Tokyo Keiki MRF-10 User manual

Doc No. KF09-003B

Flat Radar Level Sensor

MRF-10

Installation & Operation Manual

Safety Cautions

The caution message shown in the User’s Guide is defined as follows:

The following safety precautions contain important information pertaining to the safe use of

the Radar Level Gauge. Read this text carefully and make sure to fully understand its

contents before installing and operating this equipment. Follow directions given herein at all

times when operation. TOKYO KEIKI INC. is not at all liable for an injury and/or a damage

resulting from misuse of this equipment by the user that is contrary to these cautionary

notes.

For quick reference, store this manual in a designated location with easy access (preferably

near the equipment).

In this manual and on the equipment, the following safety symbols are used to ensure the

equipment is used safety and to protect operators and property from possible hazards or

damage. Read the explanations below carefully and familiarize yourself with the symbols

before reading the manual.

Safety symbols

DANGER

Indicates that incorrect usage can result directly in death or

serious injury to the operator.

WARNING

Indicates that incorrect usage may result in loss of life or

serious injury to the operator.

CAUTION

Indicates that incorrect usage may result in injury to the

operator or damage to the equipment.

Indicates referring to information for usage of the function or

features. (Put on the equipment)

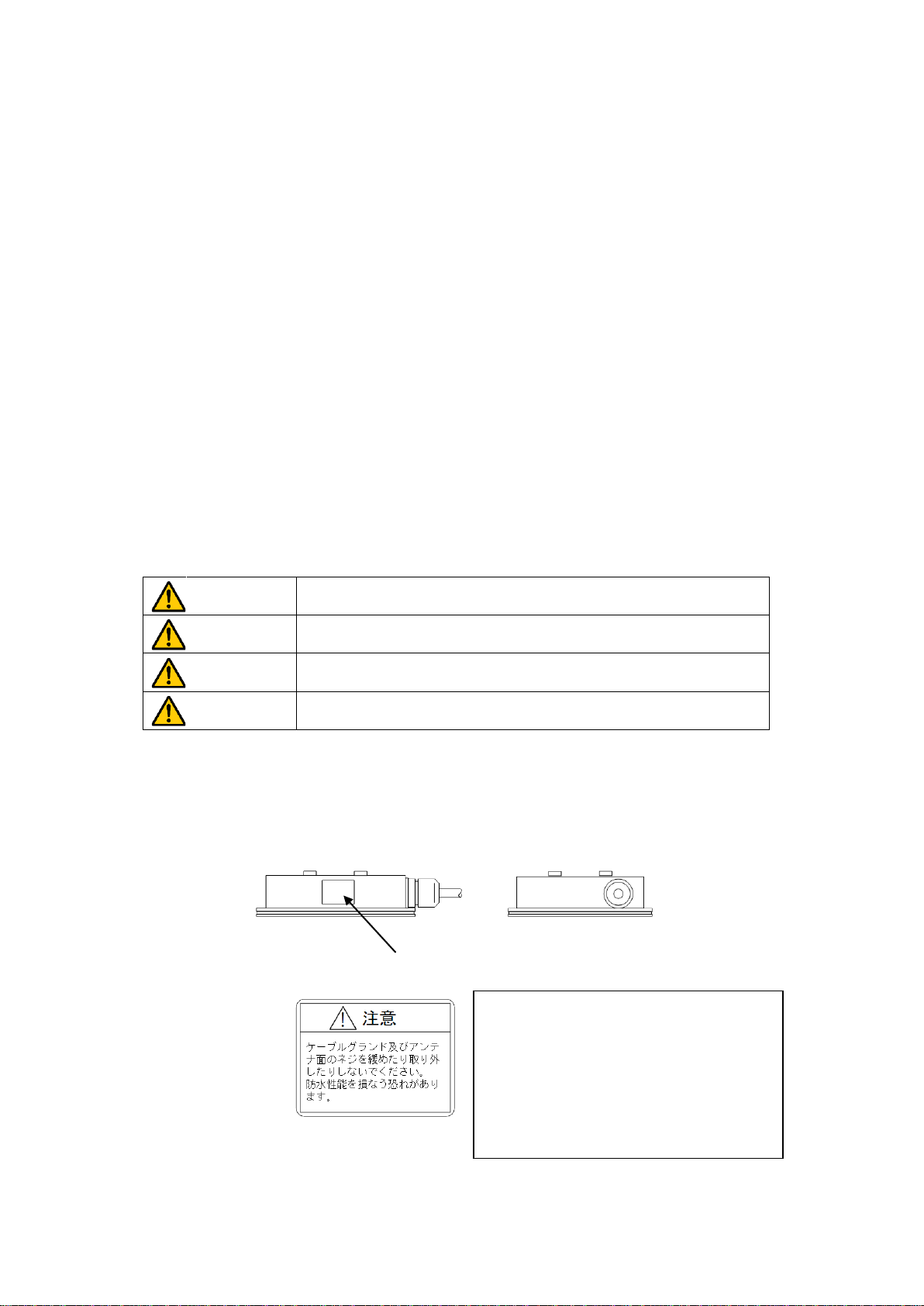

[Warning Label]

Indicates that incorrect usage may result in death or serious injury to the operator.

Warning Label

Left warning label means

Caution

Do not remove cable glands

or any

screws that attached with main unit. In

case of removal it, main unit can not

satisfy performance of protection

class.

( )1

Usage Precautions

This instrument is used to measure level height by means of microwave. For safe usage

and optimum performance of the radar level sensor, always operate the instrument

according to the usage precautions below.

CAUTION

1. Failure to comply with one or more of the following conditions may result in poor

measurement performance or incorrect measurement values.

・

Use an appropriate power supply rated for the voltage range designated in the

specifications.

・Do not subject the main unit to vibration or mechanical shock.

・Place the main unit, transducer and cable in a location without noise interference.

・Use the equi

pment within the predetermined ambient temperature and humidity

range.

2.

If the signal level is below the minimum detection requirement of the instrument, the

alarm will be reported through analog output in accordance with alarm setting.

3. Be sure to u

se the instructions in the Manual when changing settings on the main

unit. Incorrect settings will result in poor performance or incorrect measurement

values (output signals).

4. Do not modify or disassemble the unit. Such actions may result in electrical shock or

equipment damage.

5. If this Operation manual is lost, contact the nearest dealership.

( )2

Introduction

Thank you for your selecting our radar level sensor.

This Manual includes detailed explanations regarding safety cautions, structure, set up,

operation, troubleshooting, and maintenance of the radar level sensor.

Read this manual carefully before operation to ensure an adequate understanding of the

equipment.

