EverSewn CH04AX Operating instructions

REPAIR MANUAL

CH04AX

Contents

1. Gauge & Tool List........................................................................................................................ 2

2. Remove machine covers....................................................................................................... 2

2-2. Remove face plate................................................................................................................................ 2

2-3. Remove Front cover ............................................................................................................................ 2

2-4. Remove Back cover............................................................................................................................. 2

2-5. Remove bed cover ............................................................................................................................... 2

3. Mechanical components adjustment........................................................................... 2

3-1. Play of the Arm shaft ........................................................................................................................... 2

3-2. Thread take up lever adjustment......................................................................................................... 2

3-3. Adjusting the needle drop position .................................................................................................... 2

3-4. Adjust height of the presser foot........................................................................................................ 2

3-5. Adjust the zigzag movement of the needle ........................................................................................ 2

3-6. Adjust needle drop positions.............................................................................................................. 2

3-7. Adjust the automatic needle threader ................................................................................................ 2

3-8. Adjust the needle bar height............................................................................................................... 2

3-9. Adjust the hook timing ........................................................................................................................ 2

3-10. Adjust the distance between needle and hook................................................................................ 2

3-12. Adjust the play for the rotary hook plates........................................................................................ 2

3-13. Adjust the height of the feed dog...................................................................................................... 2

3-14. Adjust the feed dog position............................................................................................................. 2

3-15. Adjust the upper thread tension ....................................................................................................... 2

3-16. Adjust the bobbin case tension ........................................................................................................ 2

3-17. Adjust motor belt ............................................................................................................................... 2

3-18. Super Adjust stitch balance.............................................................................................................. 2

3-19. BH BH adjustment.............................................................................................................................. 2

3-20. Bobbin winder adjustment ................................................................................................................ 2

4. Electronic Components.......................................................................................................... 2

5. Printed Circuit Board................................................................................................................ 2

5-2. HF transformer board .......................................................................................................................... 2

6-1. Trouble shooting –Main power .......................................................................................................... 2

6. Trouble shooting –Electronic parts............................................................................. 2

6-2. DC Trouble shooting - Motor............................................................................................................... 2

6-3. Trouble shooting –Stepping motor(stitch length)............................................................................. 2

6-4. Trouble shooting –Stepping motor(upper tension).......................................................................... 2

6-5. Trouble shooting –Stepping motor(thread trimmer)......................................................................... 2

6-6. Trouble shooting –Stepping motor(zigzag)....................................................................................... 2

6-7. Trouble shooting –Wi-Fi module (CH04AX) ....................................................................................... 2

6-8. Operation Panel Malfunction............................................................................................................... 2

6-9. Start/Stop button & Reverse button malfunction............................................................................... 2

6-10. Bobbin winder cannot stop............................................................................................................... 2

6-11. Buttonhole Sewing Failure................................................................................................................ 2

6-12. Foot Controller Failure....................................................................................................................... 2

6-13. LED Light Failure ............................................................................................................................... 2

6-14. Organize the cables ........................................................................................................................... 2

7. Embroidery Unit............................................................................................................................ 2

7-1. Main parts of the embroidery unit....................................................................................................... 2

7-2. Dissemble the embroidery unit........................................................................................................... 2

7-3. Mechanical adjustment for the embroidery unit. ............................................................................... 2

7-4. PCB Layout for the embroidery unit................................................................................................... 2

8. Quick Repair Reference.......................................................................................................... 2

1

1. Gauge & Tool List

Gauge Appearance

No

ZH SAP#

Item Description

Spec.

Purpose

1

031CAA0044

Needle bar height

gauge

29.05mm

For needle bar

height

adjustment (see

page 16)

2

031CAA0013

Hook timing gauge

3.5mm

For adjusting

the hook timing

(see page 18)

3

031CAA0014

Hook timing gauge

holder

For adjusting

the hook timing

(see page 18)

4

031CAA0010

Feed dog gauge

0.9~1.05mm

For adjusting

the height of

feed dog (see

page 25)

5

031V8D0301

Presser bar Gauge

6.0~6.5mm

For adjusting

the height of

presser foot

(see page 10)

6

031CAA0012

Zigzag movement

gauge

6.0~6.2mm

Checking the

zigzag

movement of

the needle (see

page10)

7

031CAA0042

Rotary hook plate

(1) gauge

0.3~0.5mm

Check the play

allowance for

the rotary hook

plate (1) (see

page 22)

8

031CAA0043

Rotary hook plate

(2) gauge

0.6~1.0mm

Check the play

allowance for

the rotary hook

plate (2) (see

page 23)

2

Tool Type

No

Head Type

Item Description

Specs

Remark

1

Hexagon

screwdriver

1.5mm

2

Hexagon

screwdriver

2.0mm

3

Hexagon

screwdriver

2.5mm

4

Hexagon

screwdriver

3.0mm

5

Hexagon

screwdriver

4.0mm

6

L-shape slotted

screwdriver (twin

heads)

