Timpdon Marine MRSS3 User manual

TimpdonMarine Tel 0161 -980 8054 Issue 1–May 2011

Web www.timpdon.co.uk

EMail marine@timpdon.co.uk

Features

•Switched control of a standard servo between two end points, at a

controlled rate.

•For use with slow slew rate switch controlled digital transmitter

channels –e.g. Planet T5 -Channel 5.

•User programmable servo positions, with programmable rotation

speed.

•Can be re-programmed in-situ at any time, using built-in push button

switches.

•Programmed settings retained when power removed.

•Accommodates servo position and transmitter pulse widths in range 0.6

ms to 2.4 ms. Auto zero with centre neutral joysticks.

•Digital microprocessor controlled.

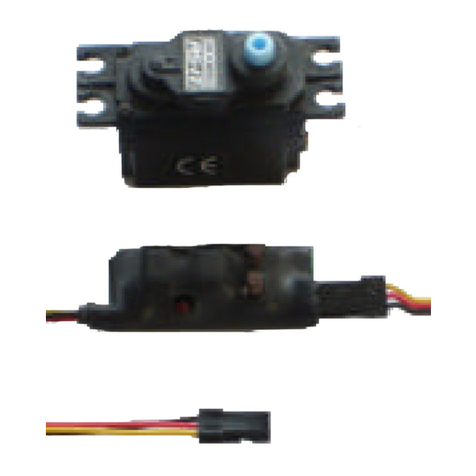

•Small size –45mm x 18mm x 12mm.

•Mounted inline between RC receiver and servo –powered from

receiver.

Timpdon

Marine Radio Servo Switch

Model MRSS3

Controlled rotation between

two servo positions.

Programmable servo

positions and rotation rate.

For use with slow slew rate

digital transmitter channels.

Inline adaptor -fitted

between RC receiver and

servo.

Powered from RC receiver.

TimpdonMarine Tel 0161 -980 8054 Issue 1–May 2011

Web www.timpdon.co.uk

EMail marine@timpdon.co.uk

Installation and Wiring

S2

S1

LED V+

Control

0V Red

Yellow

Black

Connector to Servo

MRSS3

Connector to

Radio Receiver

1Connect the flying lead to the selected channel of your radio receiver.

2Connect your servo to the 3 pin plug on the MRSS3, with the black

servo lead adjacent to edge of unit, and the yellow or white data lead

towards the middle.

3Power up the transmitter. Then power up the receiver.

4Check that, once the receiver has bound to the transmitter, the LED

on the MRSS3 illuminates continuously. This indicates that the

MRSS3 is receiving valid RC pulses. The MRSS3 has a in-built start

up delay of 4.5 seconds to permit binding. During this period, the LED

will flash.

5Check that, when youswitch the channel control from the 0to the 1

setting, the servo immediately rotates at a controlled rate to the set

position, and when you switch back from the 1to the 0setting, the

servo immediately rotates back to the reset position.

6If, at any time, radio communication is lost, theLED will extinguish

and the servo will maintain its last setting. Once communication is re-

established, normal operation will start again automatically.

7Now program the MRSS3, as described below, for the required servo

positions and rotation rate for your system.

On completion of programming, the programmed settings will be

saved in non-volatile memory, and the system will automatically re-

boot in normal operation mode.

8Your system is now ready for use.

TimpdonMarine Tel 0161 -980 8054 Issue 1–May 2011

Web www.timpdon.co.uk

EMail marine@timpdon.co.uk

Principles of Operation

0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2

RC Pulse

Width in ms

Set

Reset

Switches from

Reset

to

Set

on

rising

pulse width

Switches from

Set

to

Reset

on

falling

pulse width

1In a standard RC system, the output from each receiver channel is a

variable width pulse, nominally between 1.0 ms and 2.0 ms in width,

repeated at intervals of approximately 20 ms. A pulse width of 1.0 ms

corresponds to the transmitter controlat minimum, 2.0 ms to

maximum and 1.5 ms to centre.

2The MRSS3 is specifically designed for operation on switched, slow

slew rate digital channels where, when the channel control switch is

operated, the output pulse width moves from 1.0 ms to 2.0 ms, or vice

versa, over a period of several seconds. Such channels are commonly

intended for operation of aircraft undercarriage controls, or similar. The

MRSS3 is designed to detect the changing pulse width and thus

operate the output servo immediately, without any delay.