Proper use of the Operation Manual

The following points must be observed:

CAUTION

1.

Carefully read the Manual. The contents of this Manual are very important and should

be read completely.

2.

Store the Manual in a safe location. The Manual is essential for appropriate operation

of the equipment. Store the manual in a safe and access

ible location. The storage

location and person in charge should be determined after careful consideration.

3.

Ensure that the Manual is supplied to the operator of the equipment. The

representative or dealer of this equipment must provide this Manual to the user who

will actually operate the equipment.

4.

The Manual must be replaced if lost or damaged. If the Manual is lost, contact the

representative. A new manual is available for purchase.

5. Ensure that the warning label is properly attached. If the warning label is illegible or

has come off, contact the manufacturer to purchase a new label.

Precautions regarding the Manual

This Manual was written in accordance with the standard specifications of the original

instrument.

In case of discrepancies between written specifications and approved drawings, the

drawings should be given precedence.

Restrictions and precautions necessary to maintain the equipment

The following items must be observed in order to maintain the equipment.

CAUTION

1. Do not drop or bump the unit and the transducer.

2.

Do not use the unit in environmental conditions (ambient temperature, ambient

humidity) other than those prescribed in this manual.

3. Do not use the unit with a power supply other than the one prescribed in this manual.

4. Do not use damaged or worn-

out cables (power cables, coaxial cables, signal

cables).

5.

Under no circumstances attempt to modify or disassemble the instrument. Contact

the manufacturer in the event of a malfunction.

6. Do not remove cable glands or any screws that

attached with main unit. In case of

removal it, main unit can not satisfy performance of protection class.

7. Do not modify or disassembl

e the unit. Such actions may result in electrical shock or

equipment damage.

8. Do not use the unit and/or accessories in restricted hazardous areas.

( )

3

Safety Precautions ……………………………………………………………………….. (1)

Usage Precautions ………………………………………………………………………..(2)

Introduction ………………………………………………………………………………...(3)

Proper use of the Operation Manual …………………………………………………… (3)

Precautions regarding to the Manual ………………………………………………….. (3)

Restrictions and precautions necessary to maintain the equipment ………………...(3)

INDEX

1. Product Description 1-1

1.1 Features 1-1

1.2 Measuring principle 1-1

1.3 MRF-10 measuring system 1-1

2. Mechanical Installation 2-1

2.1 Requirements 2-1

2.2 Beam area in the measuring range 2-2

2.3 Recommended installation example 2-3

(1) Installation for water channel 2-3

(2) Installation for storage tank 2-4

3. Electrical Installation 3-1

3.1 Wiring connection 3-1

(1) Transmitter side 3-1

(2) Connection fro commissioning software 3-2

3.2 Cables 3-2

3.3 Load 3-2

3.4 Power Supply 3-2

3.5 Grounding 3-3

(1) Connecting only with attached standard

cable or extended with 3-core shielded cable 3-3

(2) Extended 2-core cable with shield 3-3

(3) With lightening arrester 3-3

(4) When base of the mounting position made

by metal parts which connected

with the grounding line 3-4

4. Commissioning 4-1

4.1 Working conditions 4-1

4.2 Produced File 4-1

4.3 Connection 4-2

4.4 Initial Setup 4-2

(1) Startup Screen 4-2

(2) Reading HART ID 4-3

(3) Message after data communication 4-4

4.5 Basic Operation 4-5

(1) Read parameter 4-5

(2) Rewrite of parameters 4-6

4.6 Measuring Value 4-7

( )

4

(1) Monitoring of measuring value 4-7

(2) Logging the measured data 4-8

4.7 Tank Spectrum 4-9

(1) Plotting Tank Spectrum 4-9

(2) Zoom-in a part of spectrum 4-10

(3) Save spectrum data 4-11

4.8 Noise Table 4-12

(1) Plotting points 4-12

(2) Deleting data from noise table 4-14

4.9 Parameter instructions 4-15

5. Setup 5-1

5.1 Basic Parameters 5-1

5.2 Negative level measurement 5-1

5.3 Avoiding Disturbance Echoes 5-2

(1) Dead Band 5-2

(2) Noise table 5-2

5.4 Volume calculation 5-5

(1) Defined tanks 5-5

(2) User defined tank 5-6

5.5 Analog value compensation 5-7

(1) Analog check 5-7

(2) Analog calibration 5-7

5.6 Measuring value compensation 5-8

5.7 Bottom recognition 5-8

6. Technical Information 6-1

6.1 Main unit specification 6-1

(1) Main unit specification 6-1

(2) Power 6-1

(3) Output 6-1

(4) Accuracy 6-2

6.2 Environmental resistance 6-2

6.3 Construction 6-3

(1) Cable connection 6-3

(2) Material and Mass 6-3

6.4 Dimension 6-4

( )

5

(blank)

( )

6

1. Product Description

1.1 Features

The MRF-10 is a loop-powered radar level gauge, which can be installed easily in a

variety of applications. The MRF-10 employs a non-contact radar level gauging principle

based on pulsed microwave signals and is suitable for level measurement in applications

such as liquids, pastes and slurries.

MRF-10 uses 5.8GHz low power pulsed microwave. It provides good measurement

stability, because propagation of microwaves is less affected by change of temperature,

pressure or gas conditions in tank.

1.2 Measuring Principle

The MRF-10 level gauge utilizes the time-of-flight

measurement principle involving short microwave

pulses. Installed at the top of tanks or channels, it emits

short microwave pulses toward liquids or pastes.

Reflected microwave signals from the surface are

received by the antenna, and processed by electronics.

The time from transmission to reception is determined

by the microprocessor and converted as distance from

the transmitter to the liquid surface (ullage) with output

of the calculated level from the measured ullage (Level

= Tank Height – Ullage).

