TMK JOKER DS2PM-RC Manual

Wireless remote control ready

boiler controller for stoker, blower,

central heating and domestic hot water pumps and the mixing valve

version with the return water sensor

JOKER DS2PM-RC

Instruction and installation manual

Application

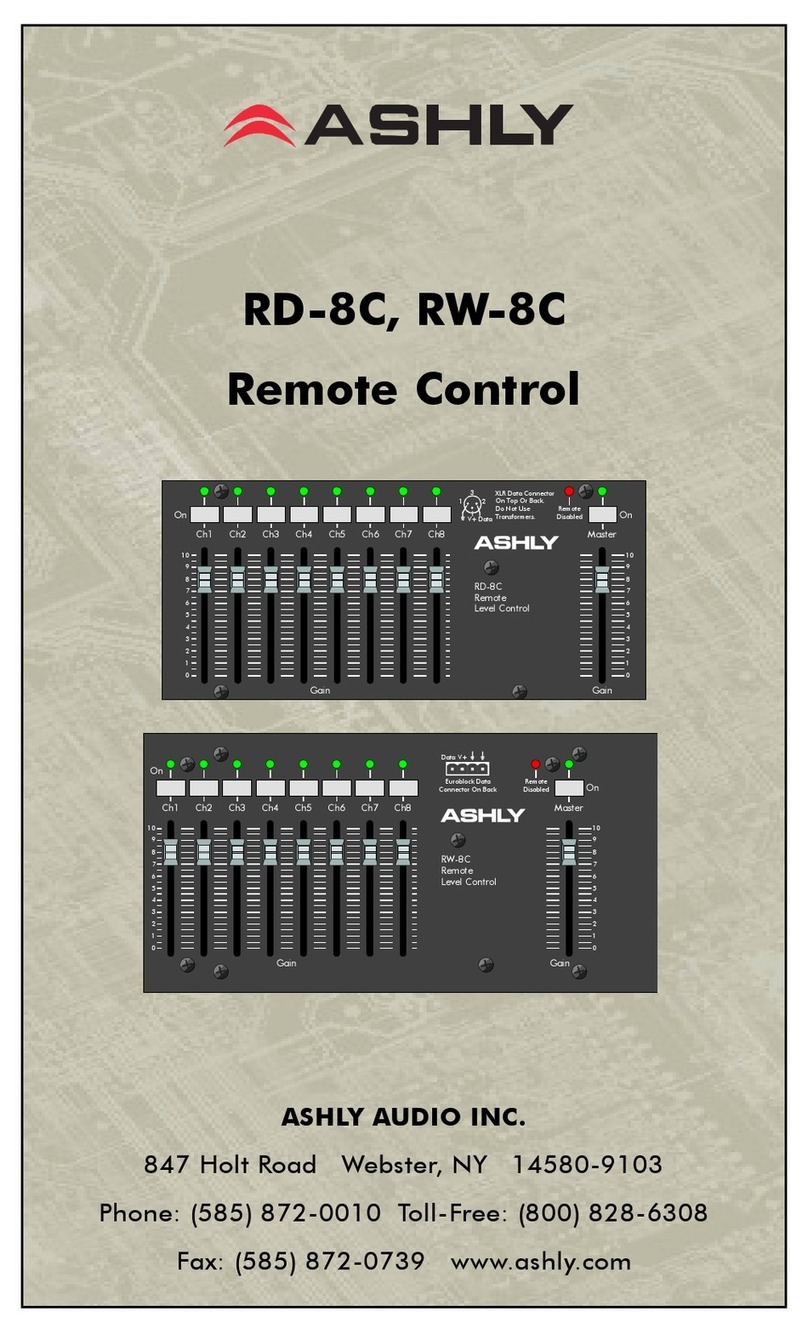

External view of the controller

Fully automatic controller JOKER DS2PM-RC is designed to dynamically control the stoker, blower, central

heating circulation pump, feeding pump of the domestic hot water tank and the four-way valve. Controller

maintains the set temperature in rooms with a wireless room panel according to the time programming.

Controller controls dynamically the amount of delivered fuel and the blower power. It features a thermal switch-

off function to protect the boiler against overheating, and is equipped with an “anti-stop” and antibacterial

protection functions. The controller may prioritize domestic hot water and additionally prevent the tank and

radiators from excessive cooling resulting from insufficient boiler temperature. It distributes boiler capacity

among central heating and domestic hot water circuits in a dynamic way, in conformity with user's settings and

preferences. The user can also select timed programmes ensuring optimisation of energy consumption.

The return water sensor protects the boiler from temperature dropping too low.

Thanks to advanced control procedures, the temperature of domestic water and heated spaces is maintained at

desired levels, while the boiler operates in optimal conditions ensuring increased life expectancy.

The user can limit the number of controlled appliances thanks to flexible configuration of the menu and the main

control screen.

MAIN SCREEN - status of the appliances and boiler temperature setting.

In order to change settings of the boiler on the MAIN SCREEN press the knob (arrows flash)

and turn it to select the desired temperature. To validate, press the [SAVE] button or press

the knob.

To exit without saving, press the [EXIT] button.

current

temperatures*

current

status of

appliances

temperature

setting

for the boiler hour

and date

parameter

menu

boiler temp.Examples of appliance status

C.H. pump switched on

C.H. timed programme "day temperature" active

C.H. pump manual mode

Multifunction touch buttons

MAIN SCREEN

Knob used for:

- switching parameters

and changing settings

(by turning)

- selecting parameters

for editing and saving

changes (by pressing)

switching between monitored

devices and temperatures*

CH

blower active

1

Firma TMK sp.j.

62-300 Września

Szosa Witkowska 105

tel./fax +48 61 437 97 60

www.tmk.com.pl

working mode

screen*

stoker helix animation means that the stoker is

feeding coal

21.3

temp.behind

the valve

the valve is being opened ( closed)

C.H. timed programme "day temperature" active

CH

boiler return

temp.

EN

working mode

*CAUTION - Temperature of the stoker is displayed on the "manual mode"

screen of the stoker and blower - press [MODE], and then [MANUAL MODE].

MONITORING OF ALL ACTIVE DEVICES AND TEMPERATURES (SENSORS) IS AVAILABLE IN THE MENU - parameter J

2

Installation instructions

Controller connection

The controller can be mounted on a wall mount (included in the kit as a standard option) or on a vertical

support (available as an extra option). The mount is fixed to a wall with rawl plugs (included in the kit),

following which the controller can be easily snapped onto the mount.

