TK TFP-9 User manual

1

Operator’s Safety and Service Manual

Scarifier

TFP-9

It is the OWNER´S RESPONSABILITY to communicate information on the

SAFE USE and OPERATION of this machine to the operators.

27112013

www.discount-equipment.com

Discount-Equipment.com

Discount-Equipment.com is your online resource for commercial and industrial

quality parts and equipment sales.

Locations:

Florida (West Palm Beach): 561-964-4949

Outside Florida TOLL FREE: 877-690-3101

Need parts? Check out our website at www.discount-equipment.com

Can’t find what you need?

Click on this link: http://www.discount-equipment.com/category/5443-parts/ and fill out

the request form.

Please have the machine model and serial number available in order to help us get

you the correct parts. One of our experienced staff members will get back to you with

a quote for the right part that your machine needs.

We sell worldwide for the brands: Genie, Terex, JLG, MultiQuip, Mayco, Toro/Stone,

Diamond Products, Magnum, Airman, Mustang, Power Blanket, Nifty Lift, Atlas Copco,

Chicago Pneumatic, Allmand Brothers, Essick, Miller Spreader, Skyjack, Lull, Skytrak,

Tsurumi, Husquvarna/Target, Whiteman-Concrete/Mortar, Stow-Concrete/Mortar, Baldor,

Wacker, Sakai, Snorkel, Upright, Mi-T-M, Sullair, Neal, Basic, Dynapac, MBW, Weber,

Bartell, Bennar Newman, Haulotte, Ditch Runner, Blaw-Knox, Himoinsa, Best, Buddy,

Crown, Edco, Wyco, Bomag, Laymor, Terremite, Barreto, EZ Trench, Takeuchi, Basic, Bil-

Jax, Curtis, Gehl, Heli, Honda, ICS/PowerGrit, Puckett, Waldon, ASV, IHI, Partner, Imer,

Clipper, MMD, Koshin, Rice, Gorman Rupp, CH&E, Cat Pumps, Comet, General Pump,

Giant,AMida, Coleman, NAC, Gradall, Square Shooter, Kent, Stanley, Tamco, Toku, Hatz,

Kohler, Robin, Wisconsin, Northrock, Oztec, Toker TK, Rol-Air, Small Line, Wanco, Yanmar

