Tollos Cirrus User manual

Cirrus®Service Manual

Pinnacle®Service Manual

Table of Contents

Manufacturer

Changing the Batteries

Replacing the Touch Pad

Replacing the Circuit Board

Replacing the On/O Switch

Replacing the Lift Strap

LCD Display Messenging

Exploded View

Maintenance Checklist

Checklist Notes

IC Belt Inspection Notes

Schematics

Troubleshooting Flow

Cleaning & Disinfection

Terms & Conditions

1

2

3

4

5

6

9

10

11

12

13

17

18

19

20

1

Manufacturer

Tollos Inc.

Corporate Oce Canadian Oce & Manufacturing

8 Easter Court, Suite J 75 Dyment Road

Owings Mills, MD 21117 USA Barrie, ON L4N 3H5 CANADA

Western Zone Oce Central Zone Oce

5560 Skylane Blvd., Suite C 930 N Beltline Road, Suite 107

Santa Rosa, CA 95403 USA Irving, TX 75061 USA

Toll Free: 888-363-7224 www.tollos.com

Parts & Service

Please contact Tollos or your local authorized representative for service.

Phone: 888.363.7224 US & Canada

Fax: 410.363.7708

Website: www.tollos.com

Serial Number: _________________________________________

Please have your serial number available when contacting Tollos for service. Please include your serial number in all

communications with Tollos.

WARNING, CAUTION,

IMPORTANT DANGER

AC Adapter Label General Product Label

Read Manual Label Marking on the Hand Controller

Fuse Label Cirrus 750 Label

Duty Cycle Label Pinnacle 1000 Label

Maximum Weight Labels 6-pt Spreader Bar

On/O Label 6-pt Bariatric Spreader Bar

Manual Emergency Down Label Sling Sizing Guide Label

Remove for Access to Manual

Emergency Down Manual Emergency Crank Label

Symbols

2

Batteries

Tools needed:

• #1 Robertson screwdriver

• 9/64” Allen wrench

1. Using a #1 Robertson screwdriver, remove the 3 screws from both

the front and back of lift.

2. Remove all cables leading to the batteries.

NOTE: Make a note of where the battery connections are.

3. With a 9/64” hex key, remove all both screws holding the battery

bracket in place. Remove the bracket.

4. Batteries can now be removed. Replace with #5004-113 12V, 2.6ah

batteries. Reverse steps 1-4 to complete installation.

3

Touch Pad

Tools needed:

• #1 Robertson screwdriver

• Wire cutters

• Utility knife

• Isopropyl alcohol

1. Using a #1 Robertson screwdriver, remove the 3 screws from both

the front and back of the lift.

2. Using wire cutters, cut away the tie strap holding the touchpad

ribbon.

3. Disconnect the touchpad from its wiring harness.

4. Use a utility knife to get under the touchpad and carefully peel the

touchpad o the lift.

NOTE: When replacing the touchpad, ensure the surface of the shroud

is clean. Wipe with isopropyl alcohol.

NOTE: Do not bend or fold ribbon cable. Faulty connections will result.

WARNING: Do not use too much force applying the touchpad.

Excess force will result in reduced life expectancy and

malfunction.

4

Circuit Board

Tools needed:

• #1 Robertson screwdriver

• Wire cutters

• Needlenose pliers

• Zip ties (x2)

1. Using a #1 Robertson screwdriver, remove the 3 screws from both

the front and back of the lift.

2. Remove all plug connectors from the circuit board.

3. Cut the 2 zip ties that are holding the electrical harness to the board.

4. Using needlenose pliers, pinch the 3 nylon board supports to allow

for removal of the circuit board. Reverse steps 1-4 to complete

installation.

NOTE: Save all nylon mounting board supports for the new board.

(Nylon mounting board supports: part no. 1008-963)

Fuse Holder

1

3

2

Before After

5

On/O Switch

Tools needed:

• #1 Robertson screwdriver

1. Using a #1 Robertson screwdriver, remove the 6 screws holding the

front plate in place.

2. Remove blue strap.

3. Unplug the on/o switch from the wiring harness.

4. While holding the top of the switch inside the lift, twist the brass

knurled end outside of the lift to remove.