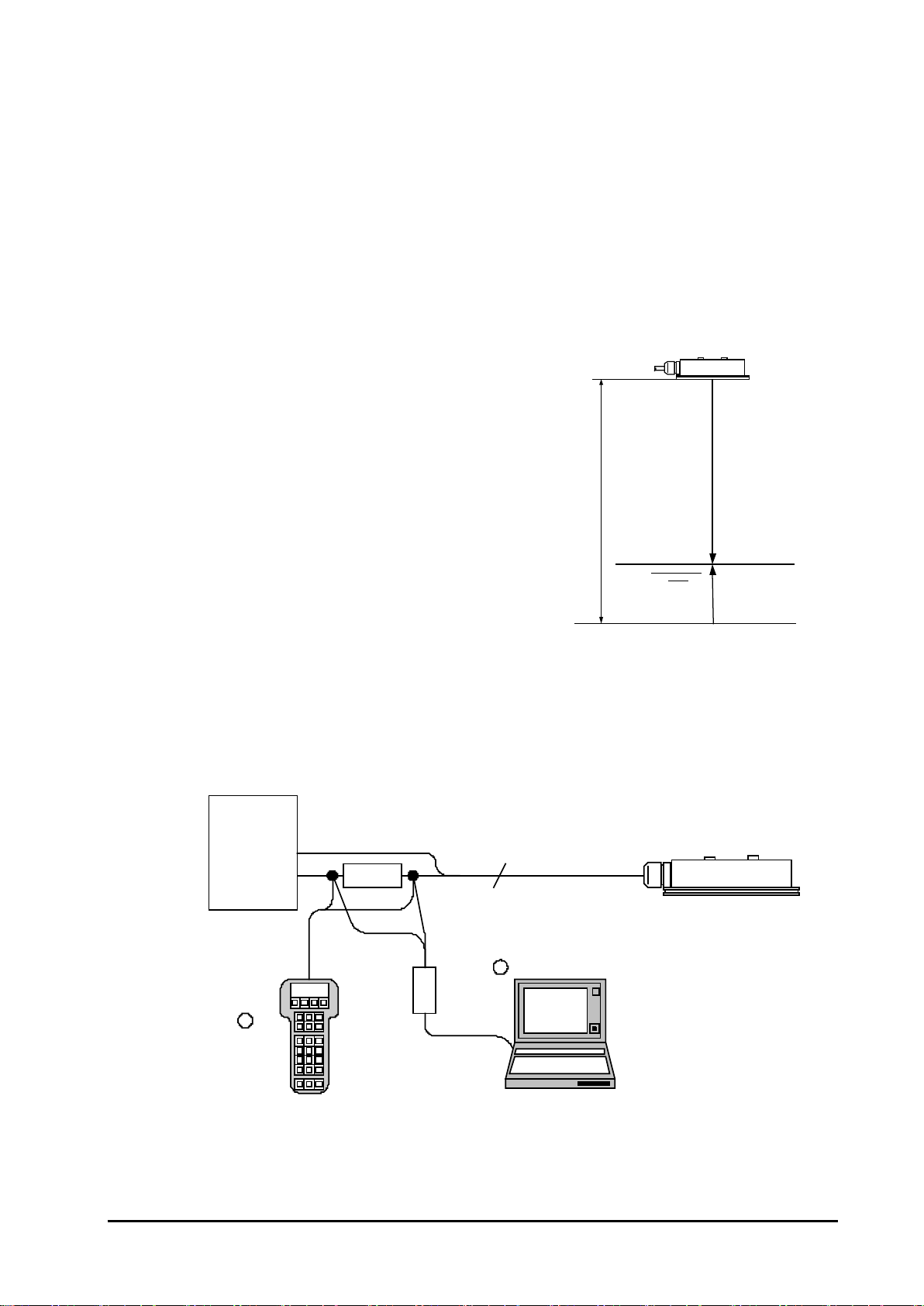

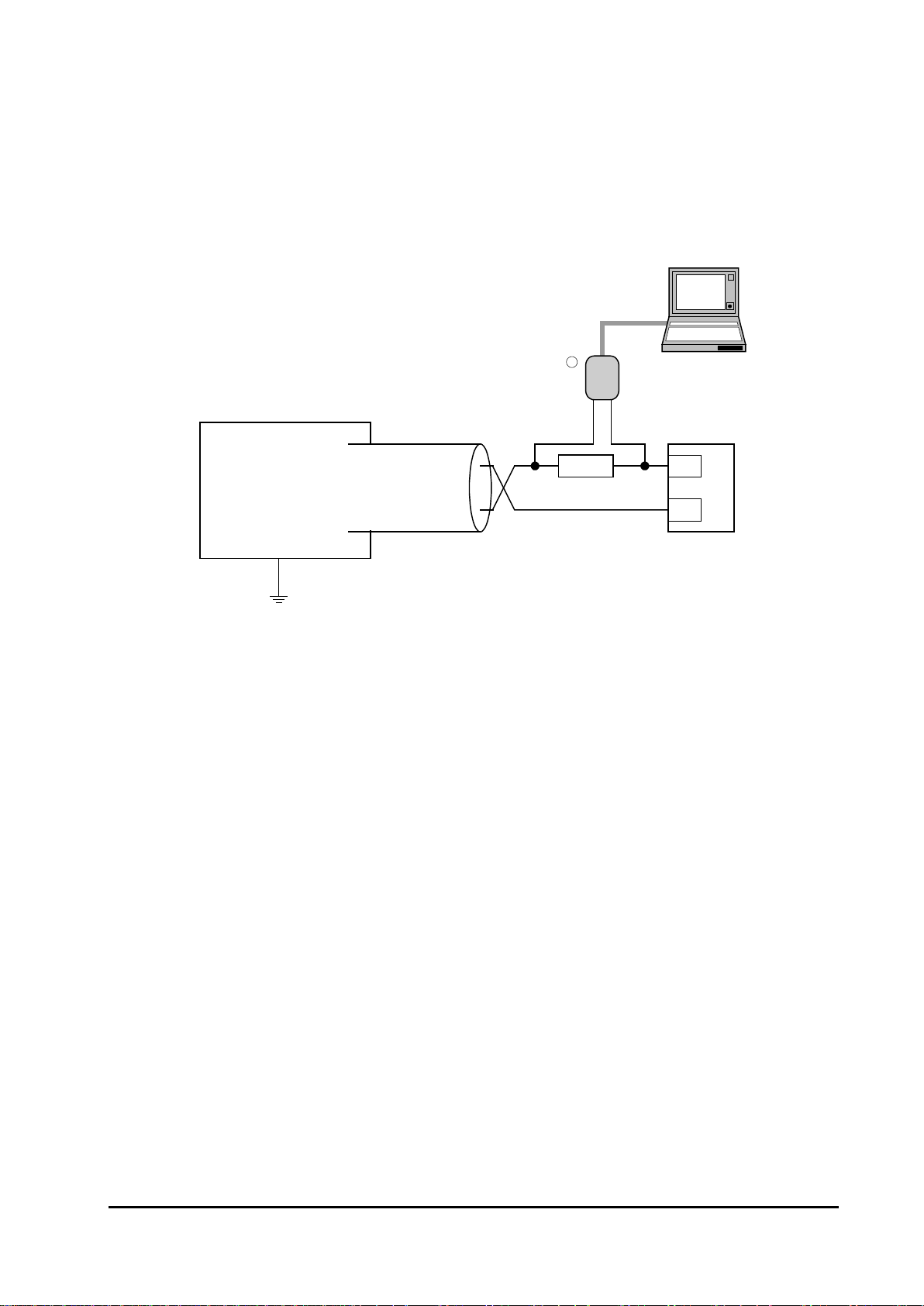

1.3 System configuration

MRF-10 can be configured with remotely from a personal computer via a modem or a

handheld terminal.