3

2. Remove machine covers

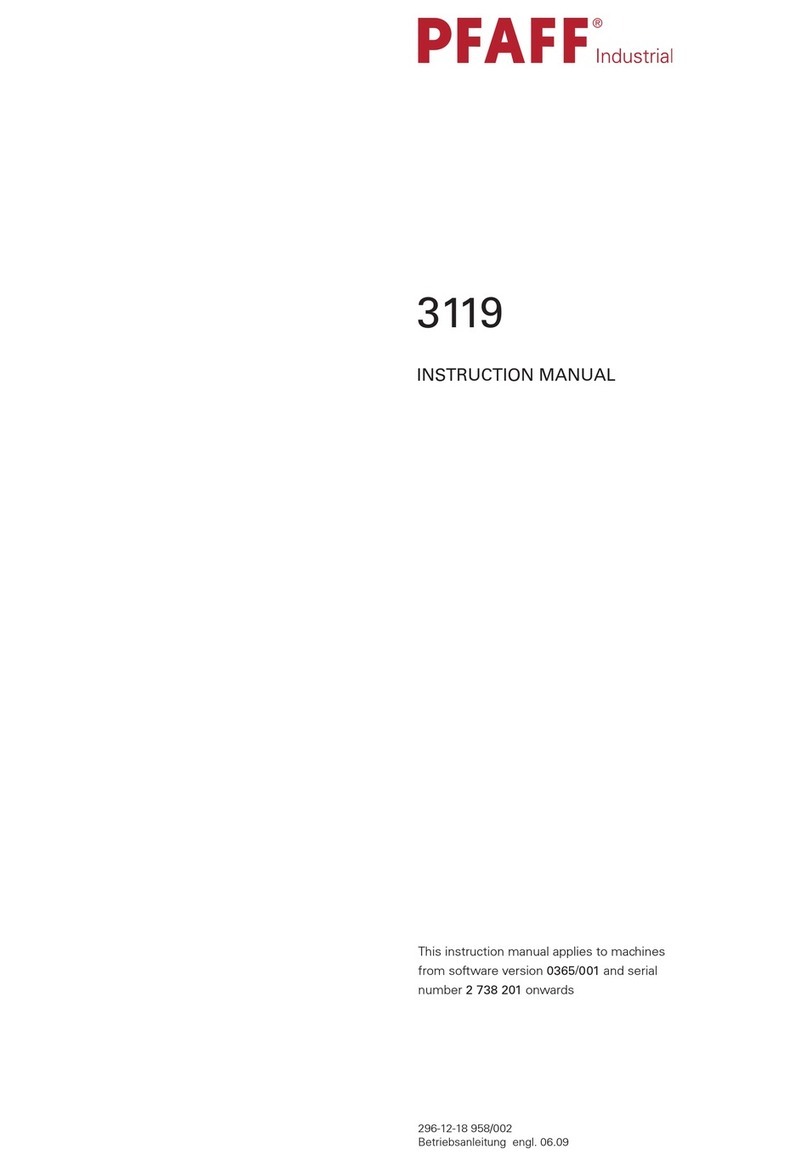

2-1. Remove accessory box

2-1-1.

Grasp the accessory box then pull toward by the

arrow direction to remove it.

2-2. Remove face plate

2-2-1

Use Philips head screwdriver to remove the setscrews of the

face plate, free arm cover, free arm base cover and bed cover.

4

2-3. Remove Front cover

2-3-1

Use Philips screwdriver to remove the front cover

2-3-2

Remove the harness &WIFI module cable

5

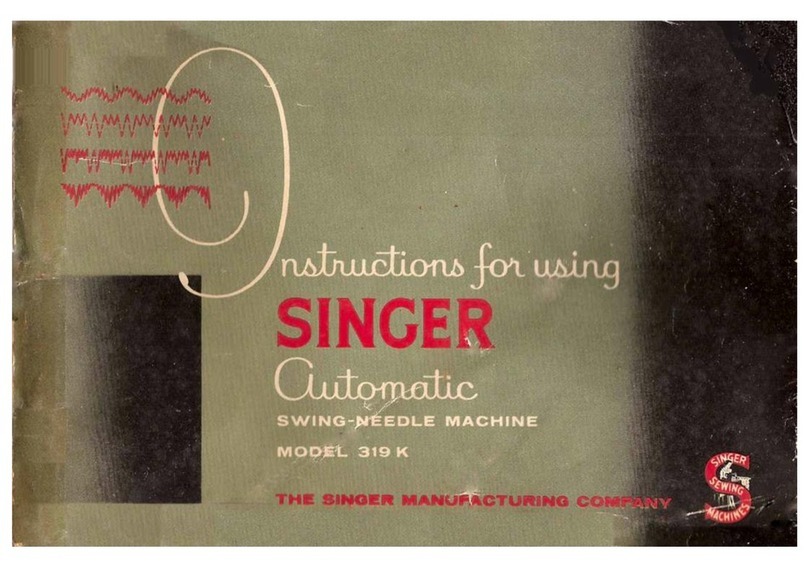

2-4. Remove Back cover

2-4-1

Use Philips screwdriver to remove the back cover (Please

lower the presser foot lever first)

2-4-2

When removing the back cover, please pay attention to avoid

hitting the receptacle holder and break it.

