Solcon HRVS-DN series User manual

H

HR

R

V

VS

S-

-D

DN

N

M

Me

ed

di

iu

um

m

V

Vo

ol

lt

ta

ag

ge

e

D

Di

ig

gi

it

ta

al

l

S

So

of

ft

t

S

St

ta

ar

rt

te

er

r

6

60

0-

-1

1,

,2

20

00

0A

A,

,

2

2,

,3

30

00

0-

-1

15

5,

,0

00

00

0

V

V

I

In

ns

st

t

r

ru

uc

ct

ti

io

on

n

a

an

nd

d

C

Co

om

mm

mi

is

ss

si

io

on

ni

in

n

g

g M

Ma

an

nu

ua

al

l

Ver.27/12/2010

2 • List of Figures

_____________________________________________________________________________________________

HRVS-DN Instruction and Commissioning Manual

Table of Contents

1.List of Figures...........................................................................................................................6

2.Safety & Warnings ....................................................................................................................8

2.1Safety..........................................................................................................................................8

2.2Attention......................................................................................................................................8

2.3Warnings.....................................................................................................................................8

3.Introduction...............................................................................................................................9

3.1Why Solcon? Why Soft Starters?................................................................................................9

3.2How Soft Starters Work? ..........................................................................................................10

Main Features, Options and Advantages ........................................................................................11

4.Technical Data ........................................................................................................................13

4.1HRVS-DN IP00 Unit (OEM Kit).................................................................................................13

4.2Typical Connection of the HRVS-DN IP00 Unit (OEM Kit) .......................................................14

4.3Typical Connection of the HRVS-DN in a Cabinet....................................................................15

4.3.1Typical Connection of HRVS-DN up to 6.6kV ...............................................................15

4.3.2Typical Connection of HRVS-DN from 10kV and up.....................................................16

4.4HRVS-DN Selection..................................................................................................................17

4.4.1Motor Current and Starting Conditions..........................................................................17

4.4.2PIV (Peak Inverse Voltage)...........................................................................................17

4.4.3Rated Currents Frame Sizes.........................................................................................18

4.5Ordering Information.................................................................................................................19

4.5.1Ordering IP00 Unit (OEM kit) ........................................................................................19

4.5.2Ordering a Cabinet Installed Soft Starter ......................................................................21

4.6Power Connections Description................................................................................................23

4.7Control Connections Description ..............................................................................................24

4.7.1Input Terminal 7 - Test/Reset/MULTI SOFT STOP.......................................................30

4.7.2Input Terminal 8 - Dual Adjust/Reset ............................................................................30

4.7.3Output Terminals 10, 11 & 12 – Immediate/# Strts PreAlarm .......................................30

5.Recommended Wiring Diagrams ..........................................................................................31

5.1Control Supply and Control Inputs From a Single Source ........................................................31

5.2Separate Sources for Control Supply and Control Inputs.........................................................31

5.3Three Separate Sources for Control Supply and Control Inputs...............................................32

5.4Soft Start and Immediate Stop (No Soft Stop)..........................................................................32

5.5Soft Start and Soft Stop wiring..................................................................................................33

5.6Soft Start, Soft Stop and Immediate Stop Wiring......................................................................33

5.7Soft Start, Soft Stop and Stop...................................................................................................34

5.8External Fault............................................................................................................................34

5.9Dual Adjustment (Control Input #8)...........................................................................................34

5.10Bypass Contactor......................................................................................................................35

5.11Operating via Communication Links .........................................................................................36

5.12Control Input #7 ........................................................................................................................37

5.13Control Input #8 ........................................................................................................................37

6.Installation of IP00 (OEM Kit) in a Cabinet ...........................................................................38

6.1Mounting ...................................................................................................................................38

6.1.1Low Voltage Section......................................................................................................39

6.2Temperature Range & Heat Dissipation ...................................................................................39

6.3Control Module Main PCB and Optional PCBs.........................................................................40

6.4Dip Switch Settings on the Main PCB.......................................................................................40

6.4.1Switch # 1 – Display Modes ..........................................................................................40

6.4.2Switch # 2 – Tacho Feedback (0-10VDC).....................................................................41

6.4.3Switches # 4, 5 & 6 – Language Selection...................................................................41

6.4.4Switch # 7 – Extended Settings.....................................................................................42

6.4.5Switch # 8 – Software Lock...........................................................................................42

6.5Analog I/O (Option 5) (Terminals Gnd, Out (-), Out (+)) ..........................................................43

3 • List of Figures

_______________________________________________________________________________________________

6.6Insulation test (Option 4) (Terminals 25, 26, 27 and Leak).....................................................44

6.7Remote Key-Pad Installation ....................................................................................................45

7.Control Keypad .......................................................................................................................47

7.1LCD Arrangement.....................................................................................................................47

7.2Push-Buttons ............................................................................................................................47

7.3Status LEDs..............................................................................................................................48

7.4Reviewing and Modifying Parameters ......................................................................................48

7.5Upon first Control Voltage Connection......................................................................................48

7.6Special Actions Performed in TEST/MAINTENANCE Mode ....................................................48

7.6.1Run Self Test.................................................................................................................48

7.6.2View Software Version ..................................................................................................49

7.6.3Obtain Default Parameters............................................................................................49

7.6.4Reset Statistical Data....................................................................................................49

7.6.5Calibrate Voltage and Current (Factory Use Only!).......................................................50

7.6.6Setting Time and Date...................................................................................................50

7.7Mode Pages..............................................................................................................................51

7.8Overview of All Mode Pages and Factory Defaults...................................................................52

7.8.1Display Mode – Page 0 .................................................................................................54

7.8.2Main & Protect. – Page 1 ..............................................................................................55

7.8.2.1Tripping Curves of the Integrated Overload Protection ..........................................58

7.8.3Start Parameters – Page 2............................................................................................60

7.8.3.1Soft Start Parameters.............................................................................................65

7.8.3.2Special Control for Synchronous Motors Excitation ...............................................66

7.8.4Stop Parameters – Page 3............................................................................................67

7.8.4.1Soft Stop Parameters .............................................................................................68

7.8.5Dual Adjustment Parameters – Page 4.........................................................................70

7.8.6Fault Parameters – Page 5 ...........................................................................................71

7.8.7I/O Programming Parameters – Page 6........................................................................73

7.8.7.1Terminal 7 and 8 Programming..............................................................................74

7.8.8Comm. Parameters – Page 7 – With the Optional Modbus PCB ..................................75

7.8.9Comm. Parameters – Page 7 – With the Optional Profibus PCB..................................75

7.8.10Comm. Parameters – Page 7 – With the Optional DeviceNet PCB ..............................76

