TKR Group 83 30 5 A40 812 Repair manual

R1-22.02-V0

83 30 5 A40 812

83 30 5 A40 810

83 30 5 A40 809

83 30 5 A40 808

83 30 5 A40 814

83 30 5 A40 C20

RADAR calibration tool (RCT)

Translation of the original owner‘s manual

R0-21.09-V6

83 30 5 A40 812

83 30 5 A40 810

83 30 5 A40 809

83 30 5 A40 808

83 30 5 A40 814

83 30 5 A40 C20

RADAR-Kalibriergerät (RCT)

Originalbetriebsanleitung

?

Owner‘s manual,

digital

Europe

Worldwide

www.tkr-service.comOwner‘s Manual USB-Stick

Owner‘s manual,

digital

Europe

Worldwide

3

atent-Nr.

This owner‘s manual is protected by copyright. Any use beyond the restrictions imposed by copyright legislation undertaken without the permission of the manufacturer

is illegal and punishable by law. This also applies to the extraction of individual illustrations and use of texts as excerpts

1. Safety

1.1 General instructions 4

1.2 Explanation of symbols 5

1.3 Designations 5

1.4 System components 6

1.5 Safety instructions 7

2. Technical Data

2.1 Rail set (RCT) 8

2.2 RADAR calibration tool (RCT) 9

2.3 (Slotted) Cover 10

2.4 (Wheel) Laser 11

2.5 Side panel absorber 12

2.6 Extension for Side panel absorber 13

3. Installation

3.1 Intended use 14

3.2 Working with the tool - basic principles 14

3.3 Commissioning and safe handling 15

3.4 Rail set (RCT) 16

3.4.1 Scope of delivery 16

3.4.2 Assembly 17

3.5 RADAR calibration tool (RCT) 21

3.5.1 Scope of delivery 21

3.5.2 Assembly 22

3.5.3 Battery change: Remote control 27

3.5.4 Battery change: Control 28

3.6 (Slotted) Cover 30

3.6.1 Scope of delivery 30

3.7 (Wheel) Laser 31

3.7.1 Scope of delivery 31

3.7.2 Battery change 32

3.8 Side panel absorber 33

3.8.1 Scope of delivery 33

3.8.2 Assembly 34

3.9 Extension for Side panel absorber 39

3.9.1 Scope of delivery 39

3.9.2 Assembly 40

4. Application

4.1 Operating the control 43

4.2 Software Update 47

4.3 Adjustment of the vehicle / the RADAR

calibration tool (RCT) to each other 51

4.4 Calibration of the sensors 54

4.5 Putting out of operation and storage 58

5. Maintenance

5.1 Regular checking and maintenance 58

5.2 Troubleshooting 59

5.3 Spare parts and accessories 60

6. Service

6.1 Disposal 61

6.2 Warranty and Service 61

6.3 Declaration of Conformity /

EU Declaration of Conformity 62

4

6.3

1.1 General instructions

State-of-the-art

This tool is state-of-the-art technology. To ensure that the

equipment operates safely, it must be operated in a proper and

safety-conscious manner.

Technical changes

In the interests of quality assurance, we reserve the unrestricted

right to carry out technical changes as a result of further techno-

logical developments and product improvements without prior

notication.

Reading the owner’s manual

Before using the tool, make sure you read the own-

er‘s manual carefully and understand it. This manual

must always be available where the product is used.

Handling

All the actions necessary to ensure correct operation are de-

scribed in the owner‘s manual. Any working methods other than

those approved by the manufacturer are prohibited.

Faults

If faults occur, the operator may only eliminate those faults

through their own actions where the corresponding remedy is

described.

Warranty

The manufacturer accepts no liability for damage or injury

caused by improper repair or the use of third-party replacement

parts.

Leaking or dead batteries do not constitute a defect in the prod-

uct.

No warranty will be provided for damage caused to the device

due to the tool being used incorrectly.

Declaration of Conformity

The tool has been manufactured and inspected in

compliance with International directives. The Decla-

ration of Conformity (CE, UKCA, CB) is included with

this owner‘s manual.

Risk of damage to the tool

The tool must only be used as described in the in-

struction manual. It is expressly forbidden to misuse

the tool or to use it for any other purpose. Please

make sure that you and your sta handle the tool

correctly.

Risk of injury

In addition to the owner’s manual and the binding

provisions of the accident prevention regulations

which apply in the country and at the place of use,

you must also comply with the general (accepted)

rules for safe and professional working.

Technical personnel

Only trained and instructed personnel are authorized to carry

out the repair / maintenance work on the vehicles and vehicle

components concerned.