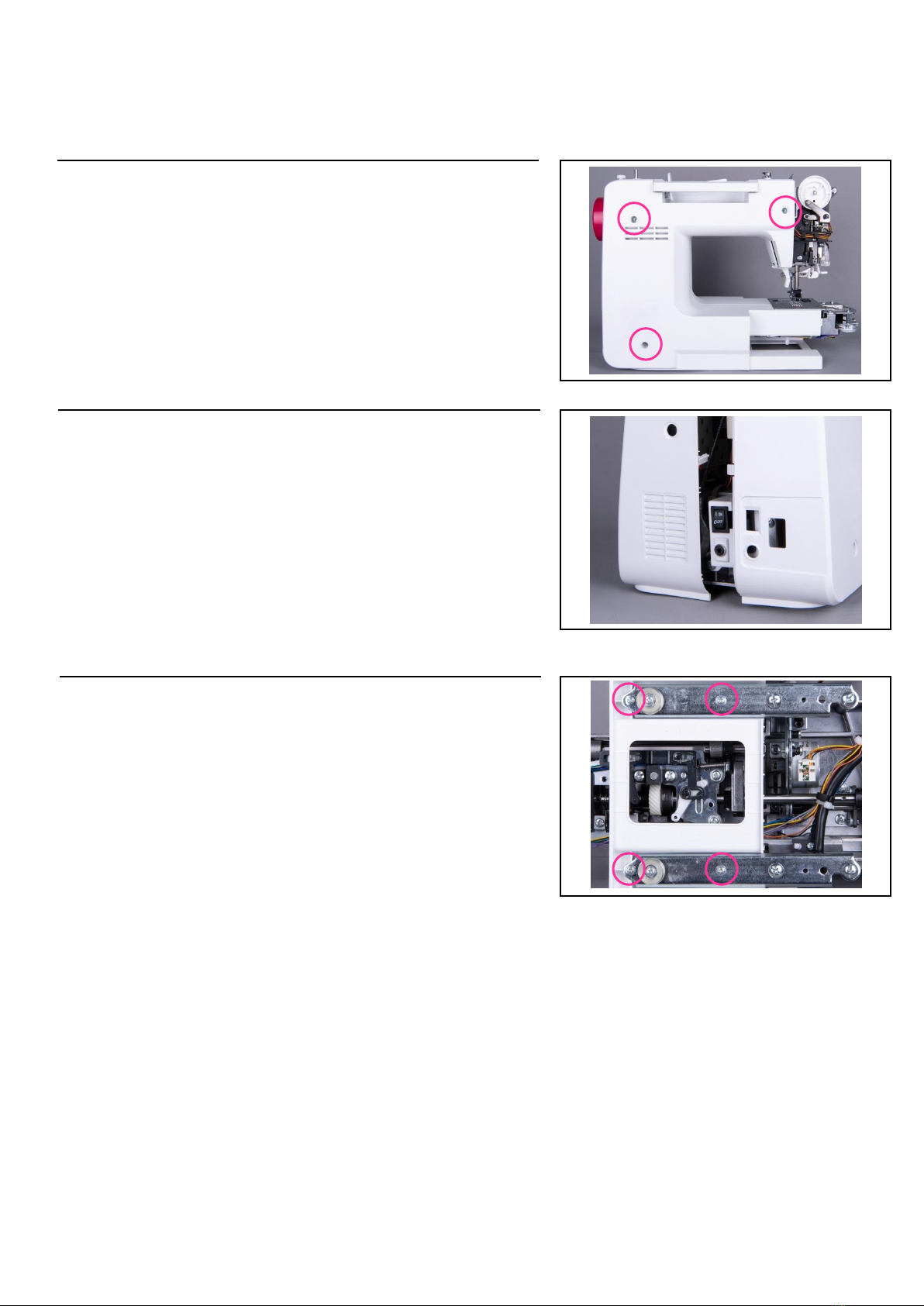

2-5. Remove bed cover

2-5-1

Use Philips screwdriver to remove the bed cover

6

3. Mechanical components adjustment

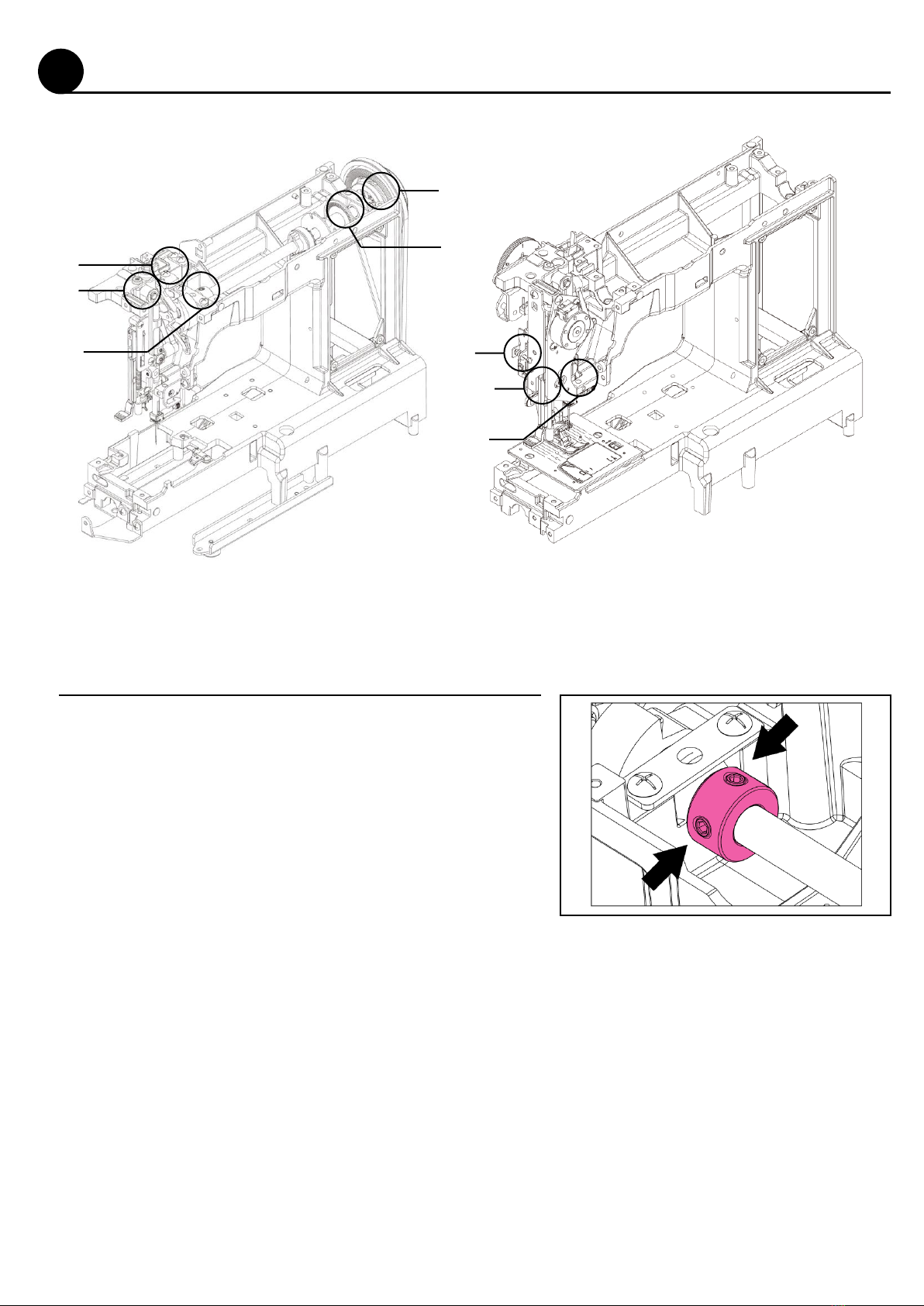

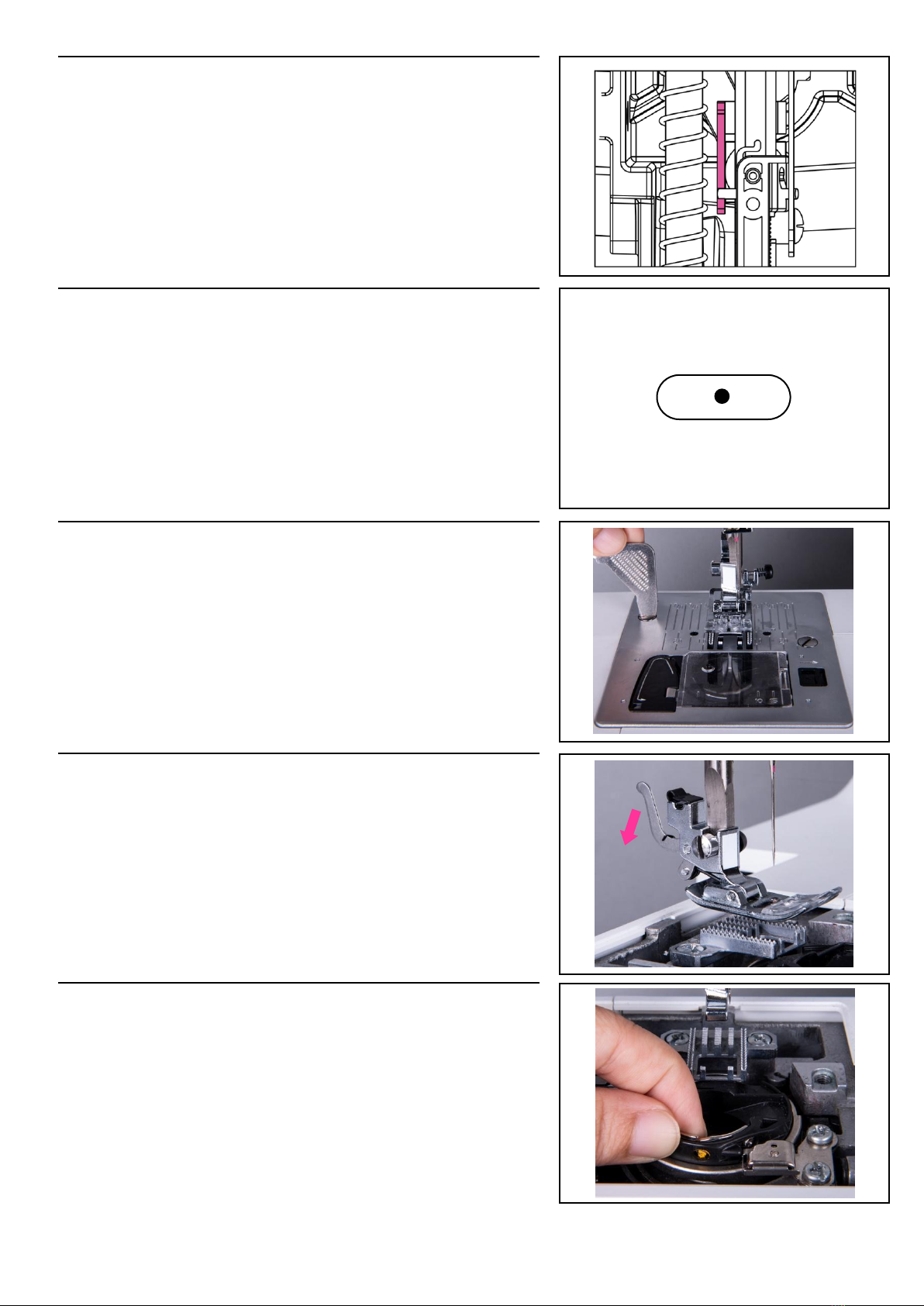

①

②

③

④

⑤

⑥

⑦

⑧

3-1. Play of the Arm shaft

(※Please remove face plate, free arm cover, free arm base

cover, base cover, front cover in advance)

Use 2.5mm hexagon screwdriver to loosen 2 setscrews on arm

shaft collar (as shown in area ⑤).

