TOHO TTM-00BT Series Operating and maintenance manual

1

TOHO ELECTRONICS INC.

Multi-Channel Board Controller

Detailed Manual

Thank you very much for purchasing a Multi-Channel Board Controller.

The Multi-Channel Board Controller outputs control signals that match an input from

a thermocouple (a K/J thermocouple) or an input from a temperature input from a

resistance bulb (Pt100/JPt100) to a predetermined setting.

The product comes equipped with an RS-485 or an RS-232C for data

communications with a host computer.

For control output, the product is provided with up to eight open collector outputs,

along with event outputs consisting of 11 open collector outputs (eight temperature

alarm outputs, one heater wire break alarm, one SSR breakdown alarm, and one error

alarm), eight current detector inputs, and one voltage input.

Please read this detailed manual carefully and use this product correctly.

2

Contents

1. Operating precautions..........................................................................................................3

2. Names and functions of the components .............................................................................4

2.1 Product diagram......................................................................................................... 4

2.2 Names and functions ................................................................................................. 4

3. Installation ...........................................................................................................................5

3.1 How to install the product ......................................................................................... 5

3.2 Where to install the product....................................................................................... 5

3.3 Outside dimensions.................................................................................................... 6

4. Making the connections.......................................................................................................6

4.1 Terminal arrangement diagram.................................................................................. 6

4.2 Terminal arrangement................................................................................................ 7

4.3 Cautions on making the connections......................................................................... 9

5. Before conducting control....................................................................................................9

6. Table of identifiers (codes) ..................................................................................................9

7. Function description ..........................................................................................................16

7.1 Display range and set range of temperature input ................................................... 16

7.2 Display range and set range of current detector input ............................................. 16

7.3 Voltage input............................................................................................................ 16

7.4 Control output.......................................................................................................... 16

7.5 Temperature alarm output........................................................................................ 17

7.6 Heater wire break alarm output ............................................................................... 18

7.7 SSR breakdown alarm output.................................................................................. 18

7.8 Error alarm output ................................................................................................... 18

7.9 Communication ....................................................................................................... 18

8. Specifications and ratings ..................................................................................................32

8.1 General specifications.............................................................................................. 32

8.2 Ratings and performance......................................................................................... 32

9. Maintenance and inspection...............................................................................................33

3

1. Operating precautions

When the product reaches you, please ensure that the product you have received is of the following

model which you ordered.

Model: TTM−00BT−①−R−②

①Input type.........................0: Thermocouple input

1: Resistance bulb input

②Communication type:.......M1: RS-485

M2: RS-232C

To allow you to use the product safely, this detailed manual uses the following symbols:

Warning: Mishandling despite this warning may result in the user's death, electric shock,

burn, or other risk.

Caution: Mishandling despite this caution may result in the user's minor injury or product

damage.

Warnings

•Erroneously wiring a meter will cause a breakdown, possibly resulting in a fire or other incident. After

making the connections, therefore, always ensure that the correct wiring has been made before

energizing the meter.

•Remodeling the product will cause a breakdown, possibly resulting in a fire or other incident. Therefore

do not under any circumstances do any such thing.

•Please make sure that the package for the product contains the following:

* Product proper: 1 unit

* Operation manual: 1 copy

Should you find anything missing or a wrong model or any other inconvenience, please

contact our Sales Department. The contact details are at the end of this manual.

•Please deliver this detailed manual to the user. Please store it with care.

•Unauthorized reproduction or copying of a part or a whole of this manual is prohibited.

•Specifications in this detailed manual are subject to change without notice.

•We may not be able to take responsibility for a nonconformity or trouble resulting from the user's

operation of the product.

