TKR Group 83 30 5 A87 F94 Repair manual

R1-23.12-V7

83 30 5 A87 F94

Disassembly and assembly tool

Translation of the original owner's manual

2

3

This owner's manual is protected by copyright. Any use beyond the restrictions imposed by copyright legislation undertaken without the permission of the manufacturer is

illegal and punishable by law. This also applies to the extraction of individual illustrations and use of texts as excerpts.

1. Safety

1.1 General instructions 4

1.2 Explanation of symbols 5

1.3 Scope of supply 6

1.4 Safety instructions 7

2. Technical data

2.1 Technical data 9

2.2 Device components 11

3. Startup

3.1 Intended use 12

3.2 Working with the tool - basic principles 13

3.3 Commissioning and safe handling 14

4. Use

4.1 Preparatory work 16

4.2 Removing the stator winding from a mild hybrid

transmission 17

4.3 Installing a stator winding in a mild hybrid

transmission 22

4.4 Removing the stator winding from a plug-in

hybrid transmission 26

4.5 Installing a stator winding in a plug-in hybrid

transmission 35

4.6 Transmission assignments for centering and

adjusting the tool 42

4.7 Completing an operation and tool storage 42

5. Maintenance

5.1 Troubleshooting 43

5.2 Regular inspection and maintenance 44

6. Service

6.1 Disposal 45

6.2 Warranty and service 45

6.3 Declaration of conformity 46

EC Declaration of conformity 47

4

1.1 General instructions

State-of-the-art

This tool is state-of-the-art technology. To ensure that the

equipment operates safely, it must be operated in a proper and

safety-conscious manner.

Technical changes

In the interests of quality assurance, we reserve the unrestricted

right to carry out technical changes as a result of further

technological developments and product improvements without

prior notification.

Reading the owner's manual

Before using the tool, make sure you read the owner's

manual carefully and understand it. This manual must

always be available where the product is used.

Handling

All the actions necessary to ensure correct operation are

described in the owner's manual. Any working methods other

than those approved by the manufacturer are prohibited.

Faults

If faults occur, the operator may only eliminate those faults

through their own actions where the corresponding remedy

is described.

Warranty

The manufacturer accepts no liability for damage or injury caused

by improper repair or the use of third-party replacement parts.

No warranty will be provided for damage caused to the device

due to the tool being used incorrectly.

Environment

Make sure that the tool is set up in a work area which is free from

corrosive liquids, greases and oils.

Declaration of Conformity

The tool has been manufactured and inspected in

compliance with European directives.The Declaration

of Conformity is included with this owner's manual.

Risk of damage to the tool

The tool must only be used as described in the

instruction manual. It is expressly forbidden to misuse

the tool or to use it for any other purpose. Please make

sure that you and your staff handle the tool correctly.

Risk of damage to the tool

The tool is designed for max. 16000 applications

according to specification EN 13155:2020.

Risk of injury

In addition to the owner's manual and the binding

provisions of the accident prevention regulations

which apply in the country and at the place of use,

you must also comply with the general (accepted)

rules for safe and professional working.

Technical personnel

Only trained and instructed personnel are authorized to carry

out the repair/maintenance work on the vehicles and vehicle

components concerned.

These personnel must also be able to prove that they have

participated in further training which enables them to carry out

the particular activities which are required for this tool.