7

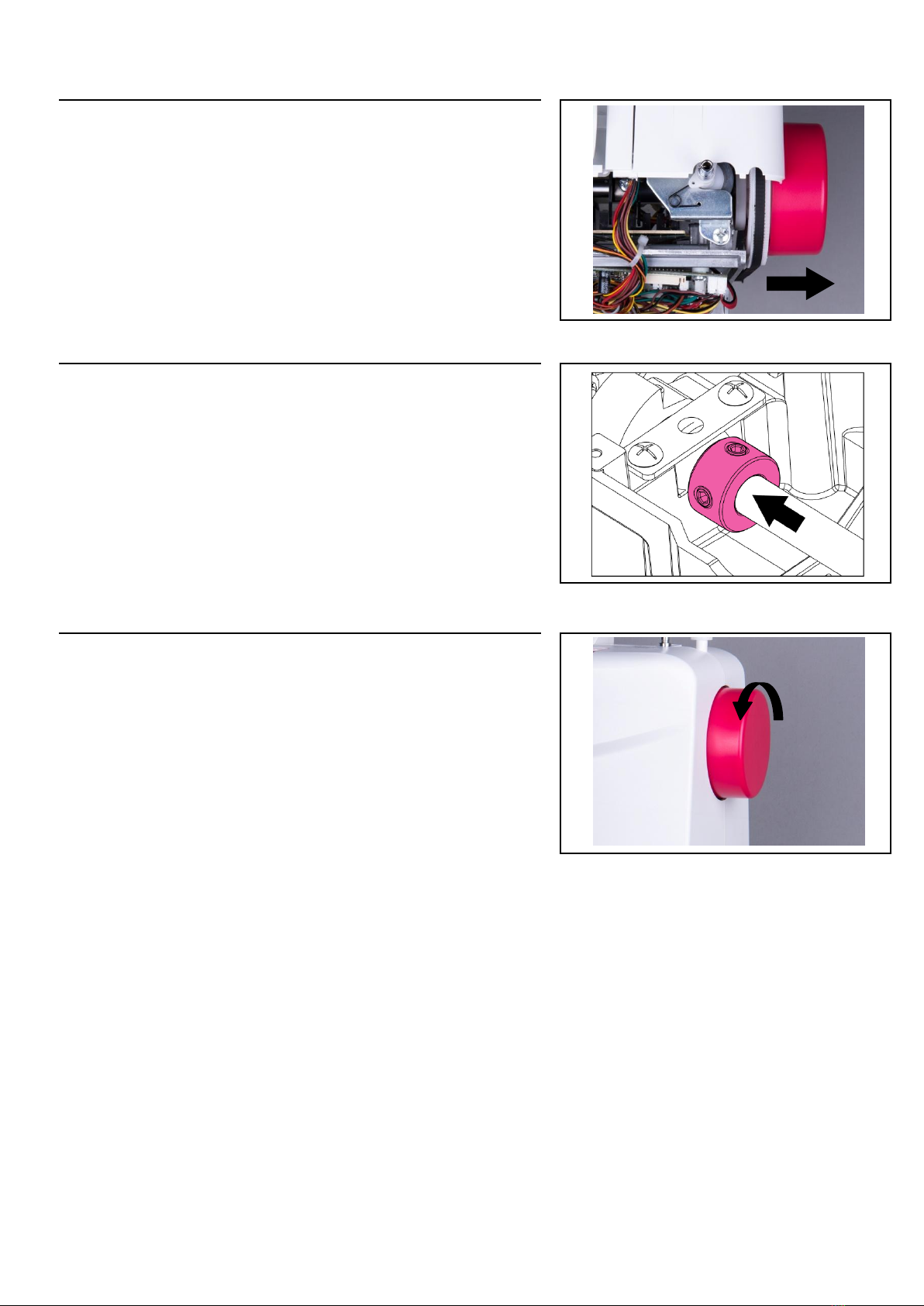

3-1-2

Follow the arrow direction to pull the hand wheel

outward.