7.8.11Statistical Data – page 8 ...............................................................................................77

8.Motor and Soft Starter Protection .........................................................................................78

8.1Adjustable Protection Functions ...............................................................................................78

8.1.1UNDER CURRENT .......................................................................................................78

8.1.2O/C –SHEAR PIN..........................................................................................................78

8.1.3OVERLOAD ..................................................................................................................78

8.1.4UNBALANCE CURRENT..............................................................................................78

8.1.5GROUND FAULT..........................................................................................................78

8.1.6UNDER/NO VOLTAGE .................................................................................................79

8.1.7OVER VOLTAGE ..........................................................................................................79

8.1.8LONG START TIME......................................................................................................79

8.1.9OPEN BYPASS.............................................................................................................79

8.1.10SET CURVE TO 0.........................................................................................................79

8.1.11PWR ON & NO STRT ...................................................................................................79

8.1.12MOTOR INSULATION ..................................................................................................79

8.1.13PHASE SEQUENCE.....................................................................................................79

8.1.14TOO MANY STARTS....................................................................................................80

8.1.15MODBUS TIME OUT ....................................................................................................80

8.1.16SET TIME & DATE........................................................................................................80

8.1.17COAST DOWN TIME....................................................................................................80

8.2Non Adjustable Protection Functions........................................................................................80

8.2.1UNDER/OVER FREQUENCY.......................................................................................80

8.2.2PHASE LOSS................................................................................................................80

8.2.3WRONG PARAMETERS ..............................................................................................80

8.2.4STORAGE ERROR.......................................................................................................80

8.2.5S. SCR OR WR. CON ...................................................................................................81

8.2.6OVER TEMPERATURE ................................................................................................81

4 • List of Figures

_____________________________________________________________________________________________

8.2.7EXTERNAL FAULT 1 & EXTERNAL FAULT 2 ............................................................81

8.2.8COMM. PORT FAILED .................................................................................................81

8.3Fault and Reset ........................................................................................................................81

8.4Auto Reset ................................................................................................................................82

8.5Timing Occurrence Table..........................................................................................................82

9.Packing, Storage, Handling and Assembly..........................................................................84

9.1Packing Specification................................................................................................................84

9.2Storage .....................................................................................................................................84

9.3Handling....................................................................................................................................84

9.4Soft starter’s Assembly Procedure:...........................................................................................85

9.4.1Mechanical Assembly....................................................................................................85

9.4.2Power and Control Cable Connections .........................................................................86

9.4.3Power Cables Connection.............................................................................................86

10.Commissioning and Operation Manual ................................................................................87

10.1Operational notes......................................................................................................................87

10.2Parts Identification in the HRVS-DN Cabinet............................................................................88

10.2.1Parts Identification in the HRVS-DN Cabinet (HRVS-DN up to 6.6kV) .........................88

10.2.2Parts Identification in the HRVS-DN Cabinet (HRVS-DN from 10kV and up) ...............90

10.2.3Low Voltage Compartment............................................................................................92

10.2.4Fuses.............................................................................................................................93

10.3Standard Control Diagram ........................................................................................................95

10.3.1How Does it Operate?...................................................................................................98

11.High-Pot Test of the HRVS-DN Cabinet ..............................................................................100

11.1High-Pot Test in HRVS-DN up to 6.6kV, EPT-Tx Connected.................................................100

11.2High-Pot Test in HRVS-DN up to 6.6kV, EPT-Tx Not Connected ..........................................101

11.3High-Pot Test in HRVS-DN from 10kV and Up, EPT-Tx Connected ......................................103

11.4High-Pot Test in HRVS-DN from 10kV and Up, EPT-Tx Not Connected................................104

12.Test Procedure for Low Voltage Testing............................................................................106

12.1Accessories Required for LOW VOLTAGE Testing of the Starter and Cabinet......................106

12.2Notes and Warnings ...............................................................................................................106

12.3Low Voltage Test Procedure...................................................................................................107

12.3.1Current Gain Dip Switches Setting..............................................................................110

12.3.2Test Harness Installation.............................................................................................110

12.3.2.1Test Harness Installation in HRVS-DN up to 6.6kV .............................................110

12.3.2.2Test Harness Installation in HRVS-DN from 10kV and up ...................................111

13.Start Procedure for Medium voltage Motor........................................................................112

13.1Special Attention Notes...........................................................................................................112

13.2Prior to Commissioning in Medium Voltage............................................................................112

13.3Medium Voltage Test Procedure ............................................................................................113

13.4Standard Starting Process......................................................................................................

114

13.5Examples of Starting Curves ..................................................................................................115

13.5.1Light Loads - Pumps, Etc. ...........................................................................................115

13.5.2High Inertia Loads: Crushers, Centrifuges, Mixers, Etc. .............................................115

13.5.3Special Starting Using DUAL ADJUSTMENT .............................................................116

13.5.3.1Special Starting – Using DUAL ADJUSTMENT – Wiring Diagram ......................117

13.5.4Choosing a Suitable Pump Curve (Centrifugal Pumps) ..............................................117

13.5.4.1Starting Curve ......................................................................................................117

13.5.4.2Stopping Curve.....................................................................................................117

13.5.4.3FINAL TORQUE During Soft-Stopping a Pump Motor.........................................118

13.6How to set MPS-3000 and DPM-10 when installed with HRVS-DN .......................................118

14.Trouble Shooting ..................................................................................................................120

14.1In-Out Resistance and Cathode-Cathode Resistance............................................................120

14.2Rgk (thyristors Gate-Cathode) Resistances. ..........................................................................120

14.3Firing Test...............................................................................................................................121

14.4Low Voltage Test Trouble Shooting........................................................................................123

5 • List of Figures

_______________________________________________________________________________________________

14.5Medium Voltage Trouble shooting ..........................................................................................127

15.Spare Parts............................................................................................................................130

16.HRVS-DN Communication (ModBus Protocol) ..................................................................131

16.1Introduction .............................................................................................................................131

16.2Basic Structure of the Serial Link Frame ................................................................................132

16.3SYNC (Silent Interval).............................................................................................................132

16.4Serial Link No. (Slave Address).............................................................................................132

16.5Function ..................................................................................................................................132

16.6List of Functions Supported By The HRVS-DN ......................................................................133

16.7Actual Data (3X References & 4X references) .......................................................................135

16.8Parameter Settings (4X References)......................................................................................138

16.9Control Register Write (4X Reference) ...................................................................................142

16.10Discrete Commands (Coils, 0x References)......................................................................143

16.11Discrete Hardwired Inputs (1x References).......................................................................146

16.12Diagnostics .........................................................................................................................146

16.13Exception Responses .........................................................................................................147

17.HRVS-DN Communication (Profibus protocol)..................................................................149