Reverse steps 1-2 to complete installation of new switch.

NOTE: When connecting the new switch to the harness, the cable

connects just complete a circuit. The switch cable and the harness

cable aren’t connected in any particular sequence. It doesn’t matter

which connector on the switch cable is attached an opposite harness

cable.

Emergency Down

On/O Switch

6

Lift Strap

Tools needed:

• Drill, R1 bit

• 1/8” Allen wrench

• 3/16” Allen wrench

• 5/32” Allen wrench

• Pliers or flat-head screwdriver

• Blue LoctiteTM

1. Using the drill with the R1 bit, remove 12 case screws from the end of

the lift.

2. Remove end and side panels.

3. Remove one of the battery leads.

4. With a 1/8” Allen wrench, remove 4 screws securing the bottom

panel of the lift.

5. Remove the bottom panel.

NOTE: Remove all electrical connections from circuit boards & cut zip

ties.

6. With a 3/16” Allen wrench, remove the belt guide block from the

frame. Remove the block pin to fully separate.

7. Using a 5/32” Allen wrench, remove the screw from the end of the

belt spool shaft. Lift the red strap and move level out of the way so the

screws can be removed.

(continued)

7

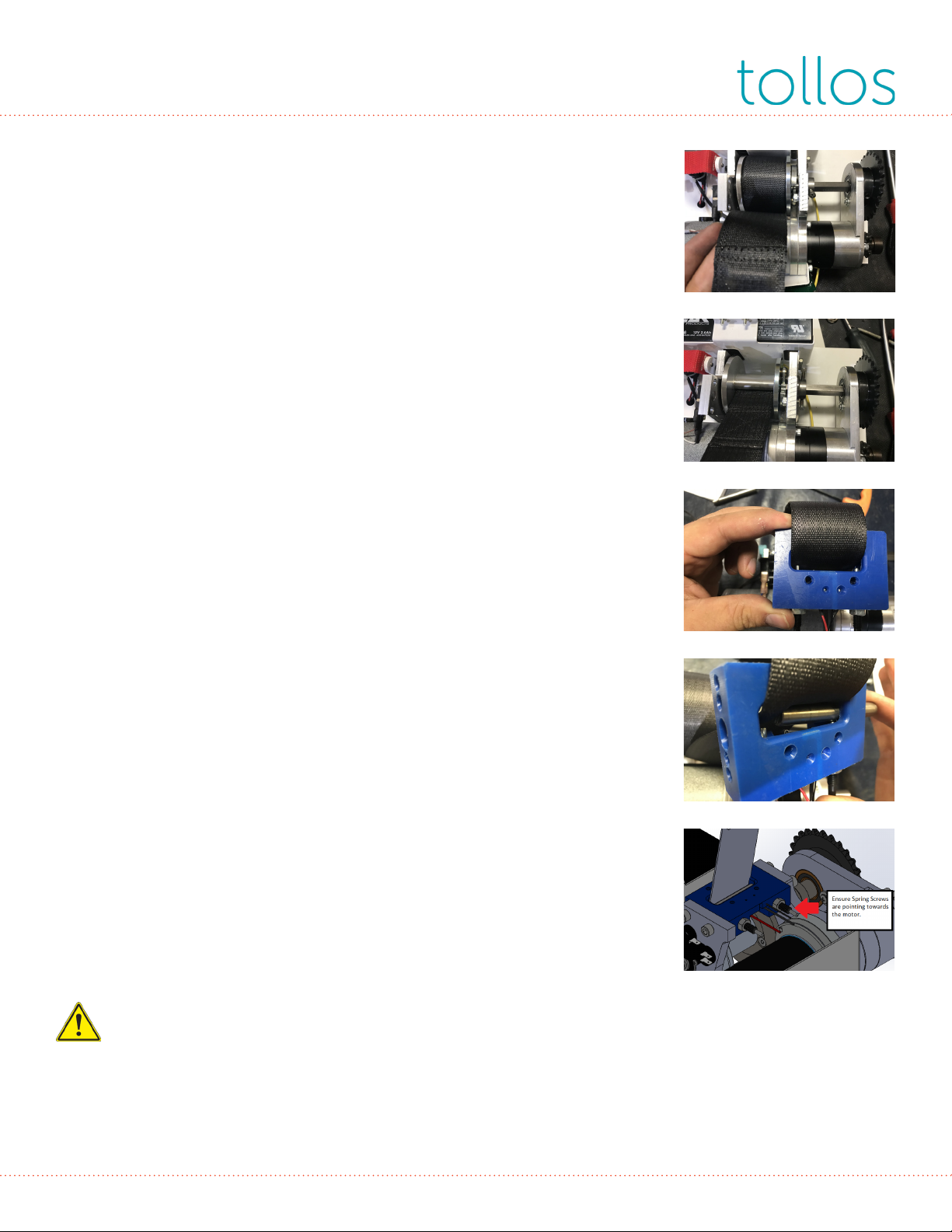

Lift Strap (cont.)

8. Using pliers or a flat-head screwdriver, gently pop o the master link

from the drive chain.

9. With the 5/32” Allen wrench, loosen the set screws on the shaft

collar.

10. With the flat screwdriver, gently tap on the motov spool support to

drive the shaft out of the spool.

11. Remove the belt spool assembly through the top hole (where the

belt guide block was).

12. Remove the damaged strap.

13. Insert the new strap as shown.

NOTE: Make sure the belt is facing up and the belt spool assembly is

properly positioned.

(continued)

8

Lift Strap (cont.)

14. Place the shaft back into the spool and reassemble.

NOTE: Use Blue Loctite on the shaft collar screws, the spool shaft

screw, and the hex bushings.

15. Wind up the belt by moving the large sprocket towards the motor.

16. Insert the end of the new belt through the belt guide block.

17. Move the pin through the block. Make sure the plunger pin is on

one side of the shaft pin and the belt is on the other. A screwdriver