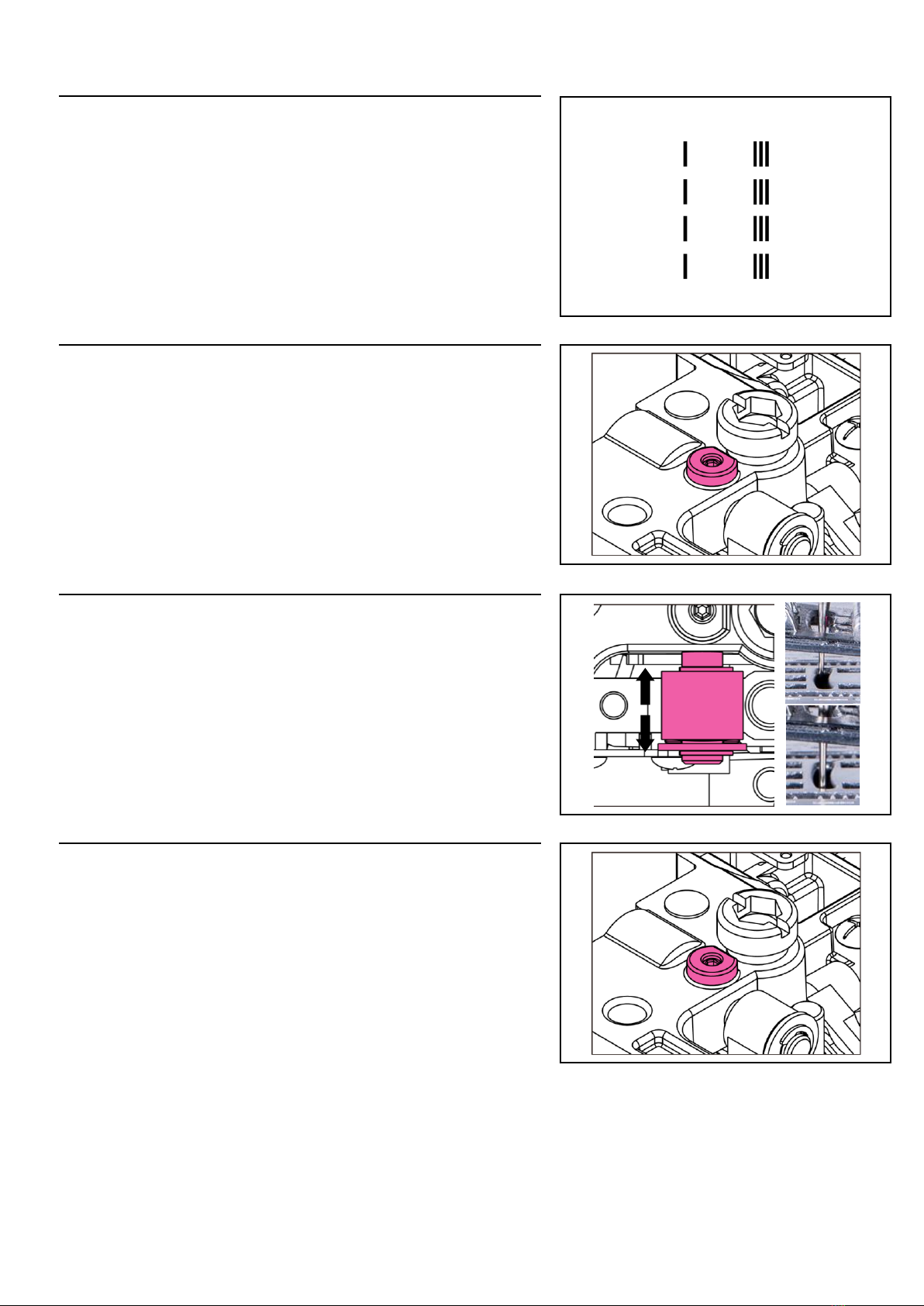

3-1-3

Pull arm shaft collar to left (as shown in area ⑤) and fit tightly

against the arm shaft bushing. Then tighten 2 setscrews on

the arm shaft collar

3-1-5

Follow 3-1-2 to pull the hand wheel outward and turn the

hand wheel to move the needle to three different positions

(highest, lowest, center). Then check if the play of the arm

shaft is sufficient.

3-1-4

Check if the arm shaft can rotate smoothly. If not, the arm

shaft collar may fit too tightly against the arm shaft bushing.

3-1-6

If the play of arm shaft is still too loose or too tight, follow the

above procedures (3-1-1~3-1-5) to re-adjust.

8

(※Please remove face plate, free arm cover, free arm base cover,

bed cover, front cover and back cover in advance)

3-2-1

Turn the hand wheel to check the noise location

3-2-2

Loosen the screw M4X8A (as shown in area ③) . Check and

adjust the tightness of thread take up lever supporter.

3-2-3

If it is set too tightly, the hand wheel will be difficult to turn.

3-2-4

On the contrary, if it is set too loosely, abnormal noise may occur

during operation.

3-2. Thread take up lever adjustment

9

3-3. Adjusting the needle drop position

(※Remove the face plate)

3-3-1

Select straight stitch pattern

3-3-2

Loosen the 2.0mm hex socket setscrew. (as shown in area

④)

3-3-3

Pull the needle bar supporter backward to move the needle

forward and vice versa. (as shown in area ④)

3-3-4

Adjust the needle position to the hole center of the needle

plate then tighten the setscrew. (as shown in area ④)

