Table of Contents

Lite-Check CERTIFIER 1200 Operations Manual

COVER………………………………………………………………………………………..……..

CAUTIONS……………………………………………………………………………………..……

TABLE OF CONTENTS……………………………………………………………………….…..

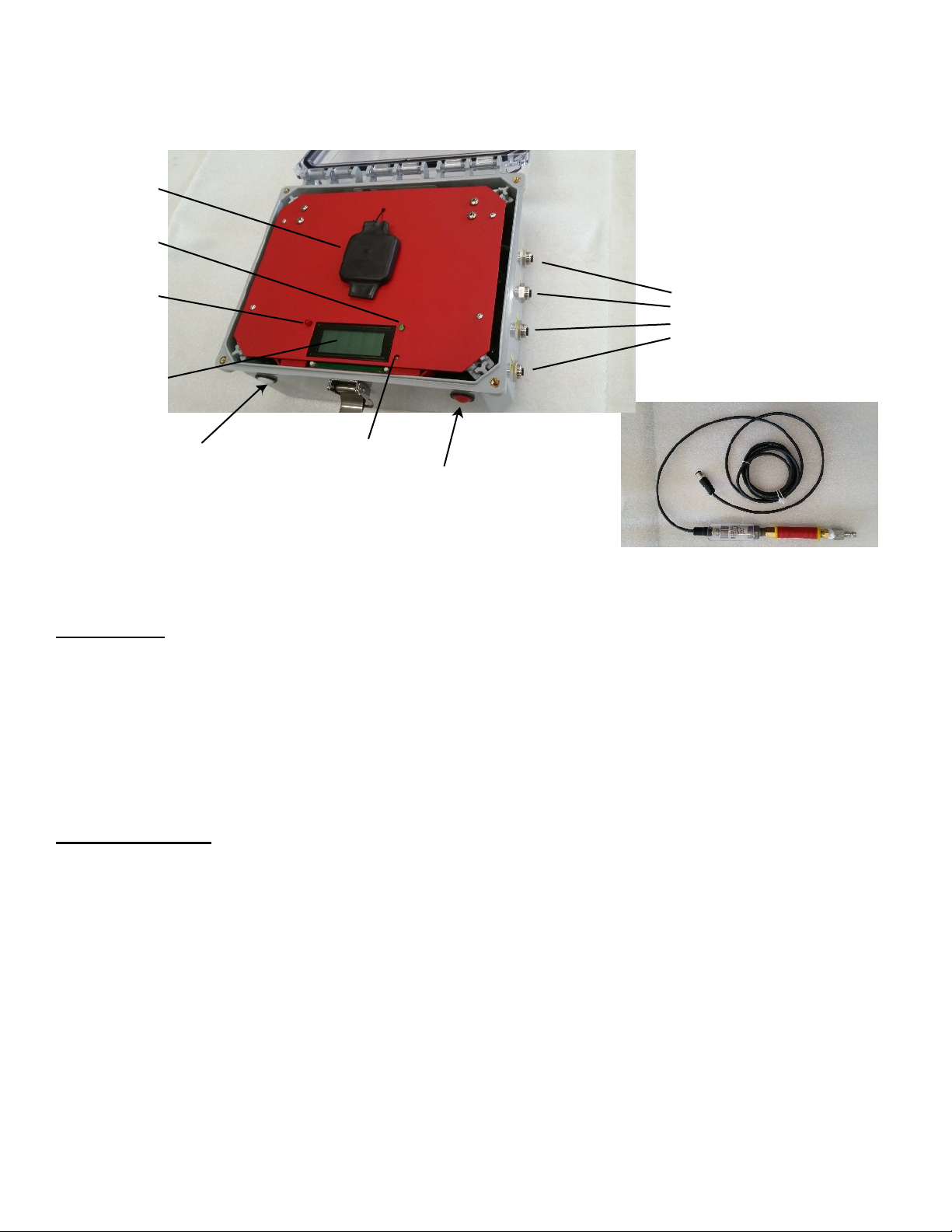

LITE-CHECK CERTIFIER 1200..……………………………………………………………..…..