4

2. Names and functions of the components

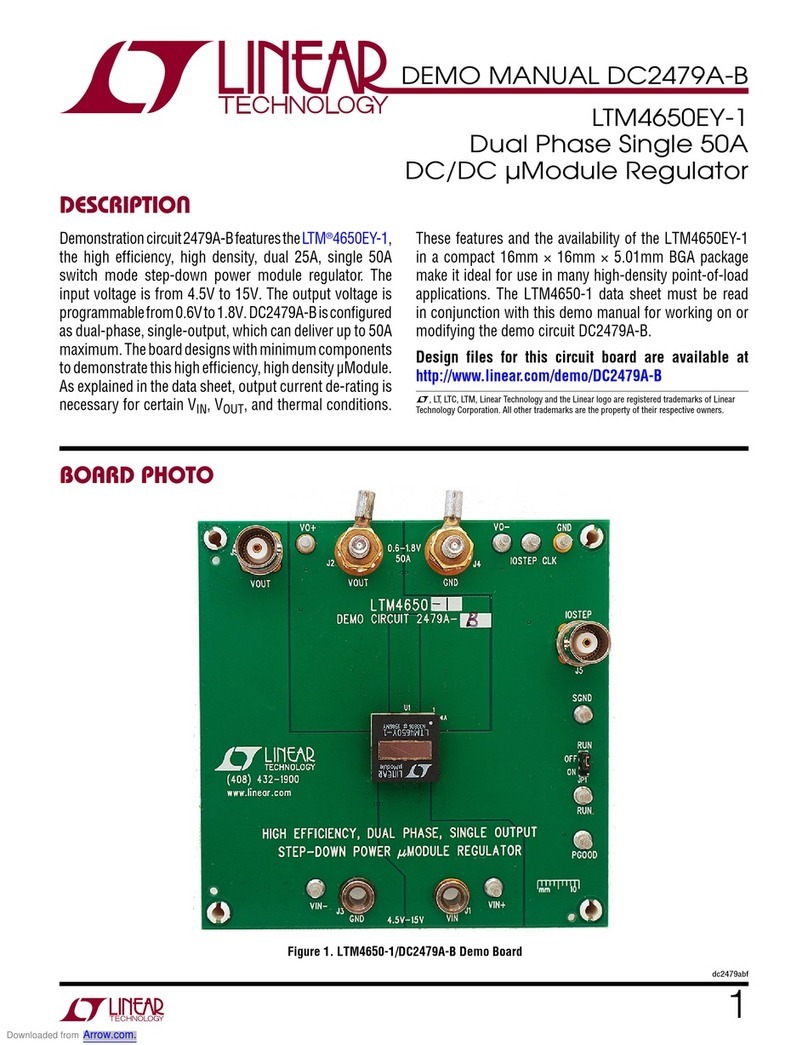

2.1 Product diagram

Event output Control output

CT input

Voltage

input Communi-

cation Power

Temperature

input

2.2 Names and functions

2.2.1 SW1: Unit number change --- Change product unit numbers with the rotary switch.

Unit number: 0 to F (hexadecimal)

2.2.2 SW2: Communication speed change --- Change the communication speed with DIP

switches.

Communication speed setting: 4800/9600/19200/38400 bps

2.2.3 CN1: Control output connector

Connector: XG4A-1634 (Omron) or equivalent (eight open collector outputs)

2.2.4 CN2: Event output connector

Connector: XG4A-1634 (Omron) or equivalent (eleven open collector outputs)

2.2.5 CN3: CT input connector

Connector: XG4A-1634 (Omron) or equivalent (eight CT inputs)

2.2.6 TB1: Temperature input terminal

Sensor input terminal for thermocouple input or resistance bulb input

Thermocouple input: Two-level terminal block: ML-740-W1BF-16P (a Sato part)

or equivalent

Resistance bulb input: Three-level terminal block: ML-740-W3BF-24P (a Sato

part) or equivalent

2.2.7 TB2: Power terminal

Power voltage terminal (power voltage: 24V DC + 10% -15%)

Through-type terminal block: ML-40-S1BYF-2P (a Sato part) or equivalent

2.2.8 TB3: Communication terminal

RS-485 or RS-232C communication terminal

Through-type terminal block: ML-40-S1BYF-3P (a Sato part) or equivalent

5

2.2.9 TB4: Voltage input terminal

Voltage input terminal (input voltage range: 12 to 24V DC ±10%)

Through-type terminal block: ML-40-S1BYF-2P (a Sato part) or equivalent

2.2.10 LED1: Communication A RXD lamp (green)

2.2.11 LED2: Communication B TXD lamp (green)

2.2.12 LED3: Power lamp (green)

2.2.13 LED4 to 11: Temperature alarm output lamps (red)

2.2.14 LED12: Alarm output lamp for heater wire break (red)

2.2.15 LED13: Alarm output lamp for SSR breakdown (red)

2.2.16 LED14: Error alarm output lamp (red)

2.2.17 LED15 to 22: Control output lamps (orange)

Recommended socket for connector

MIL type socket (with strain relief): XG4M-1630-T (manufactured by Omron)

3. Installation

3.1 How to install the product

•See "3.3 Outside dimensions" and install the product with nine screws (φ3.5).

•Install the board as floated by at least 5mm with a spacer or something similar.

•Install it horizontally. Or install it vertically with its power supply facing upwards.

•When installing two or more products of this kind, install them at least 50mm apart.

•Connecting crimp terminals: Use crimp terminals of specified dimensions (M3, no more than

6.9mm wide).

•Connecting exposed wires: Use wiring of AWG22 to 16.

•Terminal screws: Tighten them to a specified torque (about 0.5N-m). A loose screw may cause a

fire or malfunction.

3.2 Where to install the product

Please install the product in either of the following places:

•Places where the temperature, humidity, and other conditions are within the operating

environmental ranges

•Places free of dust, greasy fumes, and other foreign matter

•Places protected as much as possible from mechanical vibration, impact, and other external forces

•Places as far as possible from devices using high-pressure ignition equipment

•Places away from high-voltage lines, welding machines, and sources of electric noises