10

3-4. Adjust height of the presser foot

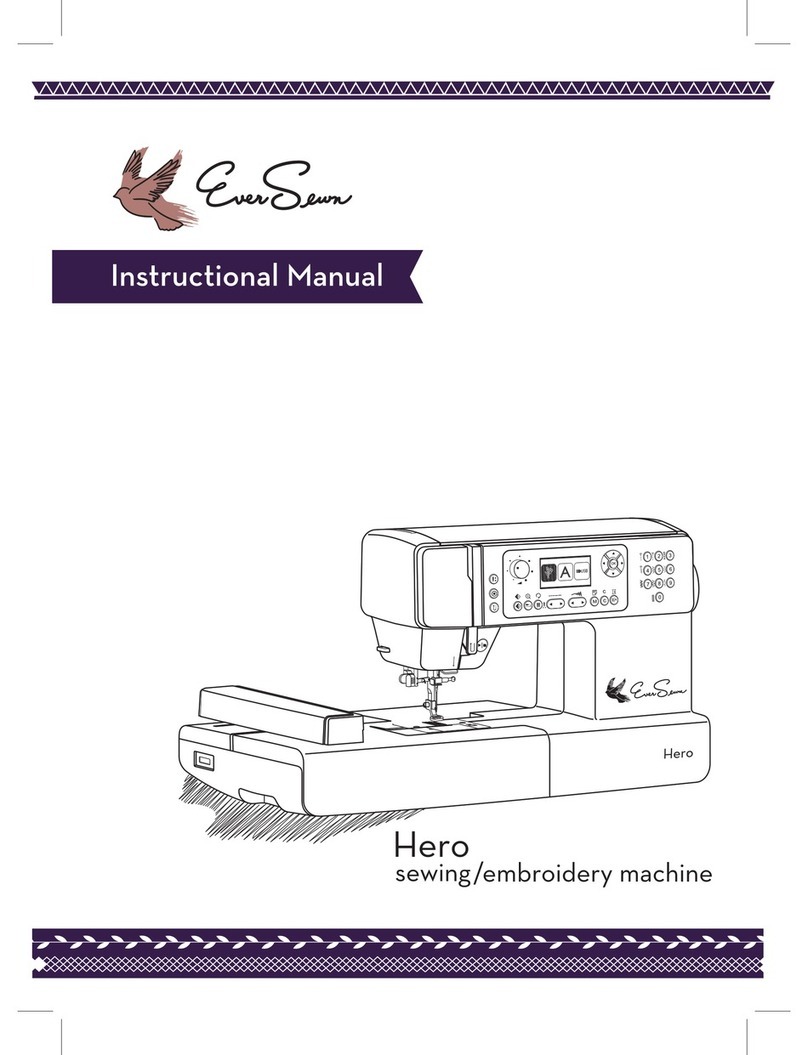

(※Remove the face plate)

3-4-1

Drop down the feed dog

3-4-2

Raise the presser foot lifter

3-4-3

Use a 2.0mm hexagon screwdriver to loosen the setscrew.

(as shown in area ⑥)

3-4-4

Put the gauge with the smaller side down below the presser

foot.

11

3-4-5

Adjust the presser bar position to make it fit against the

gauge.

3-4-7

Slightly tighten the hex socket setscrew. (as shown in area

⑥)

3-4-8

Use the gauge to check the height of the presser foot. By

the smaller side, the gauge can be put beneath the presser

foot

3-4-9

On the contrary, the taller side of the gauge cannot be put

beneath presser bar

3-4-10

If the height of the presser foot fits the standard, tighten

the hex socket setscrew firmly. (as shown in area ⑥)

3-4-6

Drop down the feed dog

12

OK

NG

3-5. Adjust the zigzag movement of the needle

(※Remove the face plate, free arm cover, free arm base cover,

bed cover and front cover)

3-5-1

Choose the stitch pattern “ ” ,and set the stitch width to 7mm

3-5-2

Set the needle position to its left lowest position.

Then turn the hand wheel to raise the needle and stop at the

point when it starts to move rightward.

At this point, the vertical distance between the needle tip and the

needle plate should be between 6.0~6.5mm.

3-5-3

If the vertical distance is less than 6mm, loosen the screw

M4*8Aon the rotary sensor collar first. (as shown in area ②)

Then turn the rotary sensor collar backward.

3-5-4

If the vertical distance is higher than 6.5mm, adjust the rotary

sensor collar position in reverse direction.

3-5-5

Re-check if the vertical distance fits to the standard.

If yes, tighten the screw M4*8Afirmly.

Note:

The presser foot should be aligned with the feed dog hole of

the needle plate without slanting.