When the vertical support is used, first it needs to be fixed to the surface, and then the rails at the back of

the controller can be used to snap it securely on the support.

Connect the supply cable to a 230 V, 50 Hz power outlet with an earth contact.

The ambient temperature in the controller mounting location may not exceed 40°C.

CAUTION: The connection cable of the regulator may only be replaced by the manufacturer.

CAUTION: JOKER controller is only able to operate when the system is filled with water. If the system is

empty, the controller must be disconnected from the power supply. Otherwise the pump may become

damaged.

General technical data:

- Supply voltage 230V/50Hz

- Maximum pump output 3x100VA, 1x250VA(stoker), 1x5VA(valve)

- “Anti-stop” function (pump protection against “jam”) – activated for 30 sec. every 14 days

- Antibacterial protection of tank water against Legionella bacteria _ _ _ _ _ _ _ _ _ _ _ _ SWITCHED OFF

Default

settings

blower and stoker

switch off

blower and stoker

switch on

manual mode

screen

CAUTION - if no button is pressed, after five seconds the display returns

automatically to MAIN SCREEN.

WORKING MODE SCREEN press [MODE]-

on the MAIN SCREEN

CAUTION - pressing [START] or [STOP] buttons will be confirmed on the

display. Current working status is visible only after re-entering the

WORKING MODE screen.

......................................................................

MONITORING OF DEVICES AND TEMPERATURES

(SENSORS) SCREEN - press [MENU] to open-par. J

CAUTION - the "Monitoring of devices and sensors" screen does not

return automatically to the MAIN SCREEN.

30 current blower speed

device is switched off

%

device is switched on

C.H. timed programme "day temperature" active

D.H.W. tank timed programme "night temperature" active

„M” - manual mode

C.H. HEATING BOILER CONTROL (OF THE BLOWER AND STOKER)

Installation

MANUAL MODE OF THE STOKER AND BLOWER

The user can flexibly switch on and off the stoker as well as the blower. It may useful for instance when the

boiler is ignited with empty stoker.

The screen "Manual mode of the stoker and blower" is available on pressing [MODE], and then within five

seconds [MANUAL MODE]. The manual mode screen is available alternatively under parameters B4 and

C8.

FIRING UP OF THE BOILER WITH EMPTY STOKER

After the coal container is filled, switch on the stoker by pressing [START stoker] until coal appears in the

retort.

Then switch off the stoker by pressing [STOP stoker], and ignite coal in the retort. Next, switch on the

blower [START blower] and set its optimal speed by turning the knob (current blower speed is displayed on

the screen in per cent).

When coal in the retort has been ignited switch to automatic mode - press [EXIT] and then [START] on the

main screen. Automatic mode is described on page 4.

Screen of the MANUAL MODE OF THE STOKER AND BLOWER:

3

Animated movement of the helix means that the stoker is feeding coal.

CAUTION - the controller does not automatically return from "Manual mode of the stoker and blower"

menus to the MAIN SCREEN. .

START / STOP

manual mode

current temperature

of the boiler

Turn the knob

to set blower speed

(arrows are flashing)

1. Installation of the boiler temperature sensor and thermal breaker switch

Fix the sensor and thermal breaker switch to an uninsulated exit pipe of the C.H. boiler with two provided strips so

that they adhere well.

It is recommended to additionally wrap the sensor and thermal breaker switch with some thermal insulation

material.

2. Installation of the stoker temperature sensor

The stoker sensor must be fixed to the feeding pipe where designated by the boiler producer.

If the boiler producer provided no instructions, for best results install the sensor on the feeding pipe 50 cm from where

coal enters the furnace.

Attach the sensor to the pipe with the provided metal strap so that it adheres well.

CAUTION: Incorrect installation may damage the sensor.

CAUTION: The sensor and thermal breaker switch are not made for direct use in water.

3. Connecting the power cord to the blower and the stoker

źConnect the yellow-green wire (zero protection) to the marked terminal of the blower/stoker.

źConnect brown and blue wires to L and N terminals of the blower/stoker.

źin case of the version with IEC connector, plug in the controller and the blower/stoker

CAUTION: The regulator must be installed by a qualified electrician only.

current temperature

of the stoker

current temperature

of the boiler return

S

BOILER AUTOMATIC MODE (BLOWER AND STOKER)

4

Use MANUAL MODE OF THE STOKER AND BLOWER to fire up the boiler (page 3). When coal in the retort has been

ignited switch to automatic mode by pressing [EXIT], then pressing [MODE], and then within five seconds []START. The

controller starts automatic FIRE UP of the boiler - the blower works at its maximal speed setting, while the stoker regularly

feeds new portions of coal. FIRE UP mode will start only if the temperature at the boiler sensor is lower than the extinguish

temperature setting (parameter A3). Over the first 6 hours after the FIRE UP precedure has been started the controller does

not take into account the minimal temperature at the return to the boiler (parameter E3).

When the boiler temperature exceeds current extinguish temperature setting (parameter A3), the controller enters

HEATING mode.

If the parameter A8 is set to YES (default: NO), as the temperature of the boiler approaches the temperature set by the user

(parameter A1) displayed on the MAIN SCREEN, the amount of coal and air is automatically reduced. When the

temperature selected by the user is achieved, the controller enters into STANDBY mode. In this mode the stoker and blower

switch on at regular intervals to prevent furnace from extinguishing.

The controller enters HEATING mode again when the temperature drops by the hysteresis value (parameter A2) below

boiler temperature.

During heating up of the D.H.W. tank automatic reduction of boiler power is not performed.

In HEATING mode, when boiler temperature drops below the current extinguish temperature setting (parameter A3), the

controller enters EXTINGUISH mode - the blower and stoker are switched off.

EXTINGUISH will not start unless FIRE UP has been completed (parameter A4 - default setting: 6 hours).

If during FIRE UP boiler temperature does not exceed EXTINGUISH temperature, once FIRE UP time has passed, the

controller enters into NOT FIRED UP mode.

In all modes of the controller pumps are run depending on selected settings.

OPERATION WITH THE WIRELESS REMOTE CONTROL ROOM PANEL

Operation of the JOKER DS2PM-RC controller with the wireless room control panel is described on pages 12 and 13.

