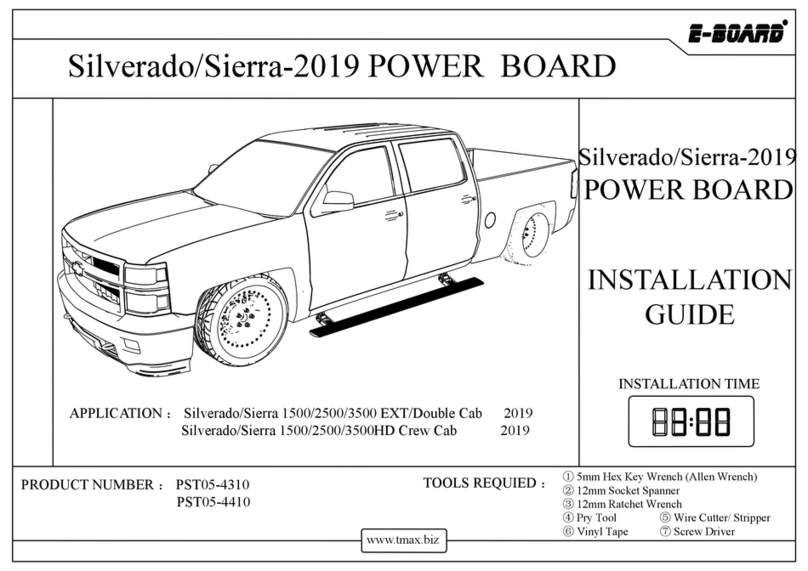

TMAX Digital E-BOARD PST01-0210 User manual

JEEP WRANGLER POWER BOARD

JEEP

WRANGLER

POWER

BOARD

JEEP WRANGLER

POWER BOARD

INSTALLATION

GUIDE

INSTALLATION TIME

Product Number :PST01-0210/PST01-0230

APPLICATION :2012-UP

Tools Re

q

uired :

①5mm Hex Key Wrench (Allen Wrench)

②13mm Socket S

p

anne

r

www.tmax.biz

q

p

③18mm Socket Spanner ④Vinyl Tape

⑤Wire Stripper/Cutter ⑥Scissors

⑦Electric Hand Drill ⑧φ10 Drilling Bit

JEEP WRANGLER

Contents

Product Technical Specification................02

Product Packing List.................................03

Mechanical Installation.............................08

Electrical Installation................................16

Maintenance..............................................25

Warranty Card...........................................27

The product is developed and produced by T-MAX, and the related patents are blow.

Patents:US8,469,380;US9,656,609;US9,308,870;US9,688,205;US9,669,766

01

www.tmax.biz

JEEP WRANGLER

Rated Volta

g

e: 12V

Product Technical Specification

g

Specified Load: ≤350kg

Gross Weight: 30kg

Forward extension size: 93mm

(Horizontal distance between the edge of power board

(Horizontal

distance

between

the

edge

of

power

board

and the vehicle door when the board extends)

Board falling dimension: 273mm

(Vertical height difference between the edge of power

bddth hild hilbdtdi)

b

oar

d

an

d

th

e ve

hi

c

l

e

d

oor w

hil

e

b

oar

d

ex

t

en

di

ng.

)

(Both dimensions of forward and falling are theoretical,

which may vary due to uncertainties such as installation

error, manufacturing errors of vehicle bottom and etc.)

Note:Impact load is not allowed.

02

Please make sure the children and the aged will keep 20cm safe distance while power board is working to avoid any

b

ump or jam.

www.tmax.biz

JEEP WRANGLER

Product Packing List

①

Board Assembly

JP4

×

2 6124101 2

①

-

Board

Assembly

JP4

×

2

6124101

.