•Places free of sulfide gases and corrosive gases

•Places protected from direct sunlight

•Places protected from water splashes

•Places protected as much as possible from electromagnetic effects

6

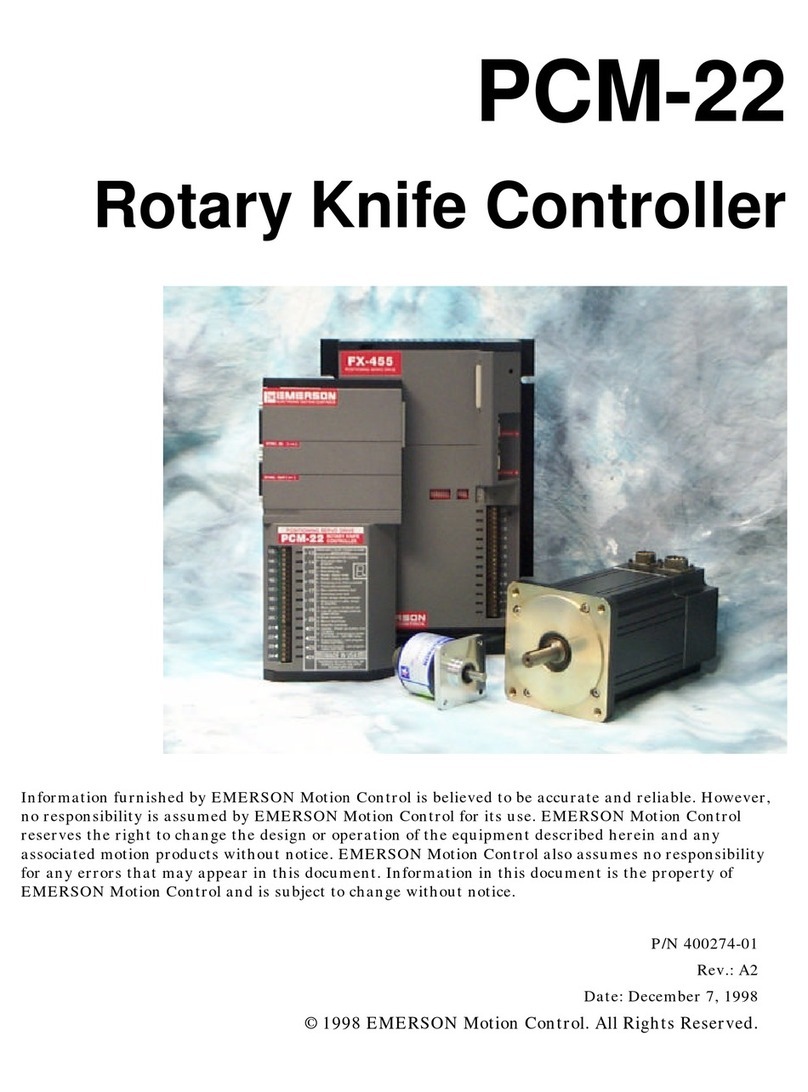

3.3 Outside dimensions

4. Making the connections

4.1 Terminal arrangement diagram

4.1.1 Thermocouple input

Board height

•Thermocouple input

29.2mm maximum

•Resistance bulb input

39.1mm maximum

(from the bottom of the board

to the top of the part)

9-

φ

3.5 drill

Sub-board 36

×

114.5

Event output

Control output

CT input Voltage

input Communi-

cation Power

Temperature input

7

4.1.2 Resistance bulb input

4.2 Terminal arrangement

4.2.1 Temperature input (TB1: terminal block): For thermocouple input

* For terminal numbers, see the carvings in the terminals.

Terminal

No. CH

Terminal

name Terminal

No. CH

Terminal

name Terminal

No. CH

Terminal

name Terminal

No. CH

Terminal

name

A1 +A3 +A5 +A7 +

B1 1

−B3 3

−B5 5

−B7 7

−

A2 +A4 +A6 +A8 +

B2 2

−B4 4

−B6 6

−B8 8

−

4.2.2 Temperature input (TB1): For resistance bulb input

Terminal

No. CH

Terminal

name Terminal

No. CH

Terminal

name Terminal

No. CH

Terminal

name Terminal

No. CH

Terminal

name

A1 AA3 AA5 AA7 A

B1 BB3 BB5 BB7 B

C1

1

bC3

3

bC5

5

bC7

7

b

A2 AA4 AA6 AA8 A

B2 BB4 BB6 BB8 B

C2

2

bb4

4

bC6

6

bC8

8

b

4.2.3 Power (TB2: terminal block)

Terminal

No. Polarity

Power

voltage

1+

2−24V

4.2.4 Communication (TB3: terminal block)

Terminal

No. RS-485 RS-232C

1ARXD

2BTXD

3SG

Event output

Control output

CT input Voltage

input Communi-

cation Power

Temperature input

8

4.2.5 Voltage input (TB4: terminal block)

Terminal

No. Polarity

1+

2−

4.2.6 Control output (CN1: connector)

Connector

No. CH Terminal

name

11O.C

21COM

32O.C

42COM

53O.C

63COM

74O.C

84COM

95O.C

10 5COM

11 6O.C

12 6COM

13 7O.C

14 7COM

15 8O.C

16 8COM

O.C.: open collector output

COM: common

4.2.7 Event output (CN2: connector) 4.2.8 CT input (CN3: connector)

Connector

No. CH Terminal name

Connector

No CH

11Temperature alarm 1 output O.C. 11

22Temperature alarm 5 output O.C. 21

33Temperature alarm 2 output O.C. 32

44Temperature alarm 6 output O.C. 42

55Temperature alarm 3 output O.C. 53

66Temperature alarm 7 output O.C. 63

77Temperature alarm 4 output O.C. 74

88Temperature alarm 8 output O.C. 84

91Temperature alarm 1 to 4 output COM 95

10 2Temperature alarm 5 to 8 output COM 10 5

11 3Alarm output O.C. for heater wire break

11 6

12 4Alarm output COM for heater wire break

12 6

13 5SSR breakdown alarm O.C. 13 7

14 6SSR breakdown alarm COM 14 7

15 7Error alarm O.C. 15 8

16 8Error alarm COM 16 8

O.C.: open collector output

COM: common

9

4.3 Cautions on making the connections

Warning

•Before making the connections, turn off this product. Otherwise you may get an electrical shock.

Warnings

•This product will not begin control for about 10 seconds after being turned on. (It will not activate its

outputs or other components.) Be careful if you wish to use the product as an interlocking circuit.

•Check the operation manual and other documents to ensure that you make the correct connections for

the temperature input terminal, power terminal, and other terminals.

•To connect a resistance bulb to this product, use wiring having a line resistance of no more than

5Ωper wire.

•To connect a thermocouple to this product, use a specified kind of compensating lead wire or

element wire.

•Use a shielded wire if you wish to use this product near a noise source. Do not wire an

input/output line in the same duct or conduit tube.

•Separate the input/output signal lines at least 50cm from the power line and load line.

