MAC1E OPERATION

The MAC1E is used in conjunction with the UC1 Universal Control to interlock one additional 24 VAC, 115 VAC or millivolt (Dry Contact) con-

trolled appliance. It activates the Venter through its connections to the UC1, and in turn relies on the UC1 Fan Prover safety circuit (P1 & P2) to

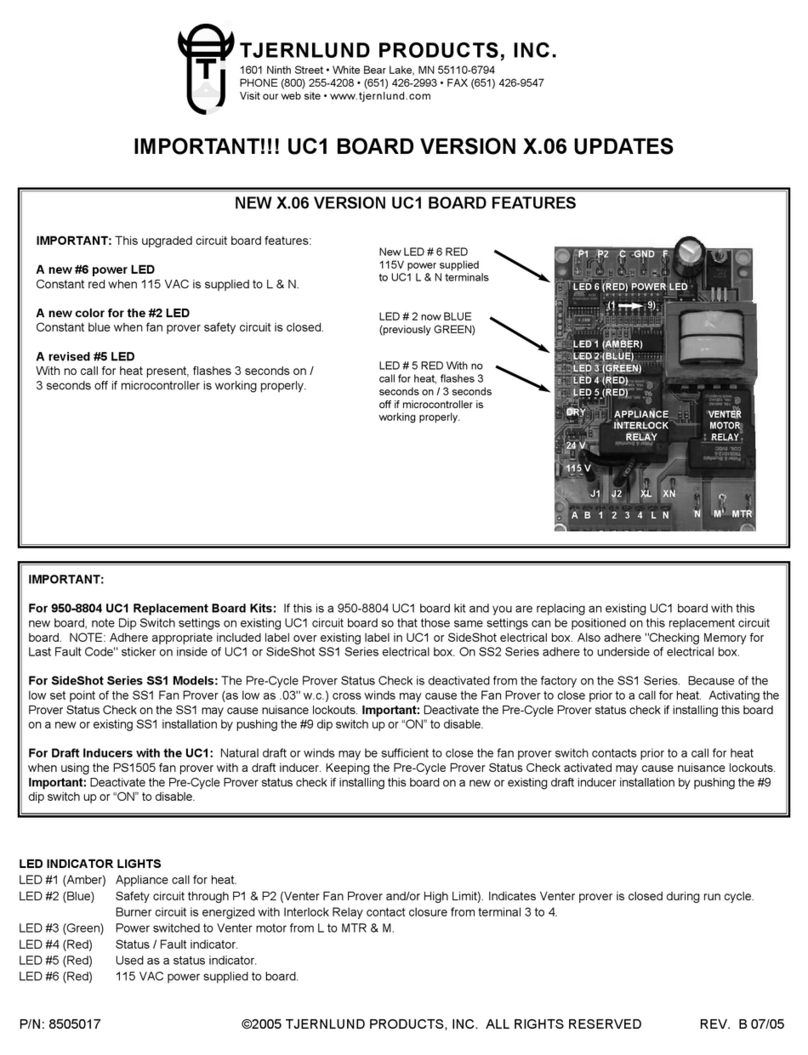

allow its interlocked appliance to operate. Any pre/post-purge settings on the UC1 will be defaulted to the MAC1E. Two LEDs are provided on

the MAC1E. LED #1 (Amber) shows an appliance call for heat. LED #2 (Green) shows that the burner is approved to fire after the Venter Fan

Prover safety circuit through the UC1 is completed.

MILLIVOLT INSTALLATIONS

Each millivolt appliance interlocked with the MAC1E must have its own WHKE kit installed. The WHKE Gas Pressure Switch actuates the Venter

through the A - B Dry contacts. The Linear Limit switch disables the heater in the event of a venting malfunction. IMPORTANT: Each millivolt

appliance interlocked with the MAC1E must have its own Linear Limit spill switch.

