Page 7SKU 97014 For technical questions, please call 1-800-444-3353.

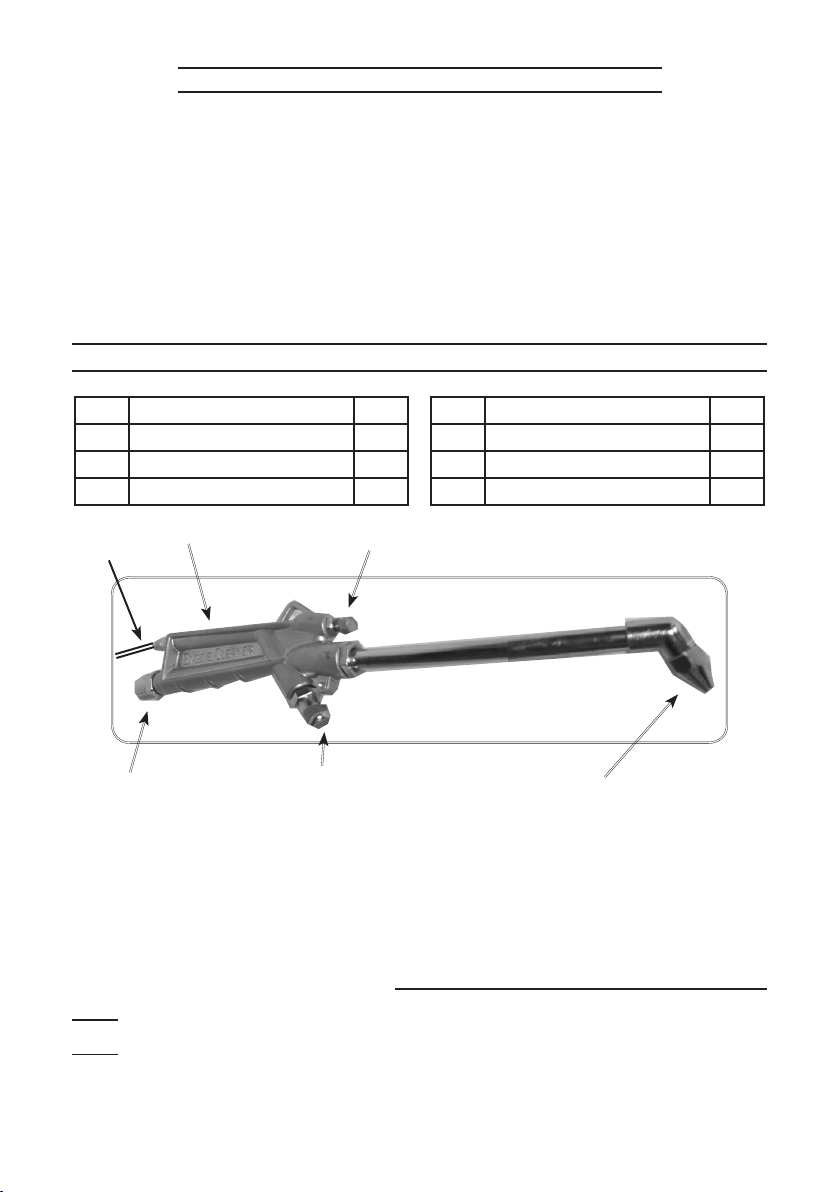

You can adjust the amount of engine cleaning solution being used by turning the

Siphon Control Knob (6) counterclockwise for more solution and clockwise for

less. See Figure 1 on page 6.

Hold the end of the Spray Nozzle (4) approximately 6 to 10 inches from the

engine and squeeze the Knurled Knob Trigger (5).

It is best to keep the Gun in motion with a back and forth action.

When the job is completed, ush the Siphon Hose (2) by placing it into a

container lled with clean, clear water and spraying it in a safe direction until

only clean water comes from the Spray Nozzle (4).

To prevent accidents, disconnect the air supply after use and store the tool

indoors out of children’s reach.

8.

9.

10.

11.

12.

MAINTENANCE AND SERVICING

Before performing any inspection, maintenance, or

cleaning procedures, disconnect the air supply.

Damaged equipment can fail, causing serious personal

injury. Do not use damaged equipment. If anything

abnormal occurs, have the problem corrected before

further use.

Cleaning, maintenance, and lubrication

BEFORE EACH USE, inspect the general condition of the tool. Check for

loose hose connections, cracked hoses, inoperative trigger and siphon control,

cracked or broken parts, and any other condition that may affect its safe

operation.

AFTER USE, clean external surfaces of the tool with clean, moist cloth.

Troubleshooting

Problem Possible Causes Probable Solutions

Tool has low air

output

Broken hoses, loose connections

Air regulator not set at proper PSI

Siphon Control Knob in a closed

position

1.

2.

3.

Check all hoses for leaks

and connections. Replace if

necessary.

Check, make sure Air Regulator is

set at 60 PSI

Open the Siphon Valve

1.

2.

3.

1.

2.

WARNINGWARNING