17.1Global Parameters:.................................................................................................................149

17.2Operation Mode in PROFIBUS:..............................................................................................149

17.3Description of the DPV0 (Cyclic) Frame: ................................................................................149

17.3.1Structure of the HRVS-DN Receiving Frame ..............................................................150

17.3.2Structure of the HRVS-DN Transmitting Frame ..........................................................150

17.3.3Choosing the Receiving DPV0 Registers....................................................................150

17.3.3.1Selection of the DPV0 Registers by the GSD ......................................................151

17.3.3.2Selection of the DPV0 Registers through Data Request (DPV1) .........................151

17.3.3.3Reading of the DPV0 (Cyclic) Registers via Data Request (DPV1) .....................153

17.4Operations that are Available in DPV1 ...................................................................................154

17.4.1Read and Write from Random Registers via Data Request........................................154

17.5Configure the PROFIBUS in the HRVS-DN............................................................................156

17.6Watch Dog Definition ..............................................................................................................156

17.7Numbers of actual data Register for (decimal) .......................................................................157

17.8Number of Setting Registers for Data Request.......................................................................161

17.8.1Main & protect. parameters.........................................................................................161

17.9Start Parameters.....................................................................................................................161

17.10Stop Parameters.................................................................................................................162

17.11Dual Adjust Parameters......................................................................................................162

17.12Fault Parameters ................................................................................................................162

17.13I/O Programming ................................................................................................................

162

17.14Communication Parameters ...............................................................................................162

17.15Time Parameters ................................................................................................................163

18.HRVS-DN Communication (DeviceNet™)...........................................................................164

18.1Introduction .............................................................................................................................164

18.1.1Overview .....................................................................................................................164

18.1.2Definitions....................................................................................................................164

18.1.3Reference Documents.................................................................................................164

18.1.4Open DeviceNet Vendor Association, Inc. (ODVA).....................................................164

18.1.5Rotary Switch Configuration........................................................................................164

18.1.6LED Indicators.............................................................................................................165

18.2Identity Object (01HEX - 1 Instance) ......................................................................................166

18.2.1Class Attributes (Instance 0) .......................................................................................166

18.2.2Instance Attributes (Instance 1)...................................................................................166

18.2.3Common Services.......................................................................................................166

18.3Message Router Object (02HEX - 1 Instance)........................................................................166

18.4DeviceNet Object (03HEX - 1 Instance) .................................................................................166

18.4.1Class Attributes (Instance 0) .......................................................................................166

18.4.2Instance Attributes (Instance 1)...................................................................................166

18.4.3Common Services.......................................................................................................166

6 • List of Figures

_____________________________________________________________________________________________

18.5Assembly Object (04HEX –4 Instances)................................................................................167

18.5.1Class Attributes (Instance 0) .......................................................................................167

18.5.2Output (O2T) Instance Attributes – Register 40752 ....................................................167

18.5.2.1Output Instance 112 (0x70 – Attribute 3) – Control Output ..................................167

18.5.3Input (T20) Instance Attributes – Register 40257........................................................167

18.5.3.1Input Instance 60 (0x3C) – Basic Softstart Input..................................................167

18.5.3.2Input Instance 61 (0x3D) – Extended Softstart Input ...........................................167

18.5.3.3Input Instance 100 (0x64) – Status ......................................................................168

18.5.4Common Services.......................................................................................................168

18.6Connection Object (05HEX –2 Instances) .............................................................................168

18.6.1Class Attributes (Instance 0) .......................................................................................168

18.6.2Instance Attributes (Instances 1-2) Explicit, Polled I/O ...............................................168

18.6.3Common Services.......................................................................................................169

18.7Softstart Object (2DHEX - 1 Instance) ....................................................................................169

18.7.1Class Attributes (Instance 0) .......................................................................................169

18.7.2Instance Attributes (Instance 1)...................................................................................169

18.7.2.1Extended AtReference Values .............................................................................169

18.7.2.2Extended StartMode Values.................................................................................169

18.7.3Common Services.......................................................................................................170

18.8Control Supervisor Object (29HEX - 1 Instances) ..................................................................170

18.8.1Class Attributes (Instance 0) .......................................................................................170

18.8.2Instance Attributes (Instance 1)...................................................................................170

18.8.3Common Services.......................................................................................................170

18.9Modbus / Serial Object (65HEX –1 Instance) ........................................................................170

18.9.1Class Attributes (Instance 0) .......................................................................................170

18.9.2Instance Attributes (Instance 1)...................................................................................170

18.9.3Common Services.......................................................................................................171

18.10Solcon Input Object (70HEX –1 Instance) .........................................................................171

18.10.1Class Attributes (Instance 0) .......................................................................................171

18.10.2Instance Attributes (Instance 1)...................................................................................171

18.10.3Common Services.......................................................................................................173

18.11Main Parameter Object (71HEX –1 Instance) ...................................................................173

18.11.1Class Attributes (Instance 0) .......................................................................................173

18.11.2Instance Attributes (Instance 1)...................................................................................173

18.11.3Common Services.......................................................................................................174

18.12Start Settings Object (72HEX –1 Instance) .......................................................................174

18.12.1Class Attributes (Instance 0) .......................................................................................174

18.12.2Instance Attributes (Instance 1)...................................................................................174

18.12.3Common Services.......................................................................................................175

18.13Stop Settings Object (73HEX –1 Instance)........................................................................175

18.13.1Class Attributes (Instance 0) .......................................................................................175

18.13.2Instance Attributes (Instance 1)...................................................................................175

18.13.3Common Services.......................................................................................................175

18.14Dual Settings Object (74HEX –1 Instance)........................................................................175

18.14.1Class Attributes (Instance 0) .......................................................................................175

18.14.2Instance Attributes (Instance 1)...................................................................................175

18.14.3Common Services.......................................................................................................176

18.15Fault Settings Object (76HEX –1 Instance) .......................................................................176

18.15.1Class Attributes (Instance 0) .......................................................................................176

18.15.2Instance Attributes (Instance 1)...................................................................................176

18.15.3Common Services.......................................................................................................176

19.Parameters List.....................................................................................................................177

20.General Information: ............................................................................................................180

1. LIST OF FIGURES

Figure 1- HRVS-DN Cabinet Type IP31 (NEMA1) ............................................................................................ 10

Figure 2- HRVS-DN Chassis Type (IP00) ......................................................................................................... 10

Figure 3 - Principle Diagram of Digital Medium Voltage Soft Starter (Bypass Preparations not Shown) .......... 10

Figure 4 - Phase Control of the Line Voltage Using Semiconductor (SCR) Elements ...................................... 10

