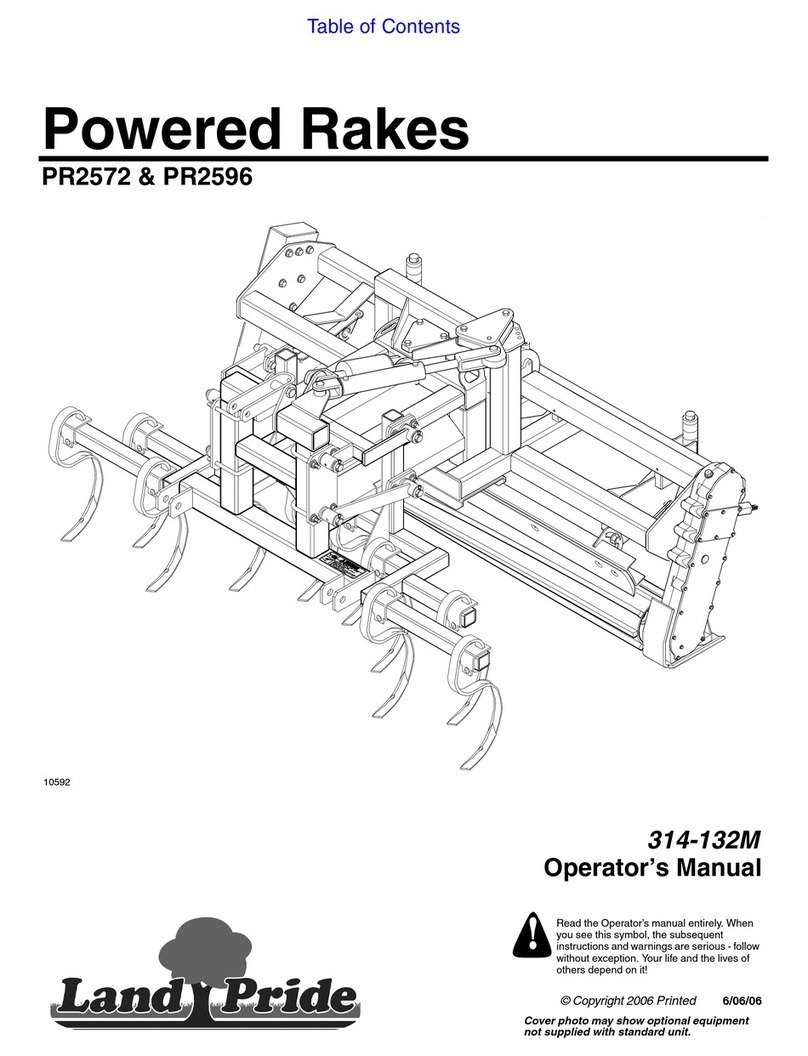

Table of Contents

RCF2784 Rotary Cutters 326-364M 5/08/13

©Copyright 2013 All rights Reserved

Land Pride provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been taken in the

preparationofthismanual,Land Prideassumes noresponsibilityforerrorsoromissions.Neitheris anyliabilityassumedfordamagesresultingfrom theuse

ofthe information containedherein. Land Pride reservesthe right toreviseand improveits productsas it sees fit.This publicationdescribesthestate of this

product at the time of its publication, and may not reflect the product in the future.

Land Pride is a registered trademark.

All other brands and product names are trademarks or registered trademarks of their respective holders.

Printed in the United States of America.

Important Safety Information . . . . . . . . . . . . . 1

Safety at All Times . . . . . . . . . . . . . . . . . . . . . . . . . 1

Look For The Safety Alert Symbol . . . . . . . . . . . . .1

Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Terminology: . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Definitions: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Owner Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Further Assistance . . . . . . . . . . . . . . . . . . . . . . . . 7

Section 1: Assembly & Set-up . . . . . . . . . . . . 8

Tractor Requirements . . . . . . . . . . . . . . . . . . . . . . . 8

Torque Requirements . . . . . . . . . . . . . . . . . . . . . . . 8

Uncrating Instructions . . . . . . . . . . . . . . . . . . . . . . . 8

Gearbox Vented Dipstick . . . . . . . . . . . . . . . . . . . . . 8

3-Point Cutter Assembly & Set-up . . . . . . . . . . . . . . 9

3-Point Hitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3-Point Single Tailwheel Option . . . . . . . . . . . . . 10