5. Before conducting control

Selecting PID control Selecting ON/OFF control

This product is factory-configured to a "proportional

band" of 3.0. This product can conduct control in that

state. For better control, however, auto-tune (AT) this

product. AT automatically sets settings (values P, I, and

D) required for control. For AT, put this product into an

actual operating state (a state where the sensor input,

control output, and other components are wired). AT

takes some time.

This product is factory-

configured to a "sensitivity" of 0.

If conducting control causes the relay to flutter, increase

the sensitivity to reduce the flutter. If conducting

control causes this product to stabilize at a level lower

than the set temperature, increase the parameter "OFF

point" to change the ON/OFF point without changing the

setting.

6. Table of identifiers (codes)

a) Identifier: A code that represents an item. Enter the code into the identifier field in the message.

(The code is a three-digit figure.) The □in the frame represents SP (:space:ASCII code...20H).

b) Name: Item name

c) R/W: Specifies which function (read or write) is possible for an identifier into the current memory

bank, or whether both of those functions are possible.

r/w: Specifies which function (read or write) is possible for a memory bank other than the current

one, or whether both of these functions are possible. (This identifier can be read and written in a

memory bank.)

d) Description: Gives a description and specifies a set range and other details.

Note: For the R/W to a character not meeting the display conditions, this product responds with

"NAK2."

10

Parameter

a) Identifier b) Name c) R/W d) Description and set range e) Remark

Initial value (communication

numerical data)

TC, thermocouple;

Pt, resistance bulb

SV1

00000

Setting R/W

r/w R/W of the control settings

Thermocouple input:

Thermocouple K, 0.0 to 1300.0°C

Thermocouple J, 0.0 to 800.0°C

Resistance bulb input: PT100/JPT, -199.9 to 500.0°C

□CF

00000

Set a temperature unit R/W R/W of the °C/°F

°C: 00000

°F: 00001

Channel not specified

INP

TC: 00000

Pt: 00010

Set an input type R/W R/W of the input type settings

Thermocouple input models:

Thermocouple K: 00000

Thermocouple J: 00001

Resistance bulb input models:

Pt100: 00010

JPt: 00011

Neither the

thermocouple input nor

the resistance bulb

input can be changed.

PVG

00100

Set a PV correction gain R/W

r/w R/W of the PV correction gain setting

Set range: 0.50 to 2.00 times Measurement

Gain correction

PVS

00000

Set a PV correction zero

point R/W

r/w R/W of the PV correction zero setting

Set range: -199 to 999°C/-199.9 to 999.9°CMeasurement

Zero correction

PDF

00001

Set an input filter R/W R/W of the input filter setting

Set range: 0 to 99 seconds

□DP

TC: 00000

Pt: 00001

Set a decimal point R/W R/W of the decimal point setting

No decimal point: 00000

Decimal point provided: 00001

□AT

00000

Start/release AT R/W R/W of the AT start/release

Start: 00001

Release: 00000

The W is not possible

during ON/OFF

control.

11

Event output parameters

a) Identifier b) Name c) R/W d) Description and set range e) Remark

Initial value (communication

numerical data)

TC, thermocouple;

Pt, resistance bulb

E * F

*: 1 to 8

00000

Temperature alarm

output*functional setting R/W R/W of the temperature alarm output*functional

setting

000 **PV temperature alarm functions

Type

0

None

1

Deviation top/bottom limit alarm

Additional functions

2

Deviation top limit alarm

Type

3

Deviation bottom limit alarm

0

None

4

Deviation range alarm

1

Hold

5

Absolute value top/bottom limit

alarm

2

Standby sequence

6

Absolute value top limit alarm

3

Hold + standby

sequence

7

Absolute value bottom limit

alarm

8

Absolute value range alarm

*1

E * H

*: 1 to 8

00000

Set a temperature alarm

output*top limit R/W

r/w

R/W of the temperature alarm output*top limit setting

Set range: -199 to1500°C/-199.9 to 1500.0°C

*1

E * L

*: 1 to 8

00000

Set a temperature alarm

output*bottom limit R/W

r/w

R/W of the temperature alarm output*bottom limit

setting

Set range: -199 to1500°C/-199.9 to 1500.0°C

*1

E * C

*: 1 to 8

00000

Set a temperature alarm

output*sensitivity R/W R/W of the temperature alarm output*sensitivity

setting

Set range: -199 to1500°C/-199.9 to 1500.0°C

*1

CTF

00000

CT function R/W R/W of the presence or lack of an alarm about heater

wire break and SSR breakdown

00000: None

00001: Heater wire break alarm function

00002: SSR breakdown alarm function

00003: Heater wire break + SSR breakdown alarm

function

Heater wire break:

LED12

SSR breakdown:

LED13

C * I

*: 1 to 8

00000

CT allocation channel R/W R/W of the status about the channel to which CT*(1 to

8) should be allocated

00000: None (not allocated)

00001 to 00008: (CH)

Channel not specified

ALB

00000

Error alarm function R/W R/W of the presence or lack of memory errors, A/D

errors, and sensor error alarms

00000: None

00001: Present

Error alarm: LED14

CT*

*: 1 to 8

00000

Set an output current error R/W R/W of the current of the heater current detector

Set range: 0.0 to 50.0A AC Channel not specified

12

Voltage input parameters

a) Identifier b) Name c) R/W d) Description and set range e) Remark

Initial value (communication

numerical data)

TC, thermocouple;

Pt, resistance bulb

DIF

00000

Set a voltage input function

R/W R/W of the voltage input function setting

Numerical

data Function type When voltage is

applied

00000 None

00001 SV/SV2 function SV2

00002 RUN/READY function READY

00003 Auto/manual function Manual

00004 Forward/reverse operation

function Forward

operation

00005 Auto-tuning function AT start

00006 Forward operation

(SV2)/reverse operation

(SV) function

Forward

operation (SV2)

SV2

00000

Setting 2 R/W

r/w R/W of the control setting 2

Set range: SLL to SLH

Unit common parameters

a) Identifier b) Name c) R/W d) Description and set range e) Remark

Initial value (communication

numerical data)

TC, thermocouple;

Pt, resistance bulb

AWT

00000

Response delay setting R/W R/W of the response delay setting

Set range: 0 to 250mS Channel not specified

MBK

00001

Memory bank reading R/W Replaces the specified memory bank with the current

memory bank.

