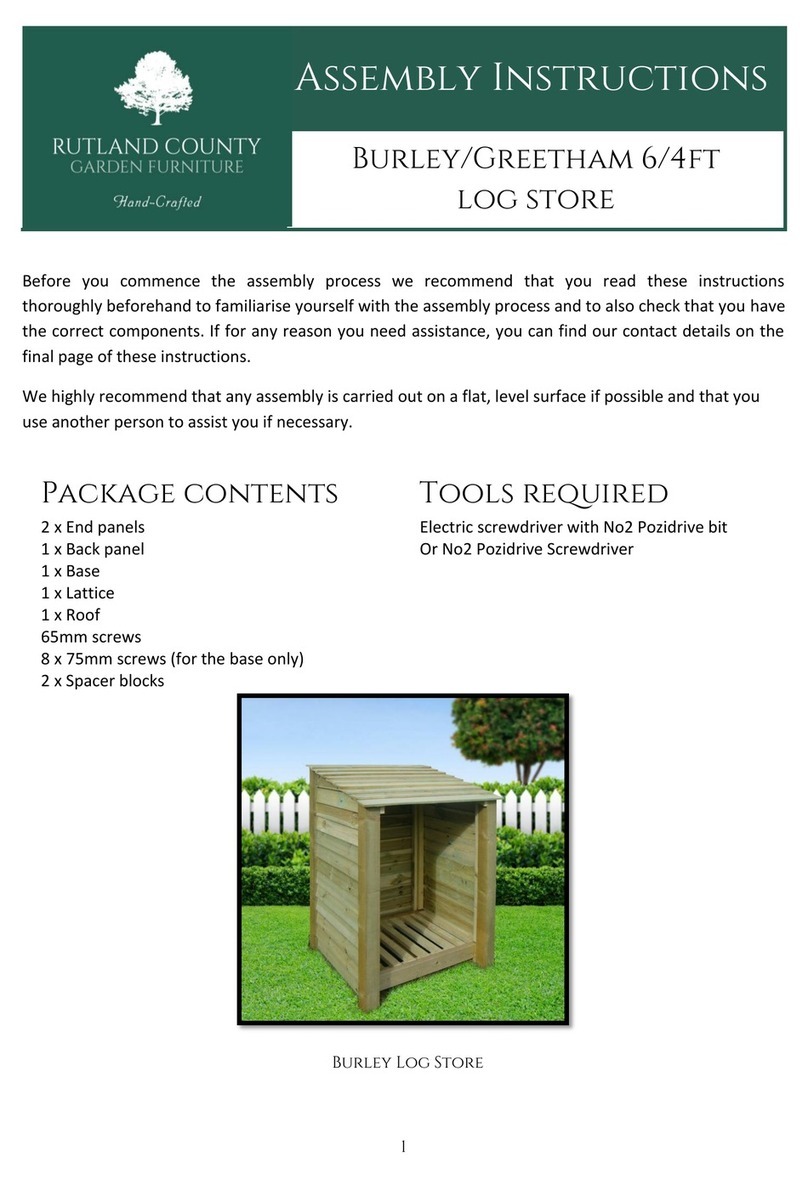

Rutland County

Rutland County Burley 6ft Assembly instructions

Palmako

Palmako Roger 27,7 installation manual

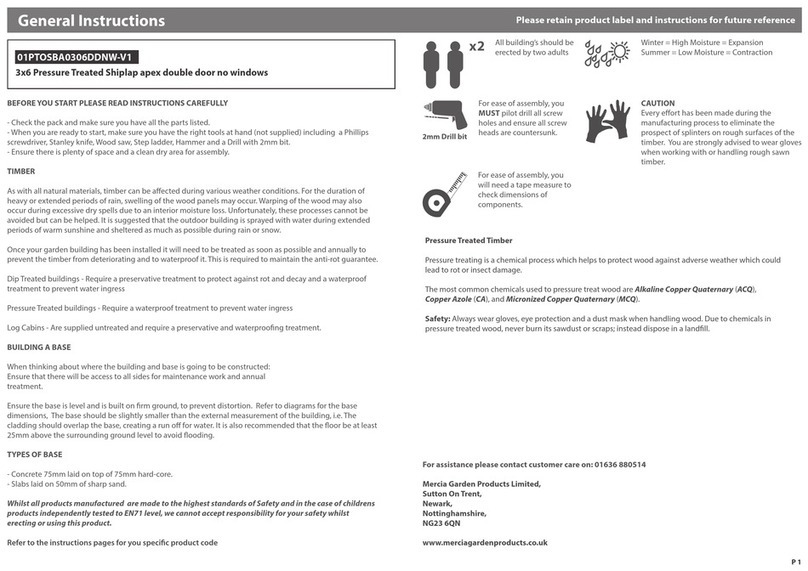

Mercia Garden Products

Mercia Garden Products 01PTOSBA0306DDNW-V1 General instructions

Gartenhaus-King

Gartenhaus-King Valery manual