3-Point Dual Tailwheel Option . . . . . . . . . . . . . . 11

3-Point Tractor Hook-up . . . . . . . . . . . . . . . . . . . . 12

Driveline Installation . . . . . . . . . . . . . . . . . . . . . . . 12

Check Driveline Collapsible Length . . . . . . . . . . 13

Shorten Driveline . . . . . . . . . . . . . . . . . . . . . . . . 13

Check Driveline Maximum Length . . . . . . . . . . . 14

Check Driveline Interference . . . . . . . . . . . . . . . 14

Pull-Type Cutter Assembly & Set-up . . . . . . . . . . . 15

Hitch Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 15

Driveline Installation . . . . . . . . . . . . . . . . . . . . . . 15

Axle Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Pull-Type Tractor Hook-up . . . . . . . . . . . . . . . . . . 17

Hydraulic Hook-up . . . . . . . . . . . . . . . . . . . . . . . 18

Purge Hydraulic System . . . . . . . . . . . . . . . . . . . 18

Assembly of Optional Guards . . . . . . . . . . . . . . . . 18

Front Rubber Guard . . . . . . . . . . . . . . . . . . . . . . 18

Front Single or Double Chain Guard . . . . . . . . . 18

Rear Single or Double Chain Guards . . . . . . . . . 19

Section 2: Adjustments . . . . . . . . . . . . . . . . . 20

3-Point Leveling & Cutting Height . . . . . . . . . . . . . 20

Deck Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Cutting Height Adjustment . . . . . . . . . . . . . . . . . 20

Single & Dual Tailwheel Adjustment . . . . . . . . . .21

Center 3-Point Link Adjustment . . . . . . . . . . . . .21

Pull-Type Deck Leveling & Cutting Height . . . . . . .22

Deck Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Front To Back Deck Leveling . . . . . . . . . . . . . . .22

Cutting Height Adjustment . . . . . . . . . . . . . . . . .23

Section 3: Operating Instructions . . . . . . . . . 24

Operating Checklist . . . . . . . . . . . . . . . . . . . . . . . .24

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . .24

Pre-inspection of Tractor & Cutter . . . . . . . . . . . . .25

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Blade Engagement & Disengagement . . . . . . . . . .26

Blade Engagement . . . . . . . . . . . . . . . . . . . . . . . 26

Blade Disengagement . . . . . . . . . . . . . . . . . . . .26

Field Operation . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Unhooking the Rotary Cutter . . . . . . . . . . . . . . . . .26

General Operating Instructions . . . . . . . . . . . . . . .27

Section 4: Maintenance & Lubrication . . . . . 28

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Cutter Blade Maintenance . . . . . . . . . . . . . . . . . . .28

Slip-Clutch Protected Drivelines . . . . . . . . . . . . . .29

Clutch Run-In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Clutch Assembly and Disassembly . . . . . . . . . . . .30

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Skid Shoe Maintenance . . . . . . . . . . . . . . . . . . . . .30

Long Term Storage . . . . . . . . . . . . . . . . . . . . . . . . 31

Ordering Replacement Parts . . . . . . . . . . . . . . . . .31

Lubrication Points . . . . . . . . . . . . . . . . . . . . . . . . .32

Gauge Wheel Spindle Tube (3-Point Cutters) . . .32

Gauge Wheel Hub . . . . . . . . . . . . . . . . . . . . . . . 32

Gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Driveline U-Joints . . . . . . . . . . . . . . . . . . . . . . . .33