13

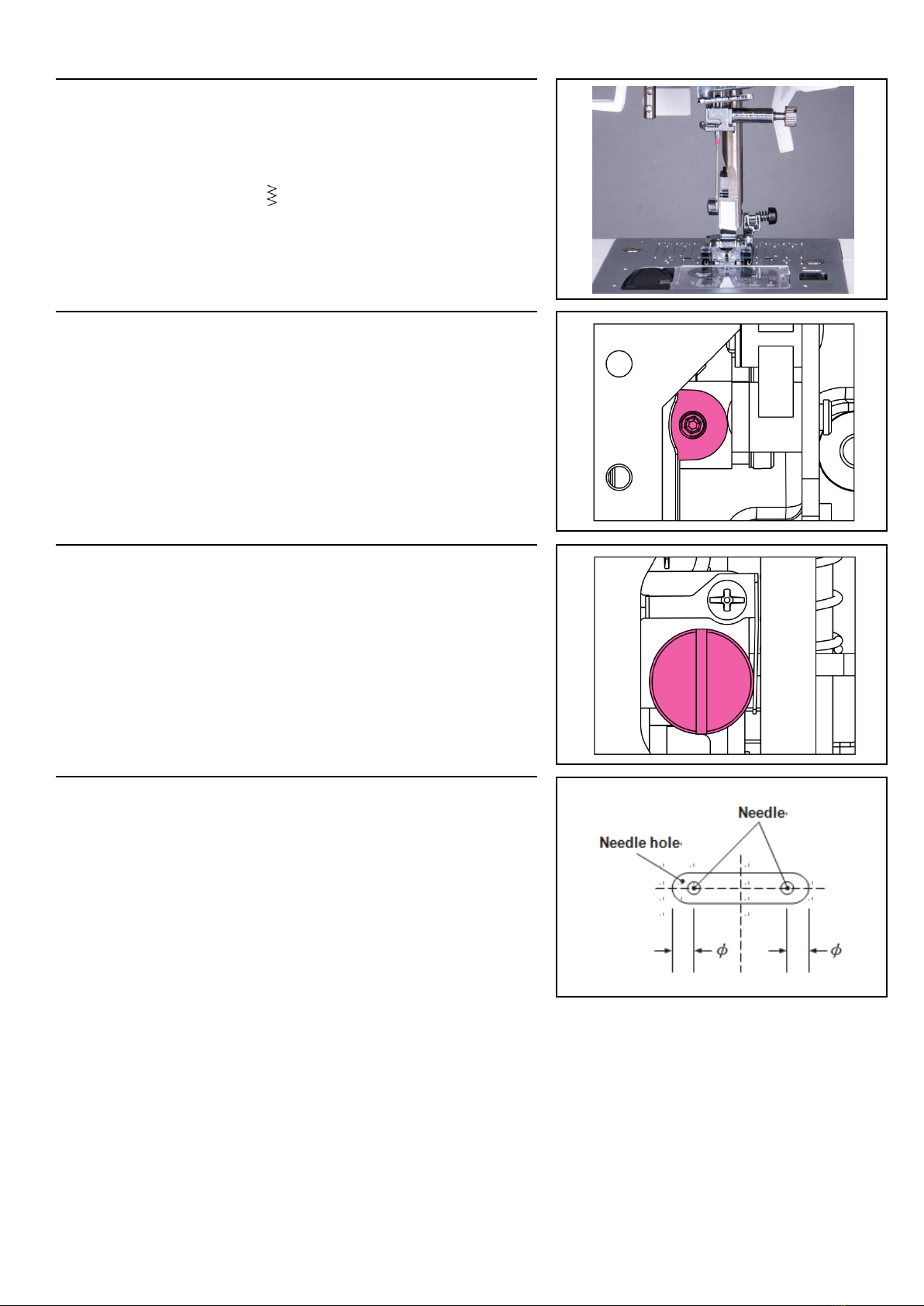

3-6. Adjust needle drop positions

3-6-1

Choose the stitch pattern “ ” ,and set the stitch width to 7mm

3-6-2

Use a 1.5mm Hex screwdriver to loosen the setscrew of the

needle bar supporter. (as shown in area ⑦)

3-6-3

Turn setscrew (as the picture shown below) to adjust the

needle bar position. (as shown in area ⑧)

Turn the setscrew in clockwise direction will make the needle

position go left; Turn it in counterclockwise direction will go

right.

3-6-4

Make sure needle drop on the left / right of needle hole with

even distance to the edge of the needle hole then tighten the

setscrew.

(※Remove the face plate)

14

3-7. Adjust the automatic needle threader

3-7-2

Turn the hand wheel and move the needle to its highest

position.

3-7-3

Use a 1.5mm hex screwdriver to loosen the setscrew of

threader stopper.

3-7-4

Move the threader stopper upward to make the threader hook

go up.

3-7-5

Move threader stopper in another direction to make the

threader hook go down.

3-7-6

Adjust the threader stopper to the

correct position so as to let the

threader hook insert into the

needle eye smoothly.

(※Remove the face plate)

15

3-7-7

Tighten the threader stopper firmly and make sure the

threader stopper is not skewed.

3-8. Adjust the needle bar height

3-8-1

Remove the face plate

3-8-2

Move the needle to its center position

3-8-3

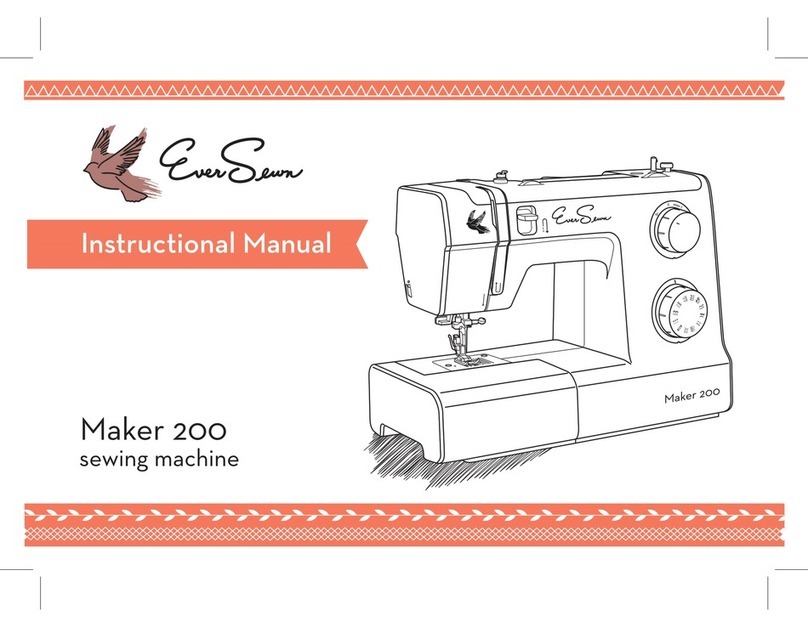

Use a flathead screwdriver to remove the needle plate.

3-8-4

Press the shank complete lever to release the presser foot

3-8-5

Take out the shuttle hook

16

3-8-5

Use a flathead screwdriver to loosen the needle clamp and

remove the needle.

3-8-6

Install the needle bar height gauge (29.05+/-0.05mm)

3-8-7

Turn the hand wheel to let needle go to its lowest position

3-8-8

When the needle is at lowest position, the gauge will slightly

touch the inner brink of the shuttle hook holder

3-8-8

If the needle bar height is set too high or low, use a 2.0mm hex

screw driver to loosen the setscrew for the needle bar bracket.

Then raise or lower the needle bar for adjustment.

17

3-9. Adjust the hook timing

3-9-1

Use a flathead screwdriver to remove the needle plate

3-9-2

Choose the stitch pattern “ ” ,and set the stitch width to 7mm

3-9-3

Turn the hand wheel to move the needle to the left side and

down to its lowest location

3-9-4

Install the timing gauge (3.5mm) and its holder then tighten the

setscrew.

3-9-5

Turn the hand wheel back and forth to make sure that the

gauge does not shake up and down.

Table of contents

Other EverSewn Sewing Machine manuals

EverSewn

EverSewn Hero User manual

EverSewn

EverSewn sparrow 20 User manual

EverSewn

EverSewn Celine User manual

EverSewn

EverSewn sparrow 15 Series Operating instructions

EverSewn

EverSewn Sparrow X User manual

EverSewn

EverSewn Maker 200 User manual

EverSewn

EverSewn sparrow 15 User manual

EverSewn

EverSewn Sparrow QE User manual