Discount-Equipment.com

2

TABLE OF CONTENTS

1.Serial Number Location.............................................. 3

2.Parts Ordering Procedure .......................................... 3

3.Assembling Instructions ............................................. 4

4.Safety Precautions ..................................................... 6

5.Safety Notice & Decals ............................................... 7

6.Before Operating...................................................... 10

7.Starting Engine ......................................................... 11

8.Operating Instructions ............................................. 12

9.Recommended Cutters Type ................................... 13

10.Service Instructions................................................ 14

11.Maintenance Schedule .......................................... 18

12.Replacements......................................................... 18

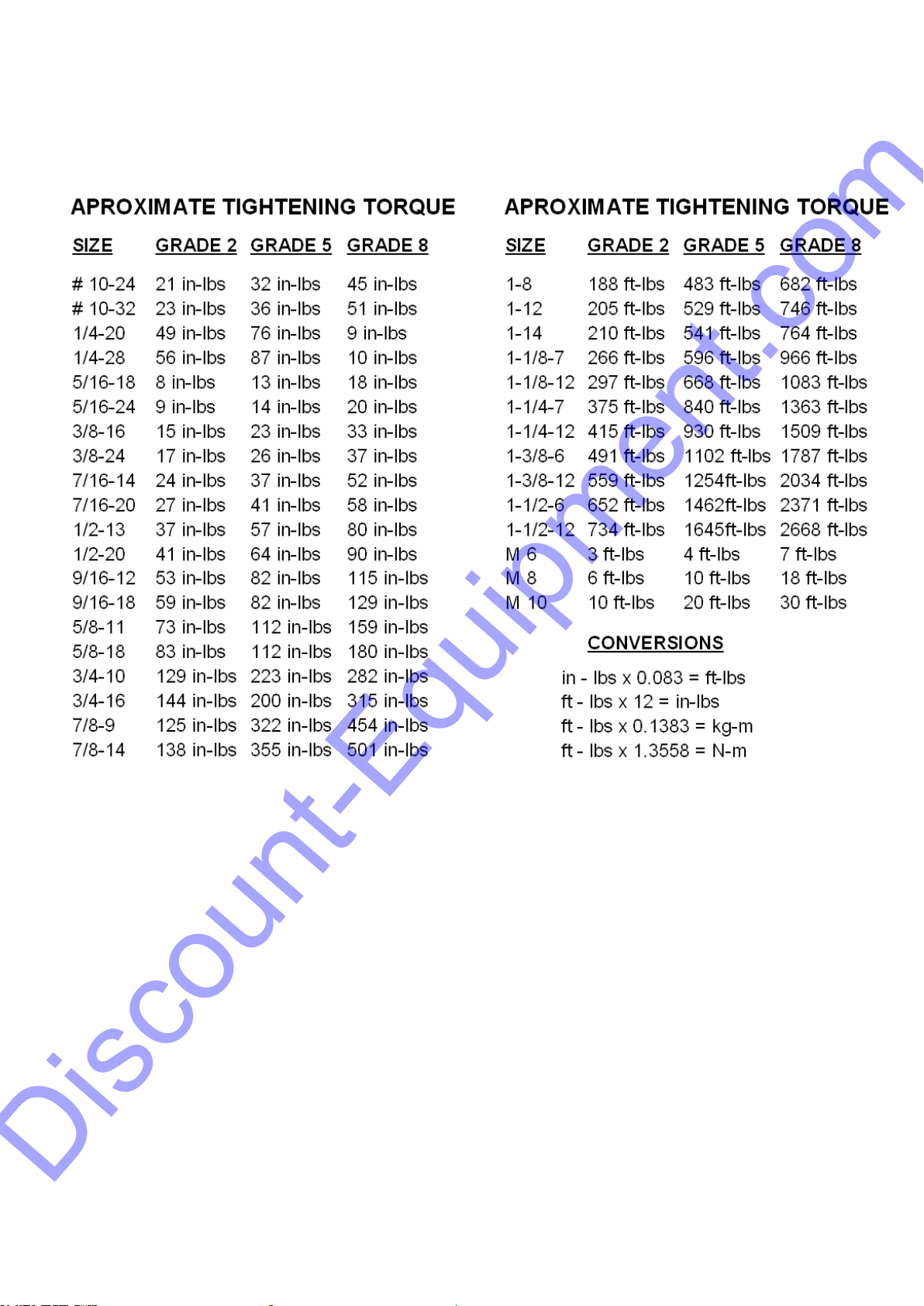

13.Torque Chart .......................................................... 19

Discount-Equipment.com

3

1. SERIAL NUMBER LOCATION

The model/serial number decal is located on the shroud assembly (black).

(Write model number)

(Write serial number)

The unit’s year of manufacture can be determined by the serial number. Contact your nearest

sales branch or for more information.

This Unit warranty is stated in this Operational and Safety manual on page 16. Failure to

return warranty registration card renders the warranty null and void.

An engine owner’s manual is also attached to every unit. Engine parts may order from any

authorized dealer. Refer to the engine owner´s manual lo learn about specifications and part

identification.

2. PARTS ORDERING PROCEDURE:

Parts are available worldwide and must be ordered through your local distributor. If you

can’t locate the distributor in your area refer to page 17 of this manual to locate the

nearest branch and contact numbers for assistance.

Scarifiers are intended for use in several applications. They are powered by four stroke

gas engines or electric motors and are available in different sizes and manufacturers.

This Operation manual contains only standard parts. Variations of these parts as well as other

special parts are not included. Contact your local distributor for assistance in identifying

parts not included in this manual.

ALWAYS HAVE READY:

1. Model and serial number of machine when ordering parts.

2. Model and serial number of engine when ordering engine parts.

3. Item part number(S), description, and quantity.

4. Company name, address, zip code, and purchase order number.

5. Preferred method of shipping.

Discount-Equipment.com

4

REMEMBER –You own the best. If repairs are needed, use

only purchased parts from authorized distributors.

3. ASSEMBLING INSTRUCTIONS

UNPACKING

1. Remove the unit and all components from its shipping crate. You will see:

Preassembled scarifier with carbide cutters, or tungsten cutters if they were

purchased separately.

Scarifier handle control.

FINAL ASSEMBLING

Surface Scarifiers are shipped completely assembled with the exception of the handle

control.

Note: All installation hardware must be inserted into its respective location on the

equipment, see parts explosion for more details.

1. Using appropriated equipment, bring the unit to the ground from its shipping pallet.

Warning: failure to use proper lifting equipment could cause

the equipment to fall and cause serious injury.