6.3

5

XX Nm

13

12

T25

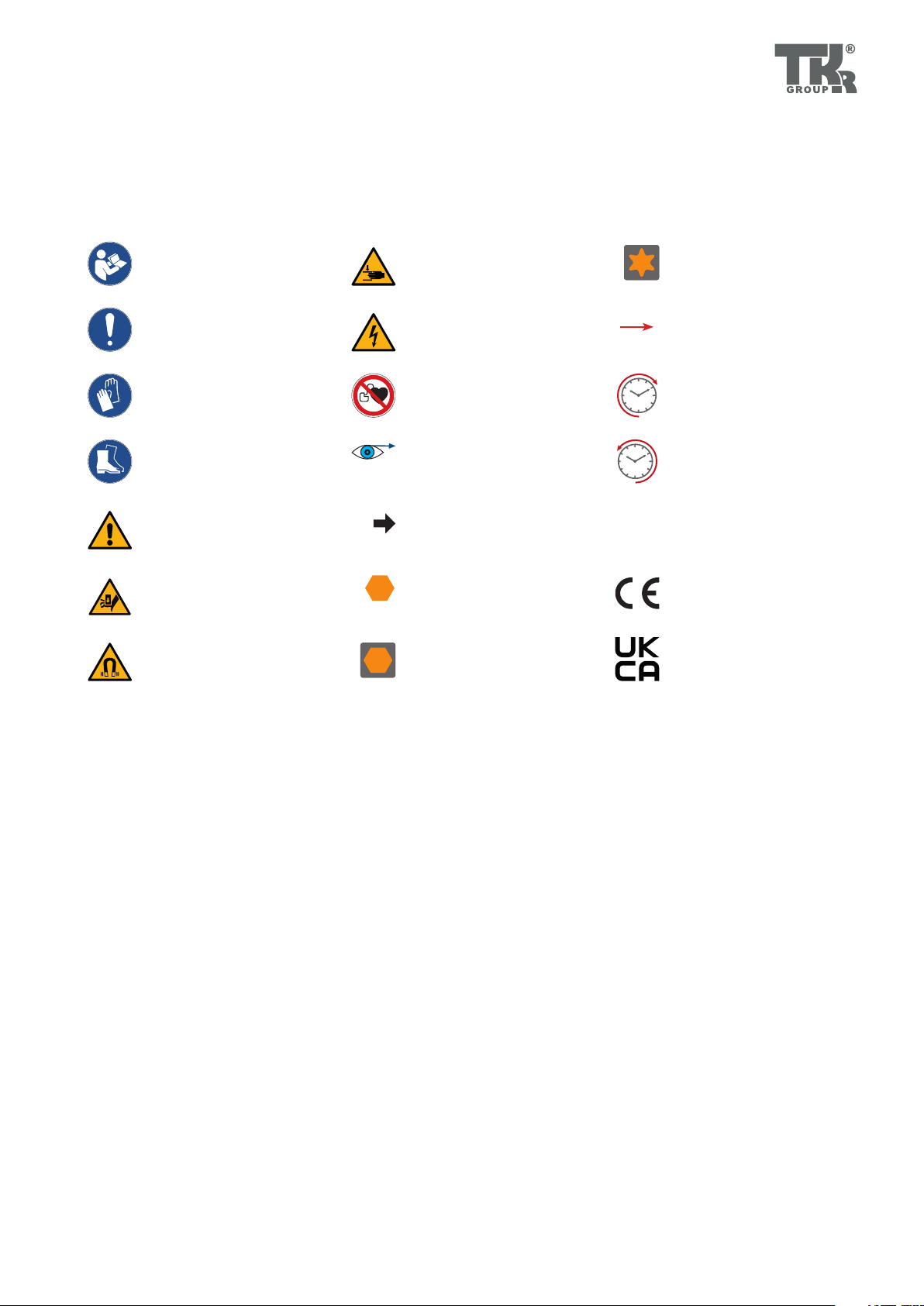

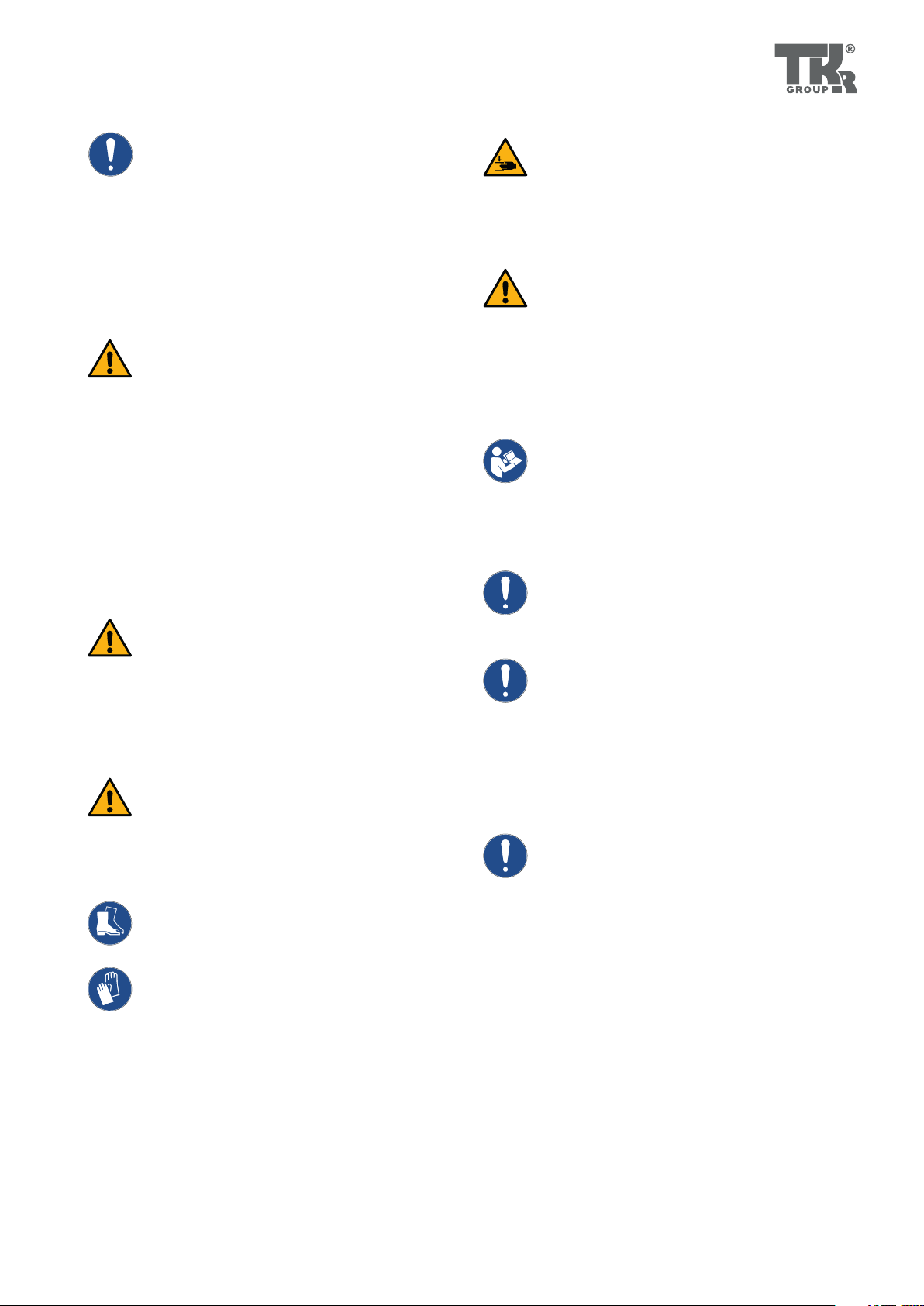

1.2 Explanation of symbols

Follow the manual

Follow the general instruc-

tions

Wear protective gloves

Wear safety shoes

Warning!

General source of danger

Warning!

Fingers could become

trapped

Warning

Magnetic field

Warning!

Hands could become trapped

Warning! Danger from

electrical voltage

Pacemaker-wearers prohibited

Please note the...

For more information, see

section …

Hexagon, width across flats

Allen screw, size

Torx, size

Arrow showing direction

Turn clockwise

Turn counterclockwise

Observe the torque

CE symbol

UK Conformity Assessment

Some sections in this instruction manual use internationally recognised warning symbols, warning notes and general in-

struction symbols.

The individual symbols are explained below. Follow all the instructions and safety rules.