2

②- Front Motor Linkage Left ×1

6124100.1LF

③- Front Motor Linkage Right ×1

6124100.1RF

④- Rear Motor Linkage Left 4D×1

6124101.1LB

⑤- Rear Motor Linkage Right 4D×1

6124101.1RB

03

www.tmax.biz

JEEP WRANGLER

⑧- Spring Washer×2

GB/T93-1987 12

⑥- Motor Protective Plate Left

JP-L×1

6124100.0-2L

⑦- Motor Protective Plate Right

JP-R×1

6124100.0-2R

⑨- Larger Washer Grade A×2

GB/T96.1-2002 12

⑩- Flat Washer×3

GB/T95-1985 8

⑪- Spring Washer×15

GB/T93-1987 8

⑫- Larger t Washer Grade A×12

GB/T96.1-2002 8

04

www.tmax.biz

JEEP WRANGLER

⑬- Socket Cap Screw ×8

GB/T70.1-2000 M6×25

⑭- Hexagon Head Bolt×8

GB/T5781-86 M8×20

⑮-Hexagon Head Bolt×3

GB/T5781-86 M8×25

⑯-Hexagon Head Bolt×4

GB/T5781-86 M8×35

⑰-Hexagon Head Bolt×2

GB/T5783-2000 M12×35

⑱-M12 Tension Block×2

6124110.0-4

⑲- Mounting Plate JP4×2 6124100.0-1

05

www.tmax.biz

JEEP WRANGLER

-LED Lamp Module×4

6110100.4.8

(Optional)

⑳- Mounting Bracket of

Controller ×1

21 22 23

- Hexagon Flange Bolt ×1

QC/T340-1999 M8×25

- Iron Wire Tie×3

4.5×300

-WireTie×25

GB/T22344

-

2008 5

×

300

-20A Fuse×2

25

24

-

Wired Magnetic Induction Module

×

2

Magnet

2

6

06

GB/T22344

2008

5

300

www.tmax.biz

Wired

Magnetic

Induction

Module

2

- Magnet ×4

N ti A h i th i t th

JEEP WRANGLER

N

o

ti

ce:

A

s s

h

own

i

n

th

e p

i

c

t

ure ,

th

ere

are four-core waterproof plug, six-core

waterproof plug and four-core

water

p

roof

p

lu

g

of LED lam

p

from the

LED Lamp Plug

(

Four

)

Motor Plug

(

Four

)

ppg p

controller assembly .

- Controller Assembly 10×1 6110100.4.4

LED

Lamp

Plug

(

Four

)

Motor

Plug

(

Four

)

27

Four-core waterproof plug

(Brown)

(

Whit

)

Four-core waterproof male plug of

LED lamp

Two-core Male Plug

Six

-

core waterproof plug

(

Positive

-

Red

)

(Negative-Black)

(

Whit

e

)

Six

-

core

waterproof

plug

05

(

Positive

-

Red

)

- Control Input Wire 10×1 6110100.4.1B

www.tmax.biz

28

JEEP WRANGLER

Mechanical Installation

Mechanical

Installation

Front Motor Linkage

Front

Motor

Linkage

Right JP-RF Rear Motor Linkage

Right JP4-RB

Front Motor Linkage

Left JP-LF

Rear Motor Linkage

Left JP4-LB

Graph of Motor Linkage

08

Graph

of

Motor

Linkage

www.tmax.biz

JEEP WRANGLER

1. Mounting plate installation

2. Tighten bolt for mounting plate

3. Tighten bolt for linkage

4. Board installation

Step

1:

Screw the stud bolt A

Stud Bolt A

Step

1:

Screw

the

stud

bolt

A

.

22

09

www.tmax.biz

JEEP WRANGLER

Mounting Plate JP4

23

⑩

Φ8Flat

Step 2: Install the mounting plate as shown in the picture

(Tighten Torque 23Nm) .

⑩

Φ8

Flat

Washer

⑪Φ8 Spring

Washer

⑰M8×25 Hexagon Head Bolt

Drilling

Position Front

Original hole for

installing motor linkage

Step

3:

As shown in the picture drill a new hole on the side skirt based on the original hole (

Dia

of new hole is 6 5mm

-

8 5mm) Please

Original hole as

the base

New drilling hole as the base for

installing motor linkage

10

Step

3:

As

shown

in

the

picture

,

drill

a

new

hole

on

the

side

skirt

based

on

the

original

hole

(

Dia

of

new

hole

is

6

.

5mm

-

8

.

5mm)

.

Please

adjust the hole position due to different vehicles.

www.tmax.biz

JEEP WRANGLER

I t ll ti

I

ns

t

a

ll

a

ti

on

of Left

Front

Motor

Linkage

Step 4: As shown in the picture , screw

the hexagon head bolt into the thread

hole only 3-4 thread to install the motor

linka

g

e.

Φ8 Spring Washer

Φ8 Larger Washer Grade A

M8×35 Hexagon Head Bolt

g

Step 5: As shown in the picture, pull

the board base with 30N force to

ensure that the hole in the mounting

surface is corresponding to the hole

Board

base

Mounting

surface of

motor

linkage

in the side skirt, and then screw the

bolt and pre-tighten it (Tighten

Torque 6Nm) .