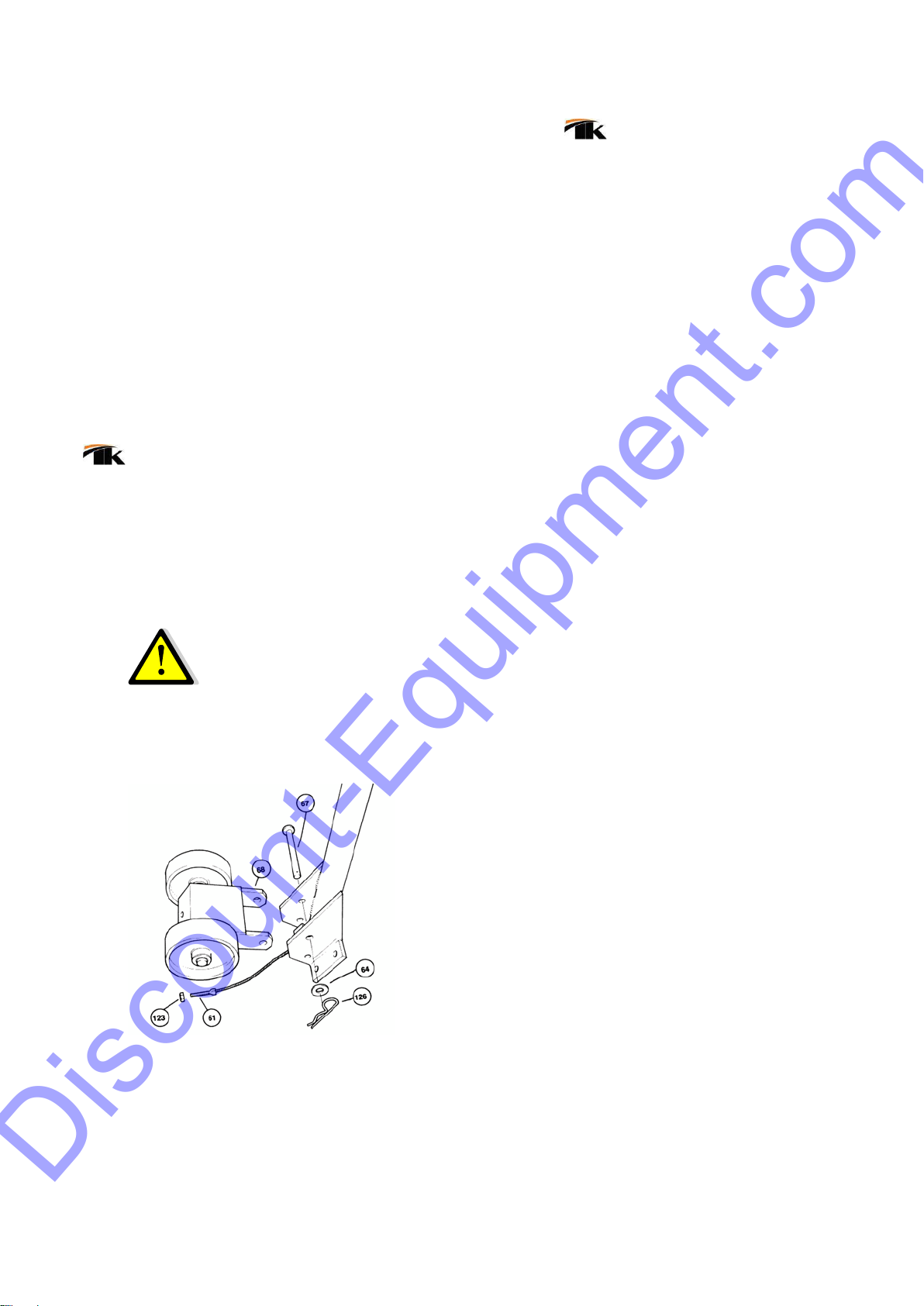

2. Remove the pin (67) from the handle assembly. Align the lift plate (68) and re-insert the top pin (67).

Place flat washer (64) on pin. Insert spring clip (126) through hole in pin. Feed threaded bolt end of

cable (61) through hole on lift plates.

Discount-Equipment.com

5

3. Tighten cable by attaching nut (123).

4. Remove the four bolts (70) and lock washers (69) from machine housing (104). Match up the holes on

the handle assembly to the machine housing and insert the bolts (70) and the washers (69).

Tightenbolts corner-to-corner. Before final tightening, place the machine on a flat surface to ensure all

wheels contact the surface.

EDGER ASSEMBLING/INSTALLATION

Make sure that the power source is disconnected; unplug the electric unit; disconnect spark plug and

turn off fuel supply on gas unit; disconnect air supply on air unit.

1. Tilt machine back onto handle (if your unit is equipped with a Honda GX engine, unit must be tilted

forward or cylinders will be flooded with oil).

2. Remove cutter cage and retainer shaft.

3. Facing underside of machine, slide dummy shaft (110) through outboard bearing on left side (if

engine is a Honda GX this will be on the right side of the housing).

4. Slide retainer shaft (108) through edger cage. The roll pin in the shaft head should fit into the slot

on the end plate of the cage.

5. Slide retainer shaft through the outboard bearing and the dummy shaft.

6. Using a 15/16” socket or wrenches tighten the retainer shaft by turning counter clockwise.

7. Install edger housing (106) using the three bolts supplied (107).

8. NOTE: Edger operation is not to be performed with main TFP cage in place.

Discount-Equipment.com

6

4. SAFETY PRECAUTIONS

READ AND STUDY THE FOLLOWING SAFETY INFORMATION BEFORE ATTEMPTING TO OPERATE THIS

EQUIPMENT. IN ADDITION, ENSURE THAT EVERY INDIVIDUAL WHO OPERATES OR WORKS WITH

THIS EQUIPMENT IS FAMILIAR WITH THESE SAFETY PRECAUTIONS.

WARNING - LETHAL EXHAUST GAS!

An internal combustion engine discharges carbon monoxide, which is a poisonous and odorless

invisible gas. Death or serious illness may result if inhaled. Operate only in an area with good

ventilation, NEVER IN A CONFINED AREA!

WARNING - DANGEROUS FUELS!

Use extreme caution when storing, handling and using fuels - they are highly volatile and explosive in

the vapor state. Do not add fuel while engine is running. Stop and cool the engine before adding fuel.

DO NOT SMOKE WHEN REFUELING!

SAFETY GUARDS

It is the owner's responsibility to ensure ALL GUARDS AND SHIELDS are in place and in working order.

IGNITION SYSTEMS

Breakerless magneto and batteries ignition systems CAN CAUSE SEVERE ELECTRICAL SHOCKS, avoid

contact with these components or their wiring.

SAFE DRESS

DO NOT WEAR loose clothing, rings, wristwatches, etc., near machinery.

NOISE PROTECTION

Wear O.S.H.A. specified hearing protection devices.

FOOT PROTECTION

Wear O.S.H.A. specified steel tip safety shoes.

HEAD PROTECTION

Wear O.S.H.A. specified safety helmets.

EYE PROTECTION

Wear O.S.H.A. specified eyes shields, safety glasses, and sweat bands.

DUST PROTECTION

Wear O.S.H.A. specified dust mask or respirator.

OPERATOR

Keep children and bystanders off and away from the equipment. Only trained Operators who fully

understand its safety operation must use this equipment.

For details on safety rules and regulations in the United States, contact your local Occupational Safety

and Health Administration (O.S.H.A.) office. Equipment operated in other countries must be operated

and serviced in accordance and compliance with any and all safety requirements of such country. The

publication of these safety precautions is done for your information does not by the publication of

these precautions, imply or in any way represent that these are the sum of all dangers present near

equipment. If you are operating a unit it is your responsibility to insure that such operation is

in full accordance with all applicable safety requirements and codes. All requirements of the United

Discount-Equipment.com

7

States Federal Occupational Safety and Health Administration Act must be met when operated in

areas that are under the jurisdiction of that United States Department.

