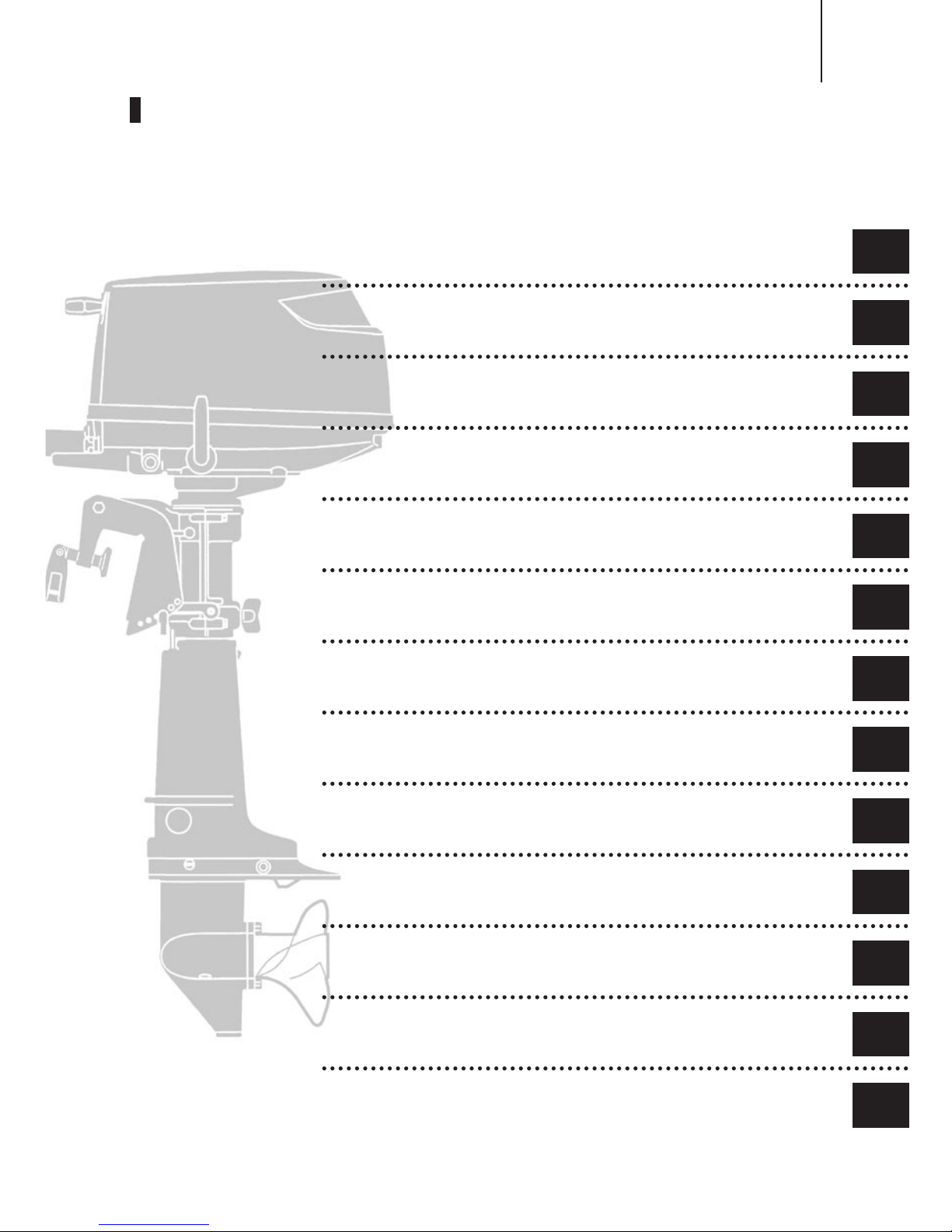

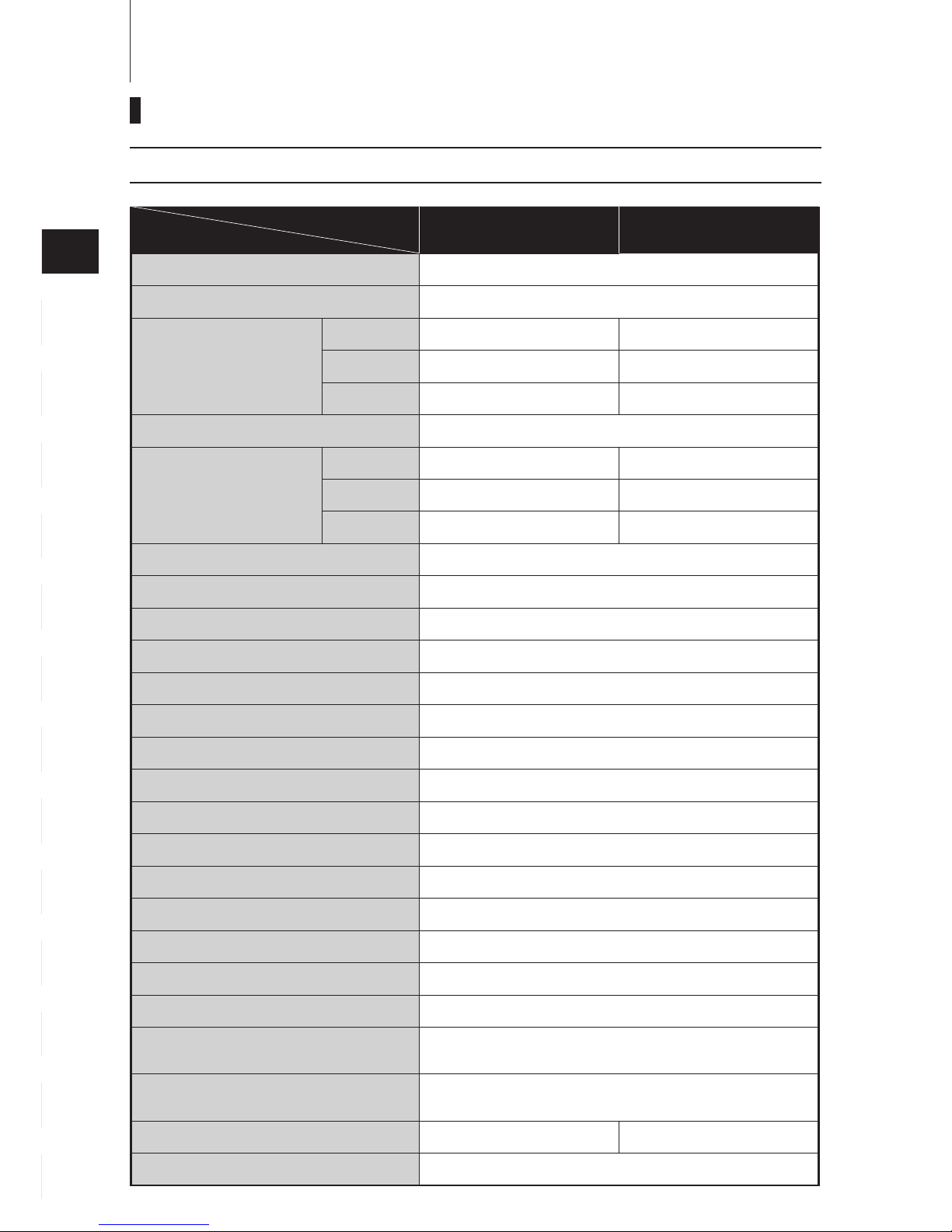

GENERAL SAFETY INFORMATION・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

SPECIFICATIONS・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

NAMES OF PARTS・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

INSTALLATION・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1. Mounting the outboard motor on boat・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

PRE-OPERATING PREPARATIONS・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1.Gasoline and engine oil・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

2.Break-in・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

3.Engine oil warning lamp ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

4.ESG ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

ENGINE OPERATION・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

Before starting・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1.Starting・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

2.Warming up the engine・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

3.Forward and reverse・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

4.Stopping・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

5.Trim angle・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

6.Tilt up, tilt down and shallow water operation ・・・・・・・・・・・・・・・・・・・・・・・・・

7.Shallow water operation・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

REMOVING AND CARRYING THE OUTBOARD MOTOR・・・・・・・・・・・・・・・・

1.Removing the outboard motor・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

2.Carrying the outboard motor・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

3.Storing the outboard motor・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

TRAILERING・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

ADJUSTMENT・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1.Steering friction・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

2.Throttle grip・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

3.Reverse lock・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

INSPECTION AND MAINTENANCE・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1.Daily inspection・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

2.Periodic inspection・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

3.Off-season storage・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

4.Pre-season check・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

5.Motor submerged in water ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

6.Cold weather precautions・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

7.Checking after striking underwater object ・・・・・・・・・・・・・・・・・・・・・・・・・・・・

TROUBLESHOOTING・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

TOOL KIT AND SPARE PARTS・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

OPTIONAL ACCESSORIES・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

PROPELLER TABLE・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

■

■

■

■

■

■

■

■

■

■

■

■

■

■

1

2

3

4

5

6

7

8

9

10

11

12

13

8

10

11

12

12

14

14

16

17

17

18

18

18

21

22

23

24

25

26

28

28

28

28

29

30

30

30

30

31

32

37

41

42

43

43

44

45

48

49

50

CONTENTS