may be necessary to move the plungers out of the way of the pin.

18. Ensure belt block is replaced in the correct orientation. Black

plunger screws should be pointed towards the motor as shown. Use

new chain and link provided in the service kit.

Reverse the procedure to complete reassembly of the lift.

NOTE: Thoroughly test the lift to ensure proper and safe function.

CAUTION: Previously used/old chain links and clips should not be

reused due to possible mechanical damage to the holding chain

clip and the cyclical fatigue that the chain link has endured during

its operation.

9

LCD Display Messages

Two sets of messages can be displayed, depending on whether the lift is in normal operation

mode or charging mode.

Normal Operation

During normal operation, the lift will display the current action and the number of times that

action has been performed during the life of the lift.

There are four possible actions:

LIFT UP: #### - Lifetime-accumulated number of Lift Up movements.

LIFT DN: #### - Lifetime-accumulated number of Lift Down movements.

TRAVEL L: #### - Lifetime-accumulated number of Traverse Left movements.

TRAVEL R: #### - Lifetime-accumulated number of Traverse Right movements.

Charging Mode

During the charging period, the display will toggle through several predefined messages. The

message changes every 7.5 seconds.

TTL CYCL: #### - Lifetime-accumulated number of up/down cycles. Please note, this number

will be dierent from the numbers displayed for LIFT UP and LIFT DOWN.

TTL HRS: #### - Lifetime-accumulated number of hours the lift has operated; defined as the

number of hours the motor (lifting or traversing) has been operating.

CHARGES: #### - Lifetime-accumulated number of times the batteries have been charged.

BATT CAP: % - Current level of charge in the batteries; displays as a percentage in increments of

10%.

LOW CHRG: #### - Lifetime-accumulated number of times the batteries have experience a very

deep discharge.

SERVC IN: #### - Displays the number of lift cycles remaining before service is required.

A.S.: % - Displays the lifespan of the lift, takes into account number of lift cycles and patient

weight.

TTL LR: #### - Active when lift is in transverse mode; tracks the number of times the lift has been

moved.

