9

OPERATION INSTRUCTIONS

•Work platform operator must acquire appropriate qualification or license to work in

elevated height according to requirements of local regulations.

•Forklift or telehandler operator must acquire appropriate qualification or license and

fully trained to maneuver elevated loads.

•Operator must be mentally sound and not being affected by drugs or alcoholic drinks

during operating the equipment. Alcohol and drugs could reduce alertness and

coordination causing catastrophic accidence with serious personal injury or death. An

operator taking prescription or over the counter drugs should seek medical advice as to

whether he or she can safely operate the equipment.

•Work platform operator must put on OSHA safety lanyard or harness that is locked in

place to the harness ring of the platform.

ENVIRONMENTAL FACTORS

•Avoid working in bad weather including but not limited to heavy rain, snowing, stormy

and windy weather.

•Do not operate in environment that is not well-lite.

•Avoid working on a slope, uneven and slippery ground. Make sure the ground is solid

enough to hold the forklift or telehandler stably and use outrigger if available.

•Beware of overhead power, communication lines and other obstacles to plan safe lifting.

INSPECTIONS BEFORE USE

•Make sure that the forklift or telehandler can be stopped quickly in case of emergency.

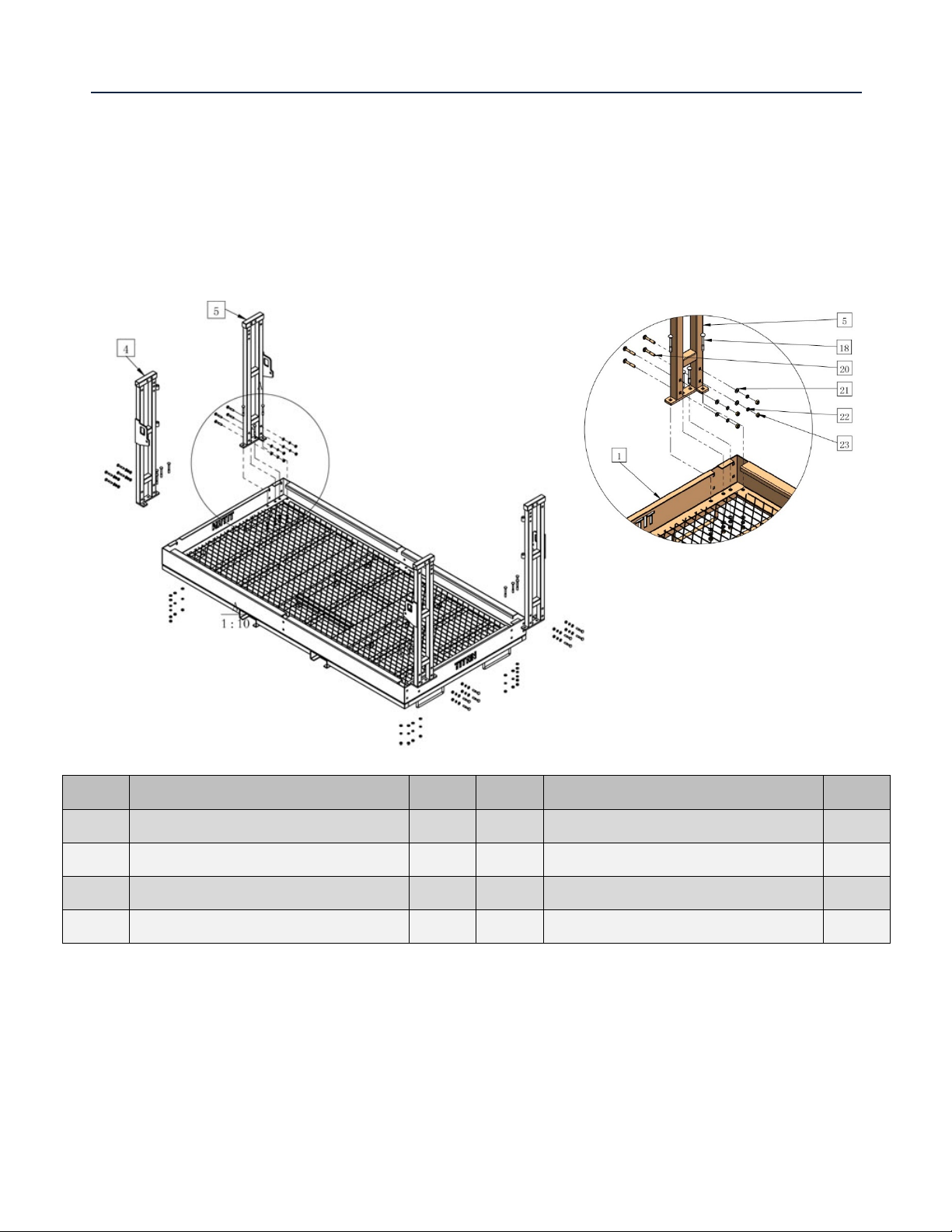

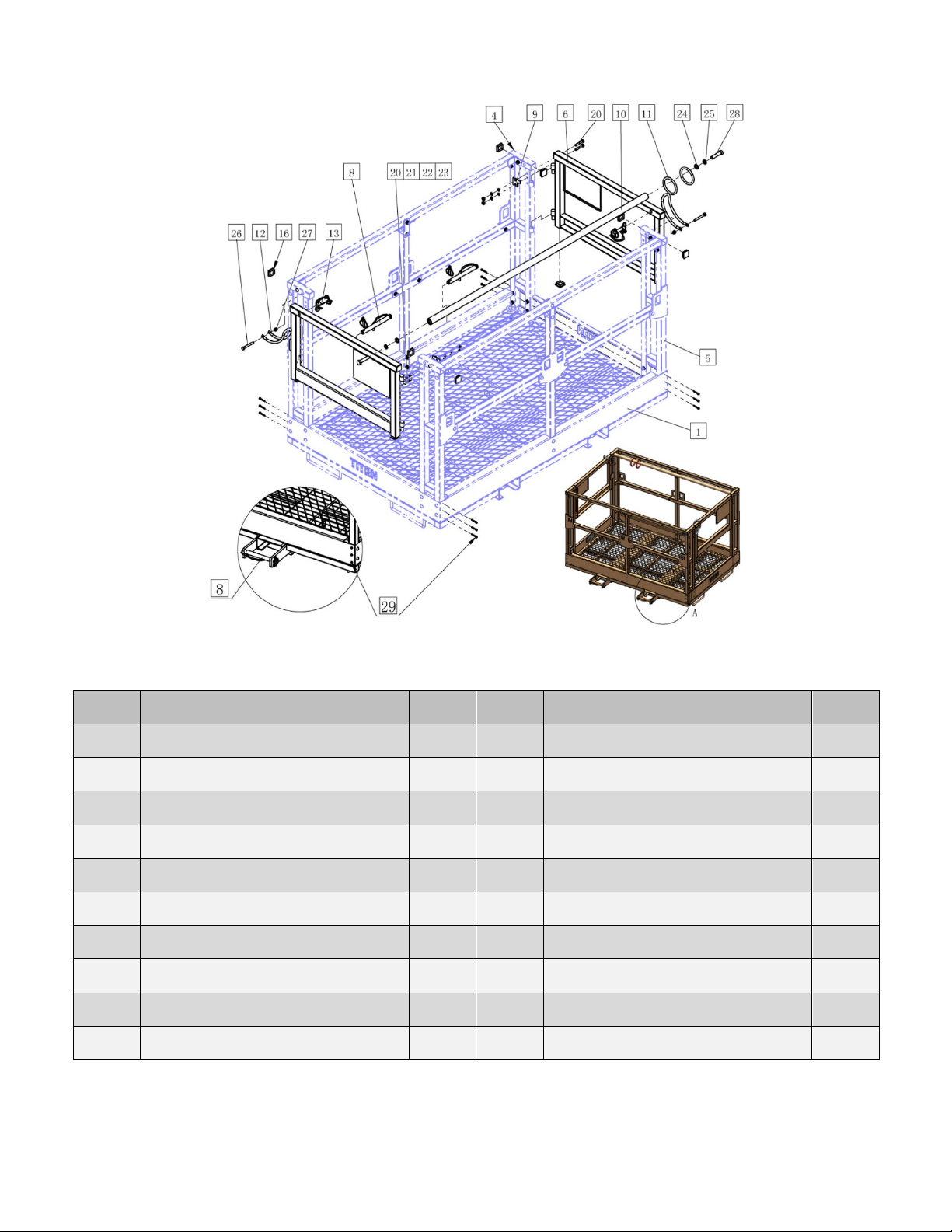

•Check structural integrity of platform including, damaged, deformed and wearing of

parts and hardware, cracks in welds, and excessive erosions caused by rusting. Replace

or repair if necessary.

•Check for loosen bolts, nuts and pins and tighten.

•Double check gate latch can be locked securely.

•Double if guard rails are tightly locked onto the work platform.

•Check communication link between forklift operator and personnel on platform is in

good order.

USING THE WORK PLATFORM

•Make sure that the work area is in good working conditions as stated in the previous

ENVIROMENTAL FACTOR section, and all necessary inspections stated in the previous

INSPECTION BEFORE USE section is satisfactorily performed.

•Insert the fork tines fully into the fork channels and secure the fork heel tightly against

the safety pins. Double check if the fork is locked tightly without allowing movements.