2

WARNING: This gun is not a toy nor is it intended

for unsupervised use by persons under the age

of 18 years. Always keep in mind that the sport

of Paintball will be viewed and judged upon your

safe and sportsman like conduct.

SAFETY IS YOUR RESPONSIBILITY(Continued from page 1)

•Pressurize and load the weapon only when you are using it.

Unloadand removeCO2 cylinderimmediatelyafteruseforsafe

storage.

•Dressforsafety when playing the game, avoid any areas of

exposed skin especially the face and throat. Even a light

layer will absorb some of the impact and protect your skin

from cuts produced by the gelatin paintball shell fragments

when hit at close ranges.

•Keep exposed flesh away from escaping CO2 gas when

installing or removing bottles or cartridges of gas from the

weapon or from a filling cylinder. CO2gas is very cold and

can cause frostbite under certain conditions.

•Use only .68 caliber paintball pellets. Never load or fire any

foreign objects.

•DoNot field strip orotherwisedisassemble this gun whileit is

pressurized with gas. Remove CO2cylinder or CO2cartridge

before doing any disassembly.

•Do not look directly into the barrel. Accidental discharge

into the eyes may cause permanent injury or death.

•Avoid alcoholic beverages before and during the use of this

weapon. Handling guns while under the influence of drugs

or alcohol is a criminal disregard for public safety.

•Avoidshooting anopponentat pointblank(three feetorless).

•If you purchased a 12 gram cartridge adaptor with this

gun be sure to read and follow the instructions that came

with the adaptor.

•Never fire your weapon at personal property of others, the

paintball can stain the paint of automobiles and houses if left

on the surface for a few hours.

GENERAL

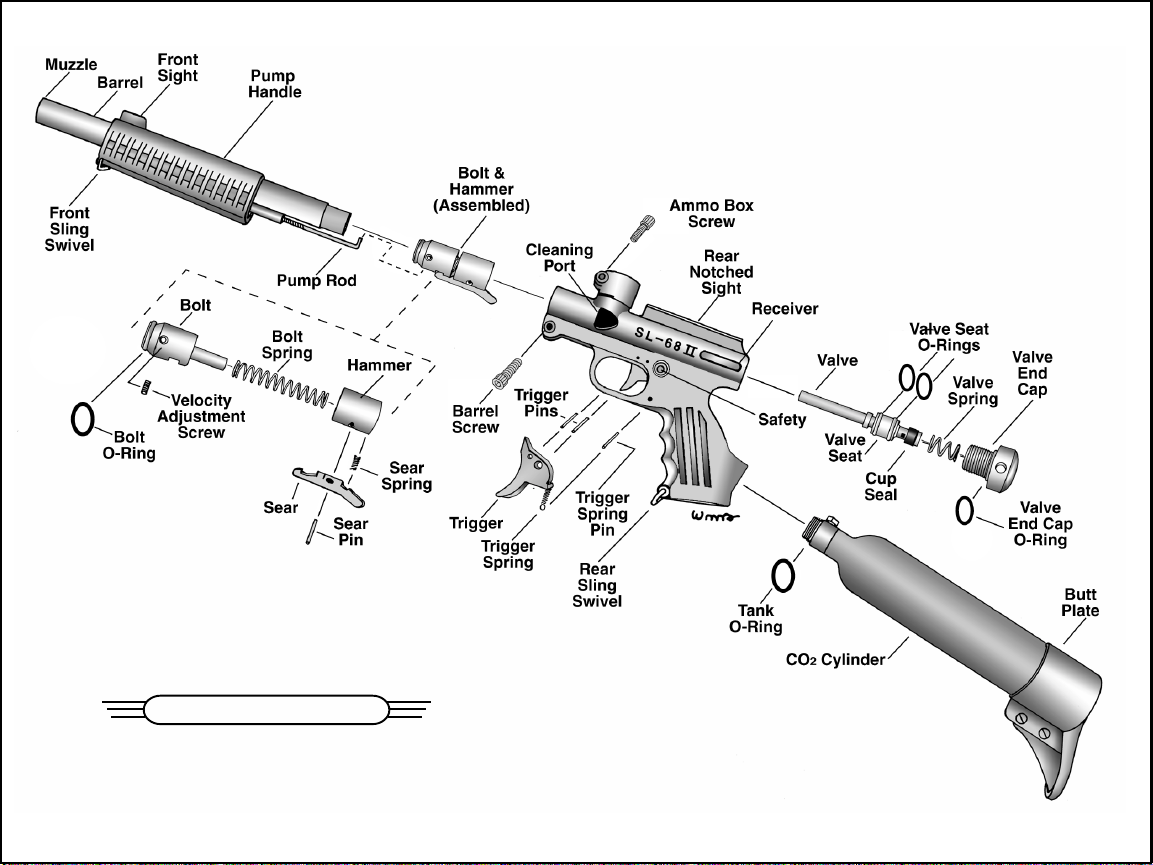

The SL-68 II represents a totally original design by

Tippmann Pneumatics, Inc. It's design objectives were

durability, extreme accuracy and low cost. We have met our

objectivesandare proudto offeryouthis highqualityweapon.

The receiver is super strong aluminum—magnesium alloy

and has the feed elbow and gas port cast in place for the

ultimate in simplicity and durability. The barrel is aluminum

and is also held in place by a built in clamp on the receiver,

both clamps are operated by a 3/16 allen wrench. All

internal parts are noncorrosive including trigger and sear

group. The valve system has been redesigned to eliminate

the common breakage of tubes with other guns and we

guarantee the seal to last a lifetime. The cleaning port on

the left side of the receiver has been designed to clean

barrel from the breach end, to visually inspect chamber and

feeding, and allow velocity adjustment without gun disassembly .

To load a ball pull the pump handle rearward until it bottoms

against the receiver. This will cock the weapon and a ball

will drop into the receiver to be loaded. Push the pump back

forward and the bolt will push the ball into the barrel.

Pull the trigger to fire the ball (this gun cannot be recocked

until previous has been fired). The design of the trigger

incorporates an auto-trigger effect, with a constant pull on

thetrigger the SL-68 II willfire each time thepump is cycled.

SPECIFICATIONS

Model ................................................... Tippmann SL-68 II

Caliber........................................................................... .68

Action .....................................................Slide action pump

Power .............Optional CO2 gas in cylinders or cartridges

Muzzle Velocity ..........Approx. 215-315 F.P.S. (adjustable)

CO2 Capacity........ 450+ shots per (optional) 9 oz. cylinder

Feed ........................................................................ Gravity

Standard Barrel Length ................................................. 11"

Sniper Model Barrel Length .......................................... 14"

Length - Overall (with Standard barrel & 9 oz. tank) ..... 27"

Weight with 9 oz. tank (empty).................................. 4 lbs.

Effective Range...................................................... 150+ ft.

Sight ............ Front post and combination dovetail grooved

................................. scope mount, and notched rear sight

Material ................................Aluminum and stainless steel

3