6

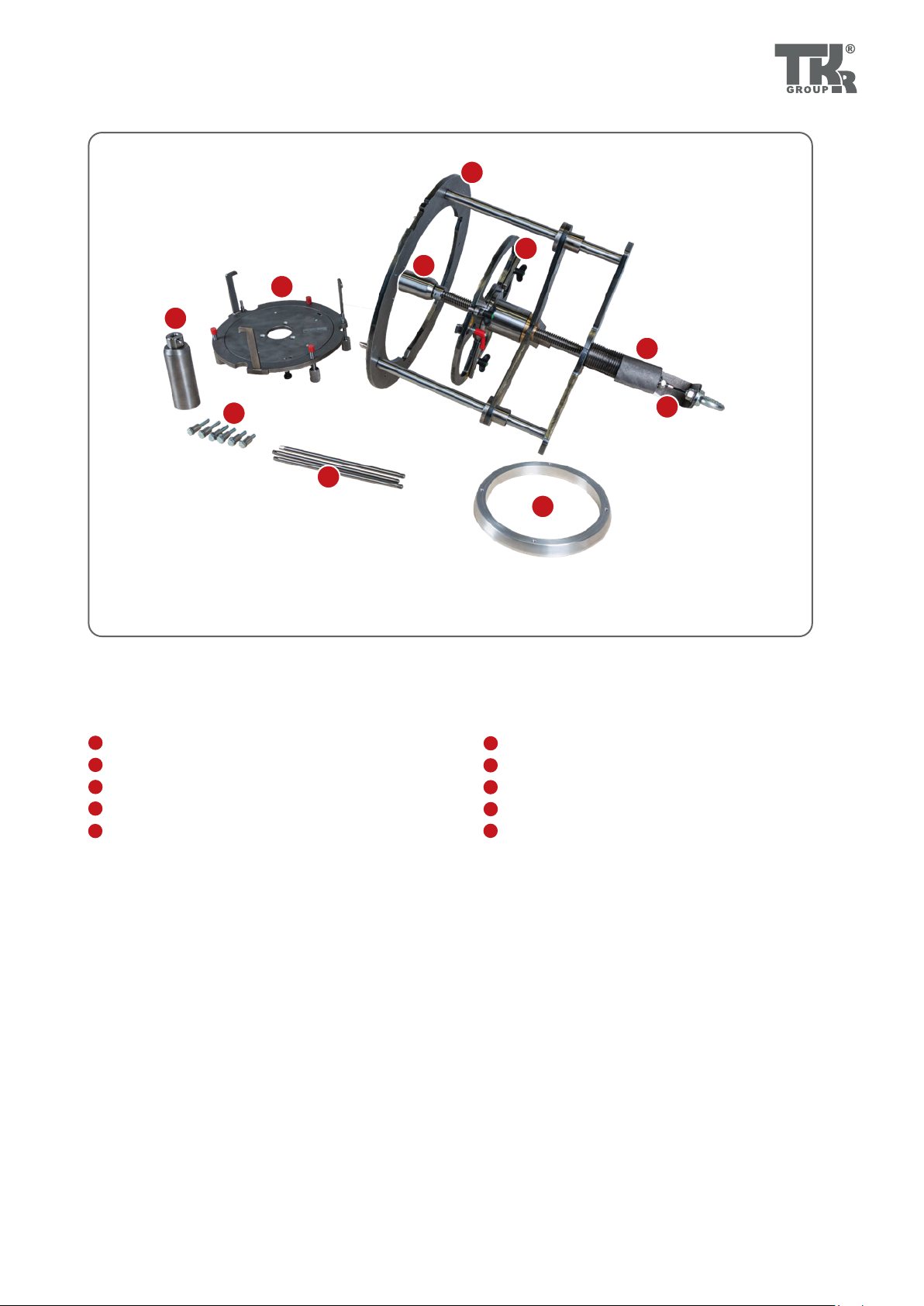

1

2

3

8

83 30 5 A87 F94

4

5

6

7

83 30 5 A87 FB1

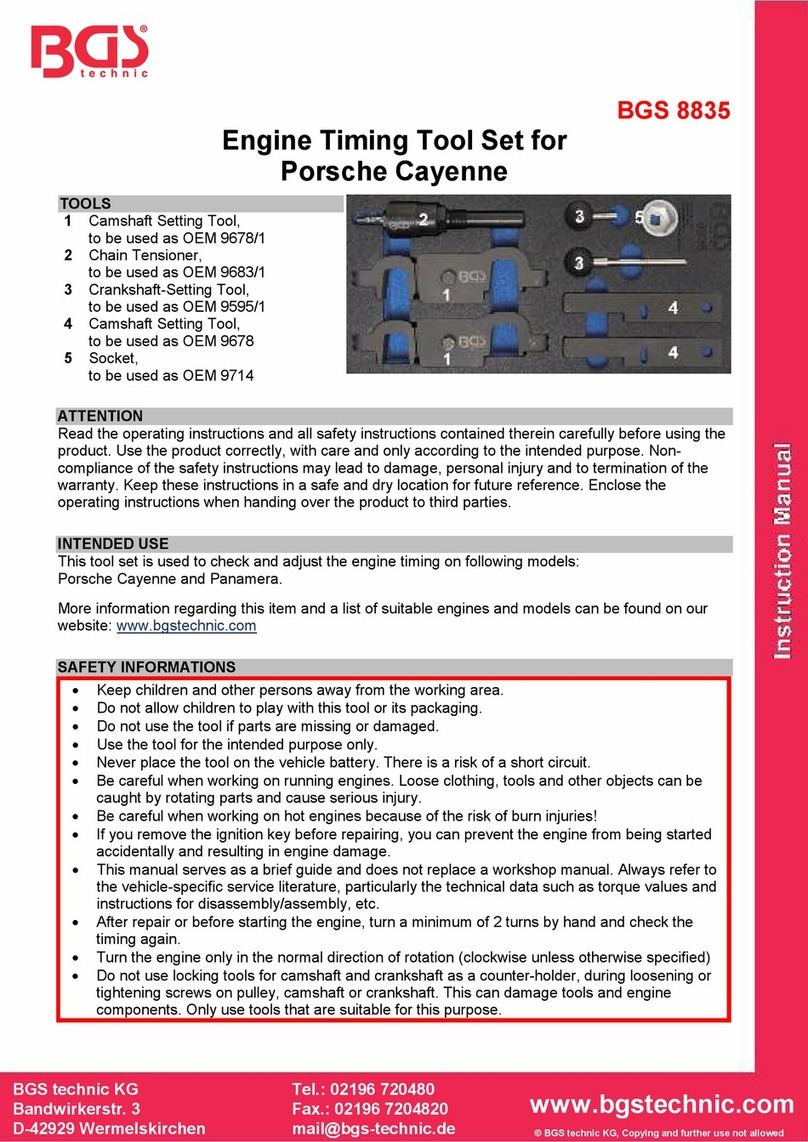

1.3 Scope of supply

Item Designation pc.

1Disassembly and assembly tool with lifting eye (83 30 5 A87 F94_A), lifting plate (83 30 5 A87 F94_C), and spacer

(83 30 5 A87 F94_D) 1

2Hexagon screws with centering sleeves 6

3 Owner’s manual German/ English 1

4 USB stick with foreign language versions of the owner's manual 1

5 Spacer 2 long (83 30 5 A87 FB1_B) 3

6 Lifting plate 2 (83 30 5 A87 FB1_A) 1

7 Centering pins 3

8 Centering ring 1

7

1.4 Safety instructions

The tool is strictly approved solely for the purpos-

es for which the manufacturer has designed it.

The tool must only be used for the activities described in this own-

er's manual. Never use the tool for anything but its intended pur-

pose. Safety is no longer guaranteed if the tool is used incorrectly.

This tool may only be used to dismantle a BMW-approved trans-

mission

CAUTION

If used with the wrong accessories, this may cause

material damage and bodily injury.

Not using original tools and original accessories will result in

a high risk to safety.Only original accessories and accessories

which have been approved by BMW may be used (see BMW

workshop manual). Only use with the screws provided..

No modifications may be made to the tool. The manufacturer is

not liable for conversions or modifications of the tool which are

not described in this manual or for any damage to material or

personal injury resulting from such conversions or modifications.

CAUTION

A falling load may cause material damage and bod-

ily injury.

Falling loads may cause serious injuries or damage to material.

Check and make sure that the load has been suspended correct-

ly before raising it.

CAUTION

Risk of material damage and bodily injury

You must read and understand the safety instructions before

carrying out the repair.

Not reading the instructions may result in serious bodily injury.

Wear safety shoes (according to ISO 20345, S2).

Wear protective gloves to prevent cut injuries.

CAUTION

Danger of crushing and serious injuries

Position hands and feet away from where there is a risk of

crushing. Only use the tool on an even, dry, horizontal floor of

sufficient load-bearing capacity.

CAUTION

Risk of material damage and bodily injury

Personnel who have not been trained or not been instructed

are prohibited from using the tool. The tool must not be lent to

untrained persons.

Ensure that the tool is only operated by trained personnel who

are instructed in its use!

Ensure that the owner's manual is made available

to the operating personnel.

Each operator must carefully read and understand this owner's

manual before using the tool for the first time. This manual must

always be available at the site where the product is used.

Follow the workshop manual from BMW AG.

Workshop manuals must be referred to under all

circumstances.

Observe the applicable national regulations for

the prevention of accidents.

In addition to the owner's manual and the binding provisions of

the accident prevention regulations which apply in the country

of use, you must also comply with the general, accepted rules for

safe and professional working.

Pay attention to the nameplate and the labelling

on the tool. The tool and the labels on it must be

inspected visually every time before use.

Never throw the tool or allow it to fall.

8

When lifting and lowering the load, avoid bump-

ing into obstacles.

Using the device to carry people or climbing on

the raised load is not permitted.

CAUTION

Risk of material damage and bodily injury

Make sure that there is sufficient light.

Make sure that there is sufficient space for working.

If any abnormality is identified, the tool must not be used.

Please contact Service ( 6.1).

