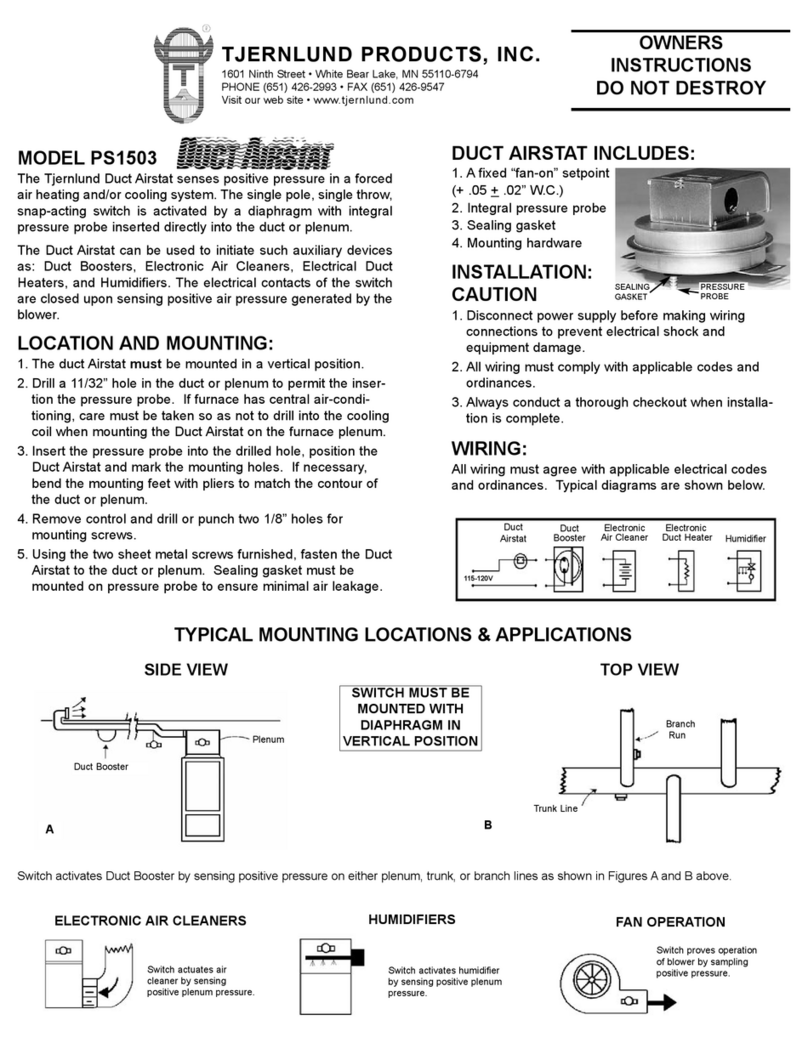

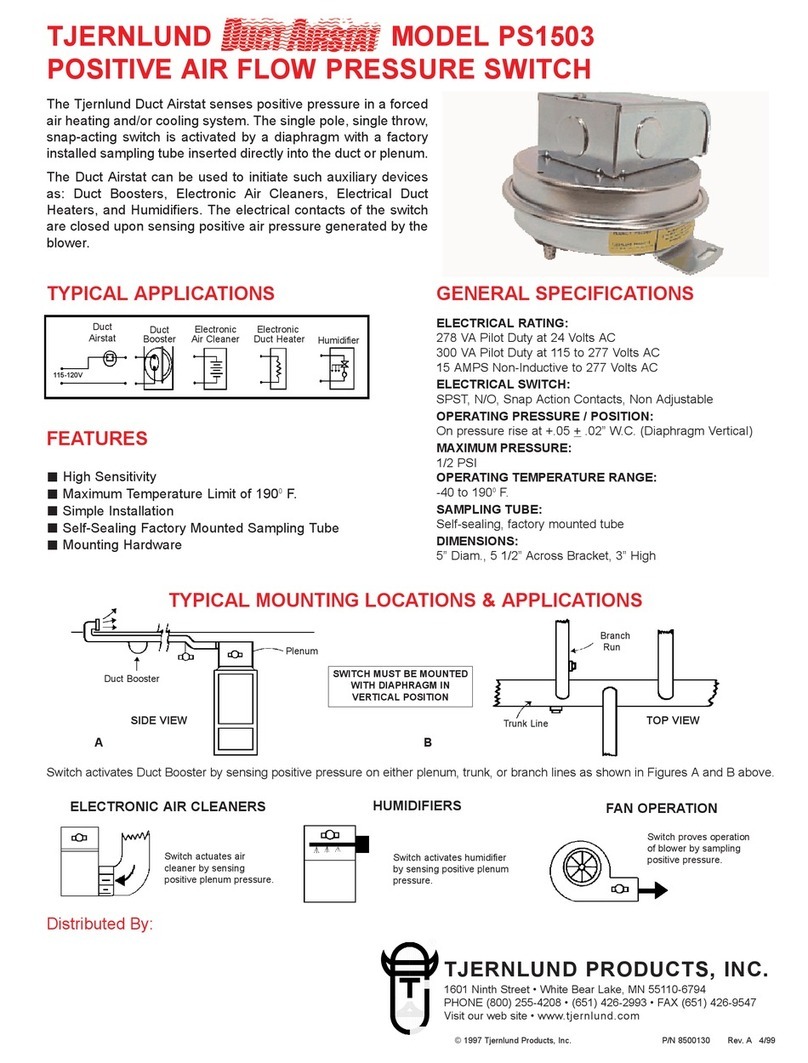

Location:

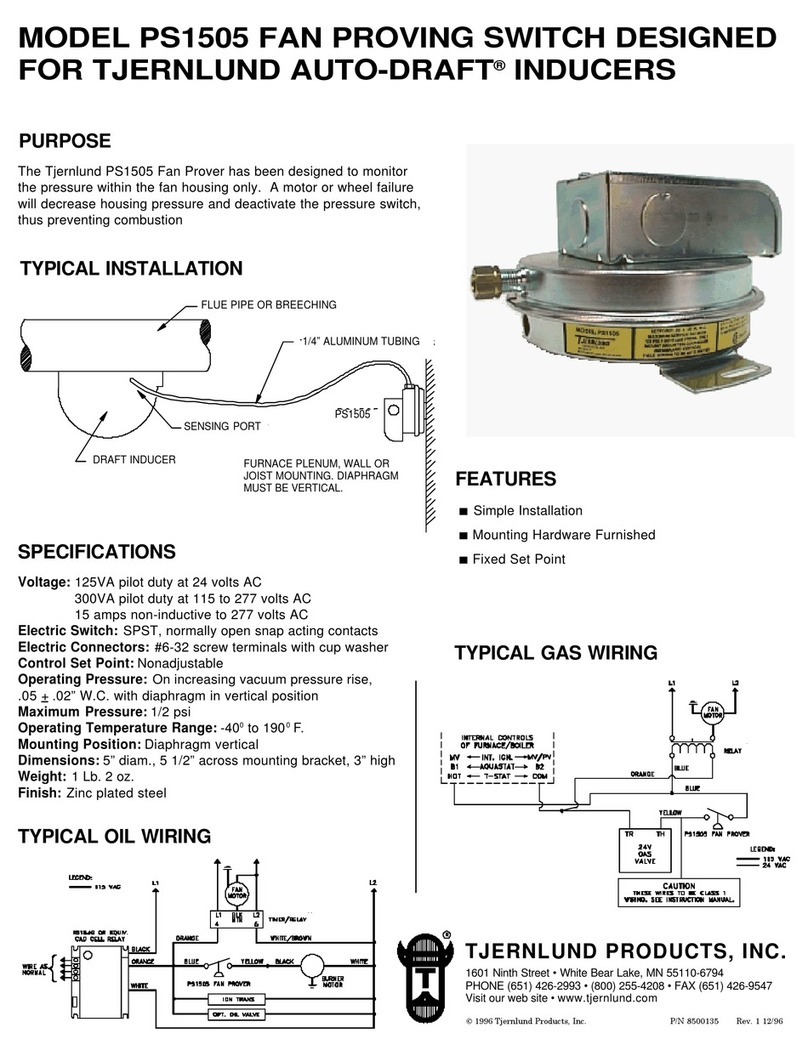

The Tjernlund Fan Prover can be mounted on any vertical surface within

five (5) feet of the draft inducer. It must not be mounted on the inducer or

any other surface with a temperature in excess of 190oF. Similarly, the

temperature of the surrounding air must be less than 190oF.