5. SAFETY NOTICE & DECALS

READ SAFETY DECALS CAREFULLY

Carefully read and follow all safety decals. Keep them in good conditions. If they become

aged, replace as required. If repainting, REPLACE ALL decals. Decals are available from your

authorized Distributors. Decals are not shown to scale.

201155

201157

IMPORTANT NOTICE

The "SAFETY ALERT SYMBOL" is used to call attention to items or operations that may be

dangerous to those operating or working with this equipment. These symbols can be found

throughout the manual and on the unit itself. Please read these warnings and cautions carefully.

IMPORTANT NOTICE

The "SAFETY ALERT SYMBOL" is used to call attention to items or operations that may be

dangerous to those operating or working with this equipment. These symbols can be found

throughout the manual and on the unit itself. Please read these warnings and cautions carefully.

Discount-Equipment.com

8

READ SAFETY DECALS CAREFULLY

Carefully read and follow all safety decals. Keep them in good condition. If they become aged,

replace as required. If repainting, REPLACE ALL decals. Decals are available from your

authorized Distributors. Decals are not shown to scale.

201003 (x2)

201005

201026

201152

201005

201006

201001 BIG

201001 SMALL

290791

201004

201154

Discount-Equipment.com

9

SAFETY PRECAUTIONS

!

DANGER

EXPLOSION HAZARD

Never operate the machine in an

explosive atmosphere, near

combustible materials or where

ventilation does not clear exhaust

fumes.

! WARNING

BURN HAZARD

Never come into contact with the

engine or muffler when engine is

operating or shortly after it is turned

off. Serious burns may occur

! CAUTION

MOVING PARTS

Before starting the machine ensure

that all guards and safety devices

are in place and functioning

properly.

! CAUTION

MACHINE DAMAGE

Advance cutter depth in small

increments to avoid premature

wear or damage.

! ATTENTION

READ OWNERS MANUAL

Read and understand operator's

manual before using this machine.

Failure to follow operating

instructions could result in serious

injury or death.

Discount-Equipment.com

10

6. BEFORE OPERATING

REMEMBER! It is the owner´s responsibility to communicate information on the safe

use and proper operation of this unit to the operators.

Before operating, review SAFETY PRECAUTIONS listed on page 6 of this manual.

Familiarize yourself with the operation of the unit and confirm that all controls

function properly BEFORE starting engine.

Locate the killing switch and assure you know how to STOP the unit.

Make sure hands, feet, and clothing are at a safe distance from any moveable parts

prior to starting.

Shrouds and guards are provided to protect the operator or structures in close

proximity to rotating hot engine parts. It is the RESPONSABILITY OF THE OPERATOR to

see that they are properly in place. NEVER operate this equipment without a guard.

OIL LEVEL - Check the oil level in the engine. For more information see "Lubrication"

under the engine "Owner's Manual" the "Maintenance" section of this manual. All

Equipment come without oil, running an engine without lubrication may damage the

engine.

AIR CLEANER - Check to ensure elements are in good condition and properly installed.

Review every decal with the OPERATOR.

FUEL SUPPLY - Engines on equipment require an automotive grade of clean, fresh,

unleaded or regular gasoline. All equipment’s come without gasoline and oil.

FUEL FILTER - Check to ensure element is in good condition... Replace if it is clogged or

damaged.

LUBRICATION POINTS –Grease wheels (4), Drive Shaft and bushing daily. ALGO MAS?

SPARK PLUG (GAS UNIT) –Check and clean spark plugs regularly. A fouled, dirty or

carbonated spark plug may cause difficulties starting and poor engine performance.

Set spark plug gap to recommended clearance. Refer to engine manual.

BELT TENSION –If there is excessive belt play, there will be a decrease in the

cutting/grinding performance, which could cause unit damages. The normal belt play

should be 3/8” to 1/2” which is measured by depressing the top section of the belt at

the belt guard mounting bracket location. When adjusting the belts, make sure that

the drive pulley is in aligned with the cage pulley.

POSITION –The only operating position for this scarifier is at the rear of the

equipment. If the operator must leave this position the engine must be shut down.

Discount-Equipment.com

11

SPECTATORS –Keep all personnel/spectators away from the Scarifier while running.

This Spinning equipment can throw segments and can cause injuries.

7. STARTING ENGINE/AIR

GAS ENGINE

1. With the Scarifier engine level in the ground check oil level and add oil and fuel

as required.

2. Pull the stop switch on the unit to its "Out" position.

3. Prior to starting engine, raise the cutter cage assembly using the hand knob

lever, so that cutters do not touch the ground surface, "IDLE" POSITION, and

secure the lever with the locking handle

4. Move the engine throttle control to the "FAST" position.

5. Choke the engine if necessary. (You may not need to choke a warm engine)

BEFORE STARTING ENGINE MAKE SURE ALL GUARDS ARE IN PLACE.

6. Pull the starter string.

7. After the engine starts, move the choke lever to the open position, move the

throttle level to the "IDLE" position and let the engine warm-up for one or two

minutes.

SLOWLY LOWER CUTTERS INTO SURFACE, AND USE A DUST CONTROL

VACUUM TO PROVIDE A CLEAN WORKING AREA.

8. To stop the engine, make sure to let the engine idle before stopping by using

the crank lift handle to raise the scarifier cutters height.

9. Push in the engine stop switch on the scarifier.

10. Close the fuel valve.

ELECTRIC MOTOR

1. With the cage in maximum raised position, plug the motor into a suitable power

source.

2. Move the switch on the motor to the "ON" position.

3. It is recommended to let the motor idle before running and stopping by using

the crank lift handle to raise the scarifier cutters height.