Description…………………………………………………………………………………………………..….

Key Features of the Certifier 1200...…………..…..….…...…..……...…..…..…….………………...…….

Set-up Requirements…………………………………………………………………………………….…….

MODEL 400 HUB AND DOLLY………….……….………….………………….………………..

Description………………………………………………………………………………………………….…..

Hub Status LEDs…………………………………………………………………………………………..…..

LITE-CHECK TABLET and DESCRIPTION……………………..……………………………..

LITE-CHECK MODEL 363 DIFFERENTIAL KIT…………………………………………….…

Description………………………………………………………………………………………………….…..

Contains…………………………………………………………………………………………………….…..

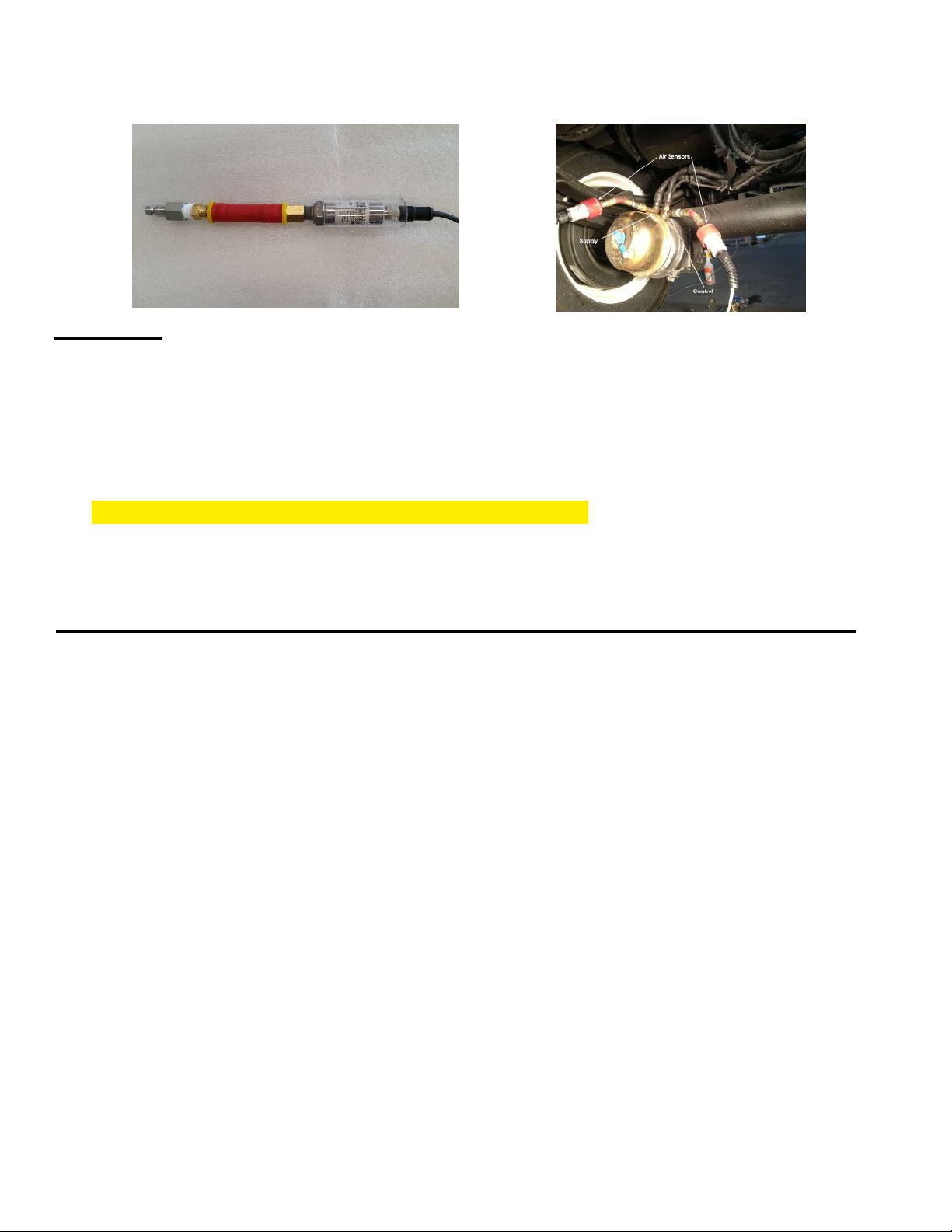

LITE-CHECK AIR PRESSURE SENSOR/TRANSDUCER and DESCRIPTION…………...