Mounting:

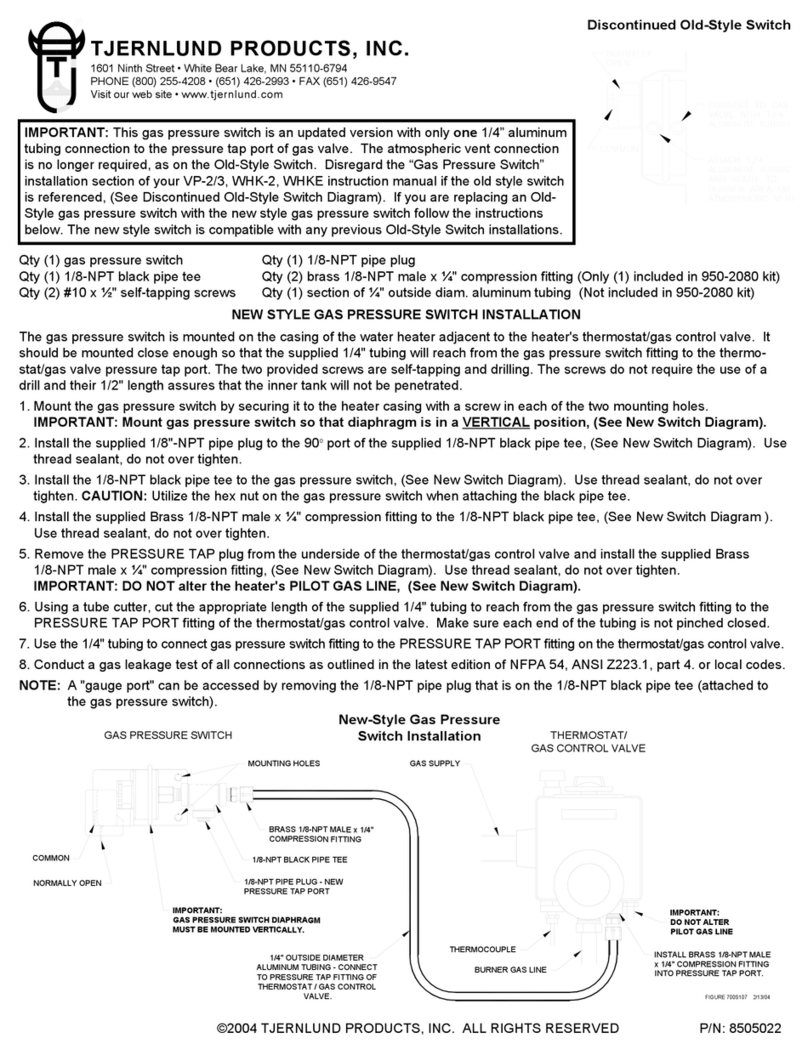

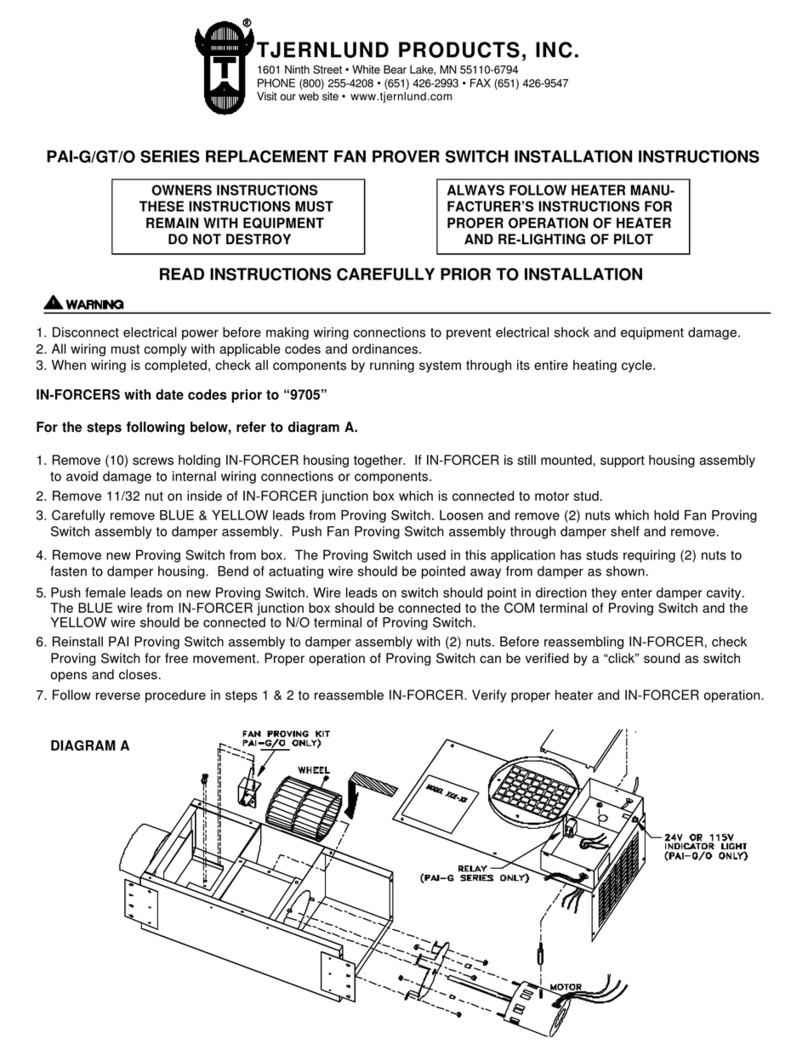

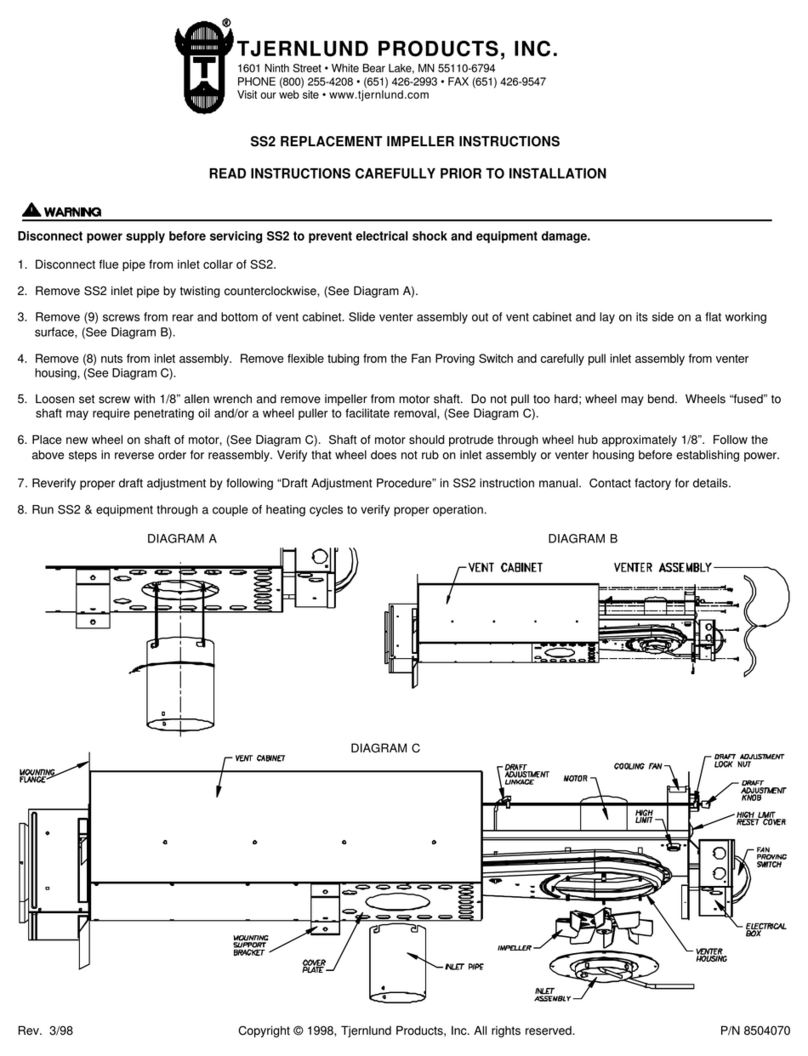

1. Locate holes to be drilled using prover mounting foot as guide.

2. Drill two (2) 1/8” holes.