7 • List of Figures

_______________________________________________________________________________________________

Figure 5 – Voltage Increase ..............................................................................................................................10

Figure 6 – Torque Reduction.............................................................................................................................10

Figure 7 – Current Limit..................................................................................................................................... 10

Figure 8 – HRVS-DN IP00 Unit (OEM Kit) ........................................................................................................ 13

Figure 9 – Typical Connection of HRVS-DN IP00 Unit (OEM Kit)..................................................................... 14

Figure 10 – Typical Connection of HRVS-DN up to 6.6kV with Line Contactor and Bypass Contactor ............ 15

Figure 11 – Typical Connection of HRVS-DN from 10kV and up With Line Contactor and Bypass Contactor . 16

Figure 12 – HRVS-DN up to 6.6kV Power Section............................................................................................ 23

Figure 13 – Control Module Input/Output .......................................................................................................... 29

Figure 14 – HRVS-DN up to 6.6kV - Phase Disassembly Accessories............................................................. 38

Figure 15 - HRVS-DN Control Module .............................................................................................................. 40

Figure 16 – Optional Analog PCB ..................................................................................................................... 43

Figure 17 – Optional Insulation PCB Wiring ...................................................................................................... 44

Figure 18 – RU-7, Resistor Unit – Dimensional Drawing .................................................................................. 44

Figure 19 - Remote Key Pad, Connection Cable and Control Module. ............................................................. 45

Figure 20 - Remote Key Pad - Dimensions ....................................................................................................... 45

Figure 21 - Remote Key Pad - Mechanical Installation and Cut-out Dimensions............................................. 46

Figure 22 - HRVS-DN Control Keypad .............................................................................................................. 47

Figure 23 – Eye Bolts Location on Top of the Cabinet...................................................................................... 84

Figure 24 – Cabinet Lifting Using 4 Lifting Cables. Top angle, A, Should be ≤60° .......................................... 85

Figure 25 – Anchor Bolts Holes Location on the Base of the Cabinet at Level 0mm. ....................................... 85

Figure 26 – Power and Control Cables Penetration to the Cabinet at Level 75mm .......................................... 86

Figure 27 – Power Cables Connection and Control Cables Routing................................................................. 86

Figure 28 – HRVS-DN up to 6.6kV Standard Cabinet – One Line Diagram...................................................... 88

Figure 29 - HRVS-DN up to 6.6kV Standard Cabinet – Doors Closed.............................................................. 89

Figure 30 - HRVS-DN up to 6.6kV Standard Cabinet – Doors Open ................................................................ 89

Figure 31 – HRVS-DN from 10kV and up, Standard Cabinet – One Line Diagram .......................................... 90

Figure 32 - HRVS-DN from 10kV and up Standard Cabinet – Doors Closed.................................................... 91

Figure 33 - HRVS-DN from 10kV and up Standard Cabinet – Doors Open ...................................................... 91

Figure 34 - HRVS-DN Low Voltage Compartment ............................................................................................ 92

Figure 35 – Power Supply to Firing PCB (HRVS-DN Models up to 6600V). ..................................................... 93

Figure 36 – Power Supply to Firing PCB (HRVS-DN Models From 10000V and up)........................................ 94

Figure 37 – EPT-Rx Fuse Replacement Procedure .......................................................................................... 94

Figure 38 - HRVS-DN - Typical Control Wiring of Standard Cabinet ............................................................... 95

Figure 39 – HRVS-DN up to 6.6kV – Preparations for High-pot Test.............................................................. 100

Figure 40 – HRVS-DN up to 6.6kV – EPT-Tx not Connected Preparations for High-pot Test, Testing L1 ..... 101

Figure 41 – HRVS-DN up to 6.6kV – EPT-Tx not Connected Preparations for High-pot Test, Testing L2 ..... 102

+Figure 42 – HRVS-DN up to 6.6kV – EPT-Tx not Connected Preparations for High-pot Test, Testing L3 ... 102

Figure 43 – HRVS-DN from 10kV and Up – Preparations for High-pot Test................................................... 103

Figure 44 – HRVS-DN from 10kV and up, EPT-Tx not Connected, Preparations for High-pot Test, Testing L1

................................................................................................................................................................. 104

Figure 45 – HRVS-DN from 10kV and up, EPT-Tx not Connected, Preparations for High-pot Test, Testing L2

................................................................................................................................................................. 105

Figure 46 – HRVS-DN from 10kV and up, EPT-Tx not Connected, Preparations for High-pot Test, Testing L3

................................................................................................................................................................. 105

Figure 47 – Current Gain Dip Switches Location ............................................................................................ 110

Figure 48 – HRVS-DN up to 6.6kV – EPT-Tx and Test Harness .................................................................... 111

Figure 49 – HRVS-DN From 10kV and up – EPT-Tx and Test Harness......................................................... 111

Figure 50 – Firing PCB – SCR#1 Gate-Cathode Testing ................................................................................ 120

Figure 51 – DPV0 parameters (Cyclic parameters)......................................................................................... 150

Figure 52 – Updating the register number that will show at DPV0 (by Data Request).................................... 152

Figure 53 – Reading the register number that is shown in the DPV0 (cyclic) list............................................ 153

Figure 54 – Choosing register number 80 hex ................................................................................................ 154

Figure 55 – Reading 4 following register by Data Request (DPV1) ................................................................ 155

Figure 57 - Data rate (Baud rate) rotary switch layout..................................................................................... 165

8 • Safety & Warnings

_____________________________________________________________________________________________

2. SAFETY & WARNINGS

2.1 Safety

1 Read this manual carefully before operating the equipment and follow its

instructions.

2 Installation, operation and maintenance should be in strict accordance

with this manual, national codes and good practice.

3 Installation or operation not performed in strict accordance with these

instructions will void manufacturer’s warranty.

4 Disconnect all power inputs before servicing the soft starter and/or the

motor.

5 After installation, check and verify that no parts (bolts, washers, etc.)

have fallen into the Power Section (IP00) of the HRVS-DN.

2.2 Attention

1 This product was designed for compliance with IEC 60947-4-2 for class A

equipment and EN 50178.

2 For further information, see the Technical Specifications.

2.3 Warnings

1

Internal components and PCBs are at mains potential when the HRVS-

DN is connected to mains. This voltage is extremely dangerous and

contact with it will cause death or severe injury.

2

When the HRVS-DN is connected to mains full voltage may appear on

the HRVS-DN’s output terminals and motor’s terminals, even if control

voltage is disconnected and motor is stopped.

3 The HRVS-DN must be grounded to ensure correct operation, safety and

to prevent damage.

4

Check that power factor capacitors are not connected to the output side

of the HRVS-DN (U, V, W).