9

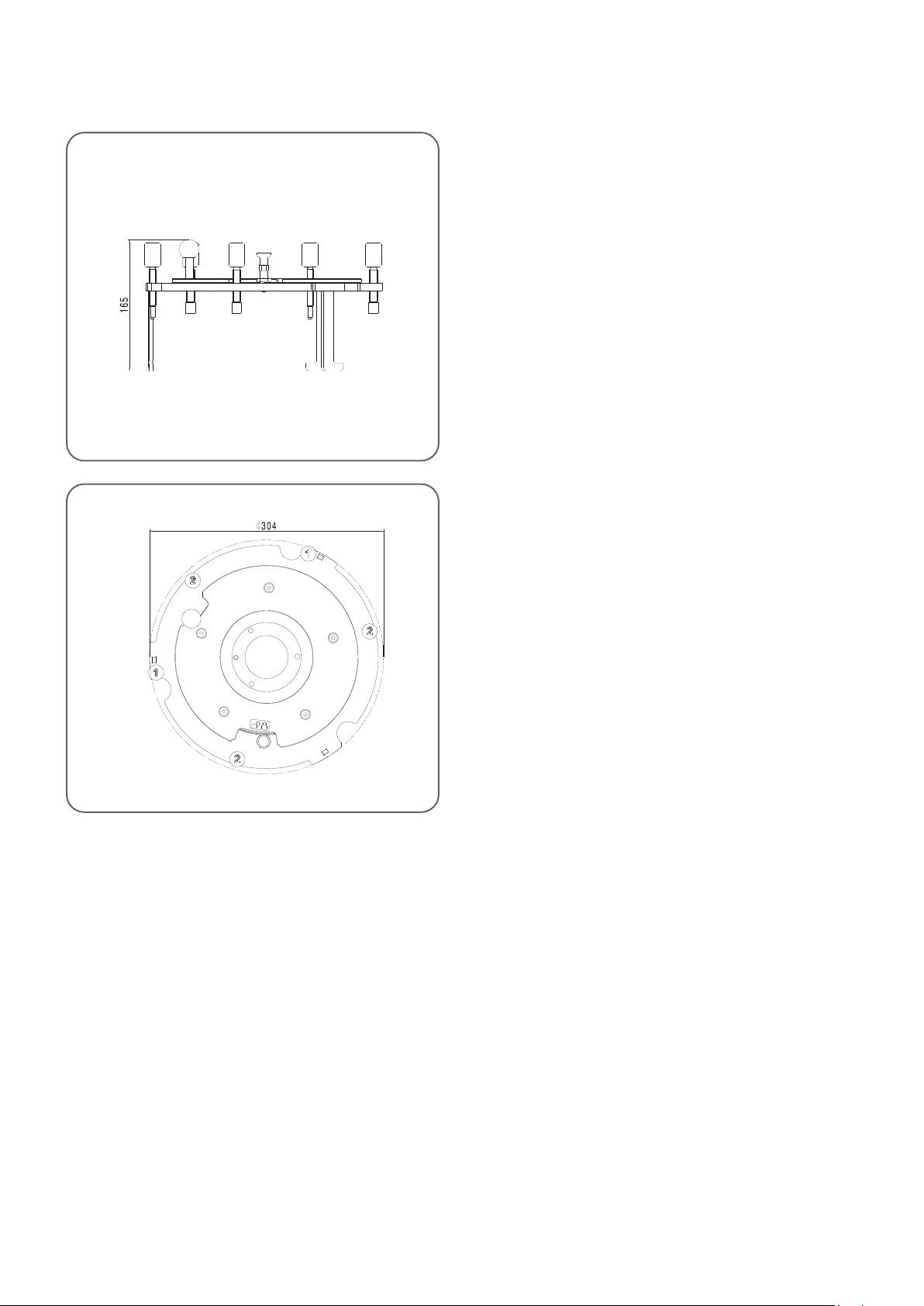

2.1 Technical data

Disassembly and assembly tool

Product type Disassembly and assembly tool

Item number 83 30 5 A87 F94

Weight 32 kg

Max. Dimensions (W x H) in mm 450 x 725 mm

Ambient temperature -20°C to +60°C/ -4°F to 140°F

front left

top Disassembly and assembly tool 83 30 5 A87 F94

(with lifting eye 83 30 5 A87 F94_A, lifting plate 1 83 30 5

A87 F94_B, and spacer 1 83 30 5 A87 F94_C)

Width: 450 mm

Min. height: 675 mm

Max. height: 725 mm

10

front

top

Accessory kit: Lifting plate 2

83 30 5 A87 FB1_A

Width: 450 mm

Min. height: 675 mm

Max. height: 725 mm

11

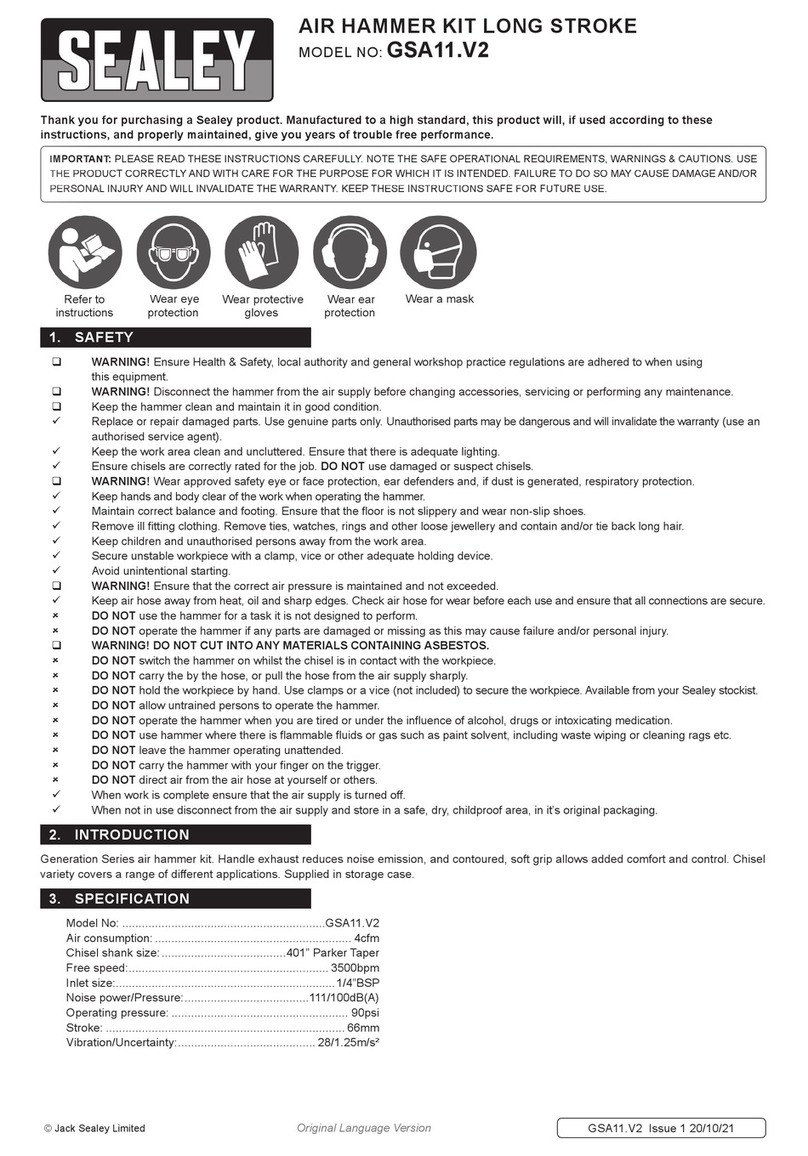

A1

2.2.1

A2

K

H

E

G

F

D

C

B

2.2 Device components

2.2.1 Disassembly and assembly tool

Spindle with square 8 AF

Adjustment nut

Lifting plate 1

Baseplate

Spacer 1 (short)

A1

A2

B

Hexagon screws with centering sleeves

Lifting plate 2

Spacer 2 (long)

Centering pins

Centering ring

C

D

E

F

G

H

K

12

3.1 Intended use

The disassembly and assembly device 83 30 5 A87 F94 is designed exclusively for install-

ing and removing the transmission cover and stator winding from a BMW AG mild hybrid

transmission for which it has been approved. The accessory kit 83 30 5 A87 FB1 can be used

to convert the device for installing and removing the stator winding from BMW AG plug-in

hybrid transmissions for which it has been approved.

Make sure that everything is clean when working. Only place transmission components on

suitable receptacles. Objects must not be allowed to get into the transmission.

Raising or lowering the tool is prohibited while people are in the danger zone of the load.

Standing beneath the load while it is being lifted or lowered is prohibited.

The operator may only initiate a raising or lowering operation once he has satisfied himself

that the tool is properly secured.

Undoing the screws of the tool while it is under load is forbidden.

Lifting the loaded tool without securing it by attaching it to the workshop crane is

forbidden.

Consult the manufacturer before using the tool in specific atmospheres (high humidity,

salty, acidic or basic).

The tool is suitable for use at ambient temperatures between -20 °C and +60°C.