MAC1E MOUNTING

Do not mount the MAC1E junction box on a heat source that exceeds 104oF (40oC). Examples of improper mounting surfaces include vent pipe,

top of appliance casing or any place where radiant or convective heat would cause the junction box temperature to exceed 104oF.

The MAC1E is intended for indoor installation only.

The MAC1E has a 2 foot whip that contains 1 ground, 2 power and 3 communication leads. Mount MAC1E adjacent to UC1 control.

Using the key hole slots on the back of the MAC1E junction box as a template, mark 4 holes on the mounting surface, drill pilot holes if neces-

sary, and secure junction box using provided screws.

MAC1E SAFETY INTERLOCK TEST

PERFORM THE FOLLOWING INTERLOCK TEST AFTER CONNECTING MAC1E TO UC1 AND INTERLOCKING ALL BURNERS

1. Confirm power is supplied to MAC1E control from the UC1.

2. Initiate an appliance call for heat. MAC1E LED #1 (AMBER) should be on indicating an appliance call for heat.

3. If the UC1, P1 & P2 Prover safety circuit is closed, indicating an approved condition, the appliance interlock relay will close making

terminal #3 closed to terminal #4. MAC1E LED #2 (GREEN) shows that the burner is approved to fire. Fire all appliances

to make sure each burner fires properly.

4. Remove power to the UC1 and any interlocked appliances. The Power LED #5 (RED) on UC1 or any LED’s on UC1 or MAC1E

should not be on. Test the safety circuit by removing either lead from Fan Prover switch connected to UC1 P1 and P2 Fan Prover

safety circuit. Do not let the opened LEAD touch a ground or damage may occur to the control when power is reestablished.

Reestablish power to the UC1 and interlocked appliances and initiate a call for heat. After 60 seconds a Prover Start Up fault

should arise with UC1 LED #4 flashing 3 times.

5. Remove appliance call for heat and power to the UC1 and any interlocked appliances. The Power LED #5 (RED) on UC1 or any

LED’s on UC1 or MAC1E should not be on. Reconnect Fan Prover switch lead removed in step 4.

6. Reestablish power to UC1 and interlocked appliances and initiate a call for heat from each appliance to confirm proper operation of

UC1, MAC1E and appliances.

7. Perform Draft Adjustment and Combustion air safety check as outlined in Venter/Inducer installation manual.

IMPORTANT: DO NOT OPERATE AN APPLIANCE THAT OPERATES WITH THE PROVER SAFETY CIRCUIT DISCONNECTED!

RESETTING FAULT CODE CREATED BY STEP 4 OF SAFETY INTERLOCK TEST

IMPORTANT: Prior to accessing the fault code memory, note the settings of the UC1 dip switches so that they can be returned to their original

Pre / Post-Purge positions. When power is supplied to the UC1 use caution when moving dip switches.

The last fault code can be retrieved at any time by setting all dip switches 1-8 to the up, or “on” position. The last fault code, or lack there of, will

be indicated by counting the number of times LED 4 flashes. By moving any of the dip switches back to their original position, the fault code will

be cleared. NOTE: The UC1 board must have its 115 VAC power supply present when any of the (1-8) dip switches are moved back to their

original position for the fault code to clear.NS WIT

TJERNLUND PRODUCTS, INC.

1601 Ninth Street • White Bear Lake, MN 55110-6794

PHONE (800) 255-4208 • (651) 426-2993 • FAX (651) 426-9547

Visit our web site • www.tjernlund.com

Copyright © 2004, Tjernlund Products, Inc. All rights reserved. P/N 8504110 REV A 1204

Multiple heaters firing at the same time will result in varying volumes of flue gas and varying vent system draft pressures. Make sure all

heaters interlocked with the MAC1E operate within the normal draft range specified by the heater manufacturer. All heaters utilizing a fixed

speed Venter/Inducer must be equipped with a draft hood, draft diverter, or barometric draft control. Tjernlund ABD-Series Balancing Baffles

may be utilized for balancing draft on each heater.