Contents

Warnings, Safety information and Guidance

Important Information . . . . . . . . . . . . . . . . . . . . . . . . 2

Product Overview

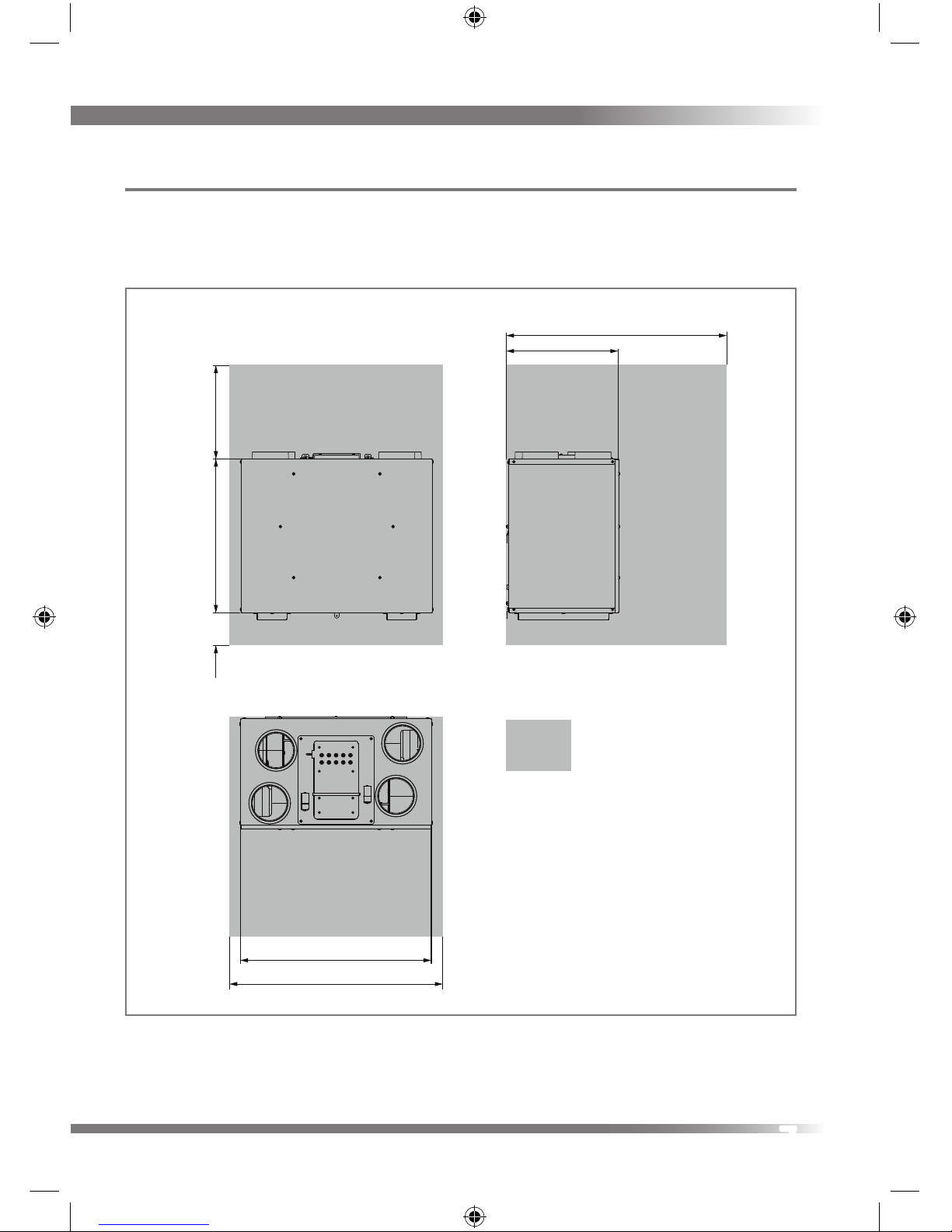

Dimensions HRV10 Q Plus. . . . . . . . . . . . . . . . . .6

Dimensions HRV10M Q Plus . . . . . . . . . . . . . . . .7

Product Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Controls & Features . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

auralite® . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Auto Setback Speed. . . . . . . . . . . . . . . . . . . . .10

Continuous Speed . . . . . . . . . . . . . . . . . . . . . .10

Boost Speed with Overrun Timer . . . . . . . . . .10

auralite® Boost Alert . . . . . . . . . . . . . . . . . . . .10

Summer Bypass . . . . . . . . . . . . . . . . . . . . . . . .11

SUMMERboost® . . . . . . . . . . . . . . . . . . . . . . . .11

Automatic Frost Protection. . . . . . . . . . . . . . .12

Integrated Humidity Sensor. . . . . . . . . . . . . .12

Packaging Contents. . . . . . . . . . . . . . . . . . . . . . . . . .12

Installation

Fixing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Condensate Drain . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Ducting Connections. . . . . . . . . . . . . . . . . . . . . . . . .19

Wiring Connections Access. . . . . . . . . . . . . . . . . . . .20

auralite Wiring Diagrams . . . . . . . . . . . . . . . .21

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . .22

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . .23

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . .24

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . .25

Commissioning

Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Control Parameters . . . . . . . . . . . . . . . . . . . . .26

Continuous Supply & Extract Speeds. . . . . . .27

Boost Supply & Extract Speeds . . . . . . . . . . .27

Boost Overrun. . . . . . . . . . . . . . . . . . . . . . . . . .28

Humidity Sensor . . . . . . . . . . . . . . . . . . . . . . .28

Controller Reset . . . . . . . . . . . . . . . . . . . . . . . .29

Hardware Reset . . . . . . . . . . . . . . . . . . . . . . . .29

Maintenance

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . .30

HRV 10 Q Plus Front Cover Removal . . . . . . .30

HRV 10M Q Plus Front Cover Removal. . . . . .31

Cleaning Interior . . . . . . . . . . . . . . . . . . . . . . .31

Cleaning Exterior . . . . . . . . . . . . . . . . . . . . . . .31

Filter Replacement. . . . . . . . . . . . . . . . . . . . . .32

auralite® Filter Notication Reset . . . . . . . . .33

Service Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Service Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

When this document is

viewed as a PDF the headings

& sub headings on this page

are hyperlinks to the content.

Additionally the page numbers in this

document are hyperlinks back to this

contents page.

4