These personnel must also be able to prove that they have par-

ticipated in further training which enables them to carry out the

particular activities which are required for this tool.

5

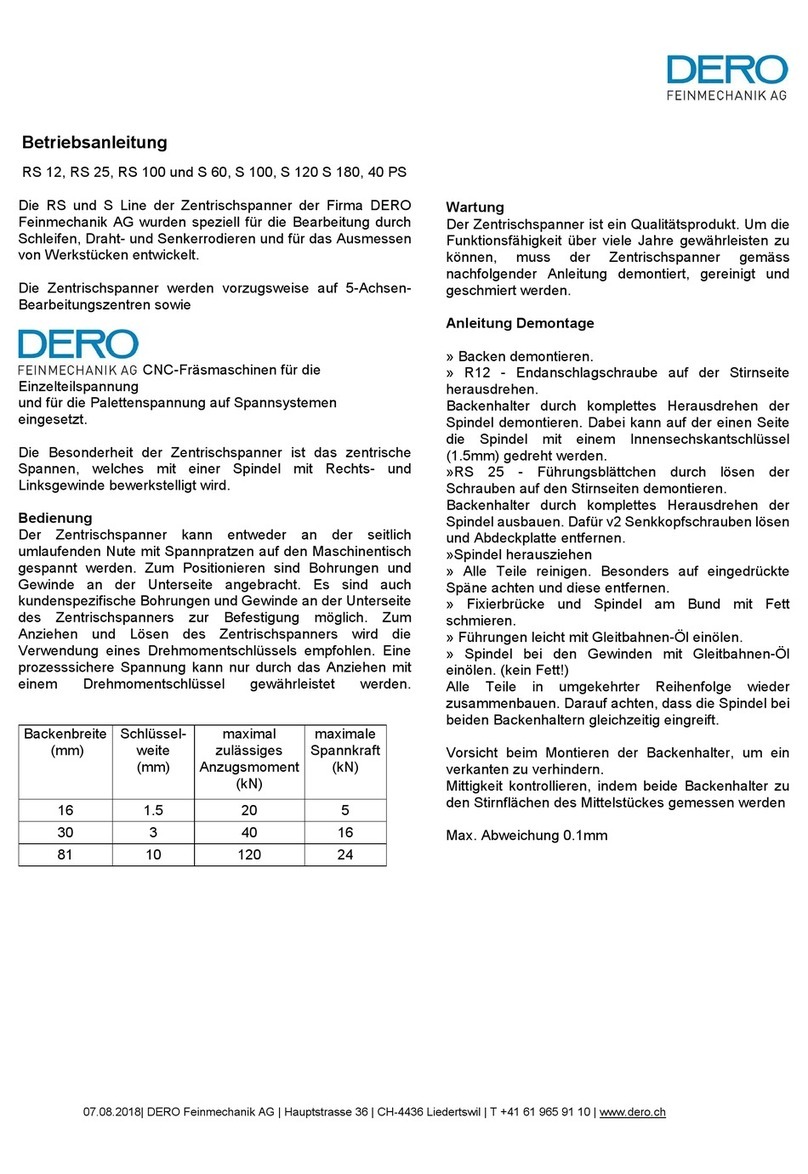

RADAR-Kalibriergerät (RCT)

83 30 5 A40 812 66

Serien-Nr.: 0250

KW: 10/22

Input: 12 V

⎓

1,0 A

TKR Spezialwerkzeuge GmbH

Am Waldesrand 9-11, D-58285 Gevelsberg

E

D

A

H

B

F

I

G

C

1.2 Explanation of symbols

Follow the manual

Allgemeine Hinweise

beachten

Wear safety shoes

Warning!

General source of danger

Warning!

Hands could become trapped

Warning!

Sharp object

Warning!

Obstacles in the head area

Warning!

(Wheel) Laser beam

Current

(DC Direct Current)

Please note the following...

Arrow to clarify compression

For more information, see

Chapter …

Arrow showing direction

CE mark

UK Conformity Assessment

Product certikate

https://www.tkrgroup.com/

83305A40812.htm

This owner‘s manual contains some sections with internationally recognized warning symbols,

hazard warnings and general mandatory signs.

The individual symbols are explained below. Follow all the instructions and safety rules.