Discount-Equipment.com

12

AIR SUPPLY

With cage in maximum raised position, attach air supply (minimum 90 C.F.M. at

90 P.S.I.) turn quick opening valve on. Run in for two (2) minutes. Turn off valve,

and then re-start.

The air regulator is equipped with a pressure gauge. The recommended operating

pressure is 90 P.S.I. at 90 C.F.M.; however when the unit is running with no load

(cutters not engaged) the gauge will read 40 P.S.I. When the cutters are engaged

the indicator needle should rise to 90 P.S.I

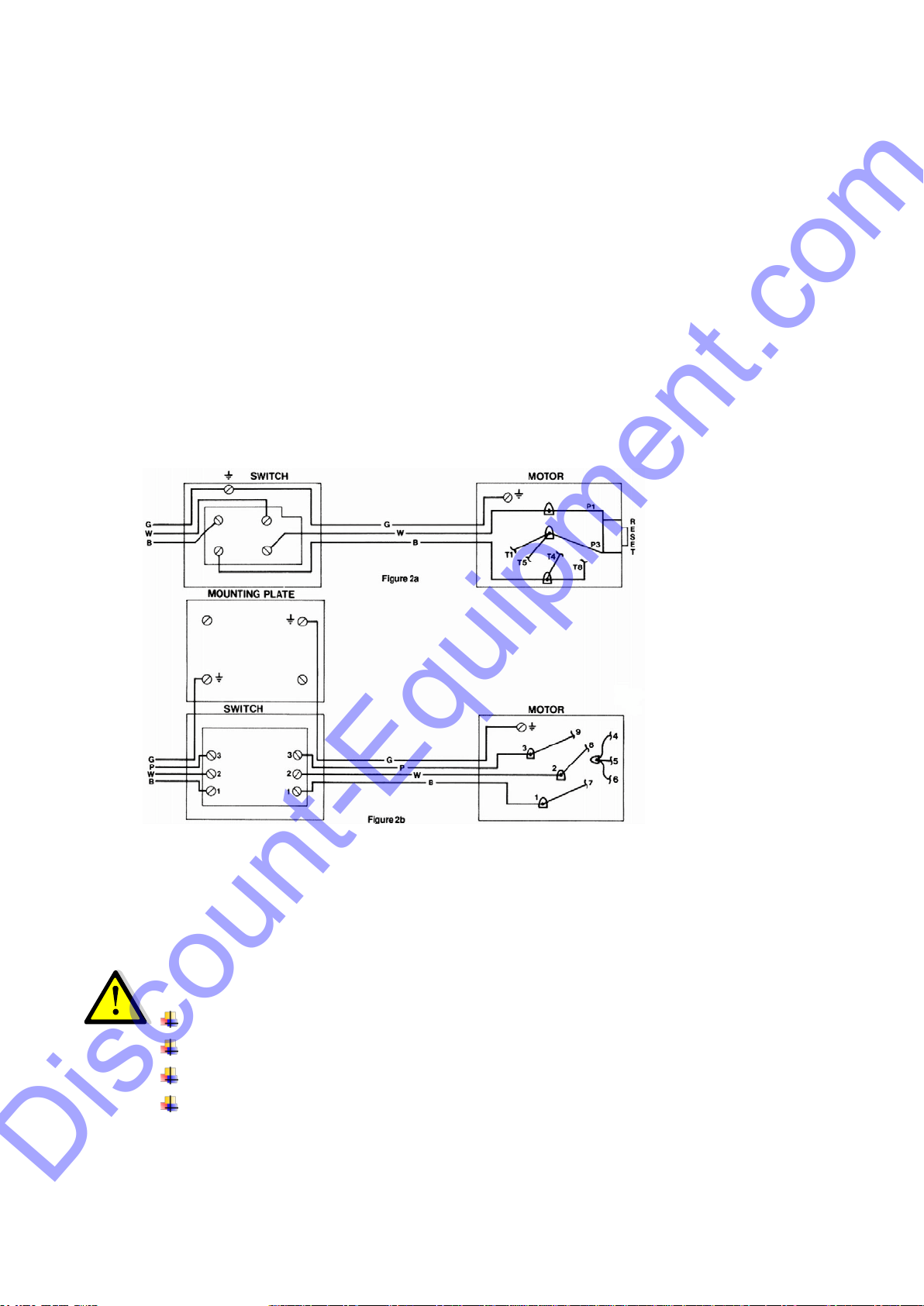

STOP/KILL-SWITCH INSTALLATION

On gas powered models, feed the attached kill switch with a wire coming all the way through the

engine terminal. Make sure to clamp the terminal with a pair of pliers

On electric models, attach bracket to the handle with screws and provided lock washers. Wire as

following figure:

2a diagram is for 220 volts and 2b diagram is for 440 volt.

STOPPING PROCEDURE:

With machine in upright position, adjust the cutter cage to maximum height by turning the height

adjustment knob to its farthest position. (This ensures clearance for the rotating cage.)

GASUNIT –Stop engine by depressing kill switch button located at top of handle.

ELECTRIC UNIT –Turn off switch on handle.

AIR UNIT –Turn off air supply valve.

STOP THE ENGINE OR ELECTRIC MOTOR BEFORE:

Adding fuel.

Leaving equipment unattended for any amount of time.

Making any repairs or adjustments to the unit.

Lifting/Transportation.

Discount-Equipment.com

13

8. OPERATION INSTRUCTIONS

OPERATING

1. After turning engine/motor “ON”, and the scarifier in its raised position, attach the air

supply (minimum 90 C.F.M. at 90 P.S.I.) turn quick opening valve on. Run in for two

(2) minutes. Turn valve off, and then re-start. The air regulator is equipped with a

pressure gauge. The recommended operating pressure is 90 P.S.I. at 90 C.F.M.;

however when the unit is running with no load (cutters not engaged) the gauge will

read 40 P.S.I. When the cutters are engaged the indicator needle should rise to 90

P.S.I.

