5075 Calibration Manual Page 9

2.3 Menu options (continued)

Please note that the Cal key does not have to be inserted to view all

options, but it MUST be inserted to edit or execute functions marked

with ‘*’

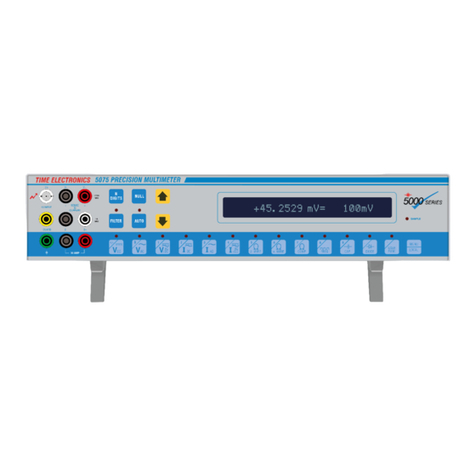

2.4 5075 push buttons

In this manual the 5075 push buttons will be referred to as the legends as printed on

them, e.g ‘MENU’. However throughout this document we will use the shorthand for

the ‘User Func’ key which is written as ‘E’ this is used to select items from the menu.

A. Self Test & Reset Run this to internally test all of the 5075 functions

B. IEEE Address Indicates the setting of the rear panel switches

C. Serial Number* Display and change the 7075 serial number

D. Certificate Number* Previous cert. Number. To be updated after calibration

E. Calibration Date* Previous cal date. To be updated after calibration

F. Calibration Due* Previous cal due date. If run out, set before cal run

G. Calibration Temperature* Ambient room temperature at time of calibration

H. Calibration Period* Normally 52 weeks, can be set from 1 to 999 weeks

I. Key press beep on/off Select as required

J. Continuity beep on/off Select as required

K. Sample beep on/off Select as required. Turn OFF for calibration run

L. Analogue filter on/off Select as required. Turn ON for calibration

M. Countdown on/off Select as required. Used with the dynamic I/O filter

N. Scanner display on/off Select if scanner fitted. OFF for calibration

O. Auto Dynamic filter on/off Select as required. Turn ON for calibration

P. PRT Temperature Select as required. Turn OFF for calibration

Q. Calibration due warning Select as required. Indicates when overdue for calibration

R. Store options* Stores options/front panel settings as power up defaults

S. Date Shows current date

T. Time Shows current time

U. Internal Temperature Shows 5075 internal temperature for reference only

V. Self Calibrate Initiates a ‘INTCAL’. Always do this before a calibration run

W. Clear Cal Factors on/off* Clears the cal factors for the selected range. LEAVE OFF

X. Display Cal Factors on/off Shows the cal factors for the current range. Replaces range info.

Y. Adjust to Value* Used to set the cal factor for non full scale inputs

Z. Calibrate to full scale* Used to set the cal factor with full scale input