SUMMER MODE (parameter K1 in )

When SUMMER mode is selected, automatic reduction of boiler power is not performed. The boiler heats up only the

D.H.W. tank. SUMMER mode is indicated on the MAIN SCREEN by the and icons.

Over the first 6 hours from switching from the SUMMER mode to the WINTER mode the controller does not take into

account the minimal temperature at the return to the boiler (parameter E3).

ALERTS

The controller features several boiler alerts: regulated alerts for low or high boiler temperature (parameters A5 and A6) and

permanent (not regulated) alerts: low temperature at 8°C and high temperature at 92°C. The 92°C alert stops the blower

and the stoker and fully opens the mixing valve. Even when boiler temperature drops, the "92°C alert" remains active until

[START] button is pressed. Once the temperature exceeds the alert threshold set by the user, both an audible and visual

(red diode) alerts are triggered. When boiler reaches the permanent alert temperature only a visual alert is activated.

When temperature of the stoker exceeds the alert temperature setting (parameter C6), the stoker is activated in order to

shove burning coal from the stoker into the boiler (preventing fire from moving into the coal container). A special screen

appears to display temperature and duration of coal shoving (parameter C7). Audible and visual (red diode) alerts are

activated and the mixing valve is fully opened.

Pressing [STOP] on the screen "Shoving fire from the stoker into the boiler' stops the shoving off procedure regardless of

the temperature of the stoker. When shoving off is discontinued, "STOKER FIRE" symbol appears on the main screen.

CAUTION: Shoving off of coal from the stoker into the boiler is activated only once in a given working cycle of the controller.

In order to activate the stoker alert again press [START] - then the "STOKER FIRE" message will disappear from the

screen.

The 92°C alert has a priority over stoker alert.

The emergency cooling of the boiler in the SUMMER mode (parameter A7) will activate the CH pump and the

, i .

CAUTION: During the there is a risk of increased domestic hot water temperature

above user settings. The careful use of hot water is recommended.

CAUTION:

CAUTION:

DHW tank

feeding pump An audible alert and a visual alert (red diode) are activated.

emergency cooling of the boiler

If the temperature at the return to the boiler falls below the setting of the parameter E3, the controller

will increase boiler temperature to 65°C.

While the D.H.W. tank is heated up, the controller raises the boiler temperature by 5°C above the current

temperature setting for the D.H.W. tank (F1).

When the blower and stoker need to be stopped press [MODE], and then within five seconds press [STOP]. Pressing

[START] restarts the blower and the stoker.

Controller settings

n such a case the valve is fully opened

Press [MENU] to change parameters of the C.H. boiler. List of groups of parameters will appear on the screen.

Select the top parameter group "A - C.H. boiler". by pressing the knob or the [SELECT] button. "A1", the first from the

group of C.H. boiler parameters will appear on the screen. Turn the knob right to go to the following parameters, and

then press [EDIT/SELECT] or the knob to change. At this point, you can change the value of a parameter either by

turning the knob or using the dynamically appearing buttons. Some parameters need to be selected for editing; use

the [SELECT] button and the knob - a flashing dot will highlight the parameter selected for editing.

Editing is confirmed by pressing the knob or the [SAVE] button.

Pressing [EXIT] will bring back the previous screen without saving any changes.

LIST OF PARAMETER OF THE C.H. BOILER (moving between parameters and change of setting - turn the knob):

A1 Boiler temperature setting (55-90°C, default: 60°C)

Boiler temperature cannot be lower than the sum of parameters: A2+A3 +5°C.

If the temperature at the return to the boiler falls below the setting of the parameter E3, the

controller will increase boiler temperature to 65°C.

While the D.H.W. tank is heated up, the controller raises the boiler temperature by 5°C above the current

temperature setting for the D.H.W. tank (F1).

A2 Boiler hysteresis (0-10°C, default: 1°C)

Boiler hysteresis can't be higher than the difference of parameters: A1 minus A3 minus 5°C.

A3 Boiler extinguish temperature (40-50°C, default: 45°C)

Boiler extinguish temperature cannot be higher than the difference of parameters: A1 minus A2 minus 5°C.

A4 Fire up duration (10-480 min, default: 6 hours)

A5 low boiler temperature alert (0-50°C, default setting: 8°C).

A6 high boiler temperature alert (60-120°C, default setting: 92°C)

The controller features also two permanent (non-configurable) alerts: of low boiler temperature (8°C) and of high

boiler temperature (92°C).

A7 (60-99°C, default setting: 80°C - CAUTION: SETTING

THE TEMPERATURE ABOVE 90°C IS ONLY PERMITTED WHEN THE BOILER IS ADDITIONALLY

PROTECTED FROM COMING TO BOIL !)

A8 Automatic reduction of boiler power as the temperature of the boiler approaches the temperature set by the user

(NO, YES, default: NO)

When this parameter is set to "NO”, parameters

Automatic reduction of boiler power is not performed d , in the SUMMER mode

and during the antibacterial protection procedure.

CAUTION:

The 92°C alert stops the blower and the stoker and fully opens the mixing valve. Even

when boiler temperature drops, the "92°C alert" remains active until [START] button is pressed.

The emergency cooling of the boiler in the SUMMER mode

CAUTION: During the emergency cooling of the boiler there is a risk of increased domestic hot water

temperature above user settings. The careful use of hot water is recommended.

B1 and C1 are inactive.

uring heating up of the D.H.W. tank

C.H. BOILER - QUICK BOILER TEMPERATURE SETTINGS

C.H. BOILER PARAMETER MENU - group A

Press the knob

To confirm, press the knob

or the SAVE button

Turn the knob to

select temperature

(arrows are flashing)

Pressing [EXIT] will bring back the MAIN SCREEN without saving any changes.

Press

MENU pressing the knob or

the [SELECT] button

on pressing

MENU

5

Press [MENU] to change parameters of the blower. List of groups of parameters will appear on the screen. Turn the

knob right (clockwise) to select group "B - Blower", and then to select press the knob or the [SELECT] button.

"B1", the first in the group of blower parameters will appear on the screen. Turn the knob right (clockwise) to go to the

following parameters. Press the knob or the [EDIT] button to change settings. At this point, you can change the value

of a parameter either by turning the knob or using the dynamically appearing buttons.

Editing is confirmed by pressing the knob or the [SAVE] button.

Pressing [EXIT] will bring back the previous screen without saving any changes.