10

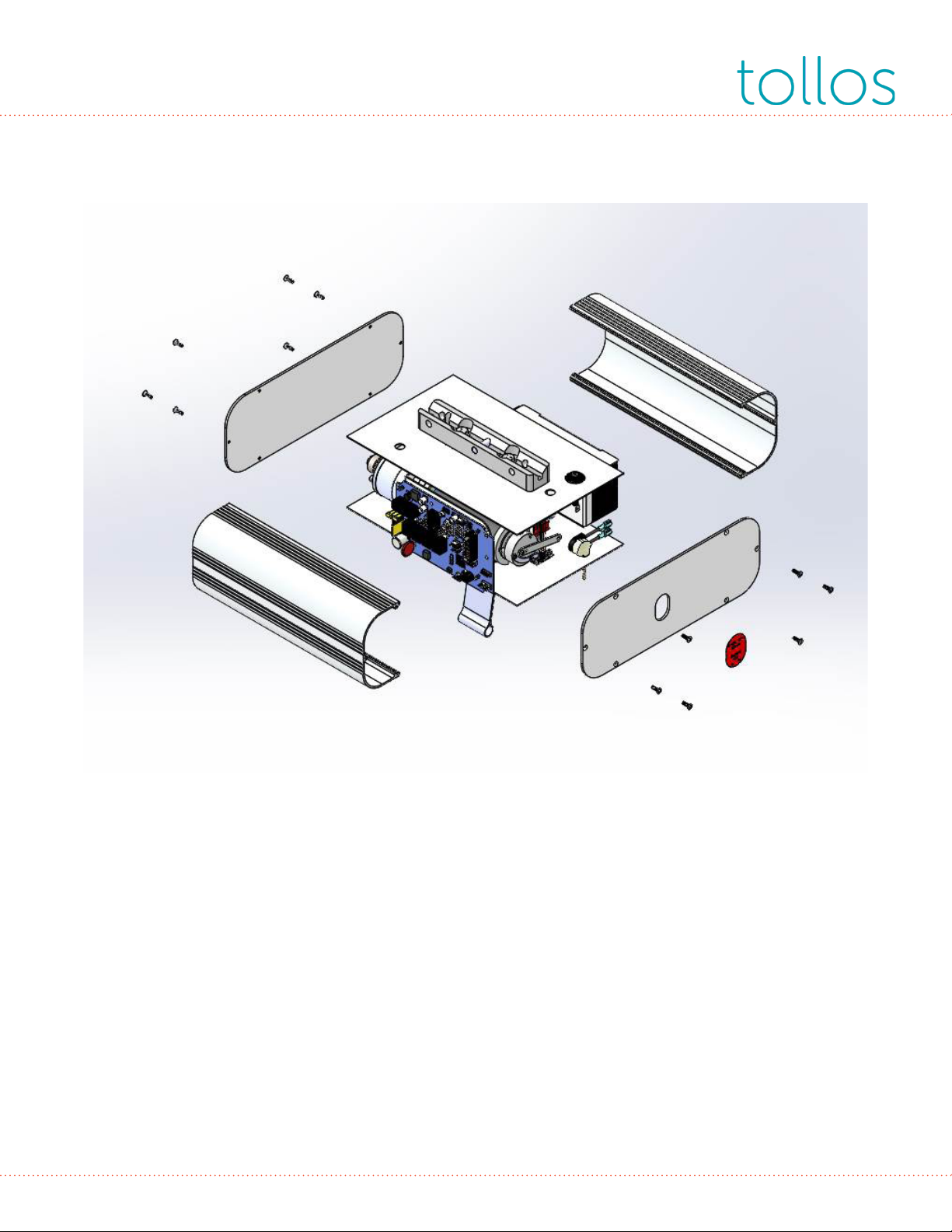

Exploded View

1. Lift Shroud

2. Quick Release Trolley

3. Control Board

4. Drive Chain

1

1

2

3

4

11

Ceiling Lift Inspection Checklist

Date: ______________________________________________________________ Model #: _______________________________________

Facility: ____________________________________________________________ Serial #: _______________________________________

Location: ___________________________________________________________________________________________________________

In Warranty? Yes No D.O.P.__________________________ TTL Cycle: _____________________

Belt OK - N/A Replace/Fix Comments

Cloth belt: stitching, fraying, folding, cuts

IC Belt: weld, folding, cuts, exposed metal strands

(see Notes, pages 13-16)