The MRF-10 is required to connect to a PLC or power supply unit.

Ullage

Level

Surface

TankHeight

MRF-10

HART

Modem

HART

Communicator

Power

Source Load

>250Ω

4...20mA

2

R

R

MRF-10

1-1

(blank)

1-2

2. Mechanical Installation

2.1 Requirements

Please regard to following points to install MRF-10 transmitter head.

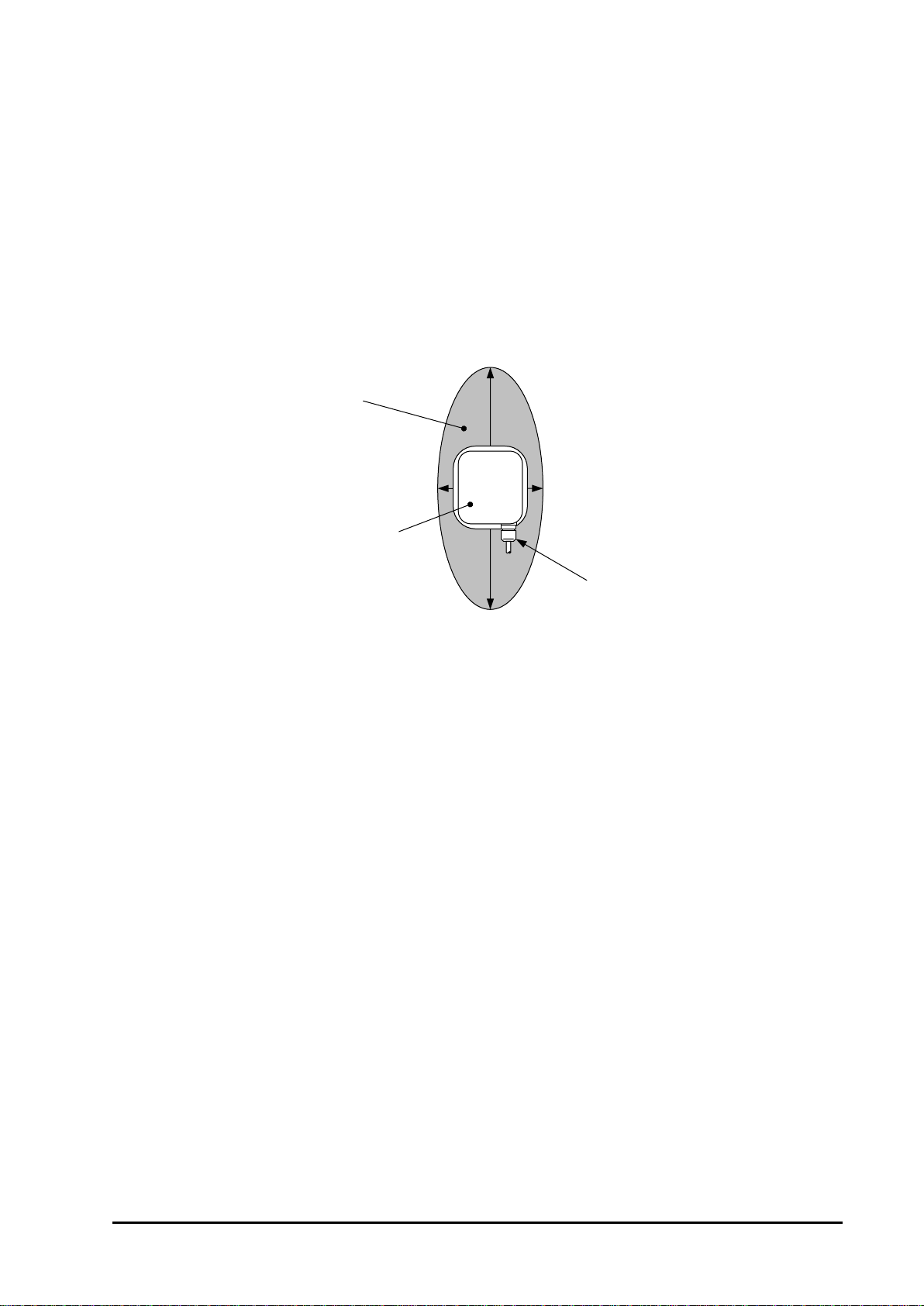

(1)Directivity angle of microwave

MRF-10 has elliptical (oval) directivity of microwave as below Fig. 2.1-1.

Please refer to chapter 2.3 example of recommended installation to install

transmitter head properly.

Fig. 2.1-1 Beam angle

(2)Free space requirement

The transmitter should be mounted so that no obstacles are present in the radar

beam. Obstacles in the radar beam may reduce the measuring range.

Please refer to list 2.2-1.

(3)Mounting allowance

Center of microwave radiation must be vertical against target fluid surface.

Allowance of the mounting angle should be +/- 1degree.

Beam angle23

°

(Crosswise direction)

Cable Entry

Beam angle 50

°

(Lengthwise direction)