LIST OF PARAMETERS OF THE BLOWER (moving between parameters and change of setting - turn the knob):

B1 Minimal blower speed (default: 30%)- this parameter is active if parameter A8 has been set to "YES".

B2 Maximal blower speed (20-100%, by default adjusted to the boiler power - see the table at the bottom of the page)

B3 Blower STANDBY duration (0-4 x parameter C4, default setting: 2 x C4 = 20 sec.)

B4 Manual mode of the stoker and blower - description on page 3.

BLOWER PARAMETER MENU - group B

Press [MENU] to change parameters of the stoker. List of groups of parameters will appear on the screen. Turn the

knob right (clockwise) to select group "C - Stoker", and then to select press the knob or the [SELECT] button.

"C1", the first in the group of stoker parameters will appear on the screen. Turn the knob right (clockwise) to go to the

following parameters. Press the knob or the [EDIT] button to change settings. At this point, you can change the value

of a parameter either by turning the knob or using the dynamically appearing buttons.

Editing is confirmed by pressing the knob or the [SAVE] button.

Pressing [EXIT] will bring back the previous screen without saving any changes.

LIST OF PARAMETERS OF THE STOKER (moving between parameters and change of setting - turn the knob):

C1 Minimal duration of stoker operation in HEATING mode (default: 5 sec.)-this parameter is active if parameter A8

has been set to "YES".

C2 Maximal duration of coal feeding in HEATING mode (1- 250 sec, by default adjusted to the boiler power - see the

table at the bottom of the page)

C3 Pausing of coal feeding in HEATING mode (0-250 sec, by default adjusted to the boiler power - see the table at the

bottom of the page)

C4 Coal feeding duration in STANDBY mode (1-250 sec, default: 10 sec.)

C5 Pausing of coal feeding in STANDBY mode (1-250 min., default: 30 min)

C6 Stoker alert temperature (70-90°C, default setting: 85°C)

C7 Duration of coal shoving once stoker alert temperature has been reached (0-20 min., default setting: 5 min)

to prevent coal in the container from catching fire

CAUTION: Setting to "0" leaves the boiler without protection and is not allowed for most boiler types!

C8 Manual mode of the stoker and blower - description on page 3.

When temperature of the stoker exceeds the alert temperature setting, the stoker is activated in order to shove

burning coal from the stoker into the boiler (preventing fire from moving into the coal container). Audible and visual

(red diode) alerts are activated.

STOKER PARAMETER MENU - group C

Press

MENU

Turn the knob to

select Blower

Turn the knob to

select Stoker

pressing the knob or

the [SELECT] button

pressing the knob or

the [SELECT] button

Press

MENU

6

...........................................................................................................................................................................................................

BOILER POWER

10kW

20kW

30kW

40kW

50kW

Blower speed [%](par.B2)

42

46

48

52

54

Stoker-feeding

[sec.](par.C2)

5

6

7

8

10

Stoker-pausing [sec.](par.C3)

19

19

21

25

28

CONTROL OF THE CENTRAL HEATING PUMP

Installation

1. Installation of the boiler sensor

źAttach the sensor to an uninsulated pipe going out of the CH boiler with two provided strips so that it adheres well.

źIt is recommended to additionally wrap the sensor with some thermal insulation material.

CAUTION: The sensor is not made for direct use in water.

2. Connecting the power cord to the CH pump

źConnect the yellow-green wire (zero protection) to the marked terminal of the pump.

źConnect brown and blue wires to L and N terminals of the pump.

źfor the version with IEC connector, plug the controller and the pump

CAUTION: The regulator must be installed by a qualified electrician only

C.H. PUMP OPERATION

The controller switches on the C.H. pump when the temperature in the boiler reaches 50°C, and switches it off

when it drops to 45°C.

When domestic hot water priority has been selected (parameter F3 is set to YES), the C.H. pump will be switched

off while the hot water tank is heated up.

C.H. pump switches on below 8°C - (ANTIFREEZE PROTECTION). A visual alert is activated. (red diode)

Press [MENU] to change parameters of the C.H. pump. List of groups of parameters will appear on the screen. Turn

the knob right (clockwise) to select group "D - C.H. pump", and then to select press the knob or the [SELECT]

button. "D1", the first in the group of C.H. pump parameters will appear on the screen. Turn the knob right

(clockwise) to go to the following parameters. Press the knob or the [EDIT] button to change settings. At this point,

you can change the value of a parameter either by turning the knob or using the dynamically appearing buttons.

Editing is confirmed by pressing the knob or the [SAVE] button.

Pressing [EXIT] will bring back the previous screen without saving any changes.

LIST OF CH PUMP PARAMETERS (to switch between parameters and to change setting – turn the knob)

D1 CH pump switch-on temperature 50°C - read only

D2 CH pump switch-off temperature 45°C - read only

D3 Manual CH pump mode ([START] button – the pump is working regardless of the settings, [STOP] button- the

pump is switched off regardless of the settings)

CAUTION: the manual mode prevails over the “anti-stop” function and the frost protection.

When the controller is powered on the pump always switches to automated mode.

C.H. PUMP PARAMETER MENU - group D

Press

MENU

7

pressing the knob or

the [SELECT] button

Turn the knob to

select C.H.pump

CONTROL OF THE MIXING VALVE

Installation

1. Installation of the temperature sensor behind the valve

- Attach the sensor to an uninsulated pipe behind the valve with two provided strips so that it adheres well (for best

results install the sensor on the pipe minimum 1 meter from the valve).

2. Installation of the boiler return temperature sensor

- Fix the sensor to an uninsulated section of the return pipe of the boiler with two provided strips so that it adheres well.

It is recommended to additionally wrap the sensor with some thermal insulation material.

CAUTION: The sensors are not made for direct use in water.

3. Connecting the power cable to the valve (230V, max. 5VA, 3-pin)

CAUTION: CONNECTING ANOTHER DEVICE MAY DAMAGE THE CONTROLLER

the three-wire cable of the mixing valve actuator should be connected as follows:

- fix the N marked wire to the common (neutral) terminal of the valve

- fix the remaining two wires to L1 and L2 screw terminals of the IEC connector, as described in the mixing valve

user manual.

Next, plug the IEC connector of the valve actuator cable into the dedicated socket of the JOKER controller.

It is recommended to check the connection by opening and closing the valve manually (parameter E5).

It is possible to reverse direction of turning of the mixing valve - parameter E6.