Φ8 Larger Washer Grade A

Φ8 Spring Washer

M8×20 Hexagon Head Bolt

11

www.tmax.biz

JEEP WRANGLER

M8×20 Hexagon Head

Bolt

Step 6: As shown in the picture, tighten the hexagon head bolt in

the step 6 to install the motor linkage (Tighten Torque 23Nm) .

Step 7: As shown in the picture, tighten the hexagon head bolt

(Tighten Torque 23Nm) .

Installation of

Left Rear Motor

Linkage

Φ8

L

Wh GdA

M8×20 Hexagon Head Bolt

Φ8 Spring Washer

Board

Mountin

g

Φ8

L

arger

W

as

h

er

G

ra

d

e

A

Φ8 Spring Washer

M8×25 Hexagon Head Bolt

Ste

p

8: As shown in the

p

icture, screw hexa

g

on head

b

olt

(

with

Φ8 Larger Washer Grade A

Board

base

g

surface of

motor

linkage

Step 9: As shown in the picture, pull the board base with 30N force

to ensure that the hole in the mounting surface is corresponding to

hhl

i

hidki dh hbl d

ih

i

12

p

pg

(

spring washer and larger washer grade A) into the threaded hole 3-4

thread to install the motor linkage.

t

h

e

h

o

l

e

i

n t

h

e s

id

e s

ki

rt, an

d

t

h

en screw t

h

e

b

o

l

t an

d

pre-t

i

g

h

ten

i

t

(Tighten Torque 6Nm) .

www.tmax.biz

JEEP WRANGLER

M8×20 Hexagon Head Bolt

Step 10: As shown in the picture, tighten the hexagon head bolt in

the step 10 to install the motor linkage. (Tighten Torque 23Nm) Step 11: As shown in the picture, tighten the hexagon head bolt.

(Tighten Torque 23Nm)

Socket Cap Screw

Step 12:As shown in the picture, tighten socket cap screw to connect board and motor linkage (Tighten Torque 12Nm). Put the light belt into the

13

groove on the back of board after connecting insert and socket. This installation step is only for glare type.

www.tmax.biz

JEEP WRANGLER

Note: Put pin of

motor protective

plate JP-L into

this hole.

Motor Protective Plate JP-L

Φ12 Flat Washer Grade A

Φ

12

Si Wh

M12 Tensioning Block

Φ

12

S

pr

i

ng

W

as

h

e

r

M12×35 Hexagon Head Bolt

Ste

p

13: As shown in the

p

icture

,

p

ut in M12 tensionin

g

block.

Step 14: Install motor protective plate JP-L according to above

picture. Screw hexagon head bolt (with spring washer and flat

washer

g

rade A

)

into the threaded hole 3-4 thread.

p

p,p g

g)

Ste

p

15: Make the motor

p

rotective

p

late reach to the vehicle bea

m

p

pp

and then tighten the hexagon head bolt.(Tighten Torque 32Nm)

14

www.tmax.biz

JEEP WRANGLER

Status of Power Board Get Back

15

www.tmax.biz

JEEP WRANGLER

El t i

El

ec

t

r

i

c

Installation of

Magnetic

Control

4 Connect white and brown signal wire

Power

Bd

4

.

Connect

white

and

brown

signal

wire

with wired magnetic induction module .

B

oar

d

Switch

1. Pull out the fuse and connect the

battery wire.

B

2 Connect the control

wire

and

arrange

all function

wires

to the pointed positions

5. Insert back the fuse and sort out

the wires.

B

attery

3. Connect motor wire and LED lamp wire.

2

.

Connect

the

control

wire

and

arrange

all

function

wires

to

the

pointed

positions

.

Chassis

Controller

Ste

p

1: Find out the control in

p

ut wire and

p

ull out the fuse

(

ensurin

g

p

p

p(g

circuit safety during installation) and connect the positive and

negative pole of wire harness to vehicle battery respectively.

Note: Battery wire can not be modified privately.

16

www.tmax.biz

JEEP WRANGLER

Mountin

g

Bracket of Controlle

r

M8×25 Hexagon Flange Bolt

g

Step 2:Install the

mounting bracket

of controller,

then screw the

hexagon flange

bolt and tighten it

(Tighten torque is

30Nm).

Step 3: Set the

controller shown

controller

shown

as in the picture

and tie with two

iron wire ties.

