4 PowrTwin Plus

GB

Safety precautions

1.3 Gasoline Engine Safety

1. Gas engines are designed to give safe and dependable service

if operated according to instructions. Read and understand

UIFFOHJOFNBOVGBDUVSFST0XOFST.BOVBMCFGPSFPQFSBUJOHthe engine. Failure to do so could result in personal injury or

equipment damage.

2. To prevent re hazards and to provide adequate ventilation,

keep the engine at least 1 meter (3 feet) away from buildings

and other equipment during operation. Do not place

ammable objects close to the engine.

3. People who are not operating the device must stay away from

the area of operation due to a possibility of burns from hot

engine components or injury from any equipment the engine

may be used to operate.

,OPXIPXUPTUPQUIFFOHJOFRVJDLMZBOEVOEFSTUBOEUIFPQFSBUJPOPGBMMDPOUSPMT/FWFSQFSNJUBOZPOFUPPQFSBUFUIFengine without proper instructions.

5. Gasoline is extremely ammable and is explosive under

certain conditions.

6. Refuel in a well-ventilated area with the engine stopped. Do

not smoke or allow ames or sparks in the refueling area or

where gasoline is stored.

7. Do not overll the fuel tank. After refueling, make sure the

tank cap is closed properly and securely.

8. Be careful not to spill fuel when refueling. Fuel vapor or

spilled fuel may ignite. If any fuel is spilled, make sure the area

is dry before starting the engine.

/FWFSSVOUIFFOHJOFJOBOFODMPTFEPSDPOñOFEBSFB&YIBVTUcontains poisonous carbon monoxide gas; exposure may

cause loss of consciousness and may lead to death.

10. The muer becomes very hot during operation and remains

hot for a while after stopping the engine. Be careful not to

touch the muer while it is hot. To avoid severe burns or re

hazards, let the engine cool before transporting it or storing it

indoors.

/FWFSTIJQUSBOTQPSUTQSBZFSXJUIHBTPMJOFJOUIFUBOLDO NOT use this equipment to spray water or acid.