CAUTION: The regulator must be installed by a qualified electrician only.

MIXING VALVE OPERATION

The role of the controller is to stabilise water temperature in the central heating system. This is accomplished by

opening and closing of the mixing valve. The controller switches the valve on and off in order to achieve the

minimal temperature setting behind the valve when room temperature has been achieved, or the maximal

temperature setting behind the valve if room temperature has not been achieved. When remote control from a

room panel is deactivated (parameter G4 set to "NO"), the controller is working to achieve maximal temperature

setting behind the valve (parameter E1), and parameter E2 (minimal temperature behind the valve) becomes

inactive.

The user can select three different maximal and minimal temperatures behind valve -"day", "night" and "economy"

(parameters E1 and E2). Temperature behind valve is programmable, different temperatures can be set for every

day and hour of the week (parameter H1). The central heating timed programme in use is displayed on the MAIN

SCREEN between the CH pump icon and the boiler return temperature:

At the time when the temperature setting is switched from "day" to "night", from "night" to "economy" or from "day" to

"economy" the valve is continuously closed for 4 minutes The closing of the valve is overridden when a need to open the

valve arises.

The valve is continuously closed for 4 minutes when the SUMMER mode is activated.

When the SUMMER mode has been selected, the CH pump is switched on only in an emergency (a visual and sound

alert are triggered) In such a case the valve is fully opened while the CH pump is working. The valve is continuously

closed for 4 minutes after the alert has been switched off.

The valve is fully, continuously open when temperature in the boiler reaches 92°C and during s

.

The user can manually open and close the valve, e.g. in order to check if it has been properly connected (parameter

E5). Press [OPEN] to open the valve, press [CLOSE] to shut off the valve.

6

The mixing valve may operate only when C.H. pump is working.

When boiler temperature at the return is lower than parameter E3 (minimal temperature at the return), the valve is

closed. When temperature at the return is equal to the E3 setting, the valve remains closed. The controller allows to

open the valve only when temperature at the return is higher than the E3 setting.

CAUTION: If return temperature sensor has not been installed or is damaged, the controller will not activate the

blower and stoker in the automatic mode - replace the sensor.

Over the first 6 hours after the FIRE UP precedure has been started the controller does not take into account the

minimal temperature at the return to the boiler (parameter E3).

When hot water tank priority has been selected (parameter F3 set to "YES"), over the first 3 hours from switching on the

C.H. pump the controller does not take into account the minimal temperature at the return to the boiler(parameter E3).

hoving fire from the

stoker into the boiler Audible and visual alerts are activated.

It is possible to reverse direction of turning of

the mixing valve - parameter E .

Valve actuator cable at the controller

L1

closing

L2

opening

neutral (common)

N

„day temperature” „night temperature” „economy temperature”

8

MENU OF VALVE PARAMETERS – group E

In order to modify valve parameters, press the [MENU] button. A list of groups of parameters will appear on

screen. Turn the knob right (clockwise) to select the E group - “Valve”. Press [SELECT] or the knob. “E1”,

the first parameter from the valve group will be displayed. To go to different parameters, turn the knob right,

and then press the [EDIT] / [SELECT] button or the knob to change a desired parameter. Now you can

change the value of the parameter using the knob or the dynamically alternating buttons.

Some parameters need to be selected for editing: use the SELECT button and the knob.

To save changes, press the [SAVE] button or press the knob.

The [EXIT] button restores the previous menu level without saving changes.

LIST OF VALVE PARAMETERS (to switch parameters and change setting – turn the knob):

E1 Maximal temperature behind the valve (setting maximal temperature behind valve E1a, E1b or E1c below

corresponding E2a, E2b or E2c [minimal temp. behind valve] results in both settings becoming equal)

E1a day (1-99°C, default: 45°C)

E1b night (1-99°C, default 30°C)

E1c economy (1-99°C, default: 25°C)

E2 Minimal temperature behind the valve(setting minimal temperature behind valve E2a, E2b or E2c above

the corresponding E1a, E1b or E1c [max temp. behind valve] results in both settings becoming equal)

E2a day (1-99°C, default: 35°C)

E2b night (1-99°C, default 20°C)

E2c economy (1-99°C, default: 15°C)

E3 Minimal temperature of the boiler return pipe regulated by the valve (40-55°C, default: 50°C)

E4 Valve downtime (valve action time is constant - 1 sec.) (0-200 sec., default setting: 10 sec.)

E5 Manual valve mode (the [STOP] button switches off the manual mode)

E6 Direction of valve turning (press [EDIT] and confirm to reverse direction of turning of the valve)

CAUTION: return to default settings will not change direction of valve turning.

When boiler temperature at the return is lower than parameter E3, the valve is closed. When temperature at

the return is equal to the E3 setting, the valve remains closed. The controller allows to open the valve only

when temperature at the return is higher than the E3 setting.

Over the first 6 hours after the FIRE UP precedure has been started the controller does not take into account

the minimal temperature at the return to the boiler.

When hot water tank priority has been selected (parameter F3 set to "YES"), over the first 3 hours from

switching on the C.H. pump the controller does not take into account the minimal temperature at the return to

the boiler.

9

Press

MENU pressing the knob or

the [SELECT] button

Turn the knob

to select

Valve

CONTROL OF THE DOMESTIC HOT WATER TANK FEEDING PUMP

Installation

1. Installation of tank temperature sensor

Mount the sensor in a location recommended by the tank's manufacturer.

CAUTION: The sensor is not made for direct use in water.

2. Connecting the power cord to the pump

źConnect the yellow-green wire (zero protection) to the marked terminal of the pump.

źConnect brown and blue wires to L and N terminals of the pump.

źfor the version with IEC connector, plug the controller and the pump

CAUTION: The regulator must be installed by a qualified electrician only.

HOT WATER TANK FEEDING PUMP OPERATION

The controller switches off the pump of the hot water tank when the temperature inside of the tank reaches

the set value (parametr F1 a,b or c). The pump is switched on when the temperature drops by the set value

of hysteresis (parameter F2 - either a, b or c).

The user can select three different temperatures of domestic hot water -"day", "night" and "economy"

(parameter F1). Temperature is set through timed programmes, different temperatures can be set for every

day of the week and every hour (parameter H2). The timed programme in use is displayed on the MAIN

SCREEN to the right of the D.H.W. pump icon:

°C

°C

°C

The user can select or unselect the priority of the hot water tank over central heating pump (parameter F3).