The load must be raised/ lowered slowly and carefully.

CAUTION

Risk of material damage and bodily injury

If the tool shows any defects, it must be taken out of use immediately.

This tool must only be used for processing the transmissions for which it has been approved

(see workshop manual).

The tool is only suitable for installing/removing the transmission components from

the BMW AG transmissions for which it has been approved, as described in this oper-

ating manual and must only be used on minor transport routes.

Use as described in

instruction manual

Incorrect use

13

3.2 Working with the tool - basic principles

Risk of injury

The tool must be positioned so there is no risk of

crushing.

Stable positioning

The tool may only be used on a level, horizontal floor.

Warranty

The manufacturer accepts no liability for damage

caused by repairs which have been carried out

incorrectly.

Using the tool incorrectly so that the equipment

is damaged will invalidate the warranty.

Only use with the screws provided.

14

3.3.23.3.1

3.3 Commissioning and safe handling

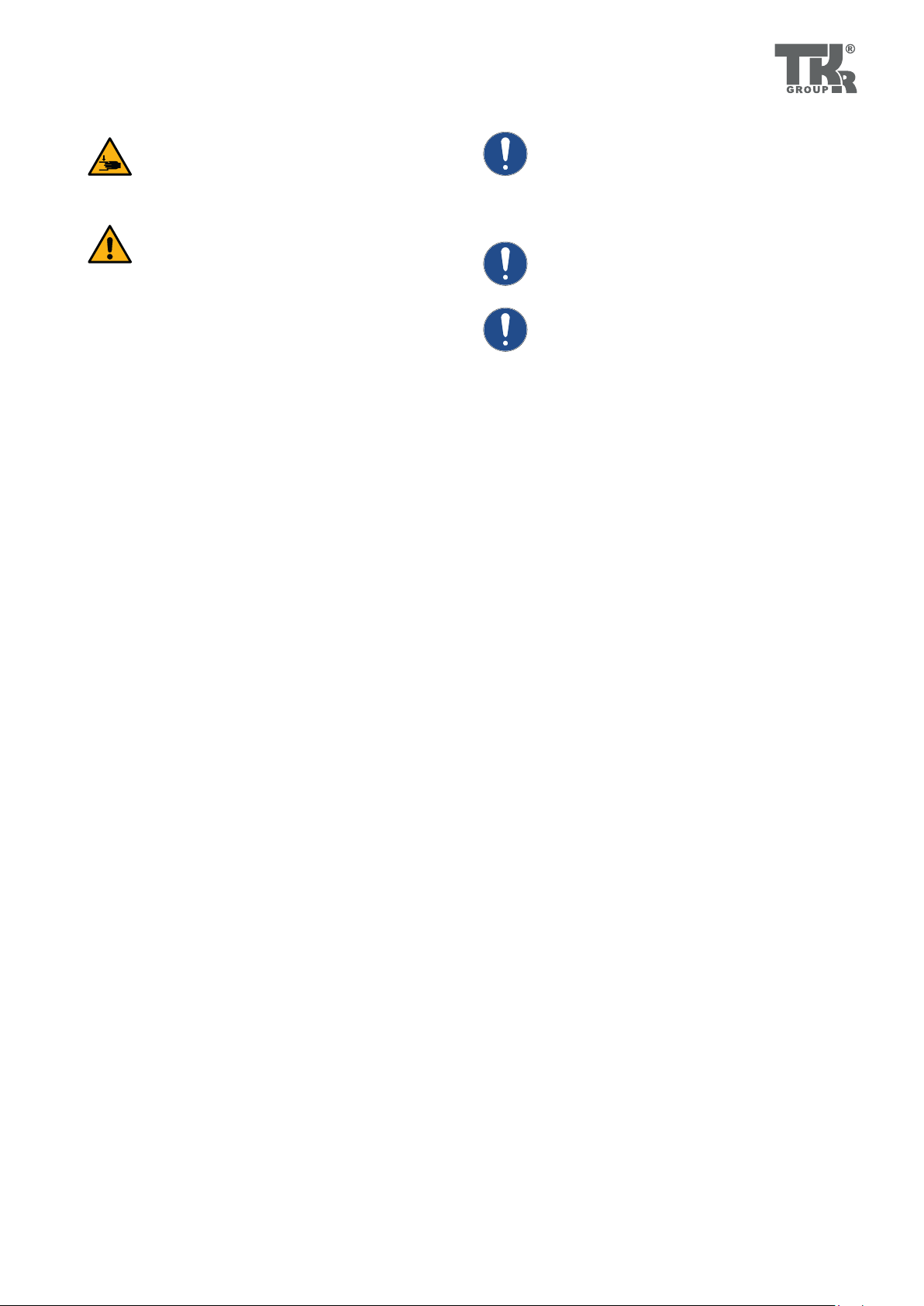

3.3.1 Engine and transmission mount 00 2 300

CAUTION

Risk of injury

Do not exceed the permissible lifting weight of the

engine and transmission mount.

CAUTION

Risk of injury

Exceeding the load-carrying capacity on the engine

and transmission mount may invalidate the CE mark

CAUTION

Risk of injury

Watch the engine and transmission mount and the

load during all movements.

3.3.2 Workshop crane WW-DHZ-1000

Lifting and lowering the transmission components

is only permissible using the workshop crane

WW-DHZ-1000 with the rope hoist attachment

WW-AFA-600 (83 30 5 A33 E60).

Do not exceed the permissible load carrying capacity

of the workshop crane.

Watch the workshop crane and load during all movements.