Trolley (if applicable) OK - N/A Replace/Fix Comments

Inspect wheel motion for free movement

Inspect wheel for visible damage/ flat spots

Inspect trolley drive wheel chain power (traverse only)

Smart Technology OK - N/A Replace/Fix Comments

Scroll through functions

Reset PM alert

Check for low charge

Service in

Operations OK - N/A Replace/Fix Comments

Test upper limit switch

Test lower limit switches

Test manual express down

Test lifting with load

Check noise level

Ensure gear box alignment

Grease brass gear/ worn gear motors only

Electrical OK - N/A Replace/Fix Comments

Test battery output V reading:

Test charge output (26-28 volts) V reading:

Test continuous charge (if applicable)

Test touch pad functions

Test hand control functions

Inspect wiring harness

Inspect circuit board

Inspect all electrical connections

Fasteners OK - N/A Replace/Fix Comments

Re-insert track end stop (if applicable)

Check spread bar side arm nuts (drilled & pinned)

Check all spreader bar retaining clips

Inspect multi-thrust pin (if applicable)

Ensure nuts/bolts are all present and secure

Miscellaneious OK - N/A Replace/Fix Comments

Test scale (if applicable)

Ensure all components are present

Inspect for visual damage

Inspection sticker

Inspected by: ________________________________________________________ Next recommended inspection: _____________________

12

Inspection Checklist Notes

1. Reset PM Alert

Press and hold the three buttons on the hand control (up, down, bottom left). Turn o motor by

pulling on the blue on/o cord. While holding the three buttons, turn on the motor by pulling

the blue on/o cord. There will be two short beeps to confirm reset and the display will read

“SERVICE RESET”.

2. Test Lifting with Load

Batteries much be fully charged. Lifting strap should not be extended to more than 3-4 feet (914

mm - 1219 mm) from the floor and then lifted 19.5” (495 mm) for the Cirrus 750lb (340 kg) lift, or

12” (305 mm)for the Pinnacle 1000lb (454 kg) lift.

3. Test Battery Output

a. Use 12V battery capacity analyzer

b. Batteries should be fully charged before testing

c. Test each battery individually by attaching the leads directly to it

d. They must show a minimum of 12.6V to pass.

4. Test Charger Output

a. Continuous Charge Rail Test:

1. Shut motor o and move lift along track. If motor goes blank, there is a break in

the track.

2. Or use the CC Test Trolley with light. Run the Test Trolley along the track and the

light should stay lit.

b. End Chargers:

1. Shut down the motor, push into charger, charge cycle should begin.

(Charge cycle shown by 1-3 flashing green lights [depends on charge level], then

solid green once charge is complete.

2. Or use the CC Test Trolley with light. Run the Test Trolley along the track and the

light should stay lit.