With this parameter unselected (the default setting is "NO") the hot water and central heating pumps work

independently from one another. If this priority is selected ("YES" setting), the central heating pump and the

valve are switched off when the hot water tank is heated up.

The feeding pump of the hot water tank is switched on if: 1. the set temperature of domestic hot water has

not been achieved and 2. when the temperature at the C.H. boiler is higher than that inside of the hot water

tank by the parameter F4 "protection of the hot water tank against cooling down". Another condition is having

achieved the value of parameter F5 -minimal temperature of the C.H. boiler at which the D.H.W. tank feeding

pump is switched on.

If SUMMER mode has been selected (parameter K1), the central heating boiler only feeds the hot water

tank.

domestic hot water tank pump F8

D.H.W. tank pump the D.H.W. tank

ANTIBACTERIAL PROTECTION FUNCTION

The user can select protection against Legionella bacteria in the DHW tank (parameter F6).

CAUTION: temperature of the active weekly antibacterial protection is 60 .

In addition to selecting automatic antibacterial protection, it is possible to override settings manually to carry

out immediately a single antibacterial protection procedure.

CAUTION: For antibacterial protection procedure to be carried out the temperature of the CH boiler must

achieve at least 65 (if that requirement has not been fulfilled, the controller will display an alert).

The maximal time of the antibacterial protection procedure is 2 hours.

If the temperature in the DHW tank reaches 60 in a given weekly cycle the next scheduled antibacterial

protection procedure will not be carried out.

icon on the main screen means a completed antibacterial protection procedure.

In order to increase efficiency of the procedure, it is recommended to open all water discharge points (taps

and others).

The user may deactivate control of the (parameter is set to "NO"). Once

it's been selected, the icon and reading of temperature disappear from

the main screen.

10

„day” temperature

of the D.H.W. tank

„night” temperature

of the D.H.W. tank

„economy” temperature

of the D.H.W. tank

Press [MENU] to change parameters of the hot water tank. List of groups of parameters will appear on the

screen. Turn the knob right (clockwise) to select group "F - D.H.W. tank", and then to select press the knob or

the [SELECT] button. "F1"- the first in the group of parameters of the D.H.W. tank will appear on the screen.

Turn the knob right to go to the following parameters, and then press [EDIT/SELECT] or the knob to change. At

this point, you can change the value of a parameter either by turning the knob or using the dynamically

appearing buttons. Some parameters need to be selected for editing; use the [SELECT] button and the knob.

Editing is confirmed by pressing the knob or the [SAVE] button.

Pressing [EXIT] will bring back the previous screen without saving any changes.

LIST OF PARAMETER OF THE DHW TANK (moving between parameters and changing of settings - turn the knob):

F8 Operation with

If "NO" has been selected, control is deactivated.

F1 DHW tank temperature

F1a day (10-85°C, default setting: 45°C)

F1b night (10-85°C, default setting: 35°C)

F1c economy (10-85°C, default setting: 25°C)

F2 DHW tank hysteresis

F2a day (1-15°C, default setting: 3°C)

F2b night (1-15°C, default setting: 3°C)

F2c (1-15°C, default setting: 3°C)

F3 DHW tank priority, YES, NO (default setting is NO)

When hot water tank priority has been selected, over the first 3 hours from switching on the C.H. pump the

controller does not take into account the minimal temperature at the return to the boiler (parameter E3).

F4 DHW tank protection from cooling down (0-15°C, default setting: 5°C)

F5 Minimal temperature of the CH boiler at which the DHW tank feeding pump is switched on (20-70°C, default

setting: 45°C)

F6 Protection of DHW against Legionella (YES, NO; default setting: NO) - CAUTION: minimal temperature

of active antibacterial protection is 60°C. The [WHEN] button opens a screen to edit the time when the

weekly protection procedure is started (default setting: Sunday, 0h.00m); the [NOW] button immediately

starts a single antibacterial protection procedure.

CAUTION: For antibacterial protection procedure to be carried out the temperature of the CH boiler must

achieve at least 65 (if that requirement has not been not fulfilled the controller will display an alert).

If in a given weekly cycle the temperature in the DHW tank reaches 60°C, the next scheduled antibacterial

protection procedure will be skipped.

F7 Manual mode of the DHW tank feeding pump. [START] button - the pump is switched on regardless of the

settings; [STOP] button - the pump is switched off regardless of the settings.

CAUTION: The manual mode overrides the "anti-stop" function and the holiday mode.

When the controller is powered on the pump always switches to automated mode.

economy

°C

icon and reading of

temperature disappear from the main screen.

D.H.W. tank pump

D.H.W. tank pump D.H.W. tank pump

the D.H.W. tank

HOT WATER TANK PARAMETER MENU - group F

11

Press

MENU pressing the knob or

the [SELECT] button

Turn the knob to

select Domestic

hot water tank

OPERATION WITH WIRELESS REMOTE CONTROL PANEL

Detailed information about the wireless remote control panel can be found in the remote control panel

manual.

JOKER CONTROLLER OPERATION WITH THE ROOM CONTROL PANEL

When the room panel is switched on, it waits for 30 seconds to be paired with the Joker main controller. If pairing is not

started within 30 seconds (parameter G3 in the menu of the Joker - press [START]), the room panel begins displaying

measured room temperature and the "no radio communication" alert icon (continuously).

To repeat pairing procedure, remove batteries from the room panel, reinsert them and (within 30 seconds) enter the "room

control panel" menu of the Joker main controller, select the parameter G3 and press [START]. A "successful" or "failed"

pairing message will appear on the main screen of the Joker controller. Additionally, before pairing procedure is repeated, it

may be useful to change radio communication channel - parameter G3 (to select channel - turn the knob).

When the room control panel and the main controller are not paired, the JOKER controller works like a version without a

room panel.

PAIRING OF THE PANEL WITH THE MAIN CONTROLLER (parameter G3)

12

SETTING TEMPERATURE BEHIND VALVE ON THE ROOM CONTROL PANEL

.............................................................................................................................................................................................

.............................................................................................................................................................................................

In order to set temperature behind valve on the room panel for the timed programme in use (indicated by one of three

icons ) - first, unblock touch buttons and then

- press the button - current boiler temperature will be displayed for 15 seconds;

- press the button within 15 seconds or - current setting of temperature behind valve begins flashing

and simultaneously one of two symbols will be displayed:

„L” (”low”) - means that room temperature has been reached

and that minimal temperature behind valve is edited.