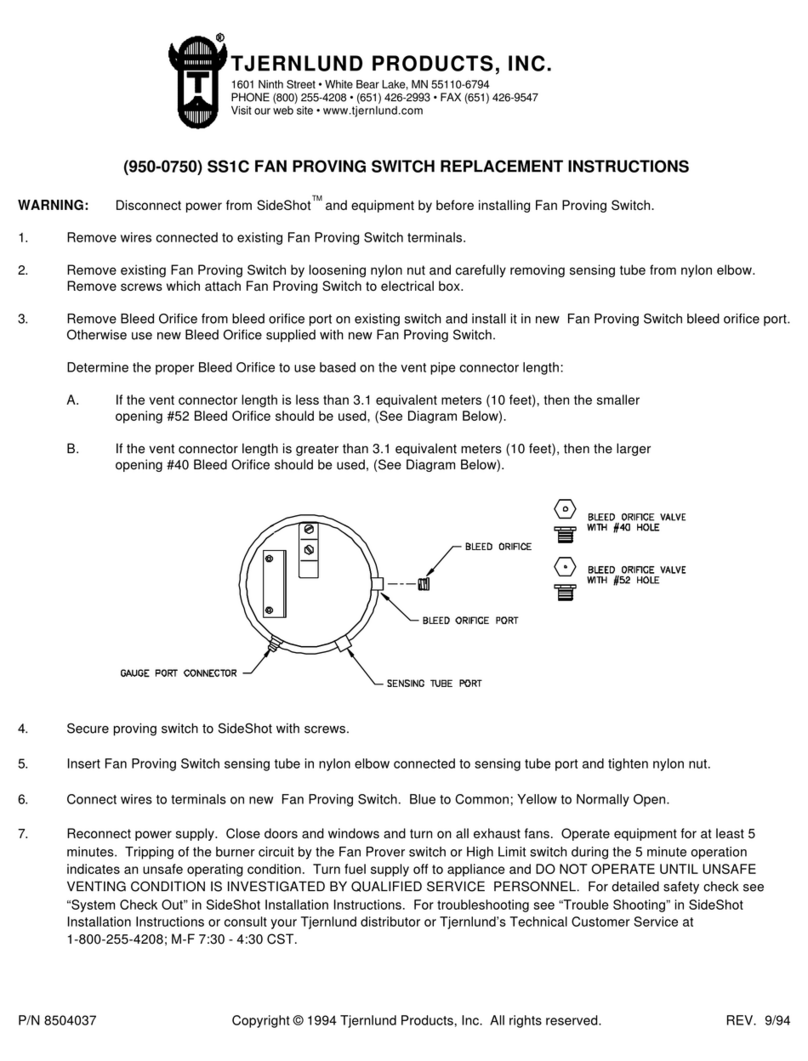

3. Use sheet metal screws enclosed to mount Fan Prover. Diaphragm

must be vertical to ensure proper operation of switch, See Diagram.

4. Remove inducer from duct if previously installed.

5. FOR MODEL D-3 ONLY

The Model D-3 DraftInducers have two pressure sensing location

knockouts. Location “A” should be used when the D-3 Draft Inducer is

mounted on 7” or 8” diameter pipe. Location “B” should be used when

the D-3 Draft Inducer is mounted on 5” or 6” diameter pipe.

