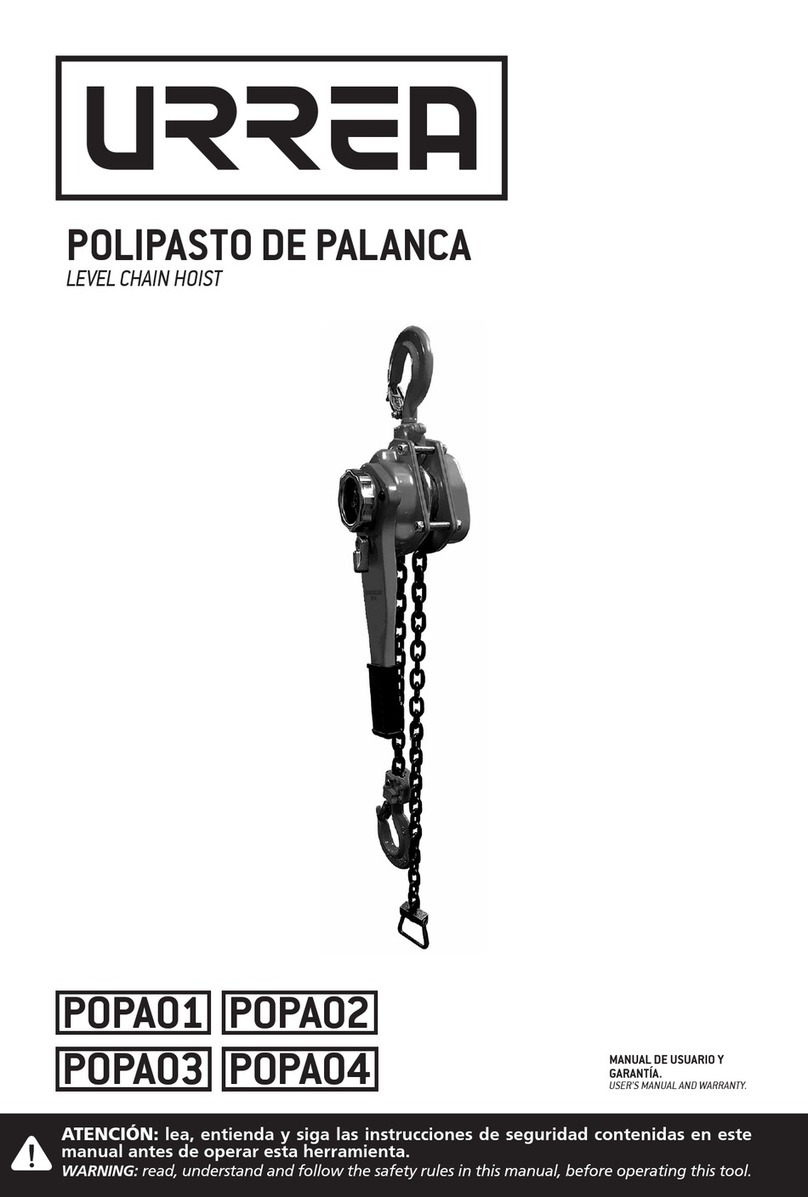

Application

With compacted design and enclosed body, this hoist is made of Aluminum,

has very light weight, easy to carry and widely be used in home, factory, filed

construction, agriculture, warehouse and so on for lifting and small equipment

installation purpose. It is also widely used in chemically industry and marine

industry where anti-corrosion properity required.

Features and Advantages

1.Compacted design, light weight, easy to carry.

2.Made of Aluminum alloy, safe and reliable with strong metallic visual sense.

3.Two-stage carburizing and quenching gear, high mechanical transmission

efficiency and durability

4.Double pawl brake system providing more safety

5.Special heat treated flexible hook, can be stretched, but will never break

6.Galvanized load chain and hand chain with high brightness.

Precaution

1.Do not pull chain inclinedly

2.Do not operate hoist over the rated load

3.Do not pull hoist other than manpower

4.Before use, check hoist and be sure no damage, gears and load chain are

well lubricated, no load operation works well.

5.Before lift, check and be sure the hoist has been well hooked and connected

with the object to move, hook latch be well closed, chain is vertical, no twisted

link, no kinked links

6.Operator should stand on hand wheel side, pull the chain to rotate wheel

clockwise for lift purpose. Change the direction to down loads slowly

7.Never lift people or load over people to avoid personal injury

8.Pull the chain uniform and gentle, do not give too much force to avoid chain

link jump or block

9.Stop operation if pulling effort is much larger than rated force to avoid inside

structure damage that may lead to loads falling

10.Detach hoist hook only when loads down to floor safely

11.After use, handle hoist gently, lubricated and keep in dry, ventilate area

Maintenance

1. Clean hoist after each use, keep in dry area to avoid rust and corrosion

2. Properly clean and lubricate the gear and bearing according to the usage

frequency

3. When assembly hoist, be sure the “0”mark on small gears well aligned and

on same line

4. When assembly brake system, be sure the ratchet gear teeth well

engaged with pawl spring tip. Pawl spring can control pawl sensitively. After

put on hand wheel, rotate wheel clockwise and press ratchet gear and brake

pad tightly on the brake disc. Rotate the hand wheel anticlockwise, there

should be small gap between wheel, ratchet gear and brake pad.

5. Never disassemble hoist by unqualified person

6. After each clean and maintenance, the hoist should be tested under no

load and under rated load for any new operation purpose.

7. During lubrication or operation, the brake disc should keep clean and

check frequently to be sure the brake system works well

P1