„H” (”high”) - means that room temperature has not been

reached and maximal temperature behind valve is

edited.

Pressing the or button again will further increase or decrease setting. When setting has been changed,

after 15 seconds it will be registered and sent to the JOKER main controller.

The most important function of the room panel is to measure room temperature and to send it to the JOKER main

controller. When room temperature setting for a given time and day has been reached, the controller is working to

achieve the minimal temperature behind valve as set by the user. If room temperature has not been reached, the

controller will be working to achieve the maximal temperature setting behind valve.

Three different room temperatures may be selected: "day", "night" and "economy"(parameter G1). Additionally, room

temperature may be controlled through programmed time settings, different temperatures can be set for every day of

the week and every hour (parameter H1). The timed programme currently in use is displayed on the MAIN SCREEN

between

When room control panel is switched off, the JOKER controller works like a version without a room panel.

the CH pump icon and the boiler return temperature.

„LOW COAL LEVEL" ALERT ON THE ROOM PANEL

The room panel informs the user about low coal level (as set by the user) by displaying the icon in the right bottom

corner. In addition a short audible signal is repeated every minute. The audible signal is switched off when the user has

checked coal level in the hopper (expressed in %). In order to check coal level, press and hold the button. Parental

control does not need to be deactivated. The icon will be displayed. The audible alert is triggered only if the timed

programme "day" is in use. The audible alert can be switched off - set the I5 parameter to "NO".

Description of how coal consumption is estimated is found on page 15.

Press [MENU] to change parameters of the room panel. List of groups of parameters will appear on the screen. Turn the knob

right (clockwise) to select group "G - Room panel", and then to select press the knob or the [SELECT] button. "G1"- the first in

the group of parameters of the room panel will appear on the screen. Turn the knob right to go to the following parameters,

and then press [EDIT/SELECT] or the knob to change. At this point, you can change the value of a parameter either by turning

the knob or using the dynamically appearing buttons. Some parameters need to be selected for editing; use the [SELECT]

button and the knob.

Editing is confirmed by pressing the knob or the [SAVE] button.

Pressing [EXIT] will bring back the previous screen without saving any changes.

(moving between parameters and changing of settings - turn the knob):

G1a day (10,0-35,0°C, default: 21,0°C)

G1b night (10,0-35,0°C, default: 18,0°C)

G1c economy (10,0-35,0°C, default: 17,0°C)

Operation with

If "NO" has been selected, oker controller operation with is deactivated.

LIST OF ROOM PANEL PARAMETERS

G1 Room temperatures

G2 Precision of room temperature control - hysteresis (0,1-0,5°C, default setting: 0,2°C)

G3 Pairing of the room control panel with the Joker controller (press [START] to begin pairing) and

selection of radio communication channel

G4 room control panel

J the room panel Room panel

the room

icon and reading of temperature disappear from the main screen.

ROOM CONTROL PANEL PARAMETER MENU - group G

Current room temperature measured by the room control panel is displayed in the top left corner of the main screen of

the JOKER controller (see drawing below). Four symbols can appear together with temperature:

- room temperature setting not reached;

- room temperature setting reached;

- no room panel/failure of the room panel/communication failure in the room panel - the main controller works like

a version without remote control;

- communication failure in the Joker controller - the main controller works like a version without remote control.

Press

MENU pressing the knob or

the [SELECT] button

Turn the knob

to select

Room panel

13

current

room

temp.

TIMED PROGRAMMES - group H

Timed programmes are managed like parameters in MENU groups A to G.

14

Central heating timed programmes - parameter H1.

CAUTION - Central heating timed programmes are common for temperature behind valve

and room temperature settings.

Timed programmes of the domestic hot water tank - parameter H2.

This screen shows a chart of timed programmes (temperatures)

for the current day of the week.

Press SELECT or the knob

In this screen turn the knob to select a day of the week. You can see

the timed programmes chart (temperature) for the selected day.

Possible operations:

- press [SELECT] to edit the selected day

- press [COPY] to copy the settings for the selected day to another day

of the week which you select with the knob

Press SELECT or the knob

Press EDIT or the knob

In this screen, turn the knob to select time interval to be edited.

Press NEXT or the knob

In this screen, turn the knob to select the suitable programme -

"day", "night" and "economy".

On pressing the [SAVE] button the screen returns to selection of

the day of the week (see the second screen).

Once you press [NEXT], the symbol of timed programmes moves

to the following hour. Possible operations:

- press [EDIT] to change timed programme for selected hour (see

the screen above)

- turn the knob to select any hour for editing

- press [SAVE] to save changes and return to the screen of

selection of the day of the week (see the second screen).

Pressing [EXIT] will bring back the previous screen without saving any changes.

„day temperature” „night temperature” „economy temperature”

COAL CONSUMPTION - group I

Application

COAL CONSUMPTION function helps the user to monitor coal level in the coal hopper. Current coal

consumption is calculated based on volume of the hopper and efficiency of the stoker. Information about

current coal level in the hopper is provided as well. Alerts of the controller and of the room panel inform the

user that coal needs to be refilled. Additionally the user can monitor average coal consumption over time.

LIST OF PARAMETERS

NO, YES

(moving between parameters and changing of settings - turn the knob):

(YES, default: )

(YES, default: )

I1 Current estimated amount of coal in the hopper (0 - 100%, default setting 100%)

I2 Actual stoker efficiency required to estimate coal consumption (1.0-20.0 g/sec, default setting: 6.5 g/sec)

I3 Coal hopper volume (5-300 kg, default setting: 120 kg)

I4 Low coal level alert (1 - 50%, default setting 10%)

I5 Audible alert of low coal level on the room panel NO, YES

Detailed description of how coal consumption is monitored is available on page 12.

I6 Estimation of coal consumption

COAL CONSUMPTION PARAMETER MENU - group I

COAL CONSUMPTION SETTINGS

CAUTION:

It is advisable to verify the estimation of coal consumption performed by the controller from time to time - parameter I1. If it is

evidently different from real consumption, it can be corrected.

If real coal consumption is lower than calculated by the controller, decrease parameter I2 (stoker efficiency). If is higher than

calculated, increase the value of I2.