00001 to 00008 (example: memory bank 1 is 00001)

No writing is possible

during AT.

13

Monitor window parameters

a) Identifier

b) Name c) R/W d) Description and set range e) Remark

PV1 Measurement RUsed as a measurement monitor

When over-scale: HHHHH (the same is true when the

sensor has a wire break)

When under-scale: LLLLL

CM*

*: 1 to 8 CT measurement RR of the measured current of the heater current

detector

When over-scale: HHHHH

When reading is impossible: -----

When reading is

impossible: The CT

value cannot be read

unless the output of no

less than 190mS is

turned on.

DIM DI monitor RR of the voltage input monitoring

00000: State where voltage input is not applied

00001: State where voltage input is applied

OM1 Monitor the control output RR of the control output monitoring

000①②

①Output 1 state…1:ON/0:OFF

②Output 2 state…1:ON/0:OFF

*2

EM1 Monitor the temperature

alarm outputs 1 to 4 RR of the temperature alarm output monitoring

0①②③④

①: temperature alarm output 4

②: temperature alarm output 3

③: temperature alarm output 2

④: temperature alarm output 1

*3

EM2 Monitor the temperature

alarm outputs 5 to 8 RR of the temperature alarm output monitoring

0①②③④

①: temperature alarm output 8

②: temperature alarm output 7

③: temperature alarm output 6

④: temperature alarm output 5

*3

ALM Monitor the alarm output RR of the alarm monitoring

00①②③

①Alarm output of heater wire break (1:ON/0:OFF)

②Alarm output of SSR breakdown (1:ON/0:OFF)

③Error alarm output (1:ON/0:OFF)

14

Control parameters

a) Identifier b) Name c) R/W d) Description and set range e) Remark

Initial value (communication

numerical data)

TC, thermocouple;

Pt, resistance bulb

SLH

TC: 01200

Pt: 05000

Set an SV limiter top limit R/W R/W of the SV limiter top limit setting

From the bottom limit to the top limit of the set range

Provided that the difference from the SV limiter

bottom limit setting is no less than 50 digits.

For the range, see 7.1

on page 16.

SLL

TC: 0000

Pt: -1000

Set an SV limiter bottom

limit R/W R/W of the SV limiter bottom limit setting

From the bottom limit to the top limit of the set range

Provided that the difference from the SV limiter top

limit setting is no less than 50 digits.

For the range, see 7.1

on page 16.

□MD

00001

Set the control mode R/W R/W of the control mode setting

00000: Control stop (bottom limit output of the

operation quantity limiter)

00001: Control execution

00002: Manual control

CNT

00010

Set a control type R/W R/W of the control type setting

00①②③

①Function

0

Type A

1

Type B (overshoot inhibition function)

②Output 1 control type

0

None

1

PID control

2

ON/OFF control

③Output 2 control type (only during heating and

cooling control)

0

None

1

PID control

2

ON/OFF control

Type A:

General and

conventional PID

control

Type B:

Our company's unique

PID control with

reduced overshoot

*4

DIR

00000

Set a forward/reverse

operation switchover R/W R/W of the forward/reverse operation switchover

setting

00000: Reverse operation

00001: Forward operation

MV1

00000

Control output 1 operation

quantity R/W R/W of the control output 1 operation quantity

Display range: 0.0 to 100.0%

Set range: ML1 to MH1

TUN

00002

Set a tuning type R/W R/W of the tuning type setting

00001:Auto-tuning output 1

00002: Self-tuning output 1

00003:Auto-tuning output 2

00004: Self-tuning output 2

00005:Auto-tuning output 1/output 2

ATG

00010

AT factor R/W R/W of the AT factor

Set range: 0.1 to 10.0 times

ATC

00020

AT sensitivity R/W R/W of the AT sensitivity

Set range: 0 to 999°C/0.0 to 999.9°C

□P1

00030

Set control output 1,

proportional band R/W

r/w R/W of the control output 1, proportional band setting

Set range: 0.1 to 200.0%

□I1

00000

Set an integral time R/W

r/w R/W of the integral time setting

Set range: 0 to 3600 seconds

□D1

00000

Set a derivative time R/W

r/w R/W of the derivative time setting

Set range: 0 to 3600 seconds

□T1

00020

Set control output 1,

proportional period R/W

r/w R/W of the control output 1, proportional period

setting

Set range: 1 to 120 seconds

ARW

01000

Anti-reset windup R/W

r/w R/W of the Anti-reset windup

Set range: 0.0 to 100.0%

15

Control parameters

a) Identifier b) Name c) R/W d) Description and set range e) Remark

Initial value (communication

numerical data)

TC, thermocouple;