Also make sure that power factor capacitors are not connected to the

bypass preparation bus bars (L1B, L2B, L3B when exist)

The company reserves the right to make any improvements or modifications to its products without

prior notice.

9 • Introduction

_______________________________________________________________________________________________

3. INTRODUCTION

3.1 Why Solcon? Why Soft Starters?

Three-phase AC induction motors are commonly used in a wide variety of drive applications. Due to their

starting characteristics, in many cases these motors cannot be connected directly to the power supply system.

When starting Direct On Line (DOL) the motor can see a very high surge current reaching up to 6 times (and

more…) the rated motor current. This excessive current puts stress on the supply system and the switchgear.

Also, when starting DOL, a very high peak torque can occur, stressing the driven motor and the mechanical

system including auxiliary power transmission parts (V-belt, gears, etc.).

There are several methods for reducing the damaging effects of this excessive starting current. Conventional

methods include reactors and autotransformers. But these methods only allow the voltage to be reduced in

steps whereas a soft starter provides step-free acceleration of the drive system by continuously increasing the

voltage over a selected period of time. This approach to starting minimizes the effect of high inrush current on

the supply system, the motor and the driven load.

Soft starters provide the following benefits:

Reduced starting current, eliminates voltage drops and dips of the supply network

Smoother acceleration of loads, eliminates process or product damage

Extended lifetime of all mechanical components, e.g. eliminates gearbox damage and results in less

maintenance & downtime

Extended motor life

Reduced maintenance and operating costs

The HRVS-DN soft starter represents a logical extension of the Solcon soft starter product range into medium

voltage applications.

With HRVS-DN, Solcon presents an innovative standard product that provides a flexible, low cost alternative

to fixed speed (DOL) starting.

Designed for use with standard medium voltage three-phase squirrel cage induction motors as well as

synchronous motors, this high-performance digital soft starter ensures smooth acceleration and deceleration.

HRVS-DN is available in all standard internationally recognized medium voltage ratings: 2.3kV, 3.3kV, 4.16kV,

6kV and 6.6kV, 10kV, 11kV, 13.2kV, 13.8kV and 15kV.

The standard current output range capability is from 200kW to 27MW.

HRVS-DN is designed and built to meet international standards including:

• IEC • EN • DIN VDE • NEMA • UL/CUL • IEEE

The HRVS-DN soft starters are manufactured at the highest quality level. The entire design, production and

delivery process, (i.e. construction, manufacturing, order processing and logistics delivery center) have been

certified DIN ISO 9001.2000.

The enclosed versions of the HRVS-DN are provided as ready-to-connect cabinet enclosed type units

(example shown in Figure 1) or - for OEM only - chassis type OEM kits (example shown in Figure 2) are

available for building into custom enclosures or other relevant equipment (note: the complete interface

engineering is the responsibility of the user).

10 • Introduction

_____________________________________________________________________________________________

Figure 1- HRVS-DN Cabinet Type IP31 (NEMA1)

Figure 2- HRVS-DN Chassis Type (IP00)

3.2 How Soft Starters Work?

By using thyristors (SCRs) in a phase angle control mode, reduced voltage control can be achieved. Phase

control makes it possible to gradually increase the motor terminal voltage from an initial set point up to the

system supply voltage level. The related starting current and the starting torque can be optimally adjusted to

the motor/load conditions.

Figure 5 shows a principal voltage increase curve.

Figure 6 demonstrates the torque reduction compared to the DOL torque. Figure 7 demonstrates typical

behavior of motor current.

Figure 5 – Voltage Increase

Figure 6 – Torque Reduction

Figure 7 – Current Limit

In addition, the Solcon HRVS-DN soft starters provide the "soft stopping" function as a standard feature.

Similar to the reduced voltage start, a stop command gradually reduces the motor voltage over time until the

motor stops. Abrupt stopping is avoided, a specific advantage in pumping applications to prevent the

damaging effects of water hammer and on conveyor belts where the load may be damaged by an abrupt stop.

Figure 3 - Principle Diagram of Digital Medium Voltage Soft

Starter (Bypass Preparations not Shown)

Figure 4 - Phase Control of the Line Voltage Using

Semiconductor (SCR) Elements

11 • Introduction

_______________________________________________________________________________________________

Main Features, Options and Advantages

Advantages at a Glance

❍Complete line of 60-1,200A, 2,300-15,000V as

standard products

❍Customized soft starters (consult the factory

for details)

❍Heavy duty, fully rated design

❍Starting capacity of 400% of FLC for 30

seconds at a rated ambient temperature of 50°C

❍Preparation for bypass - to maintain protection

when bypass is closed

❍Robust construction

❍Superior starting & stopping characteristics

❍Comprehensive motor protection package

❍User friendly

❍Unique protection for corrosive environments

❍Generator ready - auto frequency tracking

❍Sustains variations of 45-65Hz while starting

❍Unique built in optional features including:

❍Motor insulation tester

❍Modbus / Profibus /DeviceNet comm.

❍Analog output

❍Relay PCB for comm. control

❍Tacho feedback

❍Multi-start (standard)and Multi-soft

stop (optional) capability

❍Synchronous motor excitation system

control

❍Remote display

Standard Ratings

❍2.3kV, 4.16kV, 6kV, 6.6kV, 10kV,11kV,

13.2kV, 13.8kV, 15kV

Starting & Stopping

❍Soft start & soft stop

❍Current limit

❍Pump control program

❍Torque and current control for optimized

starting & stopping process

❍Dual adjustments - two starting & stopping

characteristics

❍Advanced pulse start

❍Linear acceleration

Motor & Starter Protection

❍ Too many starts

Coast Down Time

❍ Long start time (stall)

❍ Shear-pin

❍ Electronic overload with selectable curves

according to IEC classes or NEMA classes

❍ Under current with adjustable delay

❍ Unbalance current with adjustable delay

❍ Ground fault with adjustable delay

❍ Phase loss & phase sequence

❍ Under, over & no voltage

❍ Load loss (motor not connected)

❍ Shorted SCR

❍ Starter over-temperature

Displays LCD & LEDs

❍ Illuminated LCD - 2 lines x 16 characters

❍ Selectable languages: English, German, French,

Spanish and Turkish (Chinese and Russian - optional)

❍ Two display modes for basic and advanced

applications

❍ Friendly operation with default parameters

❍ Eight LEDs for quick operational status

❍ Statistical data including:

❍ Total run time

❍ Total number of starts

❍ Total number of trips

❍ Last start current

❍ Last start time

❍ Last 10 trips with time stamp

❍ Current at trip

12 • Introduction

_____________________________________________________________________________________________

Unique Built-in Options

❍Analog output, related to the motor's current

or related to the motor’s rated power.