Beam area

MRF-10

2-1

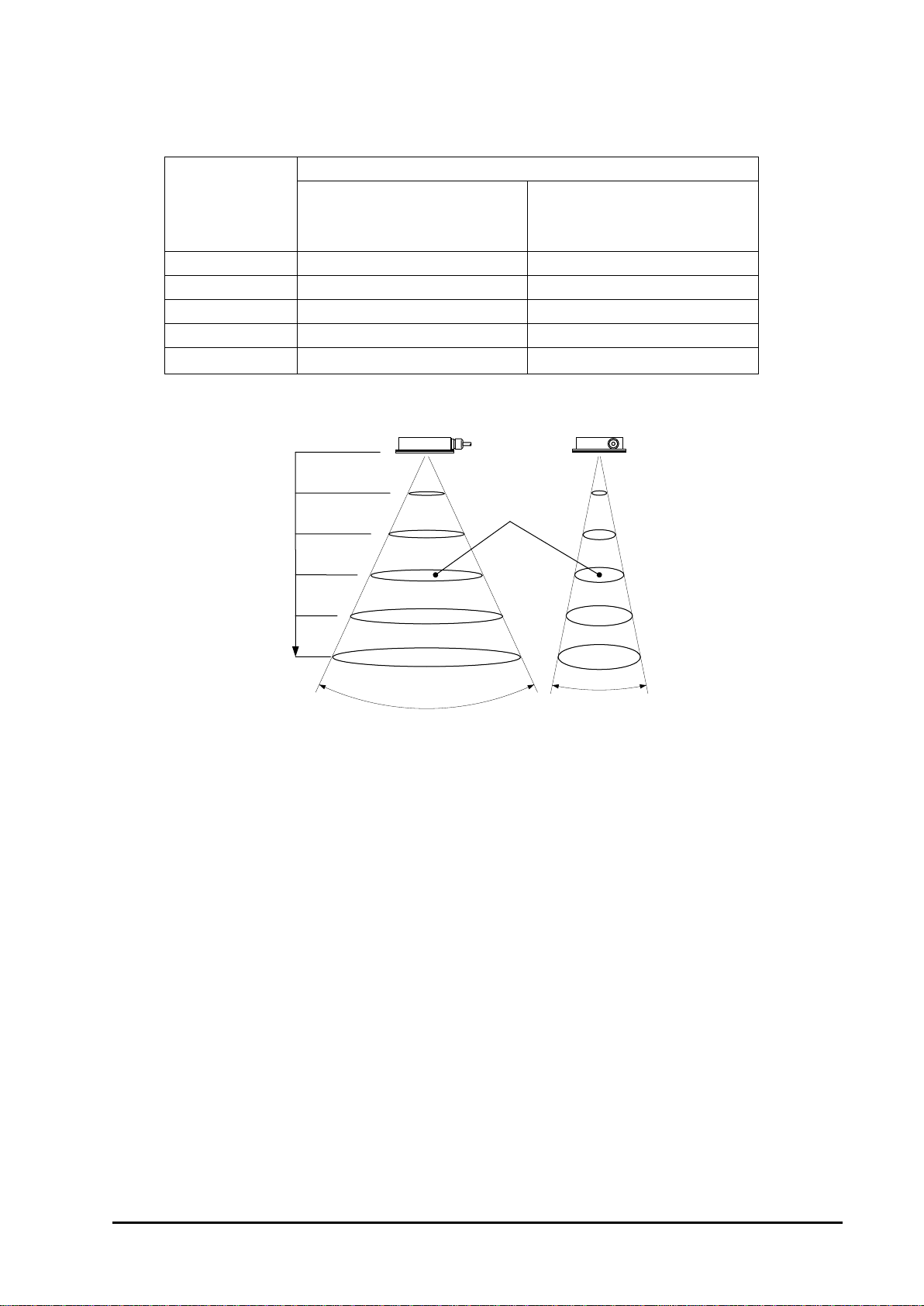

2.2 Beam area in the measuring range

List 2.2-1:Beam angle & Beam area (*-3dB Half-power beam angle)

Distance (m)

Beam area (m)

Lengthwise direction

(cable direction)

Beam angle

*

=50

°

Crosswise direction

Beam angle*=23°

2

1.9

0.8

4

3.7

1.6

6

5.5

2.4

8

7.5

3.3

10 9.3 4.1

[ Key factors for measurement ]

1. Compared to calm fluid surfaces, measuring ranges of turbulent surfaces are

reduced due to poorer reflection.

2. Deposit buildup on the antenna, foaming on liquid surfaces, powder granules in air

suspension and other interior tank conditions may affect measuring range and

performance.

3. Obstructions in the microwave radiating area or target fluid surface areas less than

the radiating area will reduce microwave reflection and decrease and narrow the

measurable range.

4. Measurable range may be varied when area of target fluid surface is smaller than

radiated beam area.

2m

4m

6m

8m

10m

Distance

23.0°

50.0°

Beam area

Long side

Short side

2-2

2.3 Recommended installation example

Following installation examples are recommended installations.

(1) Installation for water channel

Install MRF-10 lengthwise direction of transmitter head to be same direction of flow

direction as below.

Also please keep the required free space from the wall.

Fig. 2.3-1 example of wall sidemounting installation

Fig. 2.3-2 example of top roof mounting installation below grating cover

Wall

H

Required space =

H x 0.5

Water Channel

Flow Direction

Any obstructions must

not be on this wall.

H

Gratingcover

Concrete

slab

Gratingcover / Top roof mounting

Water Channel

Required space = H x 0.5

Flow Direction

2-3

Fig. 2.3-3 example of wall side mounting installation for Inlet water level measurement

(2) Installation for storage Tank

Please avoid installing MRF-10 at the very center of tank, because the reflection of

side beam will affect stable measurement.

Besides, please set the lengthwise direction of MRF-10 install to be parallel against

the nearest tank wall. In such case, required free space to the nearest tank wall will

be more than “measuring range x 0.2”.

Fig. 2.3-4 example of tank installation

Note

Any obstructions, which set as parallel to fluid surface in, the radiated beam area

may contain big disturbance noise.

In such case, reflection plate will be one of the solutions to reduce its reflection.

Tank Wall

H

Side of channel

mounting

Any obstructions must not be on this wall.