6. Remove Draft Inducer sensing port knockout using a blade screwdriver

and a pliers. Push male brass fitting through hole from inside housing

and lock into position with brass hex nut. Tighten nut with wrench.

7. Unroll tubing and cut to desired length, using a tubing cutter or hack

saw to provide squared, finished cuts. Cut ends should be free of any

burrs or foreign material.

8. Slide brass connecting nuts over tubing and tighten brass fittings.

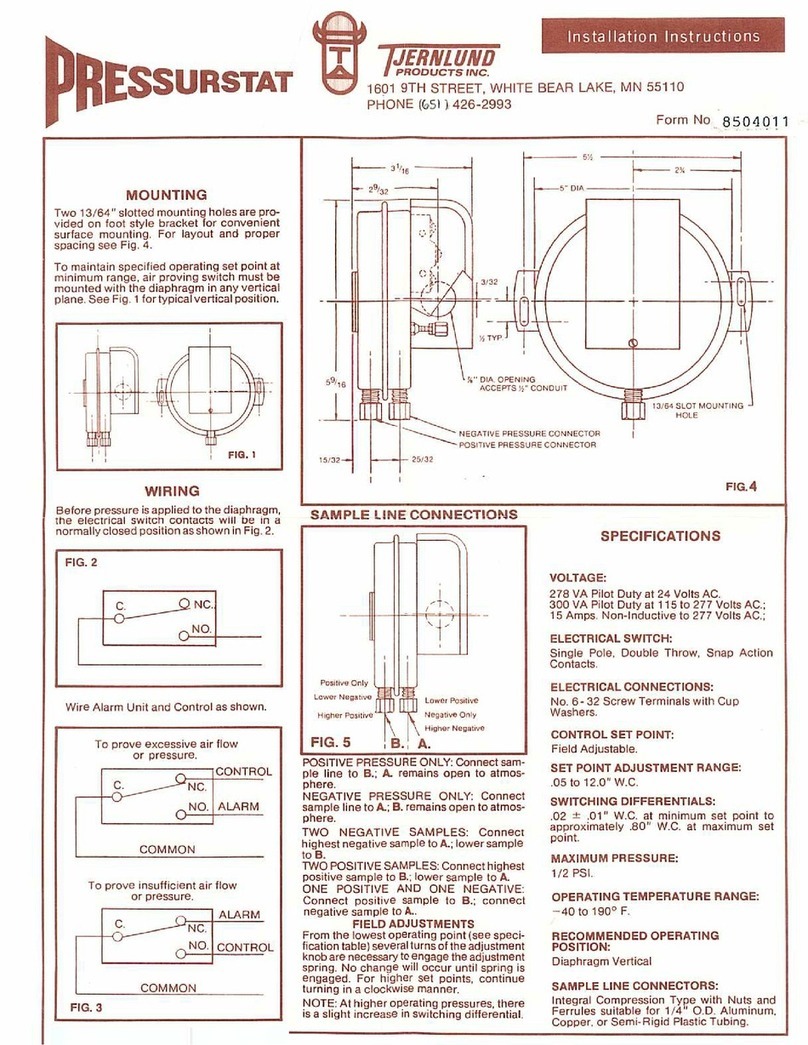

9. See electrical schematic for application which best represents your

system.

10. All wiring must be done in accordance with the NEC and applicable

Tjernlund Products, Inc. warrants its components for one year from date

of installation. This warranty covers defects in material and workmanship.

This warranty does not cover normal maintenance, transportation or

installation charges for replacement parts or any other service calls or

repairs. Products that are tampered with, damaged, installed improperly,

wired incorrectly or defective due to malfunctioning appliances are not

covered under this warranty.

Tjernlund Products, Inc. will issue credit to the original distributor or pro-

vide a free part to replace one that becomes defective during the one year

warranty period. If the part is over 18 months old, proof of date of the

installation in the form of the contractor sales / installation receipt is nec-

essary to prove the unit has been in service for under one year. All

receipts should include the date code of the PS1505. This will help pre-

vent possible credit refusal.