Programmable as 0-10VDC, 4-20mA, 0-20mA

❍Motor insulation test - a unique feature for

submersible pumps, motors installed in harsh

environments, etc

The system measures motor insulation when

motor is not running.

Two programmable levels are available:

❍ Alarm level, adjustable 0.2-5 Mohm

❍ Start disable level, adjustable 0.2-5Mohm,

preventing starting when insulation is below

acceptable levels

❍Special tacho feedback circuitry

❍Modbus RTU - enables setting, control &

supervision

❍Profibus DP – enables setting, control &

supervision

❍DeviceNet - enables setting, control &

supervision

❍Relay PCB – enables starting the application

when the soft starter is installed in a cabinet via

communication, and to control the excitation

system of a synchronous motor

❍Remote display allows the panel builder to

mount the keypad of the HRVS-DN in a remote

location of the Control Module. A standard length

of 1.5m cable length is supplied

❍Multi-soft stop special software allows to soft

stop motors when a multi-start application is

applied.

Unique External Options

❍Customized tailor-made design of a cabinet

❍Advanced motor protection MPS-3000

❍Digital multi-meter for advanced measurement

capabilities - DPM-10

❍Motor Insulation Protection – MIP-6 for

advanced tracking of motor insulation level over

more than 20 years

❍Line and Bypass Contactors/VCBs

❍Fuses and disconnectors

❍Capacitors for power factor correction

Auxiliary Relays

❍Three standard programmable relays (each relay

with one C.O. 8A, 220VAC contacts)

❍ Immediate with adjustable on and off delays

(can be dedicated for too many starts pre-alarm relay)

❍ End of Acceleration, with adjustable on delay

❍ Fault, programmable as fault or fault-fail safe

operation.

❍Low motor insulation alarm (optional relay)

Applications - Industrial

❍Pumps

❍Hydraulic systems

❍Fans and blowers

❍Compressors

❍Conveyors

Applications - Marine & Offshore

❍Water, ballast and fire-fighting pumps

❍Refrigeration chillers and compressors

❍Hydraulic pumps and power packs

❍Thrusters

❍Main propulsion motors

13 • Technical Data

_______________________________________________________________________________________________

4. TECHNICAL DATA

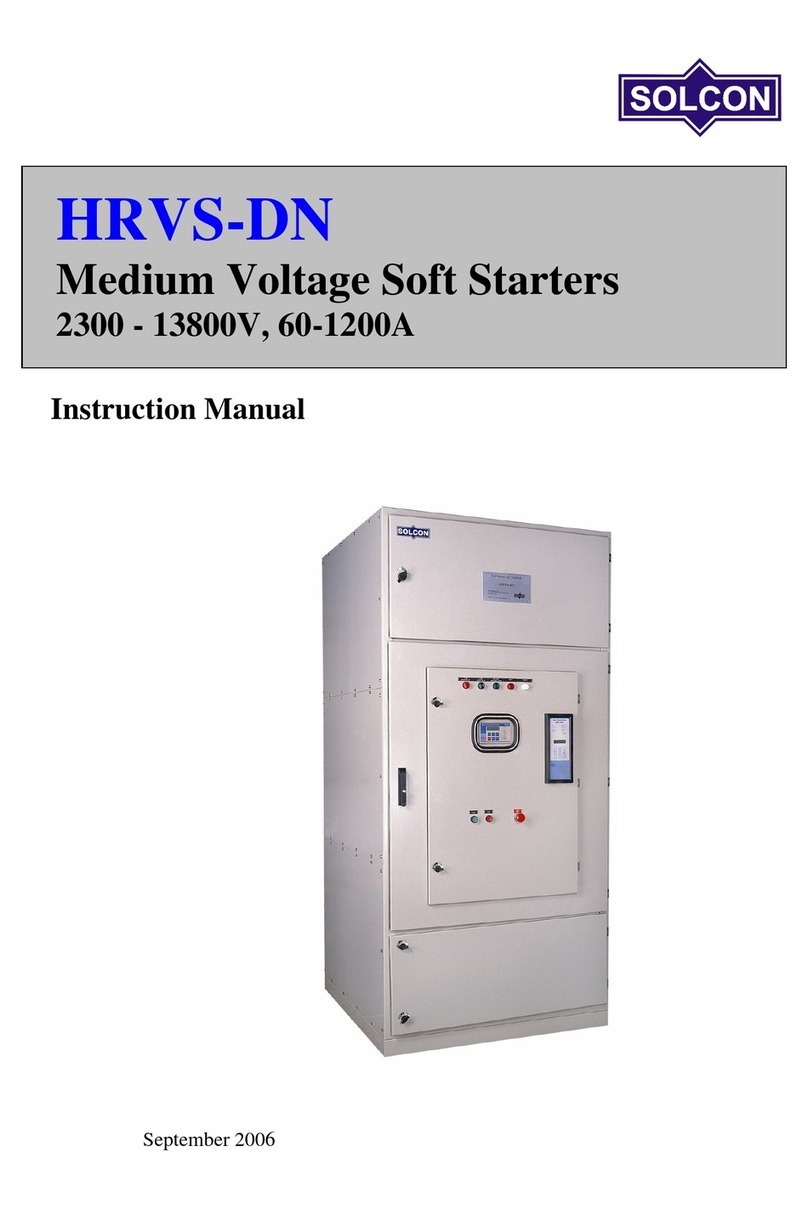

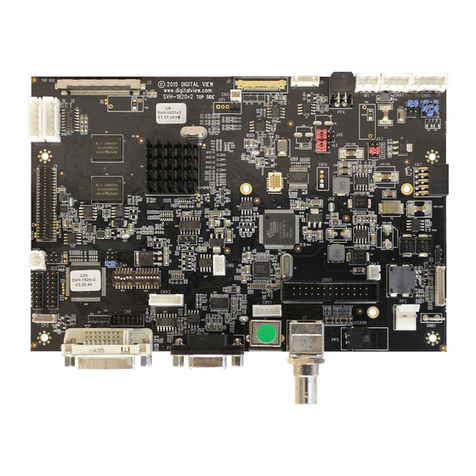

4.1 HRVS-DN IP00 Unit (OEM Kit)

Power Section and

Connection Harness

Control Module

Firing

Transformer

EPT-Tx and EPT-Rx

Figure 8 – HRVS-DN IP00 Unit (OEM Kit)

The IP00 unit (OEM kit) is available for building into custom enclosures or other relevant equipment.

It consists of the following (refer to Figure 8 above):

Power Section consists of the 3 identical phase stacks, firing PCBs, power supplies to the firing PCBs

(in HRVS-DN from 10kV and up power supplies to the firing PCBs are separated from the Power

Section), 3 CTs and the connection harness to the low voltage compartment (including copper wires

and fiber optic wires). The Power Section is installed in the medium voltage compartment of the

cabinet.