Water Channel

Flow Direction

Required space = H x 0.5

2-4

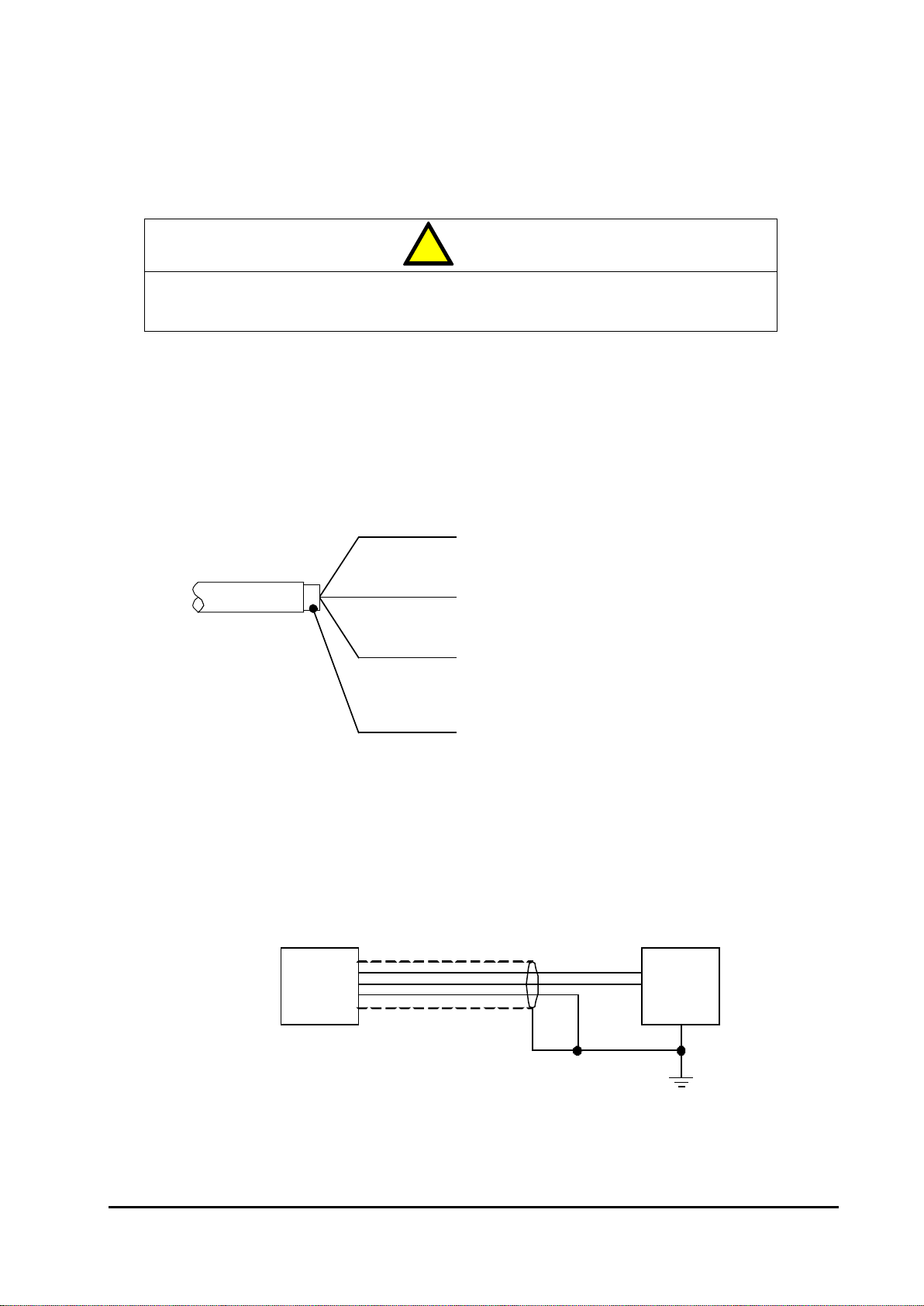

3. Electrical Installation

3.1 Wiring connection

(1) Transmitter side

!

Caution

Do not remove cable glands or any screws that attached with main unit. In case of

removal it, main unit can not satisfy performance of protection class.

Any cable work must be done at the end side of cable, not at the cable entry of the

main unit.

If cable extension is required, please use chemical binder at the end of cable to keep

water protection class.

Fig. 3.1.1-1 wiring connection

・FG (frame ground) must be connected to ground line with cable shield as below.

Fig. 3.1.1-2 Standard wiring diagram

Connet to + side power line

Frame Ground

Connect to power line shield at cabinet side.

MRF-10 Cable

+ (blue)

- (white)

FG (yellow)

Shield

Connet to - side power line

Connect to the groung terminal of the cabinetwith cable shield line.

In case of grounding alreadyattransmitterhead side, do not

connectthis line to the ground line at the cabinet.

MRF-10 +

-

FG

Power

scource

+

-

Shield

MRF-10 standard cable

3-1

(2) Connection for commissioning software

Sample connection for commissioning software through PC is indicated as below

Fig.3.1.2-1.

Any analog recorder can be connected instead of Hart modem.

Fig. 3.1.2-1 Connection to commissioning software

3.2 Cables

Requirement Use shielded twisted cable 2-core or 3 core.

Cross-sectional area of conductor is 0.2 …2.5mm2.

(AWG24 …14)

Recommended cable; KNEE-SB (1.25sq x 3C, OD 9mm)

3.3 Load

Minimum load for HART®250Ω

Maximum load 340Ω(at DC24V)