In order that coal level be calculated correctly, fill the hopper completely with coal and then correct the parameter I3 - Coal

hopper volume (default setting: 120 kg)

When coal level calculated by the controller drops below the value of the parameter I4 (default setting 10%) a red diode will

start flashing and the following icon will be displayed on the control screen (arrow flashing):

While adding coal into the hopper press [MODE] and then press [STOP] on the

[WORKING MODE] screen.

On pressing [STOP] a question will be displayed: "Have you refilled coal?"

If [YES] is selected, provide on the following screen how much coal was added and

confirm by pressing [SAVE] or press [MAX] if the hopper was filled completely.

The controller will update coal level in the hopper (parameter I1).

15

CONTROLER SETTINGS - group K

Controller settings are managed like parameters in MENU groups A to I.

CONTROLLER SETTINGS (moving between parameters and change of setting - turn the knob):

K1 Season of the year: SUMMER, WINTER (factory setting: WINTER).

and appear on the MAIN SCREEN when SUMMER has been selected.

K2 Holiday mode (1-28 days, default setting: 0 days = switched off) - over the selected period of time all economic settings

are active. "The text string "HOLIDAY" will appear on the MAIN SCREEN.

Press the [START] button to switch on the holiday mode for the number of days selected with the knob, press the [STOP]

button to switch off.

K3 Day of the week/hour (press the NEXT button or the knob to select day of the week, hour and minutes for edition)

K4 Time until the main screen is returned (10-240 secs, default setting: 60 secs) CAUTION - the controller does not return

automatically to the MAIN SCREEN from "manual mode" menus and the „Monitoring of devices and sensors”(par. J).

K5 Brightness after the main screen is returned (0-100%, default setting: 20%)

K6 Return to default settings (the controller will ask to confirm)

CAUTION: Return to default settings does not concern screen contrast (parameter K9), radio communication channel

(parameter G3), direction of valve turning (parameter E6), language (parameter K7) and inactive devices (parameters F8

and G4).

K7 Change language: Polish / Russian / English / Lithuanian / Czech

CAUTION: Return to default settings does not concern language.

K8 Information about the controller (model, software version 5.1 - 6.0) - read only

K9 Contrast of the display (1-31, default setting: 12 - CAUTION: return to default settings does not concern display contrast)

SEQUENCE OF CABLE CONNECTIONS

seen in the bottom view of the controller

ź controller

ź plastic tie straps - 4 pcs.

ź metal tie strap (for stoker sensor) - 1 pc.

ź wall mount - 1 pc.

ź rawlplug 6mm - 2 pcs.

ź IEC connector with screw terminals for valve actuator cable - 1 pc.

ź - 1 pc. (available as an option at an extra charge)vertical support

KIT COMPOSITION

top row – sensors and thermal breaker switch

Bottom row - power supply cables

Mains 230V

(length: 1.5m)

CH pump

(length: 1,5 m)

DHW tank pump

(length: 1,5m)

CH boiler sensor

(length: 1,8m) - black

DHW tank sensor

(length: 3m) - yellow

Sensor behind valve

(length:1,8m) - red

Stoker sensor

(length: 3m) - green

blower

(lenght: 1.5 m)

Boiler return sensor

(length: 1,8m) - white

S

16

Stoker

(length: 1,5 m)

Valve(length:1,5m)

GRAY

EXTENDING SENSOR CABLES

In case you require a longer temperature sensor cable please contact TMK at +48 503 141 201.

In case one of the sensors is disconnected (e.g. if domestic hot water tank is switched off - parameter F8), tape up

the unused connector to protect it from dust and humidity. In addition, wind and tie up unused cables with a tie

strap.

OPERATION WITHOUT HOT WATER TANK SENSOR

CAUTION: If return temperature sensor has not been installed or is damaged, the controller will not

activate the blower and stoker in the automatic mode - replace the sensor.

thermal breaker switch

(length: 1,8m) - blue

17

Pumps, blower, valve, stoker and the controller are protected by a 5A fuse which blows in case of malfunction

(such as a short circuit in one of the pumps, the blower, the valve, the stoker or the controller). Another

protection provided by the controller is a thermal breaker which switches off the blower (regardless of the

controller setting) when boiler temperature exceeds 90 °C, which may occur in case of mulfuction of a pump or

the controller itself. The thermal breaker returns to the initial position after temperature of the boiler has fallen

by some 30°C).

PROTECTION

WARRANTY

TMK sp.j. grants the user a warranty for the JOKER DS2PM-RC controller. The warranty period is 3

years from the date of purchase of the device, however not longer than 4 years from the date of

manufacture.

WARRANTY TERMS AND CONDITIONS

DATE OF SALE: ...................................

.............................

.....................................

DATE OF MANUFACTURE

day, month, year Seller's stamp and signature

MANUFACTURER:

Firma TMK sp.j.

62-300 Września

Szosa Witkowska 105

tel./fax +48 61 437 97 60

www.tmk.com.pl

Warranty claims shall be accepted provided that the terms and conditions of warranty, and general

rules of operation of electronic devices, are complied with as required. TMK sp.j. guarantees

appropriate workmanship, high quality and reliable operation of the controller. In the event of any

faults in the controller's operation, or defects which can be attributed to the manufacturer, TMK sp.j.

shall repair or replace the faulty controller with a defect-free device within 14 working days from the

date of returning the controller (in person or through post). The warranty scheme explicitly excludes all

defects arising due to the user's fault and, particularly, defects caused by mechanical damage, faulty

mounting, water ingress or operation of the device contrary to the general rules of operation of

electronic devices.

The warranty is only valid with a proof of purchase.

CHANGE LANGUAGE - parameter K7

The controller menu features a choice of five languages: Polish, Russian, ,

. To select language, press [MENU]. List of groups of parameters will appear on the screen.

Turn the knob right (clockwise) to select group "K - Controller settings", and then press the right

button or the knob. Turn the knob right (clockwise) to select parameter K7, and then press the

right button [SELECT] or the knob to choose language.

English Lithuanian and

Czech

Editing is confirmed by pressing the knob or the [SAVE] button.

Pressing [EXIT] will bring back the previous screen without saving any changes.

A flashing icon on the MAIN SCREEN replacing temperature reading means that the temperature

sensor is not working properly. Additionally, a visual alert is activated - a flashing yellow diode.

Failure of the stoker temperature sensor is also displayed on the MAIN SCREEN - stoker

If sensor failure occurs, the controller enters into emergency mode.

CAUTION: Manual mode overrides the emergency mode.

Table of contents