1. Lower scarifier cutters until it just touches the pavement by turning the manual lift

crank clockwise.

NEVER FORCE THE CUTTERS HEAD INTO THE SURFACE TO A POINT WHERE THE

EQUIPMENT STARTS BOUNCING

2. Slowly push scarifier forward to desired area.

This Unit can be used as several applications, make sure you know the operation

procedure of this equipment and the cutters types for each application

TYPICAL SCARIFIER APPLICATIONS

Asphalt leveling and grooving

Carpet backing removal

Coating removal

Concrete grinding

Concrete & steel surface preparation

Concrete grooving

Epoxy removal

Expansion joint leveling

Floor cleaning steel & concrete

Glue/adhesive removal

Milling joints

Non-slip removal

Paint removal

Steel de-scaling

Traffic line removal

Wheelchair ramp leveling.

Discount-Equipment.com

14

9. RECOMMENDED CUTTERS TYPE SELECTION

ADHESIVES –CARPET R120 (B-1 Cutters)

Most carpets adhesives removal

Estimated Production Rate: 100-300 sq.ft/hr. Estimated Cutter Life: 1200-1500 sq.ft.

ADHESIVES –TILE R138 (A-3, B-3 Cutters)

Most tile adhesives removal.

Estimated Production Rate: 100-250 sq.ft/hr

Estimated Cutter Life: 1200-1500 sq.ft

CONCRETE GRINDING

R150, R151, or R152 (Carbide Cutters)

Smoothing rough concrete and/or grinding high spots.

Estimated Production Rate: 200-500 sq.ft/hr.

Estimated Cutter Life: 3000-6000 sq.ft

CONCRETE SCARIFYING/GRINDING R134 or R139 (Tungsten Carbide Tipped Cutters)

Concrete preparation prior coating application or concrete overlay (1/8” depth of cut per pass.)

Estimated Production Rate: 200-400 sq.ft/hr.

Estimated Cutter Life: 8000-15,000 sq.ft

PAINTING LINES REMOVAL R132 (B-2)

Painting concrete/asphalt lines removal

Estimated Production Rate: 10-20 linear ft/min

Estimated Cutter Life: 800-2000 linear ft.

THERMOPLASTIC LINES REMOVAL R143 (B-3)

Thermoplastic concrete/asphalt base paints

Estimated Production Rate: 10-20 linear ft./min

Estimated Cutter Life: 800-1200 linear ft.

10. SERVICE INSTRUCTIONS

Never service or lubricate the unit engine while running.

After servicing the unit, restore and fasten all guards, shields, and covers to their

original positions.

Never drain oil into the ground, into open streams, or down sewage drains.

Keep air filter clean at all times. Wash away dust and debris using anon-oil based

cleaning solvent. Let the filter dry before re- installing.

WHEN LIFTING/LOWERING ALWAYS:

1. Set the machine in an upright position and adjust the cutter cage to maximum

height by turning the height adjustment knob to its farthest position. (This will

ensure clearance for the rotation cage.)

2. Stop the engine or electric motor.

3. REMOVE CUTTERS.

Discount-Equipment.com

15

4. Lift the cutting guide to avoid any contact with the head.

5. Secure any other hardware on the machine.

6. Make sure you use appropriated lifting equipment to lift equipment.

7. Do not position yourself where you could possibly be pinched / caught between

the equipment and some other obstacle.

TOWING

1. Move Scarifier on the jobsite by hand pushing. Do not tow the unit with another

vehicle. The scarifier may be damage if towed.

CUTTING

1. Must know what you are machine, before making any cuts. Be aware of all

utilities i.e. gas/pipe lines, electricity, etc. take necessary precautions to prevent

injury /death.

STORING

1. Drain fuel tank.

2. Clean drive shaft and coat parts with grease.

3. Lube all bearings

4. Empty water system

5. Clean all moving parts with WD-40 lubricant.

6. Lower unit completely.

7. Cover unit for protection.

ENGINE

See engine owner´s manual maintenance schedule.

LUBRICATION

1. Grease wheels, and knob lever daily. Use high quality gun grease.

2. Keep a coating of grease on the drive shaft and threads for easy installation or

removal and longer bushing life.

SPARK PLUG

Discount-Equipment.com

16

1. Check and clean spark plugs regularly. A fouled, dirty or carbonized spark plug

causes hard starting and poor engine performance. Set spark plug gap to

recommended clearance. Refer to engine manual.

BELT TENSION

1. If there is excessive belt play, there will be a decrease in the cutting/grinding

action, which could cause cage and machine damage. The normal belt play

should be 3/8” to 1/2” which is attained by depressing the top section of the

belt at the belt guard mounting bracket location. When adjusting the belt make

sure that the drive pulley is in alignment with cage pulley. Tighten all engine

mount bolts, adjust the two engine-stop bolts, and tighten lock nuts.

CUTTER CAGE REMOVAL/CHANGE

1. Make sure that the power source is disconnected. With gas models turn off fuel

supply to engine and disconnect sparkplug; unplug electric unit; disconnect air

supply on air unit.

2. Tilt machine back onto the handle. (If your unit is equipped with a Honda GX

engine, unit must be tilted forward to change cutters or cylinders will be

flooded with oil).