15

3.3.3 3.3.4

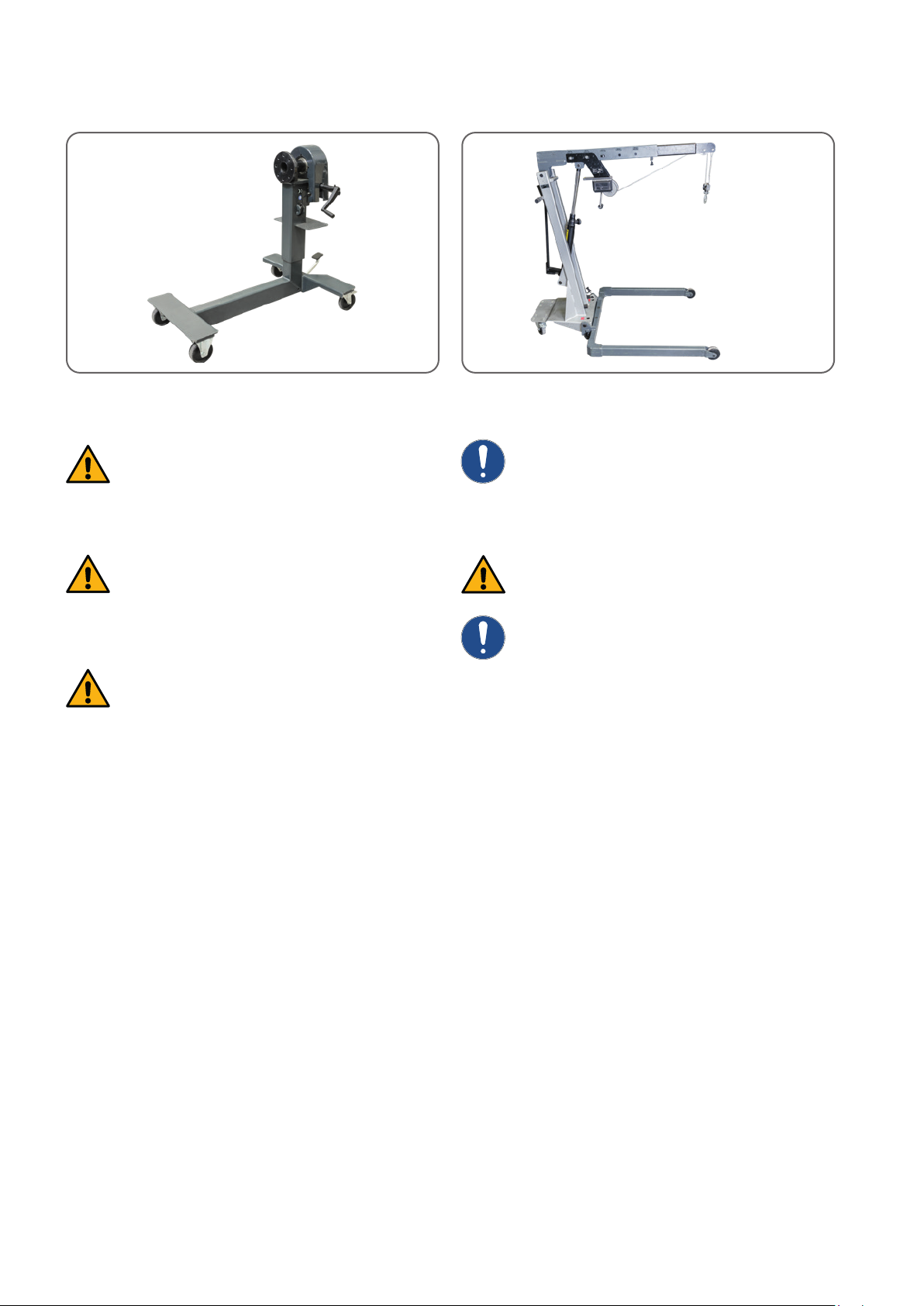

3.3.3 Support 83 30 5 A82 CC8

CAUTION

Risk of damage to aterial and personal injury

Take into account the permissible nominal load of

the support.

See the operating manual for the support.

3.3.4

Two persons are required to operate the crane and to adjust

and attach the tool.

Two persons are required to remove the tool from the packaging.

16

A1

B

A2

D

8

4.1.14.1.1 4.1.24.1.2

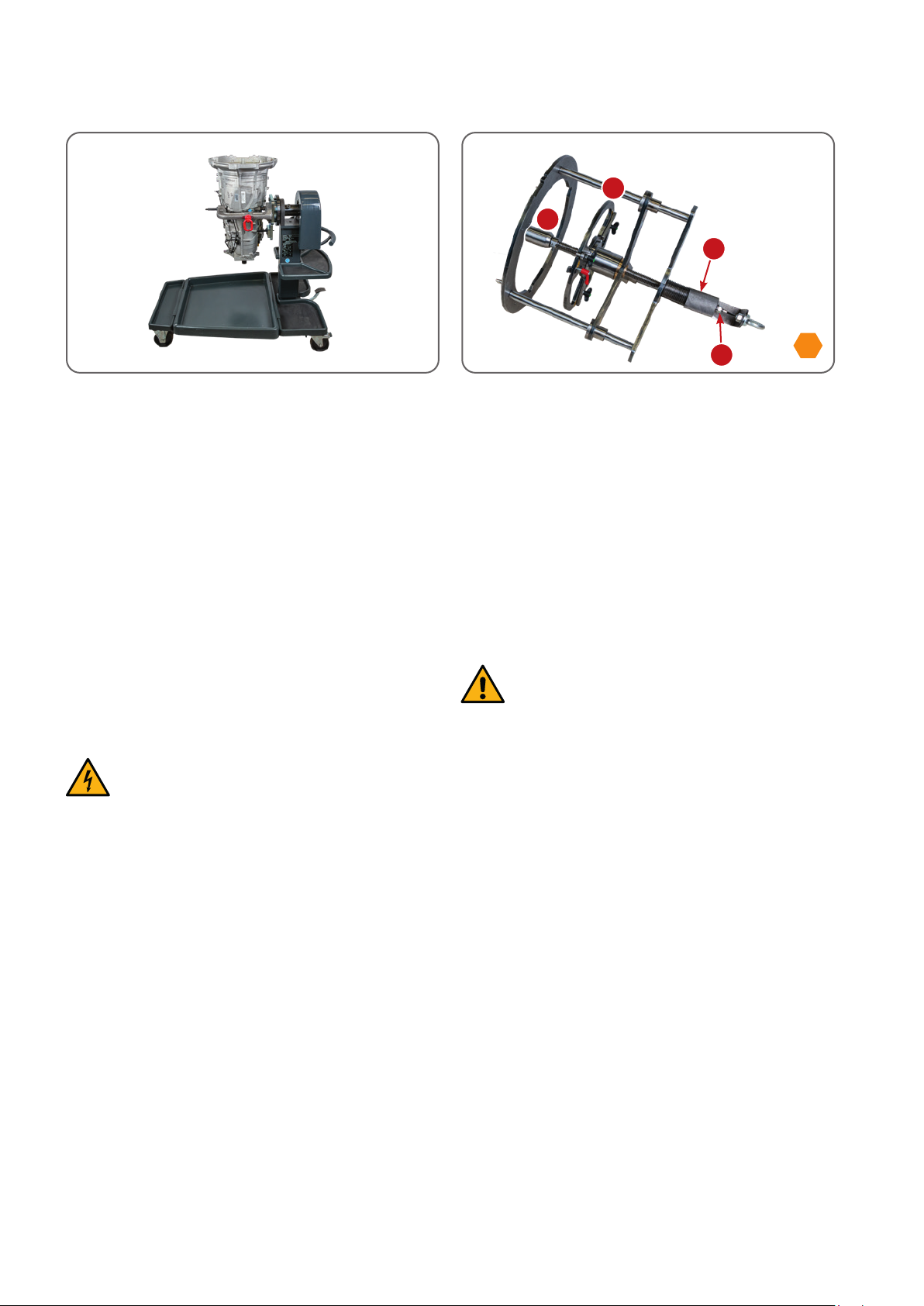

4.1 Preparatory work

4.1.1

Carry out the following activities before removing the transmis-

sion cover and the stator winding from either the mild hybrid

or plug-in hybrid transmissions (Follow BMW workshop manual):

• Attach the support 83 30 5 A82 CC8 to the transmission

(see owner’s manual 83 30 5 A82 CC8)

• Install the transmission with the support 83 30 5 A82 CC8 on

the engine and transmission holder 00 2 300 (see owner’s

manual 83 30 5 A82 CC8) and rotate the transmission 90°

(transmission cover faces up)

• If not available: Attach the rope hoist attachment WW-

AFA-600 to the workshop crane WW-DHZ-1000 (see owner’s

manual WW-AFA-600)

• Drain the transmission oil (see BMW AG workshop manual)

CAUTION

Danger from electrical voltage

Before starting work, make sure that everything is

voltage-free and dead.

4.1.2

Move the spacer 1 [short, D] to the top positon by turning the

adjustment nut [A2] counterclockwise in order to avoid damag-

ing the end of the shaft. Move the lifting plate 1 [B] to the top

position. Turn the spindle clockwise [A1] with a suitable tool on

the spindle hexagon (8 AF).

Please note: you move the spacer [D] by turning the knurled ad-

justment nut [A2] and you move the lifting plate 1 [B] by turning

the spindle hexagon [A1].

CAUTION

Risk of personal injury

Risk of crushing at the top end of the spindle.