Iron wire tie

Cll

17

C

ontro

ll

e

r

www.tmax.biz

JEEP WRANGLER

Beam

Step 4:The arrangement of motor wire and LED lamp wire: Arrange the motor

connection wire along the beam as shown in the picture, the motor wire plug

extends to motors of linkage. At least , adjust the wire harness to make sure it is tidy

db if l

an

d

b

eaut

if

u

l

.

The other side uses the same way for installation.

18

www.tmax.cn

JEEP WRANGLER

B

il

i

White signal

wire and

bd

B

rown s

i

gna

l

w

i

re

A -pillar panel

power

b

oar

d

switch

wire

Sill panel

Step 5: Connection of signal wire: Pry the sill panel and A-pillar panel on the left above . Pull the brown signal wire into the vehicle

through the

rubber grommet of chassis on the right side Then the white signal wire extends to the left side of the vehicle unde

rthe

19

through

the

rubber

grommet

of

chassis

on

the

right

side

.

Then

the

white

signal

wire

extends

to

the

left

side

of

the

vehicle

unde

r

the

carpet, and stick the power board switch to the left side under the steering wheel.

www.tmax.cn

This manual suits for next models

1

Table of contents

Other TMAX Digital Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

Yakima

Yakima K1063 instructions

Brodit

Brodit 216025 installation instructions

Mont Blanc

Mont Blanc FK206 Fitting instructions

Black Horse Off Road

Black Horse Off Road MBT-MR1512 Installation instructions & user guide

Rear view safety

Rear view safety RVS-718-5 instruction manual

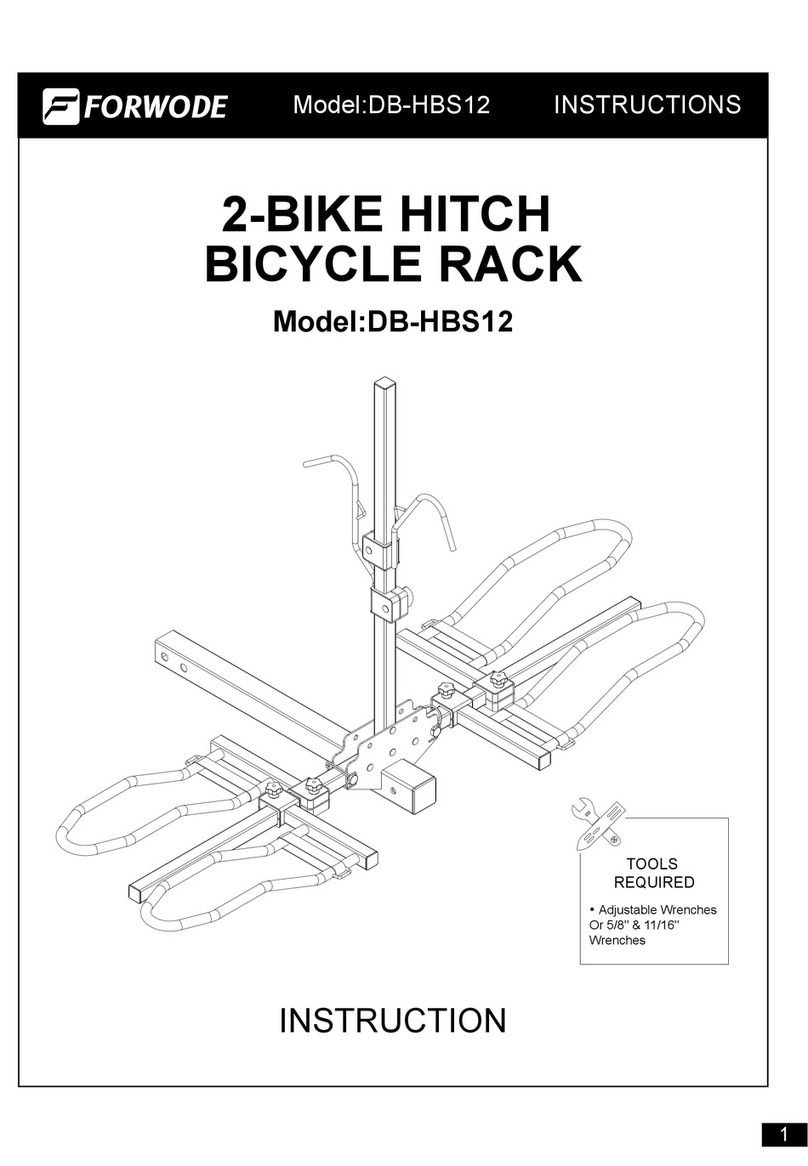

FORWODE

FORWODE DB-HBS12 instructions