If the PS1505 is defective, return it to your Tjernlund distributor for

replacement. If PS1505 date code is older than 18 months you will need

to provide a copy of the original installation receipt to your distributor.

Credit or replacement will only be issued to a Tjernlund distributor after

the defective part has been returned prepaid to Tjernlund.

MODEL PS1505

FAN PROVER SWITCH

OWNERS INSTRUCTIONS

THESE MUST REMAIN WITH EQUIPMENT

DO NOT DESTROY

PURPOSE

The Tjernlund Fan Prover has been designed to monitor the pressure

within the fan housing only. A motor or wheel failure will decrease hous-

ing pressure and deactivate the pressure switch, thus preventing combus-

tion. The Fan Prover is not a safety control designed to ensure proper

draft or to indicate chimney failure. It is the responsibility of the end user

to properly maintain both the combustion equipment and its chimney or

vent. Yearly maintenance and inspection should be conducted by qualified

service personnel. Failure to follow such maintenance and inspection pro-

cedures may result in generation of toxic carbon monoxide gas.

SPECIFICATIONS

Voltage: 125VA pilot duty at 24 volts AC

300VA pilot duty at 115 to 277 volts AC

15 amps non-inductive to 277 volts AC

Electric switch: single pole, single throw, normally open, snap acting

contacts

Electric connectors: #6-32 screw terminals with cup washer

Control set point: non-adjustable

Operating pressure: on increasing vacuum pressure rise, .05 +.02”

W.C. with diaphragm in vertical position.

Maximum pressure: 1/2 psi

Operating temperature range: -40 to 190oF.

Operating position: diaphragm mounted vertical

Sample line connector: Integral compression-type with nut and ferrule

suitable for 1/4” O.D. aluminum or copper tubing.

TJERNLUND PRODUCTS, INC.

1601 Ninth Street • White Bear Lake, MN 55110-6794

PHONE (651) 426-2993 • (800) 255-4208 • FAX (651) 426-9547

Visit our web site • www.tjernlund.com

TJERNLUND PRODUCTS, INC.

1601 Ninth Street • White Bear Lake, MN 55110-6794

PHONE (651) 426-2993 • (800) 255-4208 • FAX (651) 426-9547

Visit our web site • www.tjernlund.com

TJERNLUND LIMITED ONE YEAR WARRANTY

Tjernlund Products, Inc. warrants to the original purchaser of this product that the product will be free

from defects due to faulty material or workmanship for a period of (1) year from the date of original pur-

chase or delivery to the original purchaser, whichever is earlier. Remedies under this warranty are lim-

ited to repairing or replacing, at our option, any product which shall, within the above stated warranty

period, be returned to Tjernlund Products, Inc. at the address listed below, postage prepaid. THERE

ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF,

AND TJERNLUND PRODUCTS, INC. EXPRESSLY DISCLAIMS LIABILITY FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF THIS PRODUCT. THIS WARRANTY IS

IN LIEU OF ALL OTHER EXPRESS WARRANTIES AND NO AGENT IS AUTHORIZED TO ASSUME

FOR US ANY LIABILITY ADDITIONAL TO THOSE SET FORTH IN THIS LIMITED WARRANTY.

IMPLIED WARRANTIES ARE LIMITED TO THE STATED DURATION OF THIS LIMITED WARRANTY.

Some states do not allow limitation on how long an implied warranty lasts, so that limitation may not

apply to you. In addition, some states do not allow the exclusion or limitation of incidental or conse-

quential damages, so that above limitation or exclusion may not apply to you. This warranty gives you

specific legal rights and you may also have other rights which may vary from State to State. Send all

inquiries regarding warranty work to Tjernlund Products, Inc. 1601 9th Street, White Bear Lake, MN

55110-6794. Phone (651) 426-2993 • (800) 255-4208 • Fax (651) 426-9547.

COPYRIGHT © 1997 TJERNLUND PRODUCTS, INC. P/N 8504008 REV. 1 1/97