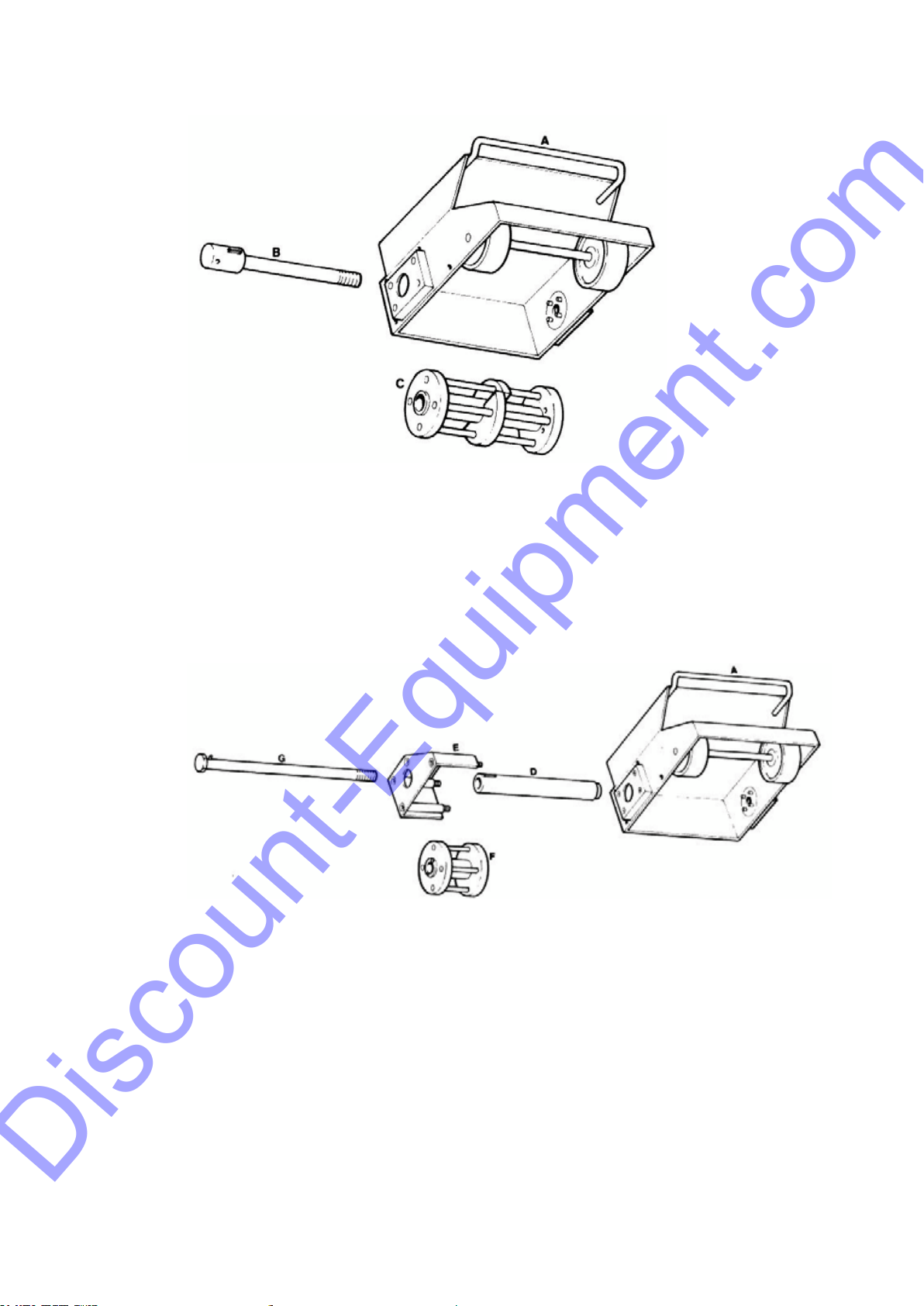

3. Facing the underside of the machine housing (figure 3-A) place a bar between

the cutter rods to jam cage C.

4. Remove end cap and with a 1” (26 mm) socket loosen and remove the shaft

by turning in clockwise direction or remove end cap and shaft guard to insert a

drift pin into the hole on the main shaft B and turn shaft clockwise to loosen and

remove shaft.

5. Disengage the cage from the drive pins by moving to the left. (The cage on the

Honda GX machines will move to the right). Remove cage.

EDGER CAGE REMOVAL

1. Make sure that the power source is disconnected. With gas models turn off fuel

supply to engine and disconnect sparkplug; unplug electric unit; disconnect air

supply on air unit.

2. Tilt machine back onto handle. (If your unit is equipped with a Honda GX

engine, unit must be tilted forward to change cutters or cylinders will be

flooded with oil).

3. Using a 15/16” socket or wrench, turn head of shaft (G) clockwise to loosen.

4. While turning the shaft outwards, cage will move towards the outer edge as

well. Free cage from locking pins on shaft by pushing cage back towards main

housing (A). Turn shaft out and move.

Discount-Equipment.com

17

5. Cage will be free to remove from edger.

Figure 3A

CHANGING CUTTERS/SHAFTS

1. Once the cage has been removed use a 5/32” Allen Key and 7/16” open end

wrench, remove screws and cover plate from cage. With drift pin tap rods from

the drive side until free of cage. Replace cutters or shafts as required. Replace

cover plate. To re-install cutter cage in machine, reverse procedure for removal.

Ensure that the shaft is tight.