13

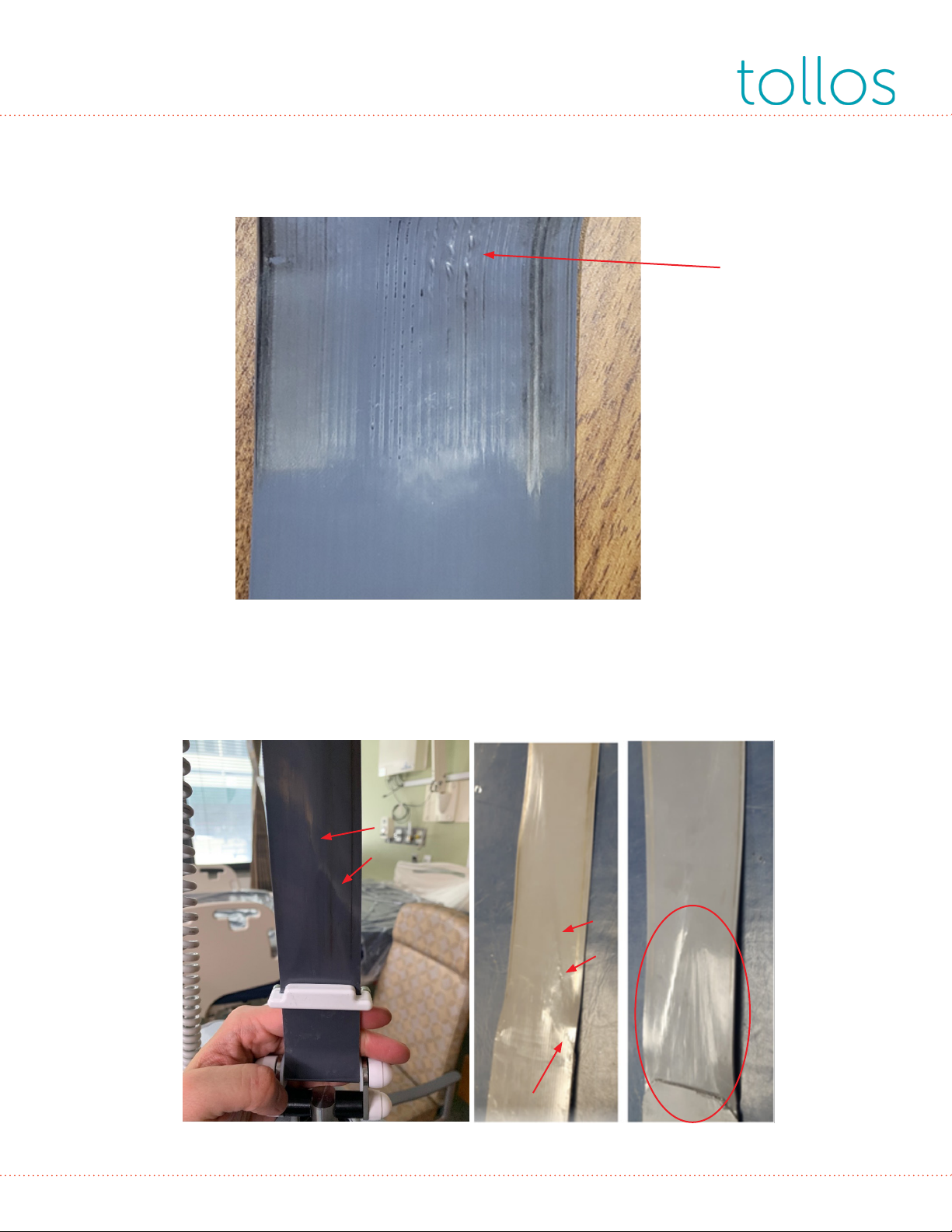

IC Belt Inspection Notes

IC Belt Inspection Details

Specific to lift straps, users should take the following steps to reduce risk:

• Routinely inspect all straps for signs of excessive wear or damage.

} Refer to the pictures on the following pages as examples of wear/damage conditions

requiring replacement.

• Discontinue use of any lifts with straps that show signs of excessive wear or damage.

• Service your facility’s Pinnacle or Cirrus lift(s) by removing and replacing worn or damaged

straps with new straps. Contact Tollos for assistance if needed.

• Educate sta to visually inspect the strap with each use, with instructions to not use lifts with

visibly worn straps and to alert lift maintenance personnel of any concerns.

• As well as having sta inspect the belts before each use, it is recommended that maintenance

or biomed sta (this function varies in dierent facilities) inspect straps on a regular basis as

determined by facility use but at least semi-annually.

All types of lifting straps, including IC straps, are prone to wear and require eventual replacement.

Tollos recommends replacement of any straps showing signs of excessive wear or damage, or at

10,000 cycles, whichever occurs first.

ILLUSTRATIONS

Illustrations 1-4 are examples of IC straps showing signs of normal wear and no structural damage.

These straps are safe to continue to use as long as they have not exceeded 10,000 cycles. If the

inspected straps are at 10,000 or more lift and lower cycles, then replace the straps.

NOTE: The images below were taken during service activities and the clasp is not shown in the

correct position. The correct location of the clasp is just below the fold, shown with the red line

on the picture furthest to the right.)

Illustration 1 Illustration 2 Illustration 3 Illustration 4

14

IC Belt Inspection Notes

Illustration 5 is an example demonstrating wear to the point that the load bearing internal steel

cables are showing. Replace any straps that are worn to this point.