2Within the MRSS3, the servo output is limited to one of two actions,

depending on the setting, 0or 1, of the transmitter control switch:

Channel Switch Action

1 = Maximum Rotate to programmed set position

0 = Minimum Rotate to programmed reset position

The rotation rate of the servo, at all times, is constant.

Note that the sense of the switch [0or 1] with respect to maximum or

minimum may be reversed on some transmitters.

3The servo output pulse widths corresponding to the 1and 0control

switch positions [set and reset] are user programmable, as is the

rotation rate of the servo between these positions. The available

range of servo output pulse widths is 0.6 ms to 2.4 ms.

TimpdonMarine Tel 0161 -980 8054 Issue 1–May 2011

Web www.timpdon.co.uk

EMail marine@timpdon.co.uk

Programming

Programming or re-programming may be performed at any time, using

push button switches S1 and S2, with indication provided by the LED.

Programming is performed in three steps, in order –Servo Reset

Position, Servo Set Position and Servo Rotation Rate

The set and reset limit positions of the servo may be set anywhere

within its operating range, subject to a limitation of RC pulse widths of

0.6 ms to 2.4ms, as described above.

Programming Procedure

Programming may be undertaken with the transmitter either on or

off.

Press and hold both switches S1 and S2 together.

The LED will flash rapidly for about 5 seconds, and then go on

continuously.Then release both switches.

If you release either switch before the LED stops flashing, the

unit will remain in normal operation.

1You are now in Step 1 –Servo Reset Position

The LED will flash with single shortflashes, and the servo will move

to the current reset position.

Adjust the required reset position using either S1to increase the

servo position or S2to decrease it. The actual rotation direction is

servo dependent.

When satisfied, press and hold both switches S1 and S2 together.

The LED will flash rapidly for about 2 seconds, and then go on

continuously. Then release both switches.

If you release either switch before the LED stops flashing, the

unit will remain in program Step 1.

The unit will then proceed automatically proceed to program Step 2.

TimpdonMarine Tel 0161 -980 8054 Issue 1–May 2011

Web www.timpdon.co.uk

EMail marine@timpdon.co.uk

2You are now in Step 2 –Servo Set Position

The LED will flash with double shortflashes, and the servowill move

to the current set position.

Adjust the required set position using either S1to increase the servo

position or S2to decrease it. The actual rotation direction is servo

dependent.

When satisfied, press and hold both switches S1 and S2 together.

The LED will flash rapidly for about 2 seconds, and then go on

continuously. Then release both switches.

If you release either switch before the LED stops flashing, the

unit will remain in program Step 2.

The unit will then proceedautomatically to program Step 3

3You are now in Step 3 –Servo Rotation Rate

The LED will flash with single long flashes, and the servo will rotate

continuously between the current set and reset positions at the

current rotation rate.

There are sixteen separate rotation rates, between 0.25 and 20

seconds for 90°rotation. Select the required rotation rate using

either S1to increase the rate or S2to decrease it. After the last step,

the rate will revert to the other end of the scale.

When satisfied, press and holdboth switches S1 and S2 together.

The LED will flash rapidly for about 2 seconds, and then go on

continuously. Then release both switches.

If you release either switch before the LED stops flashing, the

unit will remain in program Step 3.

The unit will then save all programmed values to non-volatile

memory.

The LED will then flash rapidly for about 4 seconds to indicate

completion of programming, and then the MRSS3 will automatically

reboot in normal operation mode, with the new programmed settings

operational.

The MRSS3 is now ready for use.

TimpdonMarine Tel 0161 -980 8054 Issue 1–May 2011

Web www.timpdon.co.uk

EMail marine@timpdon.co.uk

Notes on Programming

1Once you have entered programming mode, there is no exit until all

programming steps have been completed. If you enter programming

mode inadvertently, and you do not wish to re-program the unit,

remove and re-apply power, to restart in normal operation mode.

2Remember that no new programmed settings are saved until the end

of programming Step 3. All steps must therefore be completed for

programming to be valid.

3If you make an error during programming, simply repeat the

programming procedure after the unit has re-booted in normal

operation mode.