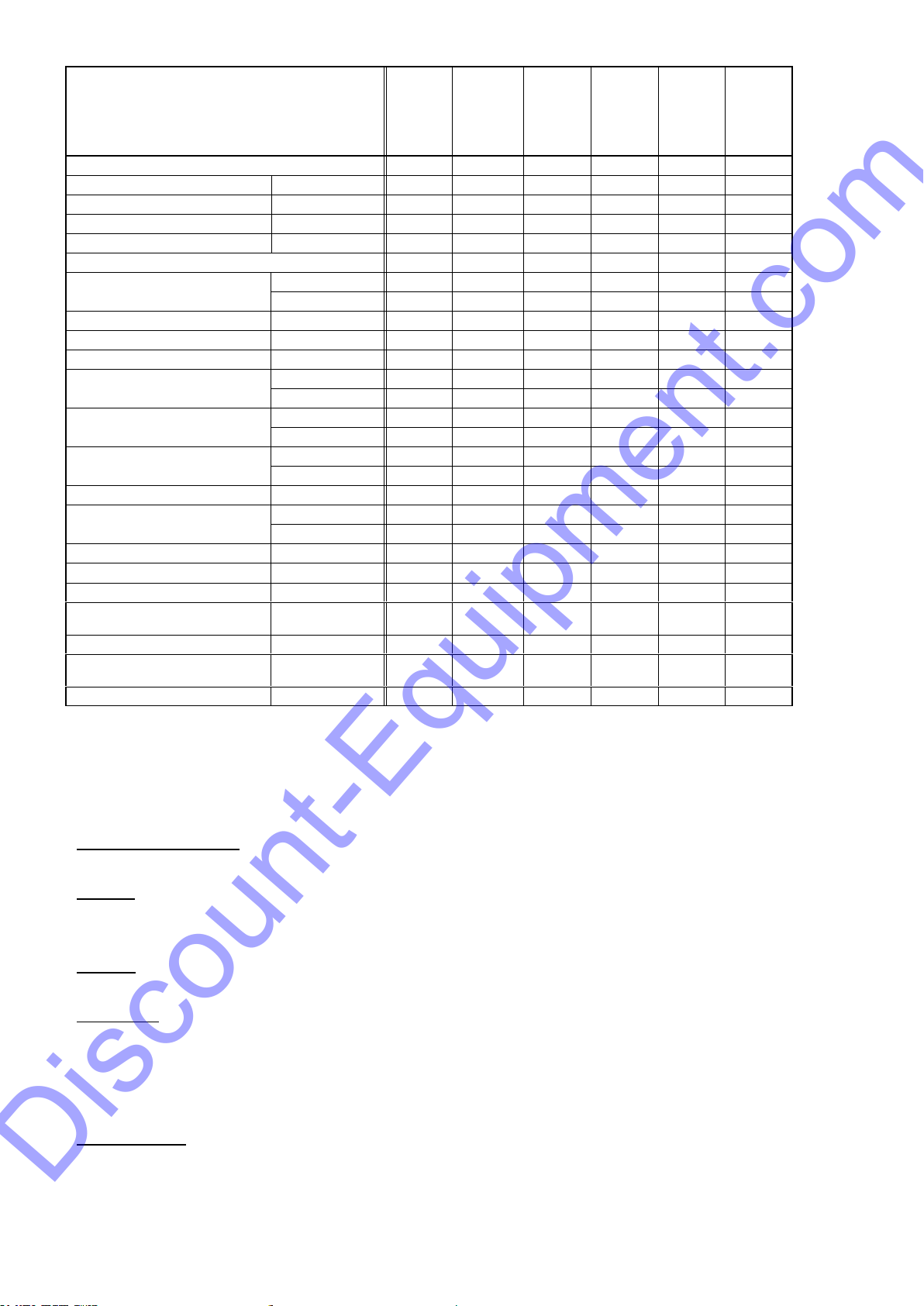

11. MAINTENANCE SCHEDULE

1. Check all hardware after the first 5 hours of use, the follow the maintenance schedule.

Discount-Equipment.com

18

Maintenance

Services Intervals

After

every use

After 45

days or

50 hrs.

Every 3

months

or

100 hrs.

Every 6

months

or

200 hrs.

Every 9

months

or

300 hrs.

Every 12

months

or

400 hrs.

General Inspection:

Guards

Check

X

X

X

X

X

Warning stickers

Check

X

X

X

X

X

Wheels

Check operation

X

X

X

X

X

X

Test run

Check operation

X

X

X

X

X

Engine:

Engine oil

Check level

X

X

X

X

X

X

Change

X

X

X

Engine oil filter

Replace

X

X

Oil cooler

Clean

X

X

X

X

Cooling Fins

Clean

X

X

X

X

X

Air cleaner

Check - clean

X

X

X

X

X

X

Replace

X

Air Intake Line

Check

X

Replace

2 years

Fan Belt

Check tightness

X

X

Replace

500 hrs.

Valve clearance

Check-adjust

X

X

Fuel filter

Check & clean

X

X

X

X

Replace

X

X

Fuel Tank

Clean

500 hrs.

Engine wiring

Check

X

Cage:

Teeth: (see Individual Cage for

specifications)

Check wear

X

X

X

X

X

X

Change

Shaft: (see Individual Cage

for specifications)

Check wear

X

X

X

X

X

X

Change

12. REPLACEMENTS

Parts

Tolerance or Replacement Cycle

Engine Components

Refer to your engine manufacturer´s Owner´s

Manual

V-Belts

Replace if stretched to the point that the idler does

not work properly. Replace the V-belts if they are

cracked or torn.

Cutters

Replace if Cutters present any missing segments or

stress cracks.

Hardware

Re-torque all bolts after the first eight hours of

operation and check hardware every 25 hours.

Replace any worn or damaged hardware as

needed. Replacement hardware should be grade 5

and zinc plated.

Safety Decals

Replace if they become aged, damaged or cannot

be easily read.

Discount-Equipment.com

19

13. TORQUE CHART

Discount-Equipment.com

Table of contents