1.3 Designations

A Manufacturer’s label

B CE-Zeichen / UKCA-Zeichen

C QR-Code

D Item number

E

Serial number

F Date of manufacture

G Input

H

Company address

I Disposal

6

83 30 5 A40 812

R0-21.09-V6

83 30 5 A40 812

83 30 5 A40 810

83 30 5 A40 809

83 30 5 A40 808

83 30 5 A40 814

83 30 5 A40 C20

RADAR-Kalibriergerät (RCT)

Originalbetriebsanleitung

83 30 5 A40 810

83 30 5 A40 809 83 30 5 A40 808

83 30 5 A40 814 83 30 5 A40 C20

3.6

83 30 5 A40 810 Rail set (RCT)

83 30 5 A40 812 RADAR calibration tool (RCT)

83 30 5 A40 809 (Slotted) Cover

83 30 5 A40 808 (Wheel) Laser

83 30 5 A40 814 Side panel absober

83 30 5 A40 C20 Extension for Side panel absorber

Owner's manual, USB stick

1.4 System components

3.5.2 Assembly

3.5.3 Battery change

3.4.2 Assembly

3.8.2 Assembly 3.9.2 Assembly

3.7.2 Battery change

7

1.5 Safety instructions

CAUTION

If used with the wrong accessories, this may cause

material damage and bodily injury.

Not using original tools and original accessories will

result in a high risk to safety.Only original accessories

may be used.

The manufacturer cannot accept any liability for con-

versions or modifications to the tool.

CAUTION

Trip hazard

Laying supply cables carelessly can lead to acci-

dents through tripping, twisting of the ankle or falls

or even damage to the cables.

Lay all supply cables so that they cannot be dam-

aged and nobody can trip over them.

CAUTION

Risk of material damage and bodily injury

You must read and understand the safety instructions

before carrying out the repair.

Not reading the instructions may result in serious

bodily injury.

CAUTION

Risk of material damage and bodily injury

Untrained or uninstructed personnel are prohibited

from operating the tool. The tool must not be lent to

untrained persons.

Ensure that the tool is only operated by trained per-

sonnel who are instructed in its use!

CAUTION

Risk of damage to the tool

Not handling the tool properly can lead to damage

to the tool. Never throw the tool or allow it to fall.

CAUTION

Risk of personal injury

To protect against electric shock, make sure the

tool is not connected to the power supply before

any configuration, cleaning or maintenance. Simply

switching off the tool does not reduce the risk.

The tool is strictly approved solely for the purpos-

es for which the manufacturer has designed it.

The tool must only be used for the activities described

in this owner's manual. Never use the tool for any pur-

pose except that for which it is designed. Safety is no

longer guaranteed if the tool is used incorrectly.

Ensure that the owner's manual is made available

to the operating personnel.

Each operator must carefully read and understand

this owner's manual before using the tool for the first

time. This manual must always be available at the site

where the product is used.

Follow the applicable national regulations for the

prevention of accidents.

In addition to the owner's manual and the binding

provisions of the accident prevention regulations

which apply in the country of use, you must also

comply with the general, accepted rules for safe and

professional working.

An administrator account may be necessary to

install the drivers.

The tool must only be used at the ambient temper-

atures for which it is intended.

2.1-2.6 Technical data

If any abnormality is identied, the tool must not be used.

Please contact Service ( 5.2).

8

3000

16

703

83 30 5 A40 810

2.1 Rail set (RCT)

Technical Data

83 30 5 A40 810 Rail set (RCT)

Type of device 83 30 5 A40 810 Rail set (RCT)

Ambient temperature (operation) 0 °C to +50 °C / +32 °F to +122 °F

Ambient temperature (storage) -20 °C to +60°C / -4 °F to +140 °F

Ambient humidity To 85 % (non-condensing)

Length 1 rail segment / 4 rail segments assembled 750 mm / 3000 mm

Width 53 mm

Height 16 mm

Weight (total = 8 rail segments) 9 kg

9

83 30 5 A40 812

2.2 RADAR calibration tool (RCT)

Technical Data

83 30 5 A40 812 RADAR calibration tool (RCT)

Type of device 83 30 5 A40 812 RADAR calibration tool (RCT)

Ambient temperature (operation) 0 °C to +50 °C / +32 °F to +122 °F

Ambient temperature (storage) -20 °C to +60°C / -4 °F to +140 °F

Ambient humidity To 85 % (non-condensing)

Protection class IP 20

Pollution category 2

Length 741 mm

Width 690 mm

Height 1587 mm

Weight 30.5 kg

(Wheel) Laser Class 1, 2 mW, 635 nm

Battery type remote control* 2x AAA

Battery type control** 1x CR 2032

Mains voltage*** 100–240 V, 0.3 A, 50-60 Hz

Overvoltage category II

Maximum altitude for use 2000 m

* Batteries are not included

** Battery is installed

*** Only the supplied mains adapter may be used for operation

10

83 30 5 A40 809

2.3 (Slotted) Cover

Technical Data

83 30 5 A40 809 (Slotted) Cover

Type of device 83 30 5 A40 809 (Slotted) Cover

Ambient temperature (operation) 0 °C to +50 °C / +32 °F to +122 °F

Ambient temperature (storage) -20 °C to +60°C / -4 °F to +140 °F

Ambient humidity To 85 % (non-condensing)