Constraints on Operation

1The MRSS3 is designed to detect a change in pulse width on

consecutive transmissions from the transmitter, at nominal intervals

of 20 ms, in order to determine a set or reset condition of the

output.

2An increase in pulse width will be interpreted as a set request, and a

decrease as a reset request.

3In order for the MRSS3 to detect a valid change in pulse width, the

slew rate of the transmitter pulse width output must be greater than

or equal to 0.17 ms per second, representing a maximum total slew

period between pulse widths of 1.0 ms and 2.0 ms of 6 seconds.

4In addition to slew rate detection, in order to accommodate the end

conditions[pulse width = 1.0 ms or 2.0 ms nominal] where the pulse

width no longer changes, the MRSS3 will, in addition, consider a

pulse width greater than 1.5 ms to represent a set condition, and a

pulse width of less than 1.5 ms to represent a reset condition, if the

pulse widths are no longer changing.

Table of contents

Other Timpdon Marine Switch manuals

Popular Switch manuals by other brands

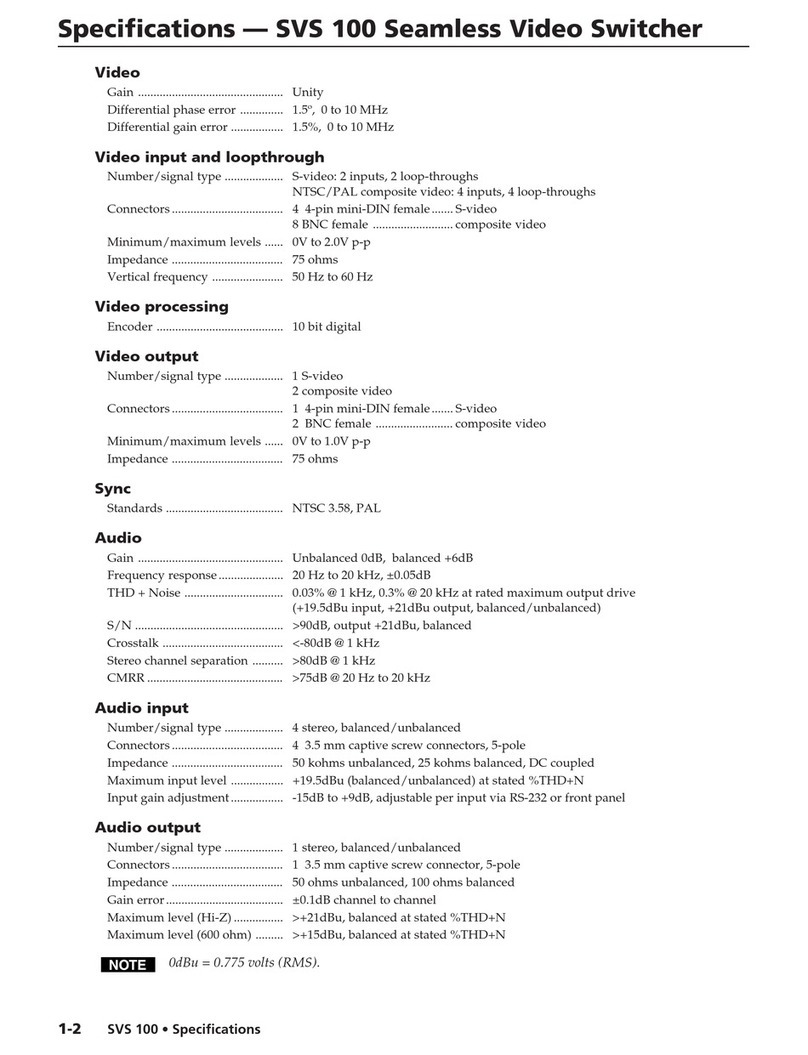

Extron electronics

Extron electronics SVS 100 Specifications

Grandbeing

Grandbeing GB07SW0301 operating instructions

StarTech.com

StarTech.com SDOCK2U33HFW instruction manual

Ubiquiti

Ubiquiti EdgeSwitch ES-16-150W quick start guide

Brocade Communications Systems

Brocade Communications Systems PowerConnect B-DCX quick start guide

KTI

KTI KFS-2621 user manual