Pt, resistance bulb

MH1

01000

Set an operation quantity

limiter, top limit R/W

r/w R/W of the operation quantity limiter, top limit setting

Set range: Operation quantity limiter, bottom limit

setting to 100.0%

ML1

00000

Set an operation quantity

limiter, bottom limit R/W

r/w R/W of the operation limiter, bottom limit setting

Set range: 0.0 to operation quantity limiter, top limit

setting

□C1

00000

Set a control output 1,

control sensitivity R/W

r/w R/W of the control output 1, control sensitivity setting

Set range: 0 to 999°C/0.0 to 999.9°C

CP1

00000

Control output 1

Set an OFF point R/W

r/w R/W of the OFF point setting of control output 1

Set range: -199 to 999°C/-199.9 to 999.9°C

MV2

00000

Control output 2 operation

quantity R/W

r/w R/W of the control output 2 operation quantity

Display range: 0.0 to 100.0%

Set range: ML1 to MH1

□P2

00020

Set control output 2,

proportional band R/W

r/w R/W of the control output 2, proportional band setting

Set range: 0.10 to 10.00 times

(Magnification for output 1, proportional band)

□T2

00020

Set control output 2,

proportional period R/W

r/w R/W of the control output 2, proportional period

setting

Set range: 1 to 120 seconds

MH2

01000

Set an operation quantity

limiter, top limit R/W

r/w R/W of the operation quantity limiter, top limit setting

Set range: Operation quantity limiter, bottom limit

setting to 100.0%

ML2

00000

Set an operation quantity

limiter, bottom limit R/W

r/w R/W of the operation limiter, bottom limit setting

Set range: 0.0 to operation quantity limiter, top limit

setting

□C2

00000

Set a control output 2,

control sensitivity R/W

r/w R/W of the control output 2, control sensitivity setting

Set range: 0 to 999°C/0.0 to 999.9°C

CP2

00000

Control output 2

Set an OFF point R/W

r/w R/W of the OFF point setting of control output 2

Set range: -199 to 999°C/-199.9 to 999.9°C

PBB

00000

Manual reset R/W

r/w R/W of the manual reset

Set range: 0.0 to 100.0%

But -100.0 to +100.0% during heating/cooling control

□DB

00000

Set a dead band R/W

r/w R/W of the dead band

Set range: -100 to 100°C/-100.0 to 100.0°C

STR Save data WSave data

*1: If the control output 2 control type is ON/OFF control or PID control (if heating/cooling control is conducted), this product cannot be

used as a temperature alarm output.

*2: If the control output 2 control type is used as a temperature alarm output, the monitor for the control output of control output 2 is fixed at

0.

*3: If the control output 2 control type is used as ON/OFF control or as PID control, the temperature alarm output monitor is fixed at 0.

*4: If the control output 2 control type is set to "None": This product produces a temperature alarm output.

For ON/OFF control or PID control: This product performs heating/cooling control.

16

7. Function description

7.1 Display range and set range of temperature input

7.1.1 Display range and set range of thermocouple input (JIS C 1602 -1995)

Set range with a

decimal point Display range with a

decimal point Set range without a

decimal point Display range without

a decimal point

K (JIS) 0.0 to 1300.0°C-40.0 to 1326.0°C0 to 1300°C-40 to 1326°C

J (JIS) 0.0 to 800.0°C-31.0 to 850.0°C0 to 800°C-31 to 850°C

7.1.2 Display range and set range of resistance bulb input (JIS C 1604 -1997)

Set range with a

decimal pointDisplay range with a

decimal point Set range without a

decimal point Display range without

a decimal point

Pt100 (JIS)

JPt100 (JIS)

-199.9 to 500.0°C-199.9 to 539.1°C-199 to 500°C-199 to 539°C

7.2 Display range and set range of current detector input

7.2.1 Display range and set range: 0.0 to 50.0A AC

7.3 Voltage input

7.3.1 Voltage input: Entering a voltage (12 to 24V DC) from outside enables the selection of

functions from "7.3.2. Voltage input functions."

7.3.2 Voltage input functions

Function type When voltage is applied

None

SV/SV2 function SV2

RUN/READY function READY

Auto/manual function Manual

Forward/reverse operation function Forward operation

Auto-tuning function AT start

Forward operation (SV2)/reverse operation (SV) function Forward operation (SV2)

7.4 Control output

Control output is ensured by open collector output. Control operations can be selected from

heating control or heating/cooling control (types A and B). Setting the output 2 control type to

"ON/OFF control" or "PID control" activates heating/cooling control.

Note that heating/cooling control is fixed at control output on the side of heating output, and at

temperature alarm output on the side of cooling output. See the table below for the allocation of

control outputs and temperature alarm outputs for heating control and heating/cooling control.

Heating control Heating/cooling control

Input

Control output Temperature alarm

output Control output Cooling output (temperature alarm output

is used as cooling output)