17

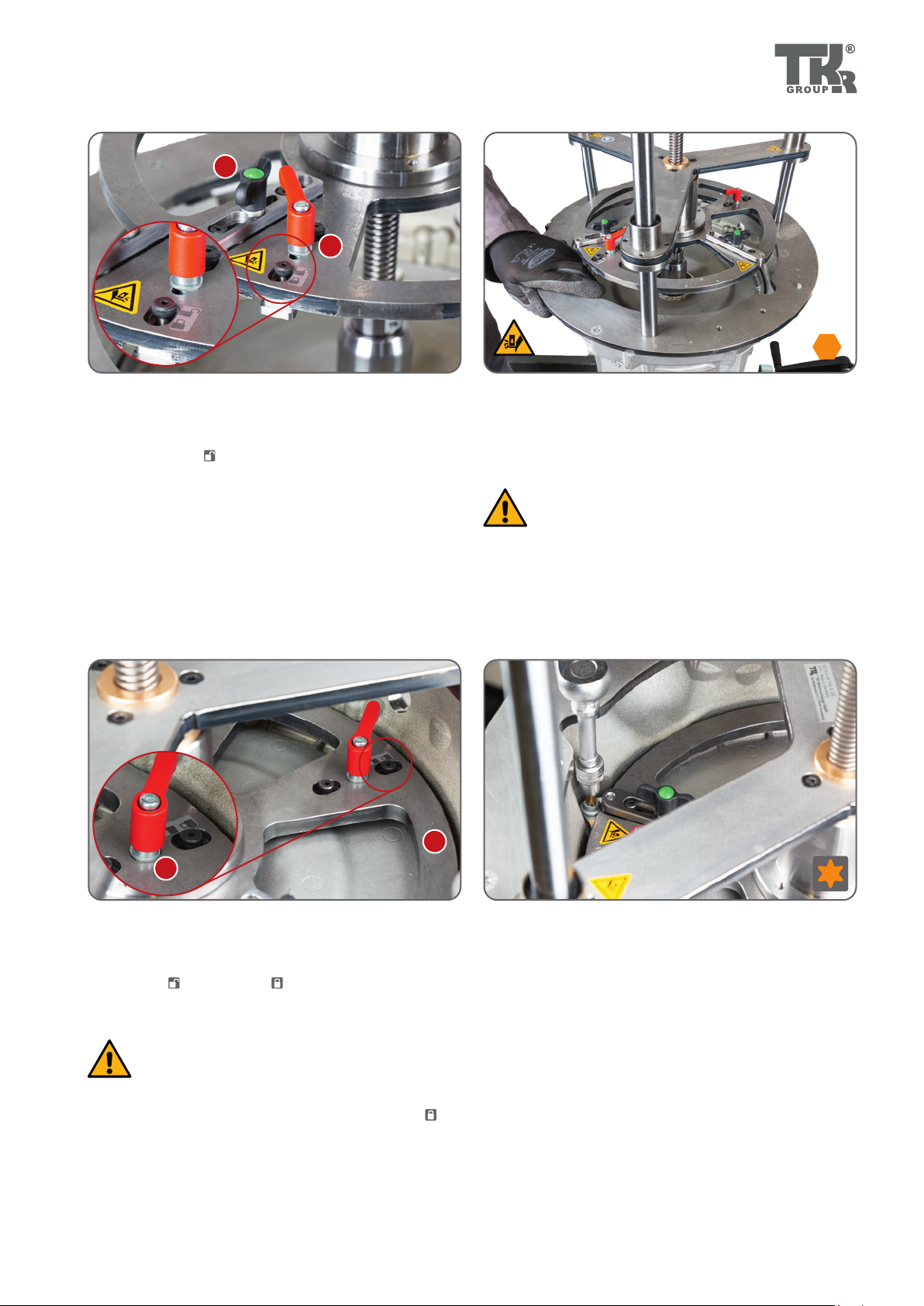

4.2.44.2.4

12

T25

4.2.14.2.1 4.2.24.2.2

4.2.34.2.3

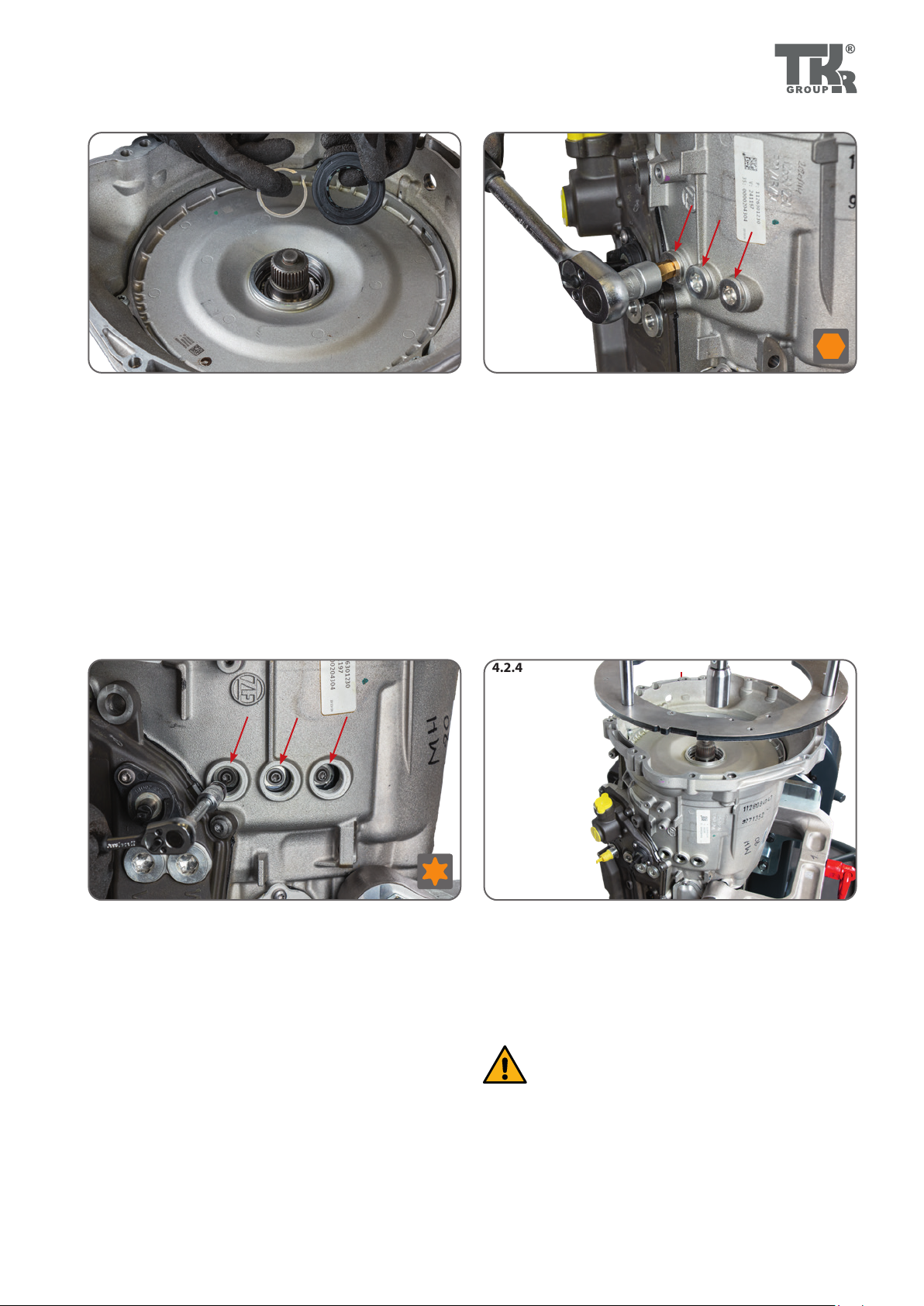

4.2.3

Remove the connecting screws of the three pole contacts (T 25).

4.2.4

Use the workshop crane WW-DHZ-1000 to place the tool 83 30 5

A87 F94 over the transmission. Align the slot in the baseplate [C]

for the middle and left pole contact of the stator winding.

CAUTION

Risk of damage to materia

Make sure that the spacer 1 [D] and the lifting plate 1

[B] are at the top (follow Step 4.1.2).