3.4 Power supply

Requirement 16…36VCD

Current capacity 22mA

HART

modem

Power

Supply Unit

250Ω

-

+

R

MRF-10

3-2

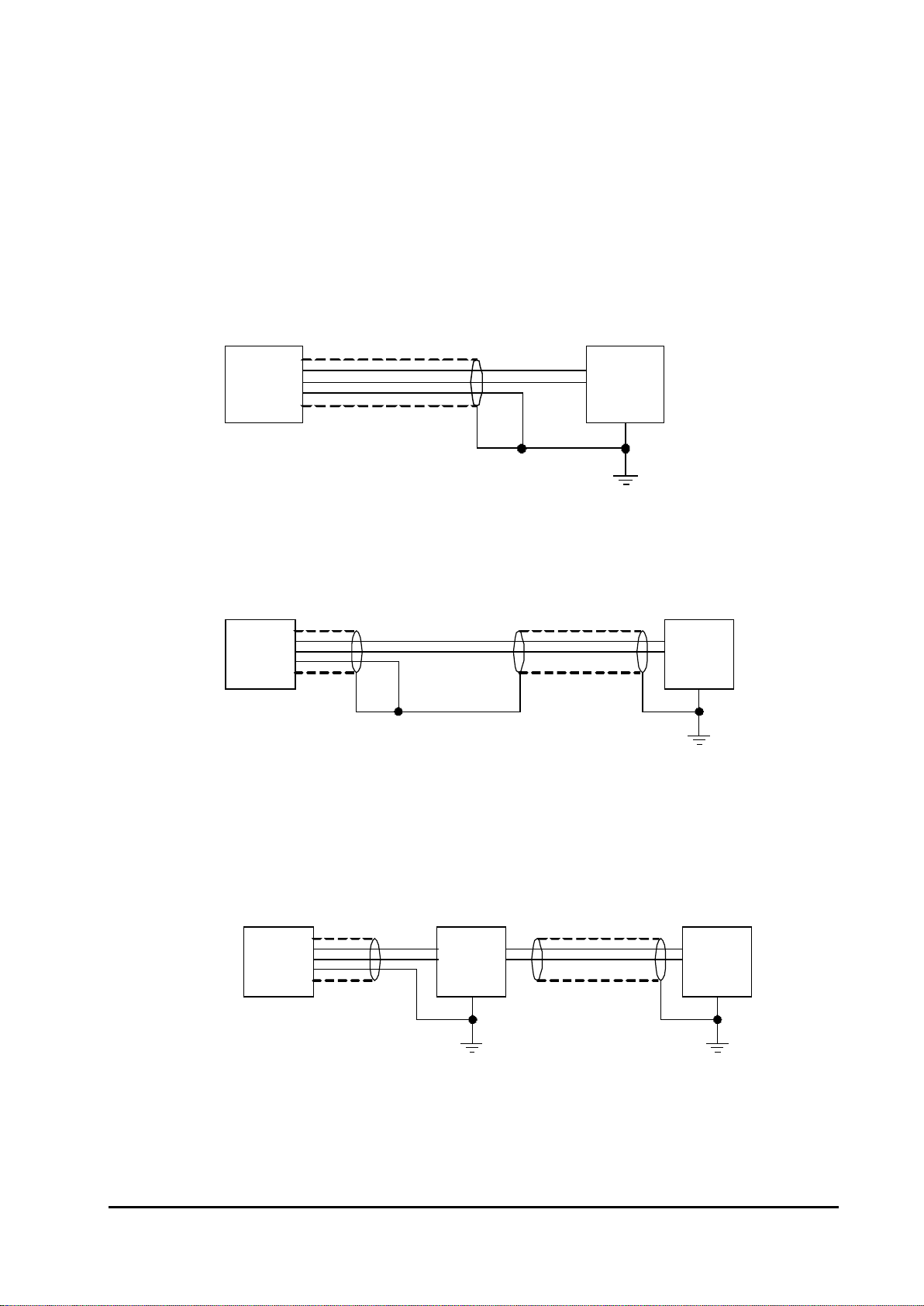

3.5 Grounding

The terminal must be connected to earth ground prior to connection to any other

equipment. The grounding resister should be less than 100 ohm.

(1) Example of connecting only with attached standard cable or extended with

3-core shielded cable

Please connect with shield & FG line to grounding line at power source side as

below.

(2) Extended 2-core cable with shield

Please connect shield line to FG line at connection part, then grounding at power

source side as below.

(3) With lightening arrester

Please connect only FG line to arrester grounding line.

The shield of extension line should be taken at ground line of power source side

as below.

The lightening arrester should be installed near-by MRF-10 transmitter head.

MRF-10 +

-

FG

Power

scource

+

-

Shield

MRF-10 standard cable

MRF-10 +

-FG

Power

source

+

-

Shield

Extention cable

MRF-10 Arrester

+

-

FG

+

-

Extention cable Power

source

3-3

(4) When base of the mounting position made by metal parts which connected

with the grounding line already.

Please connect the grounding terminal near by cable entry to the ground.

Do not use FG line, only with cable shield connects to grounding line as below.

MRF-10 +

-

FG

+

-Power

source

Shield

MRF-10 +

-

FG

+

-

Extention cable Power

source

Shield

Grounding

Terminal

3-4

4. Commissioning

4.1 Working Conditions

Microsoft Windows 2000 / XP

Personal Computer which can activate HART modem

HART Modem (* We have checked following products in the market.)

Maker : MAC Tek

Modem : VIATOR RS232 HART Interface (Model 010001)

VIATOR USB HART Interface (Model 010031)

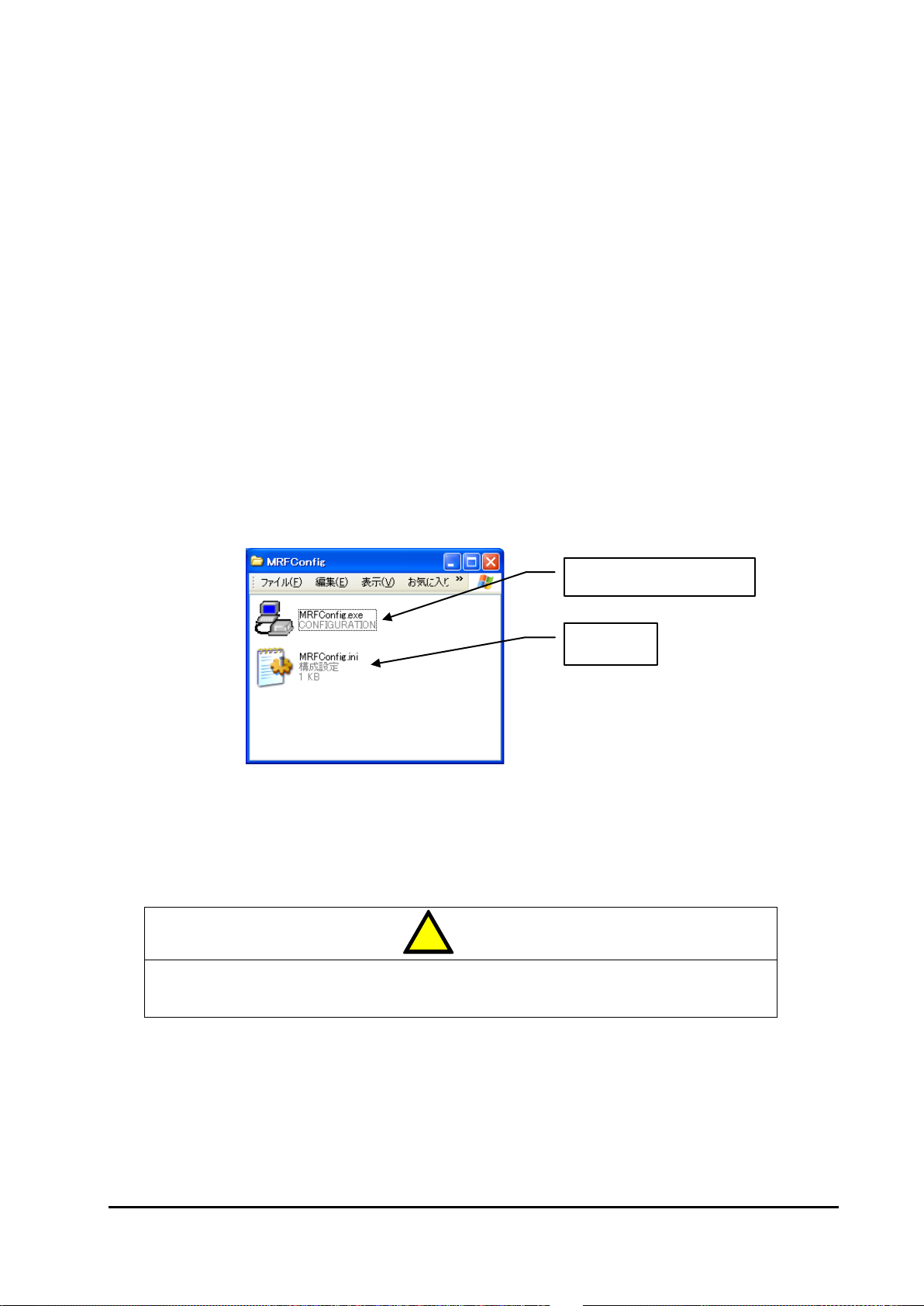

4.2 Produced file

MRFConfig.exe : Main program of configuration software

MRFConfig.ini : Initial File (When the configuration software was quitted, this file is

automatically created.)