1CH

2CH

3CH

4CH

5CH

6CH

7CH

8CH

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

17

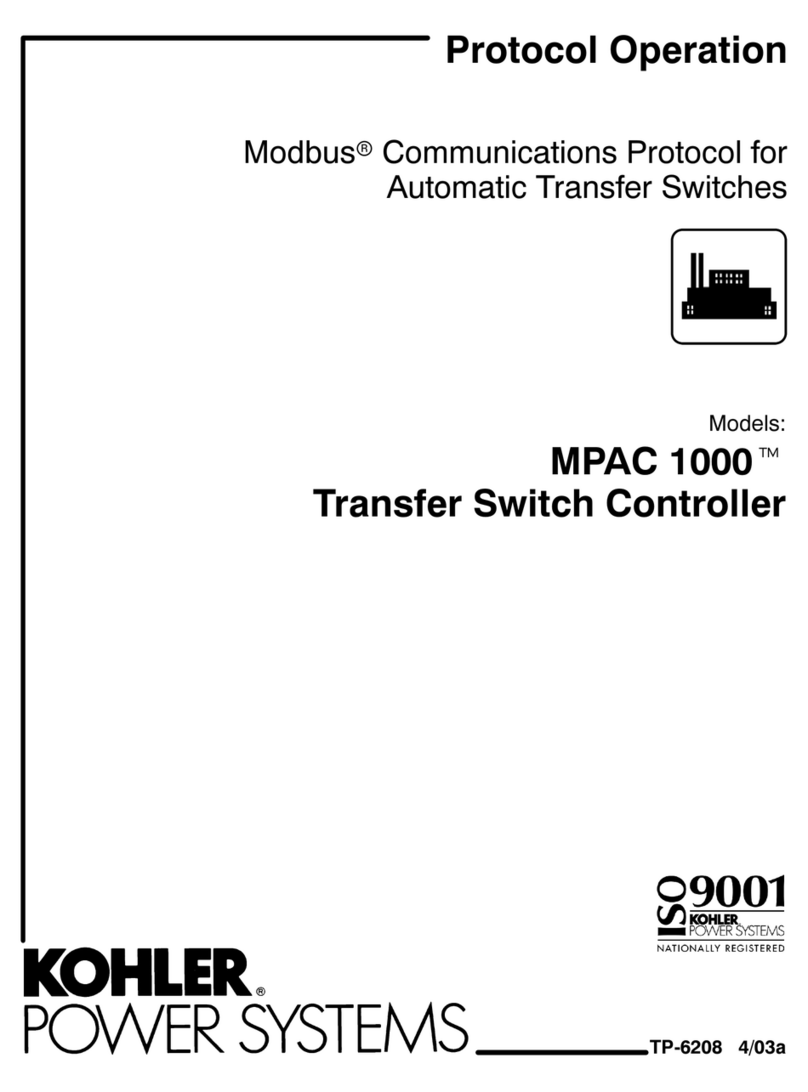

7.5 Temperature alarm output

7.5.1 Temperature alarm output: Compare the measurements with the setting value of the

temperature alarm output and turn on and off the temperature alarm output.

•Operation table of temperature alarm outputs

1. Deviation top/bottom limit

5. Absolute value top/bottom limit

E*C

SV

E*C

E*L E*H

△

0℃(v)

E*C E*C

E*L E*H

2. Deviation top limit 6. Absolute value top limit

SV

E*C

E*H

△

0℃(v)

E*C

E*H

3. Deviation bottom/limit 7. Absolute value bottom limit

E*C

SV

E*L △

0℃(v)

E*C

E*L

4. Deviation top/bottom limit range 8. Absolute value top/bottom limit range

E*C

SV

E*L E*H

△

E*C

E*C E*C

0℃(v) E*L E*H

Operation range of temperature alarm output: E*L, bottom limit setting of temperature alarm output; E*H, top

limit setting of temperature alarm output; E*C, temperature alarm sensitivity

7.5.2 Additional functions

•Standby sequence

This function inhibits temperature alarm output even if the conditions are met for temperature

alarm output when this product is turned on. Temperature alarm output is generated only when

this product deviates from the conditions for temperature alarm output and satisfies those

conditions again. This function is used for bottom temperature alarm output when this product

is turned on. This function is enabled when this product is turned on in the shaded portion in

the operation table of temperature alarm outputs.

[How to cancel this function]

This function is canceled when this product is activated or when either of the following setting is

changed: target, temperature alarm, PV correction, and temperature alarm setting.

•Temperature alarm output holding

When a temperature alarm output is generated, this function retains that state. Even if this

product deviates from the conditions for temperature alarm output, the temperature alarm output

will remain on.

[How to cancel this function]

To cancel this function, turn this product off and back on or disable the additional function for

temperature alarm output setting.

0C (

°

F)

0C (

°

F)

0C (

°

F)

0C (

°

F)

18

7.6 Heater wire break alarm output

The output will be turned on if a heater wire break (no output even if the output is turned on)

remains for at least 190mS.

7.7 SSR breakdown alarm output

The output will be turned on if an SSR breakdown (there is output even if the output is off) remains

for at least 190mS.

7.8 Error alarm output

The output will be turned on in the case of a memory error, A/D error, or sensor error.

7.9 Communication

7.9.1 What can be done by communication

Communication allows you to read and write data in "Changing settings" and "Reading

information" and other items specified in "6. Table of identifiers."

However, reading and writing with ordinary commands are conducted on the RAM inside this

product. Turning this product off and back on will restore the written data back to what it was

before the writing (the values saved on the EEPROM).

To save written data on the EEPROM of this product, execute the data storage request message

(STR).

(See "7.9.10 Communication precautions.")

7.9.2 Pre-communication settings:

Before communication, this product must be set to initial settings for "setting a communication

speed" and "setting a unit number."

1) "Setting a communication speed": Set this value with DIP switches.

Use DIP switches 1 and 2. Always turn the 3 and 4 to OFF.

Following are the possible combinations.

DIP switch

1234Communication

speed

OFF

ON

OFF

ON

OFF

OFF

ON

ON

Reserved

Reserved

4800 bps

9600 bps

192000 bps

384000 bps

Initial setting: 1: ON, 2 to 4: OFF (9600 bps)

2) "Setting a unit number": Set this value with the rotary switch.

Set a unit number in a hexadecimal number (0 to F).

Initial setting: 0 (unit No. 00)

3) "Setting a response delay": Set a time to be taken from the time when a high-level computer

finishes transmitting a "request message" to the time when the line is delivered and this

product enters an input state.