Length 190 mm

Width 191 mm

Height 461 mm

Weight 3 kg

11

83 30 5 A40 808

2.4 (Wheel) Laser

Technical Data

83 30 5 A40 808 (Wheel) Laser

Type of device 83 30 5 A40 808 (Wheel) Laser

Ambient temperature (operation) 0 °C to +50 °C / +32 °F to +122 °F

Ambient temperature (storage) -20 °C to +60°C / -4 °F to +140 °F

Ambient humidity To 85 % (non-condensing)

Protection class IP 20

Pollution category 2

Length 178 mm

Width 258 mm

Height 100 mm

Weight 1.4 kg

(Wheel) Laser Class 1, 0,4 mW, 650 nm

Battery type (Wheel) Laser* 2x AA

*Batteries are not included

12

83 30 5 A40 814

2.5 Side panel absorber

Technical Data

83 30 5 A40 814 Side panel absober (RCT)

Type of device 83 30 5 A40 814 Side panel absober (RCT)

Ambient temperature (operation) 0 °C to +50 °C / +32 °F to +122 °F

Ambient temperature (storage) -20 °C to +60°C / -4 °F to +140 °F

Ambient humidity To 85 % (non-condensing)

Length 597 mm

Width 1512 mm

Height 1099 mm

Weight (without protective cover) 16 kg

13

83 30 5 A40 C20

2.6 Extension for Side panel absorber

Technical Data

83 30 5 A40 C20 Extension for Side panel absorber

Type of device 83 30 5 A40 C20 Extension for Side panel absorber

Ambient temperature (operation) 0 °C to +50 °C / +32 °F to +122 °F

Ambient temperature (storage) -20 °C to +60°C / -4 °F to +140 °F

Ambient humidity To 85 % (non-condensing)

Length 51 mm

Width 1502 mm

Height 576 mm

Weight (without protective cover) 8 kg

14

3.1 Intended use

3.2 Working with the tool - basic principles

The RADAR calibration tool (RCT) is a tool for calibrating the

radar sensors in the vehicle. The motor system of the RADAR cali-

bration tool (RCT) species various settings to which the vehicle

sensors respond. The (Wheel) Laser and the (Slotted) Cover are

used for precise positioning.

The Side panel absorber prevent the spread of disruptive radia-

tion, which can aect the measurement.

The radar sensors suitable for calibration are dened in the BMW

repair manual.

Risk of injury

It is vitally important that you make sure that you

are handling the tool correctly.

It is expressly forbidden to misuse the tool or to

use it for any other purpose.

The tool must only be used as described in the

instruction manual.

The application is described in the diagnostic device (ISTA).

All parameters of the tool necessary for safe use are specied by

the diagnostic device (ISTA). In manual mode, it is essential to

follow the specications of the setting values from the diagnos-

tic device (ISTA). As soon as the setting ranges are outside the

adjustment possibilities of the tool, an error is indicated.

Warranty

The manufacturer accepts no liability for damage

or injury caused by improper repair or the use of

third-party replacement parts.

No warranty will be provided for damage caused to

the device due to the tool being used incorrectly.

Environment

Leave to acclimatise before starting.

Avoid the formation of condensation.

Clean the glass surface of the calibration mirror

before use. The (Wheel) Laser does not work if the

calibration mirror is dewy.

15

3.3 Commissioning and safe handling

CAUTION

Risk of injury

Lay all supply cables so that they cannot be damaged

and nobody can trip over them.

CAUTION

Risk of injury

You may only supply the tool with electrical power

after you have carried out the steps in chapters 3.4

and 3.9.

Park the tool on a level surface before use.

Once the tool is in position, apply the brakes [H] on

the casters in order to prevent it from rolling away.

3.8.2 Assembly

Release the brakes before repositioning the [H] tool.

3.8.2 Assembly

In order to avoid contamination or damage to the

tool components, do not place anything on the tool.

Protect the tool from moisture, humidity and con-

densation. Avoid using liquids of any kind in the

proximity of the tool. These can get into the tool.

Check the tool for any damage every time before

using it.

Carry out a visual inspection of the supply cables

every time before using it.

If the tool is no longer used, disconnect it com-

pletely from the power circuit by pulling out the

mains plug.