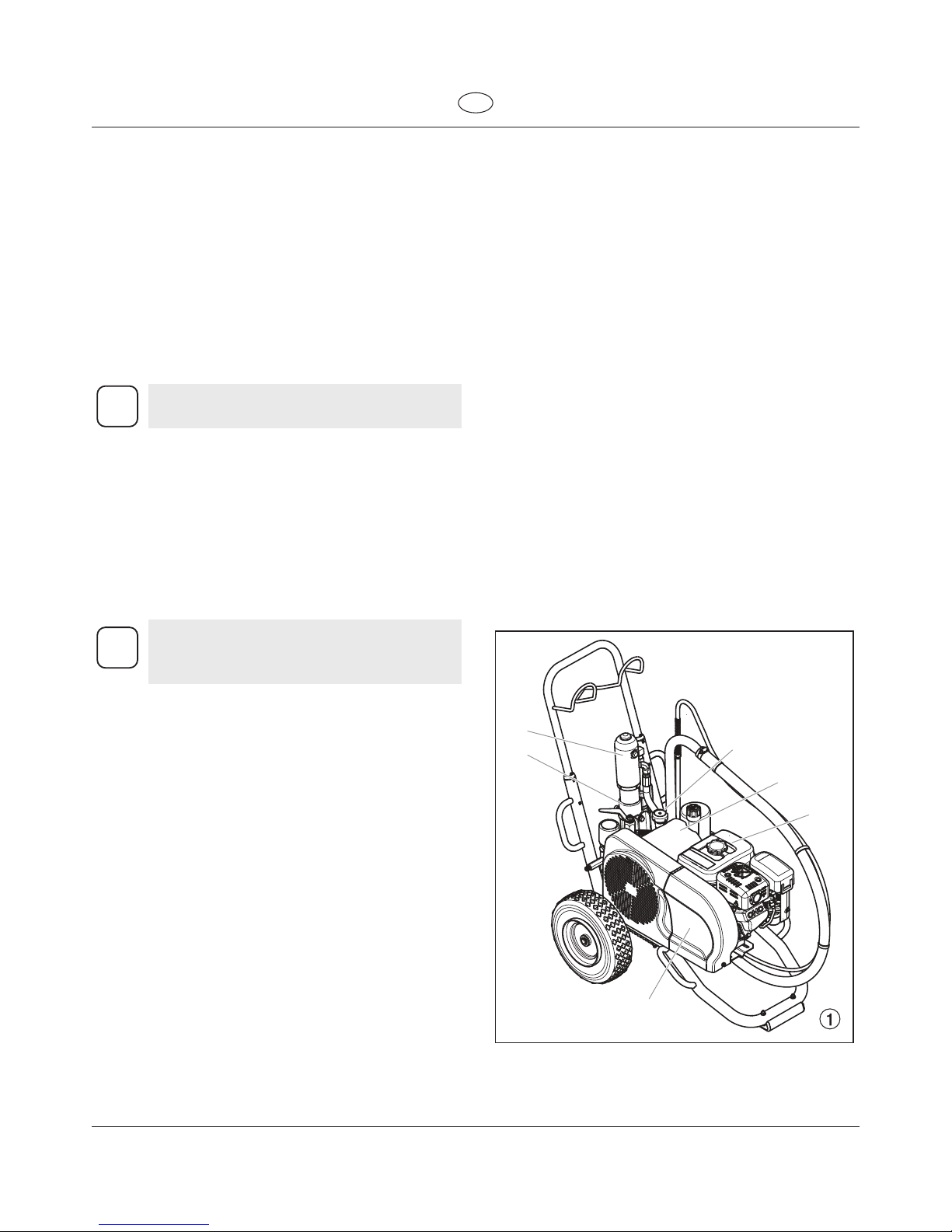

Attention

Do not lift by cart handle when loading or unloading.

Device is very heavy. Three-person lift is required.

1.4 Fueling (gas engine)

Gasoline is extremely flammable and is explosive

under certain conditions.

Fuel Specications

r6TFBVUPNPUJWFHBTPMJOFUIBUIBTBQVNQPDUBOFOVNCFSPG86 or higher, or that has a research octane number of 91 or

IJHIFS6TFPGBMPXFSPDUBOFHBTPMJOFDBODBVTFQFSTJTUFOU“pinging” or heavy “spark knock” (a metallic rapping noise)

which, if severe, can lead to engine damage.

iIf “spark knock” or “pinging” occurs at a steady

engine speed under normal load, change brands of

gasoline. If spark knock or pinging persists, consult

an authorized dealer of the engine manufacturer.

Failure to do so is considered misuse, and damage

caused by misuse is not covered by the engine

manufacturer’s limited warranty.

Occasionally you may experience light spark knock

while operating under heavy loads. This is no

cause for concern, it simply means your engine is

operating eciently.

r6OMFBEFEGVFMQSPEVDFTGFXFSFOHJOFBOETQBSLQMVHEFQPTJUTand extends the life of the exhaust system components.

r/FWFSVTFTUBMFPSDPOUBNJOBUFEHBTPMJOFPSBOPJMHBTPMJOFmixture. Avoid getting dirt, dust, or water in the fuel tank.

Gasolines Containing Alcohol

If you decide to use a gasoline containing alcohol (gasohol), be

sure its octane rating is at least as high as that recommended by

the engine manufacturer. There are two types of “gasohol”: one

containing ethanol, and the other containing methanol. Do not use

gasohol that contains more than 10% ethanol. Do not use gasoline

containing methanol (methyl or wood alcohol) that does not also

DPOUBJODPTPMWFOUTBOEDPSSPTJPOJOIJCJUPSTGPSNFUIBOPM/FWFSuse gasoline containing more than 5% methanol, even if it has co-

solvents and corrosion inhibitors.

iFuel system damage or engine performance

problems resulting from the use of fuels that contain

alcohol is not covered under the warranty. The

engine manufacturer cannot endorse the use of

fuels containing methanol since evidence of their

suitability is incomplete at this time.

Before buying gasoline from an unfamiliar station, try

to nd out if the gasoline contains alcohol. If it does,

conrm the type and percentage of alcohol used. If

you notice any undesirable operating characteristics

while using a gasoline that contains alcohol, or one

that you think contains alcohol, switch to a gasoline

that you know does not contain alcohol.