Control Module is the “brain” of the soft starter. It consists of the main CPU PCB, fireboard PCB,

power supply, optional PCBs (when ordered) and input/output interface terminals.

The Control Module for HRVS-DN is identical for all ratings and suitable for mounting in the L.V.

compartment of the cabinet which should be fully segregated from the M.V. compartment.

Interposing relays should be connected to all HRVS-DN auxiliary contacts, three relays must be

incorporated: Immediate, End of Acceleration and Fault.

Firing Transformer. This transformer is applicable for 115VAC or 230VAC control voltages.

For HRVS-DN controlled by DC control voltages - DC power supply is supplied – for details consult the

factory.

The Firing transformer is installed in the low voltage compartment of the cabinet and supplies control

power to the firing PCBs located in the Power Section of the HRVS-DN in the medium voltage

compartment of the cabinet.

EPT-Tx (transmitter) and EPT-Rx (receiver) are used instead of the traditional voltage transformer to

measure the input voltage.

The EPT-Tx is installed in the medium voltage compartment and is connected to the mains bus bars

downstream from the Line Contactor.

The EPT-Rx is installed in the low voltage compartment of the cabinet.

The EPT-Tx and EPT-Rx are connected by 2 fiber optic wires which are part of the connection

harness.

14 • Technical Data

_____________________________________________________________________________________________

4.2 Typical Connection of the HRVS-DN IP00 Unit (OEM Kit)

Figure 9 – Typical Connection of HRVS-DN IP00 Unit (OEM Kit)

Notes:

Figure 9 shows a typical connection of an HRVS-DN IP00 unit (OEM kit) of up to 6.6kV with a control voltage

of 115/230VAC. For connection diagrams for other models consult the factory.

L1B, L2B, L3B bus bars are only available in HRVS-DN up to 6.6kV.

15 • Technical Data

_______________________________________________________________________________________________

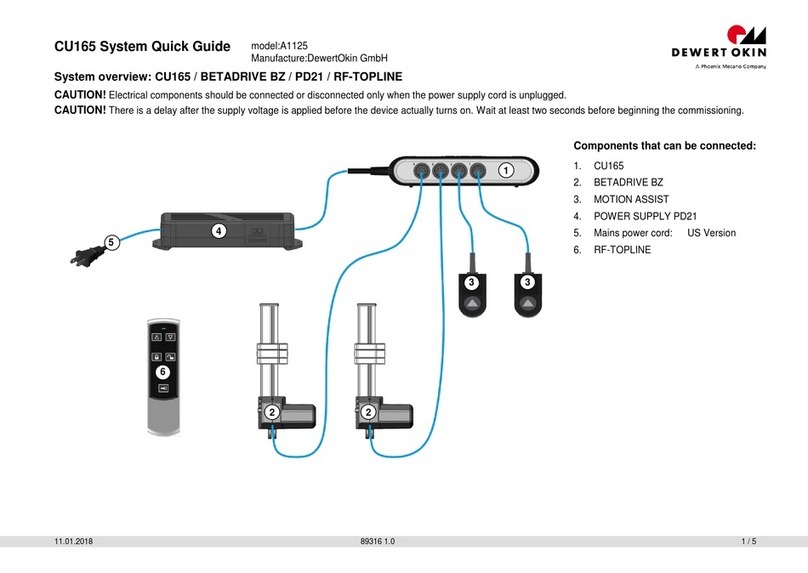

4.3 Typical Connection of the HRVS-DN in a Cabinet

4.3.1 Typical Connection of HRVS-DN up to 6.6kV

The HRVS-DN must be connected with a Line Contactor and a Bypass Contactor as demonstrated in Figure

10.

Figure 10 – Typical Connection of HRVS-DN up to 6.6kV with Line Contactor and Bypass Contactor

16 • Technical Data

_____________________________________________________________________________________________

4.3.2 Typical Connection of HRVS-DN from 10kV and up.

The HRVS-DN must be connected with a Line Contactor and a Bypass Contactor as demonstrated in Figure

11.

Figure 11 – Typical Connection of HRVS-DN from 10kV and up With Line Contactor and Bypass Contactor

17 • Technical Data

_______________________________________________________________________________________________

4.4 HRVS-DN Selection

The HRVS-DN should be selected in accordance with the criteria of motor current and starting conditions.

4.4.1 Motor Current and Starting Conditions

Select the HRVS-DN according to the motor's Full Load Ampere (FLA) - as indicated on its nameplate (even if

the motor will not be fully loaded).

Soft Starter Full Load Current (FLC) must be ≥Motor’s Full Load Ampere (FLA).

The HRVS-DN is designed to operate under the following maximum conditions:

Ambient

Temperature

[°C]

Max. Starting Current

[A]

Max. Starting

Time at 400%

FLC

[sec]

50 400%xFLC 30

Max. starts per hour: 2 starts per hour at maximum ratings.

4.4.2 PIV (Peak Inverse Voltage)

Thyristors PIV rating, internal circuitry and insulation define the following voltage levels:

2,300V, 3,300V, 4,160V, 6,600V, 10,000V, 11,000V, 13,800V and 15,000V.

Each soft starter is suitable for 50/60Hz.

PIV level is rated at 3 times the rated voltage or higher.

18 • Technical Data

_____________________________________________________________________________________________

4.4.3 Rated Currents Frame Sizes

19 • Technical Data

_______________________________________________________________________________________________

4.5 Ordering Information

4.5.1 Ordering IP00 Unit (OEM kit)

HRVS-DN (IP00) Internal Order

No: Rev.:

Solcon cat. No.:

Customer Name:

HRVS-DN

Rated

current Voltage

Control

voltage

supply

Control Input

supply Options Lexan

See below See below

115VAC

230VAC

110VDC

125VDC

220VDC

24VDC

115VAC

230VAC

110VDC

125VDC

220VDC

3M-Modbus

3P-Profibus

3D-DeviceNet

5-analog Card

D-remote display

RU-Russian characters.

ROC-Chinese characters

Relay-Relay PCB

NLR-Special software for

Multi soft stop applications

S

RU

N

No. Main Components Model - P/N QTY.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

MV Soft Starter Specification

No. ITEM Options Specify

1.

Mains Voltage

2300, 3300, 4160, 6000, 6600, 10000,11000 , 13200,

13800,15000

2.

Starter FLC (Amp.)