16

83 30 5 A40 810

1

6

2

7

3

8

4

9

5

10

1x 20x 32x 32x 20x

20x

10x

16x16x

8x

No. Article Pieces

1) Drilling template incl. cap screws 1

2) Washer 20

3) Headless pin, M6x8 32

4) Headless pin, M6x12 32

5) Headless pin, M6x16 20

6) Panhead screw with ange, M6x16 16

7) Panhead screw with ange, M6x20 16

8) Panhead screw with ange, M6x25 10

9) Expansion dowel 20

10) Rail segment 750 mm 8

83 30 5 A40 810 - Rail set (RCT)

3.4 Rail set (RCT)

3.4.1 Scope of delivery

17

83 30 5 A40 810

minimum 800 mm500 mm 640 mm

3

Vehicle test area

Driving direction

Tools required for assembly:

+ Masonry drill Ø 8 mm

+ Allen key 3 mm, 5 mm

+ Impact drill

+ Hammer

+ Punch/splint driver

with suitable Ø

+ Level

+ Prole 683 mm

(83 30 5 A40 812

RADAR calibration tool (RCT))

3.5.1 Scope of delivery:

RADAR calibration tool (RCT)

+ Vacuum cleaner

3.5.1

Illustration of fully assembled Rail set (RCT)

The Rail set (RCT) is required to move the RADAR calibration tool (RCT)

and must be permanently installed on the workshop oor according to the

specied dimensions before starting work.

When not in use, the radar calibration device (RCT) remains in a parking

position on the rails.

The system can be extended if required:

5.3 Spare parts and accessories

3.4 Rail set (RCT)

3.4.2 Assembly

18

1

10

10 10

B

1

640 mm

A

683 mm

Fig. 2

Drill holes for fastening the rail segments

Check all dimensions again before nally assem-

bling.

To x the rail segments, rst mount the drilling template [1] with

the corresponding cap screws [1] to the front rail segment [10].

Drill all holes in the workshop oor (masonry drill Ø 8 mm) using

the drilling template guide [B].

Remove dust from boreholes.

Then remove the drilling template.

During assembly, no vehicle is allowed in the

working area.

Fig. 1

Align the front rail segment centrally to the vehicle test area.

Keep an even distance of 500 mm from the vehicle test area.

Determine the correct distance between the rail segments [10]

and align them to each other.

The distance from the centre of the borehole to

the centre of the borehole must be 640 mm.

Therefor position the rail segments with the at side facing each

other.

When using the prole 683 mm [A] (from 83 30 5 A40 812 RADAR

calibration tool (RCT) as an aid, it must be placed directly against

the inner edge of the rail segments for alignment. If necessary,

remove the cover cap rst.

For correct installation, the minimum distance of

the rear rail segment to the wall must be at least

800 mm.

The item numbers in the pictures refer to the number range shown in the

scope of delivery ( 3.4.1).

Fig. 1 Fig. 2

19

3

3

6

10

33

9

2

Fig. 4

Levelling the rail segments

Position the levelling device (e.g. level, (Wheel) Laser) on the rail

segment and level the rail segments with the headless pins. If

necessary, loosen and retighten the pan-head screws. Level the

remaining rail segments accordingly.

If the length of the headless pins [3] is not su-

cient for levelling, use the longer headless pins

provided.

3.4.1 Scope of delivery: Rail set (RCT)

Headless pins should not overlap the surface,

please choose the correct length.

Ensure a smooth transition between the rail seg-

ments.

The manufacturer accepts no responsibility for

measuring errors or inaccuracies.

Fig. 3

Pre-assemble rail segments

Drive expansion dowels [9] into the holes with a hammer and

then anchor them with a punch/splint driver and a hammer.

Position the washers [2] centrally on the drill holes.

Insert 1 pan-head screw [6] through each of the middle holes

of the rail segments, through the washers into the dowels and

hand-tighten.

Hand-tighten 2 set screws [3] in each of the outer holes of the rail

segments.

If the length of the pan-head screws is not su-

cient, use the longer pan-head screws supplied:

3.4.1 Scope of delivery: Rail set (RCT)

Fig. 4Fig. 3

20

C

Fig. 5

Backlling the levelled rail system:

Before backlling, cover the area around the rail

segments and the workshop oor with protective

tape.

Observe the processing instructions of the used

adhesive.

Spray the free space [C] between the lower edge of the rail seg-

ments and the workshop oor with a suitable one-component

polymer adhesive.

Product example:

Manufacturer: Debratec

Type: MS-Polymer Pro glue transparent

Contents: 290 g

Need: 1 - 2 cans

Processing time: Approx. 10 min

Fig. 5

This manual suits for next models

5

Table of contents

Other TKR Group Tools manuals