•Set range: 0 to 250mS

•Initial value: 0mS

* Notes: An insufficient response delay may result in abnormal communication. Note also

that, in real operations, the processing time of this product will be added to the

response delay.

*Caution: Before "setting a communication speed" and "setting a unit number," always

turn off this product.

19

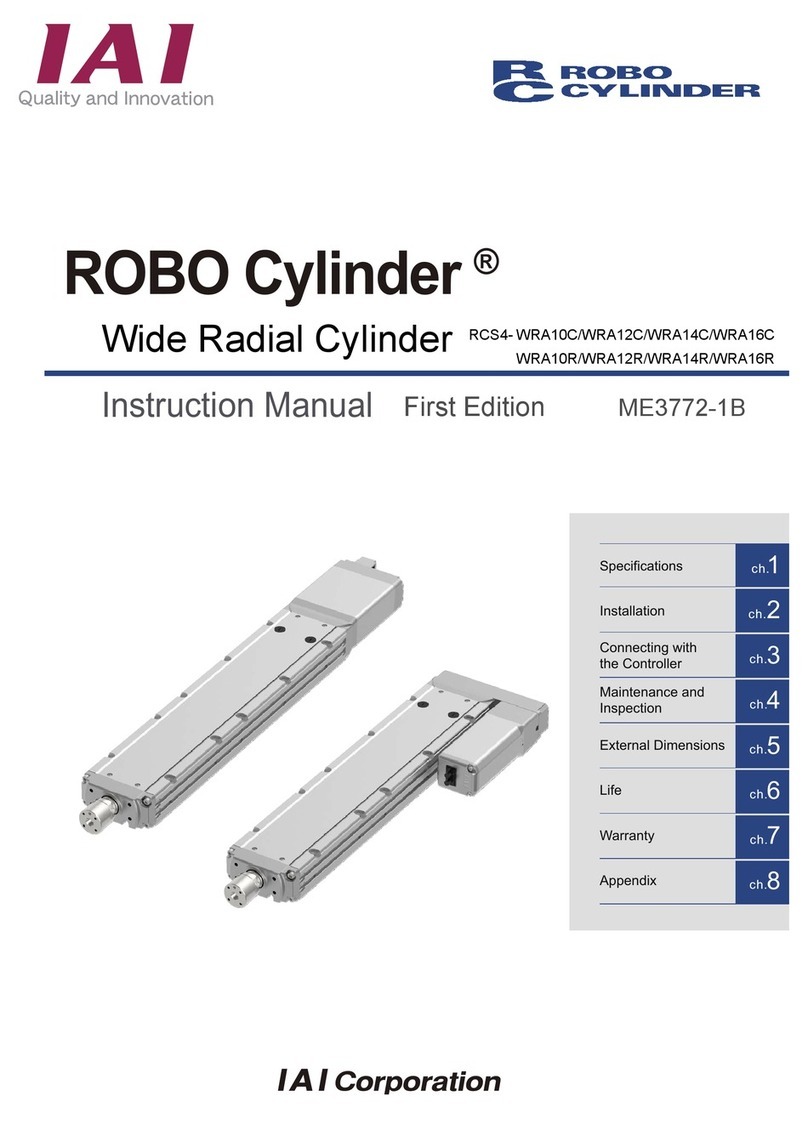

7.9.3 Communications procedure

This product returns a "response message" in response to a "request message" from a high-level

computer. It therefore does not initiate a transmission.

上位コンピュータ

本器

要求メッセージ

要求メッセージ

要求メッセージ

要求メッセージ

上位コンピュータが

送信 本器が

送信 上位コンピュータが

送信 本器が

送信

0〜250ms 1ms以上

応答遅延時間

「2.8 応答遅延時間の設定」参照

「3.7.1 送受信タイミング」参照 「3.7.2 要求間隔」参照

7.9.4 Message types

nMessages are roughly divided into the following types:

Read request message

Write request message

Store request message

Request message (transmitted

from a high-level computer) Response message (transmitted

from this product)

Receipt acknowledgement and data

response

Write complete response

Reception error and error description

response

Store complete response

: Response when a normal "request message" is received

: When a received "request message" contains an error

"7.9.5 1)", "3.5.1"

"7.9.5 2)", "3.5.2"

"7.9.5 3)"

"7.9.6 1)"

"7.9.6 2)"

"7.9.6 3)"

"7.9.6 2)"

nAll codes (except for BCC) from STX and data to ETX are expressed in ASCII codes.

nIn assembling a program for a high-level computer, see "6. Table of identifiers" and "7.9.13.

Table of ASCII codes" at the end of the book.

20

7.9.5 Composition of a request message (transmitted from a high-level computer to

this product)

nFor codes ①to ⑧, see "7.9.9 Code description."

nFor specific examples of request messages, see "7.9.11 Examples of communications to be

read" and "7.9.12 Examples of communications to be written."

1) Composition of a read request message

S

T

X

□

□

R

□

□

□

E

T

X

B

C

C

①

②

③

④

―⑤― ⑦

⑧

Start code

Unit number

Channel

Contents of the

request: read

Identifier

End code

BCC data

2) Composition of a write request message

S

T

X

□

□

W

□

□

□

□

□

□

□

□

E

T

X

B

C

C

①

②

③

④

―⑤― ―――⑥――― ⑦

⑧

Start code

Unit number

Channel

Contents of the

request: write

Identifier

Numerical data

End code

BCC data

3) Composition of a store request message

S

T

X

□

□

W

S

T

R

E

T

X

B

C

C

①

②

③

④

―⑤― ⑦

⑧

Start code

Unit number

Channel

Contents of the

request: write

Identifier

End code

BCC data

Table of contents

Other TOHO Controllers manuals