4.2 Removing the stator winding from a mild hybrid

transmission

4.2.1

Remove the radial shaft seal (RWDR) using a suitable tool

(83 30 5 A85 A86). Remove the snap ring with a suitable tool

(83 30 5 A82 CE3).

4.2.2

Remove the cover screws for the three pole contacts of the stator

winding (12 mm Allen key).

18

13 1515 NmNm

D

A2

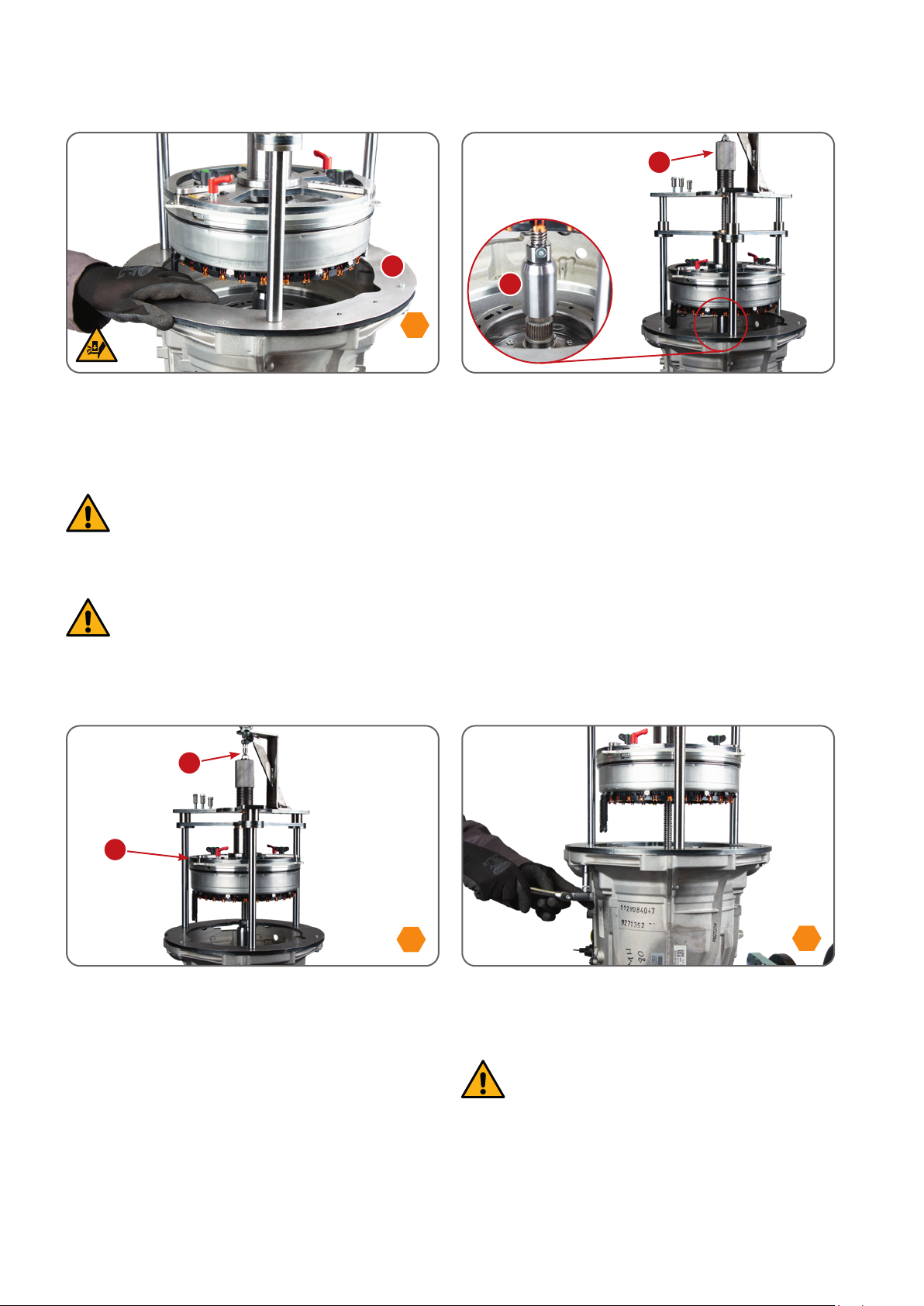

4.2.54.2.5 4.2.64.2.6

4.2.74.2.7 4.2.84.2.8

4.2.5

Lower the tool 83 30 5 A87 F94 onto the case flange. When cen-

tering, one of the centering pins P1, P2 or P3 aligns with one of

the flange holes (see Chapter 4.6).

4.2.6

Screw the baseplate [C] of the tool to the transmission flange

with three of the hex screws [E]. Make sure that the diameter of

the red or blue sleeves is suitable for the holes in the transmis-

sion flange (see Chapter 4.6). The torque setting is 15 Nm.

4.2.7

The tool is now seated in the center on the transmission flange.

The shaft end of the transmission is in line with the longitudinal

axis of the spacer 1 of the tool [D].

4.2.8

Lower the spacer 1 [D] onto the shaft end by turning the adjust-

ment nut [A2] until you feel resistance.

19

7

T40

B1

B2

B

B1

8

4.2.94.2.9 4.2.104.2.10

4.2.114.2.11 4.2.124.2.12

4.2.11

After lowering the lifting plate 1 [B], push the two clamping lugs

[B1] from the position to the position and screw them tight

with the red handle.

CAUTION

Risk of material damage and bodily injury

You may only lift the lifting plate 1 [B] after the two

clamping lugs have been pushed into position and

screwed tight.

4.2.12

Undo the three screws of the transmission cover using a suitable

tool (T40).

4.2.9

Before lowering the lifting plate 1 [B], check that the two clamp-

ing lugs [B1] are in position and all the positioning lugs [B2]

are withdrawn.

4.2.10

Lower the lifting plate 1 [B] onto the transmission cover by turn-

ing the hexagon on the spindle [A1](8 mm AF).

CAUTION

Risk of personal injury

Do not place your hands on the baseplate of the tool.

Risk of crushing! Only one person in the working area.

20

7

13

D

A2

C

B

A1

8

max. 10max. 10 NmNm

8

4.2.134.2.13 4.2.144.2.14

4.2.154.2.15 4.2.164.2.16

4.2.15

Raise the lifting plate 1 [B] to the top end position by turning the

hexagonal of the spindle [A1].

4.2.16

Undo the three hex screws between the baseplate [C] and

transmission flange.

CAUTION

Risk of material damage and bodily injury

The tool must be secured with the workshop crane

before undoing the hexagonal screws.

4.2.13

Lift the transmission cover by turning the spindle hexagon [A1]

clockwise until the fixed winding can be seen approximately above

the baseplate [C]. Use a suitable tool (8 AF, max. torque 10 Nm).

CAUTION

Risk of material damage and bodily injury

Before lifting, ensure that the three screws of the

pole contacts are undone (Steps 4.2.2/4.2.3).

CAUTION, risk of personal injury

Do not place your hands on the baseplate [C] of

the device. Risk of crushing! Only one person in the

working area.

4.2.14

Lift the spacer 1 [D] by turning the adjustment nut [A2]. The

spacer 1 [D] must hang freely above the shaft end.

This manual suits for next models

1

Table of contents

Other TKR Group Tools manuals

Popular Tools manuals by other brands

Central Pneumatic

Central Pneumatic 68293 Owner's manual & safety instructions

Power Fist

Power Fist 8843799 manual

parktool

parktool BBT-9 instructions

Thomas&Betts

Thomas&Betts Stakon COMFORT CRIMP ERG4005 Instructions for use

Central Pneumatic

Central Pneumatic 97014 Set up and operating instructions

Power Fist

Power Fist 8536609 user manual