Driveline Shield Bearings . . . . . . . . . . . . . . . . . .33

Driveline Profiles . . . . . . . . . . . . . . . . . . . . . . . .33

Ratchet Jack (Optional) . . . . . . . . . . . . . . . . . . . 33

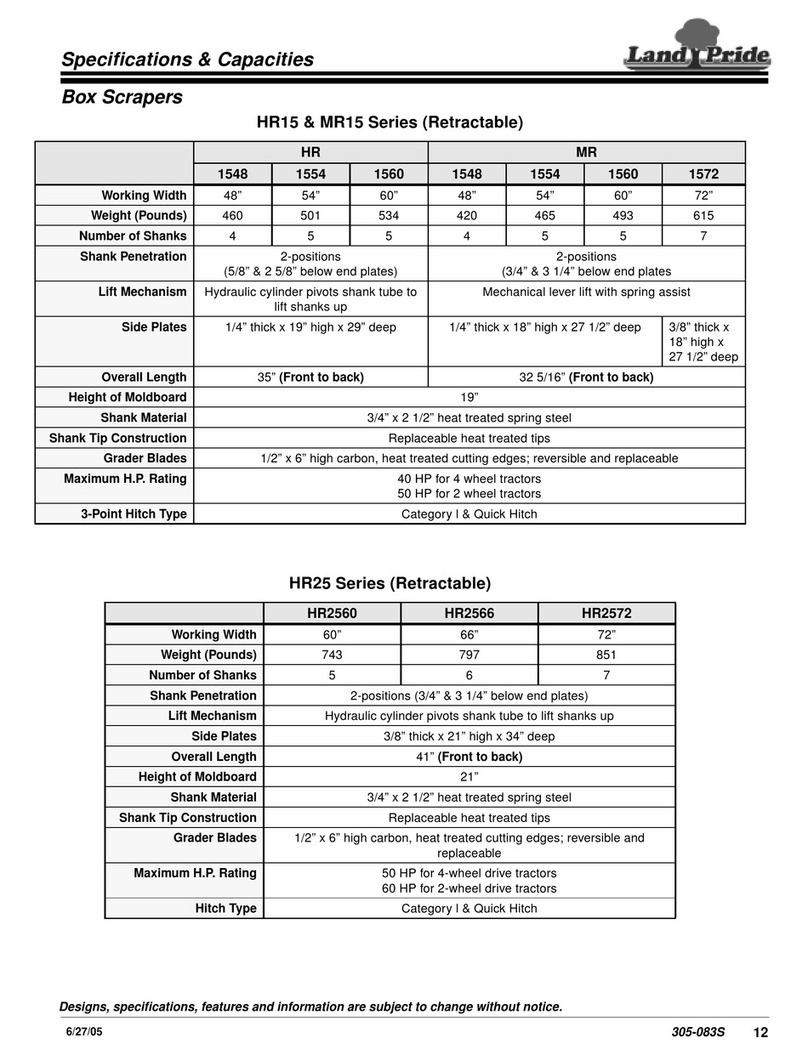

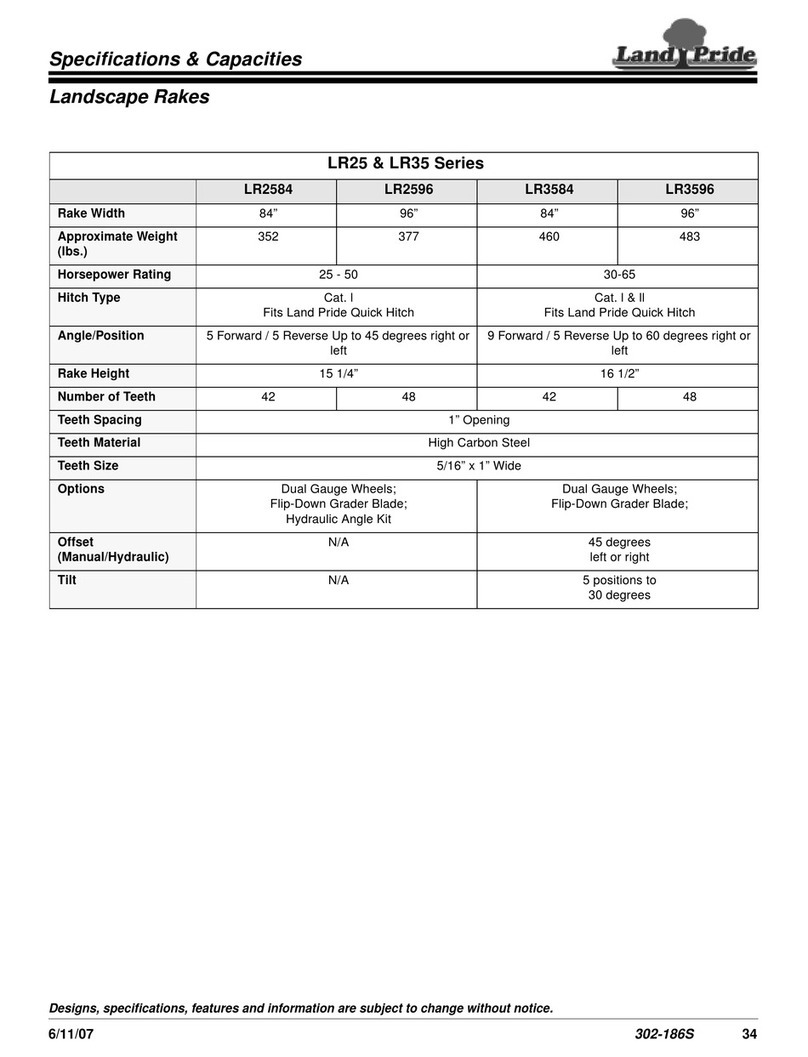

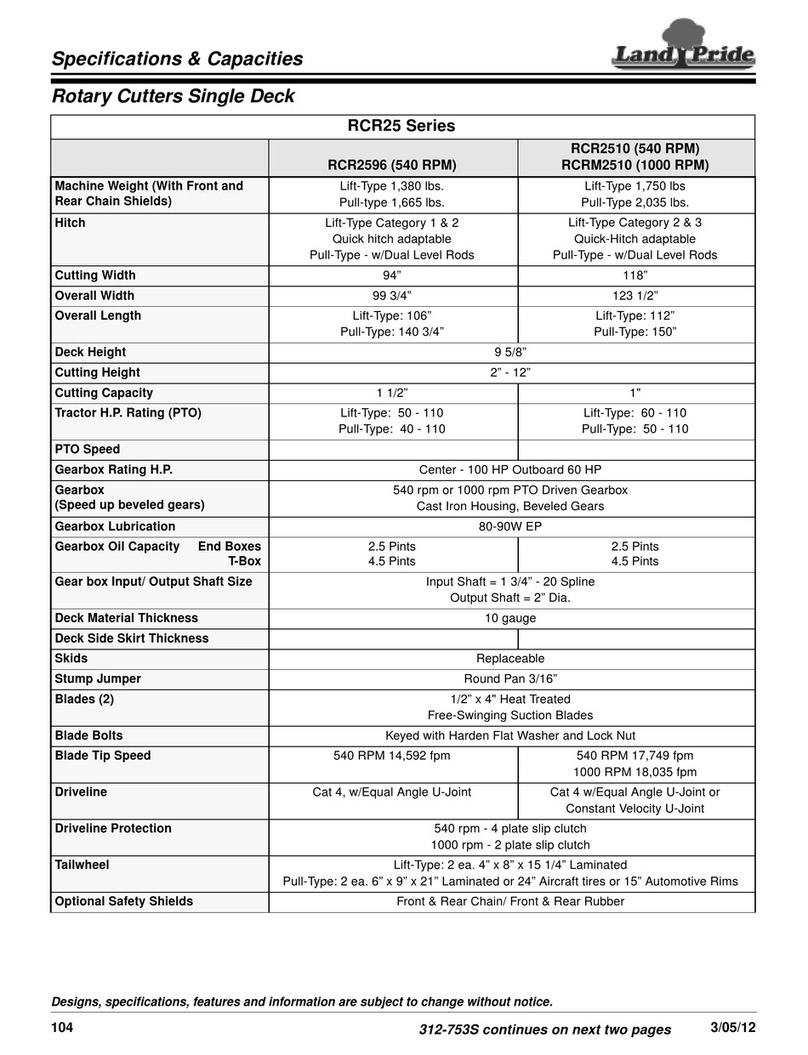

Section 5: Specifications & Capacities . . . . . 34

Section 6: Features & Benefits . . . . . . . . . . . 36

Section 7: Troubleshooting . . . . . . . . . . . . . . 37

Section 8: Torque Values Chart . . . . . . . . . . 38

Section 9: Warranty . . . . . . . . . . . . . . . . . . . . 39

Table of Contents