Illustration 5

Illustrations 6-8 demonstrate creasing. If creasing is deep, sometimes coupled with cracks, or if

the strap has exceeded 10,000 cycles the strap must be replaced.

Illustration 6 Illustration 7 Illustration 8

15

Illustration 9 demonstrates physical damage. Do not use a lift with a damaged strap, and immedi-

ately replace any straps found to have physical damage.

Illustration 9

IC Belt Inspection Notes

Illustrations 10 and 11 demonstrate a specific type of physical damage – damage to the edge of

the strap. Replace any straps that have this type of damage. (Note that illustration 10 also demon-

strates significant creasing.)

Illustration 10 Illustration 11

16

Illustrations 12-14 demonstrates the exterior appearance of a strap with severe damage to the

load bearing steel cables internally. An x-ray of this strap is included to show the internal damage

that corresponds to the exterior appearance. The close-up image of the opposite side shows the

broken cable ends visible through the polyurethane covering. (Note, this strap also demonstrates

severe creasing.)

Illustration 12 Illustration 13 Illustration 14

IC Belt Inspection Notes

17

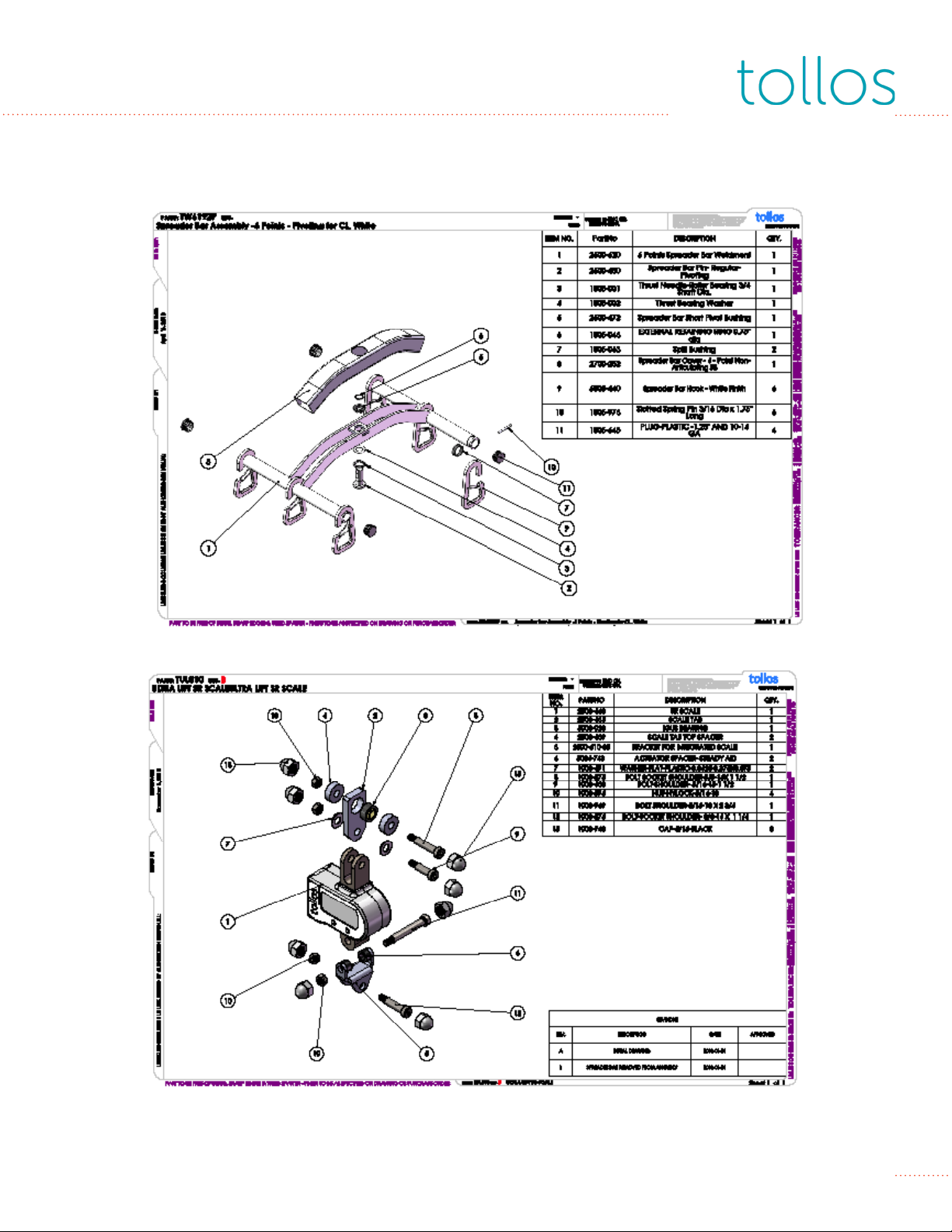

Schematics

Other manuals for Cirrus

1

This manual suits for next models

1

Table of contents

Other Tollos Medical Equipment manuals

Popular Medical Equipment manuals by other brands

ResMed

ResMed AirSense 10 AutoSet for Her Plus Clinical Guide

Otto Bock

Otto Bock Dorso Carezza Posture 50R49 Instructions for use

DryShield

DryShield DS1 user guide

Ossur

Ossur LIVINGSKIN Instructions for use

NanoVibronix

NanoVibronix UROSHIELD user manual

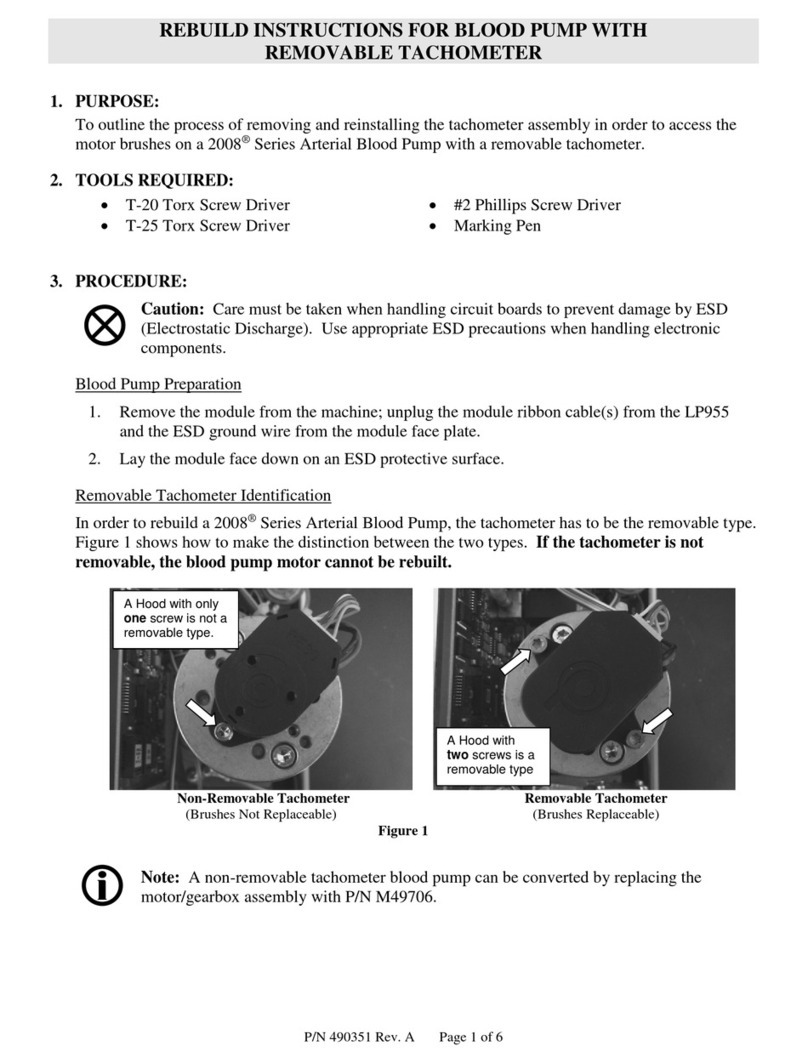

Fresenius Medical Care

Fresenius Medical Care 2008 Series Rebuild Instructions