At 2300-4160V: 60,110, 200, 320, 400, 700, 800,1000, 1200

At 6000-15000V: 70,140,250,300,400,500,700,800,1000,

1200

3. Control Supply Voltage 115VAC, 230VAC, 110VDC, 125VDC, 220VDC, 24VDC

4. Control Input Voltage 115VAC, 230VAC, 110VDC, 125VDC, 220VDC, 24VDC/AC

5. Test Voltage 230, 400, 500, 600, 690

6. Control wires type

7. Harness Side Left/Right

8. Relay Card NO / YES

9. Analogue Output NO / YES

10. MODBUS Communication NO / YES

11. PROFIBUS Communication NO / YES

Project Name: Motor Name Plate:

Contact

Person: Application:

Tel: Qty:

Fax: Delivery:

E-mail: Order number

20 • Technical Data

_____________________________________________________________________________________________

MV Soft Starter Specification

No. ITEM Options Specify

12. DeviceNet Communication NO / YES

13. Insulation Test Module NO / YES

14. Optional loose

Components YES/NO

14.1 Extended Split Phase

14.2 Motor Protection Relay

(Refer to Relay Ordering

Information Data)

MPS-6 , MPS 3000-P/C

14.3 Digital Panel Meter DPM NO / YES

14.4 Line Contactor 2300-6600V

J.C. model

MVC/SVC/Toshiba model

CV-6HA

NO / YES (Voltage & Current per selected starter rating)

14.5 Bypass Contactor 2300-

6600V J.C. model

MVC/SVC/Toshiba model

CV-6HA

NO / YES (Voltage & Current per selected starter rating)

14.6 Auxiliary Contacts

14.7 Coil Control Voltage ACV:120,240 DCV:125,250

14.8 Line Contactor 7200-

12000V

Toshiba model CV-10HA

NO / YES (Voltage & Current per selected starter rating)

14.9 Bypass Contactor 7200-

12000V

Toshiba model CV-10HA

NO / YES (Voltage & Current per selected starter rating)

14.1 Auxiliary Contacts 4NO+3NC , 6NO+5NC

14.1 Coil Control Voltage ACV:110,115,120,125,220,230,240,380,400,415,440,500

DCV:24,60,110,124.220

14.1 MIP – Motor Insulation

Protection NO / YES

15. Packing Sea fright, Air fright, No

16. Labeling

17. Instruction Manuals

18. Ex-Factory Delivery

19. Ship to Box Marking

20. Special Notes

21. Spare Parts

1. 7.

2. 8.

3. 9.

4. 10.

5. 11.

6. 12.

Issued by: Date :

Approved by (Sales Manager) : Date :

Table of contents

Other Solcon Controllers manuals

Popular Controllers manuals by other brands

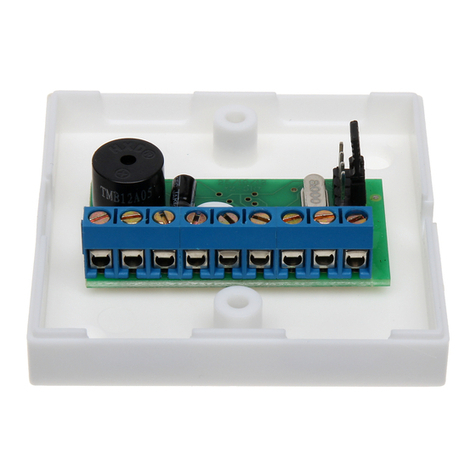

Iron logic

Iron logic Z-5R Relay Wiegand user manual

Black Box

Black Box QuikConnect ME0007A-HDSL manual

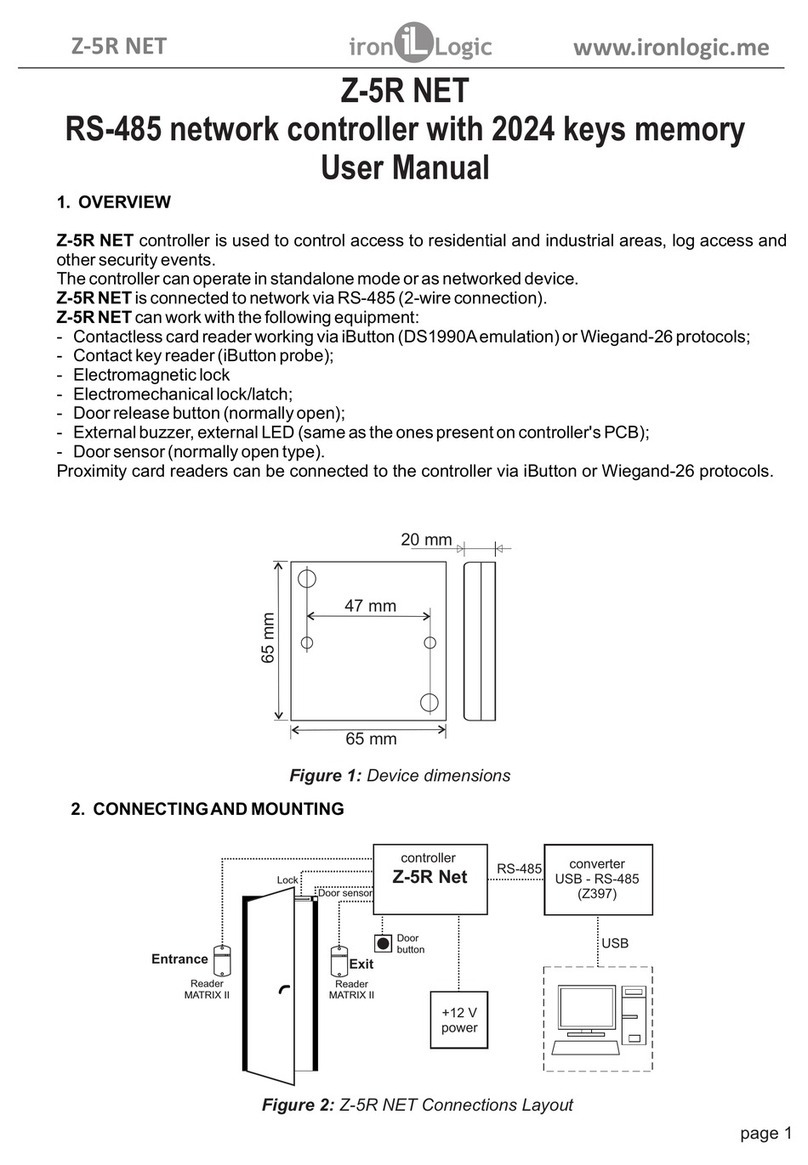

Iron logic

Iron logic Z-5R NET user manual

AutomationDirect

AutomationDirect Stellar SR35 Series quick start guide

smart home

smart home ApplianceLinc V2 user guide

Hobby-Wing

Hobby-Wing EZRUN MAX10 SCT user manual