INITIAL SET-UP PROCEDURES………….…………………………………………………..….

Shop Set-up………………………………………………………………………………………………..……

1200 CERTIFIER SELF-TEST PROCEDURES………....……………………………..….……

Test 1: Internal Self-Leak Test Without a Trailer or Dolly……………………………..……………….….

Test 2: 121 Timing Self-Test Without a Trailer or Dolly……………………………………………………

Test 3: Brake differential Self-Test Without a Trailer or Dolly…………………………….……………….

TESTER OPERATION, GENERAL………………………………………………………..……..

General……………………………………………………………………………………………….….…….

Functions of Keys, Panel and Tablet ..…...…….…..……..….……..…….….………………….…………

Notes..…..…..…..….…..……………………..……..…………………………………………………………

VERIFY THE TABLET IS CHARGED AND FUNCTIONAL……………………………………

INTERPRETING PANEL DISPLAYS, INDICATORS AND ALARMS…….…………………

General…………………………………………………………………………………………………………

Switch Indicators, LED………………………………………………………………………………………..

Audio Alarms…………………………………………………………………………………………………..

LITE-CHECK CERTIFIER SOFTWARE………………………………………………………..

General…………………………………………………………………………………………………………

Upgrading Your LITE-CHECK CERTIFIER Software……………………………………….………………

PERFORMING TESTS ON AN ACTUAL TRAILER OR DOLLY………………………..……

Performing the Air Leak Test when Attached to a Trailer or Dolly………………….…..…………………

Performing the 121 Timing Test when Attached to a Trailer or Dolly……………………………………..

Performing the Service Brake Differential Pressure Test on a Trailer or Dolly………………………..…

Performing ABS Tests.….….….….……….…..….……………………………………….…………………..

WHAT YOU WILL SEE ON THE 1200 CERTIFIER GUI SCREENS………………..………..

Main 1200 Startup Screen (General Overview)..….….….……….….….….….….…….…………………

SETUP Testing “Controller Dropdown”..……...…..….…...….….…..…..….…….…..…..….….…………

SETUP Testing “Hub Dropdown”……………………………………………………………………….…….

SETUP Testing “Help Dropdown”……….….…..….……………………………….…………………..……

SETUP Testing “Settings Dropdown (Page 1 of 2)”…………………………….…………………………..

SETUP Testing “Settings Dropdown (Page 2 of 2)”…………………………………………………………

Automatically Running Tests (Page 1 of 3) Enter Info, select tests, start tests…………..………..……

Automatically Running Tests (Page 2 of 3) Electrical tests in Progress…………..……………………..

Automatically Running Tests (Page 3 of 3) Electrical test done, Air Leak test started.………..……….

Sensor setup for 121 Timing test and Differential test…..……….….….….……..……………………..…

121 Timing test passed.…..…..……….…….….….…..…….…...…..….….…..….…...….….……….……

Differential test while running……..…………….....…….…....…...…..…………………..………………....

Passed Differential test...….…..…………....……..…..….….…..…..….….…..…………...…….……....…

Results of Failed Differential test ………………..…..……….…..…...…..…..………………………….…

Summary page which shows after tests are completed………….…..…..…..………………………….…

1

2

3

5

5

5

5

6

6

6

7

7

7

7

8

8

8

9

10

11

13

15

15

15

15

16

16

16

16

16

17

17

17

18

18

19

21

23

24

24

25

26

27

28

29

30

31

32

33

34

35

36

37

37

38

3