Note

This software has no installer. Hence, please copy all files to any folder.

!

Caution

Carefully read this manual prior to use this software because incorrect operation will

cause malfunction and/or breakdown.

This software is subject to change for upgrade without prior notice

Initial File

Configuration Software

4-1

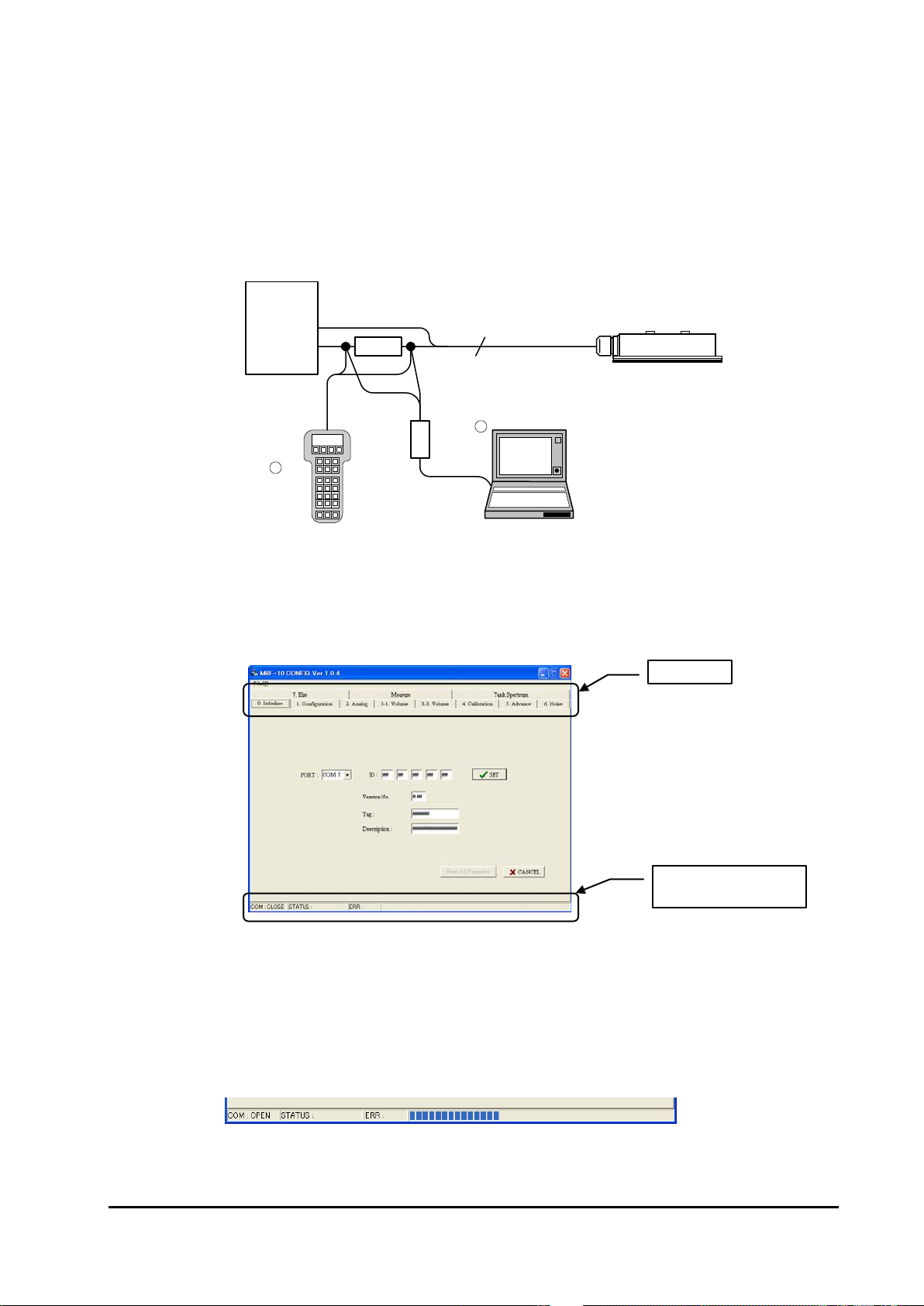

4.3. Connection

This sensor can setup by dedicated software on Notebook PC that connects with HART

modem.

As Fig1.1, HART modem connects with both end of load resister.

Fig. 1.1 Wiring

4.4 Initial Setup

(1) Startup Screen

Fig. 4.4-1 is Start-up Screen.

Fig. 4.4-1 Start-up Screen

Menu Tab in Fig. 4.4-1 can select each kind of parameter.

Progress bar at the lower-end of window shows communication status.

Fig. 4.4-2 is the progress bar under communication (online).

Fig. 4.4-2 Progress bar

Menu Tab

Progress bar to show

communication status

HART

Modem

HART

Handheld

Power

Supply

Load

>250Ω

4...20mA

2

R

R

MRF

-

10

Communicator

4-2

(2) Reading HART ID

Get HART ID from MRF-10.

Fig. 4.4-3 Start-up Screen after getting HART ID

Select serial port No. that connected with HART modem from PORT column in Fig.

4.4-3 at first.

Secondly, click [SET]button and download HART ID from the sensor.

After download of HART ID, individual ID and software version No. will be filled in each

column. All communication with MRF-10 will use this ID.

Fig. 4.4-4 After getting HART ID

[SET] button: Retrieve HART ID from the sensor.

[Read All Parameter]button: Retrieve all parameters from the sensor at one time.

[Cancel] button: Interrupt communication with the sensor on the way.

HART ID No.

Select serial port number.

Get ID by [SET] button.

Download all parameters

Cancel download

4-3

Table of contents

Popular Accessories manuals by other brands

incubato

incubato IN-7DDI user manual

R-Biopharm

R-Biopharm Premi Test Technical manual

Rockwell Automation

Rockwell Automation Allen-Bradley 875L AC user manual

Nooploop

Nooploop TOFSense-F user manual

Parker

Parker Sporlan SD-245 Installation and servicing instructions

Waeco

Waeco CoolPower MPS50 Installation and operating manual