Operation Precautions

DANGER:

COMPLETELY READ AND UNDERSTAND THIS MANUAL BEFORE ATTEMPTING TO OPERATE

THE SNOW BLOWER

1. Keep all safety guards in place and in proper working order at all times.

2. NEVER place fingers, hands, or body near the snow blower when it is running. Do not lean or reach

over the snow blower when the machine is running.

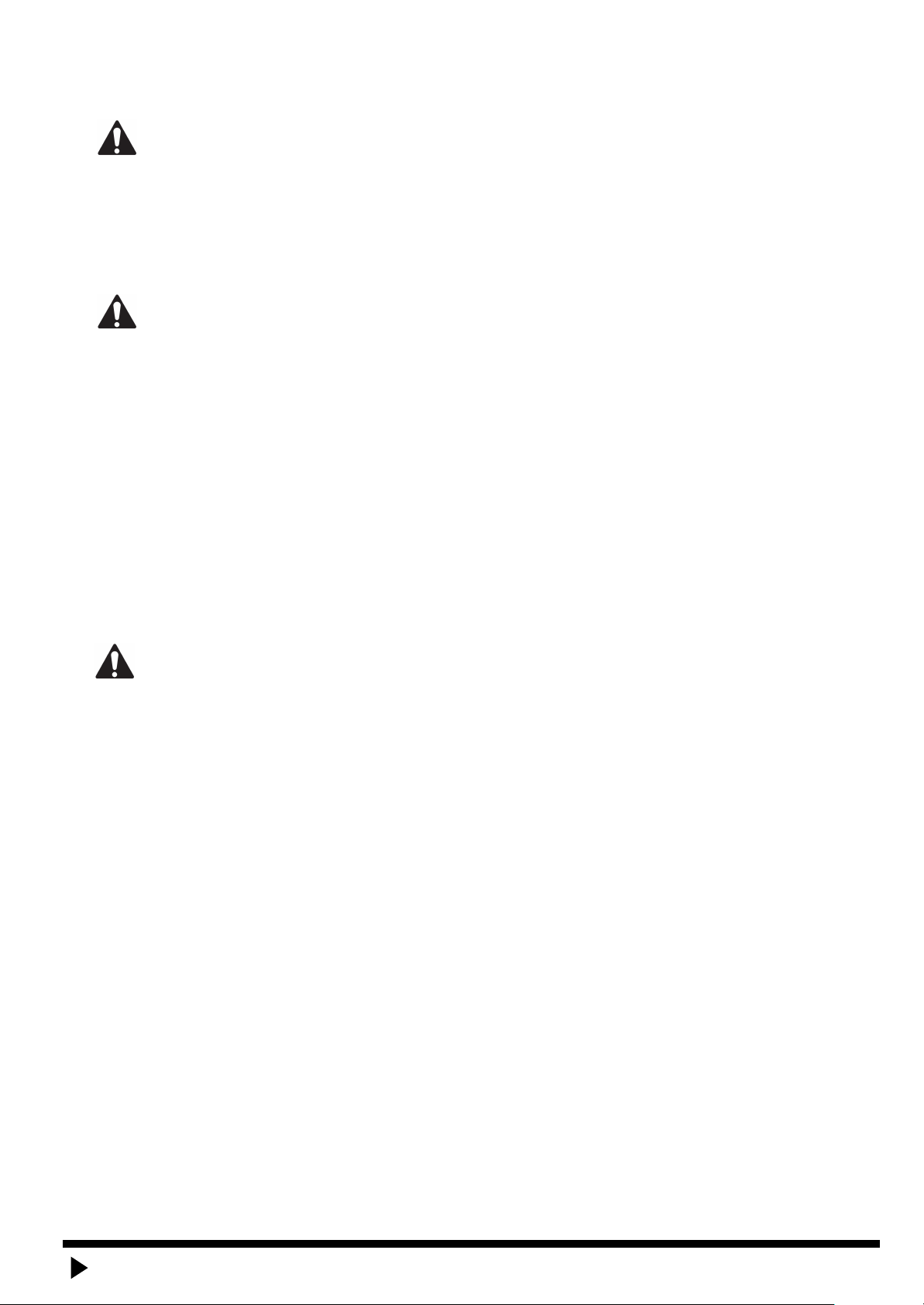

DANGER:

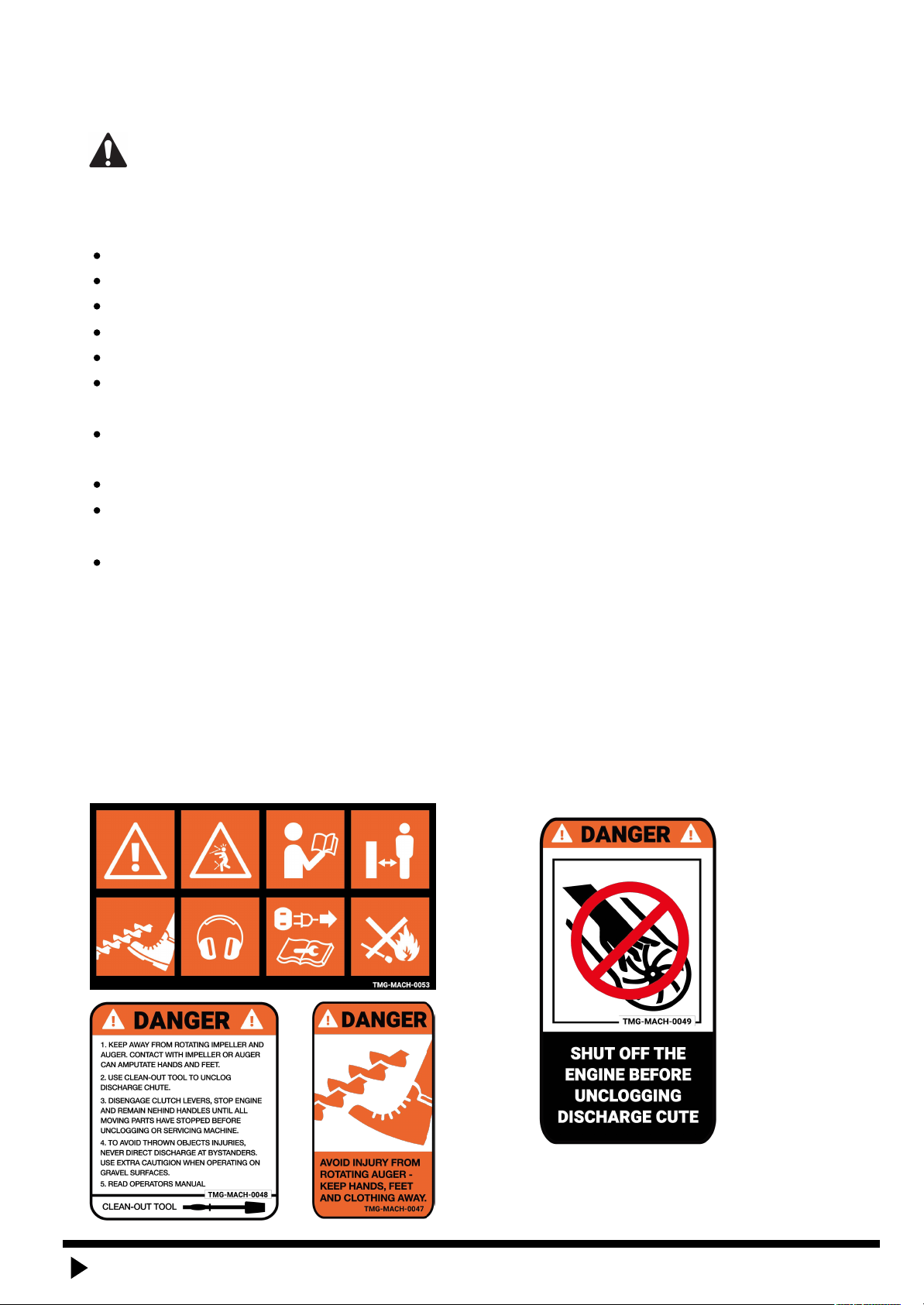

STOP THE ENGINE TO UNCLOG THE DISCHARGE CHUTE. NEVER USE YOUR HAND TO CLEAN OUT

THE DISCHARGE CHUTE OR AUGERS.

3. Always stop the engine to dislodge snow from the discharge chute or from the augers. Wait ten

seconds for the augers to stop rotating. Never use your hands to clear out the augers or discharge

chute. Always use the clear-out tool provided or a similar tool.

4. Keep all people (except the operator) a minimum of 25 feet from the snow blower during operation.

5. Always aim the discharge chute away from people and animals.

6. Do not leave the snow blower unattended when it is running. Turn off the engine before leaving the

area.

7. Do not use this piece of equipment while tired or under the influence of drugs, alcohol or medication.

8. Parts, especially exhaust system components, get very hot during use. Stay clear of hot parts.

9. Use extra caution when operating on gravel or other loose material.

CAUTION:

DISENGAGE ALL CONTROL LEVERS AND STOP THE ENGINE BEFORE YOU LEAVE THE OPERATING

POSITION.

Wait until the auger/impeller comes to a complete stop before unclogging the chute assembly, making

any adjustments, or inspections.

1. Exercise caution to avoid slipping or falling, especially when operating in reverse.

2. Thoroughly inspect the area where the equipment is to be used. Remove all foreign objects, which

could be tripped over or thrown by the auger/impeller.

3. Always wear safety glasses or eye shields during operation and while performing an adjustment or

repair to protect your eyes. Thrown objects which ricochet can cause serious injury to the eyes.

4. Operate the equipment with appropriate footware, gloves and clothing. Avoid loose fitting clothing

that can get caught in moving parts.

5. After striking a foreign object, stop the engine, remove the wire from the spark plug, thoroughly

inspect the snow blower for any damage, and repair the damage before restarting and operating the

snow blower.

6. The auger and drive controls must be depressed to operate. Do not override this safety feature. Both

control levers must operate easily and automatically return to the disengaged position when released.

7. Do not overload the snow blower by attempting to clear snow too quickly.

8. Do not operate at high speed on icy or slippery surfaces.

9. Always be sure of your footing especially when driving in reverse.

10. If the snow blower should vibrate abnormally, stop the engine immediately, disconnect the spark

plug and inspect for damage.

www.tmgindustrial.com 09/35 Toll Free:1-877-761-2819