1.2

Operating Safety

DO NOT modify the power tool without the prior consent of the manufacturer.We

do not assume responsibility for any accident due to equipment modification.

NEVER operate the power tool in purpose for which it is not intended.

NEVER allow anyone to operate the machine without proper training. People

operating the machine must be familiar with the risks and hazards associated

with it. And familiar with the safety precautions and operationtechniques.

KEEP bystanders, children, and visitors away while operating a powertool.

ALWAYS operate the tool with all safety devices and guards in place and in

working order.

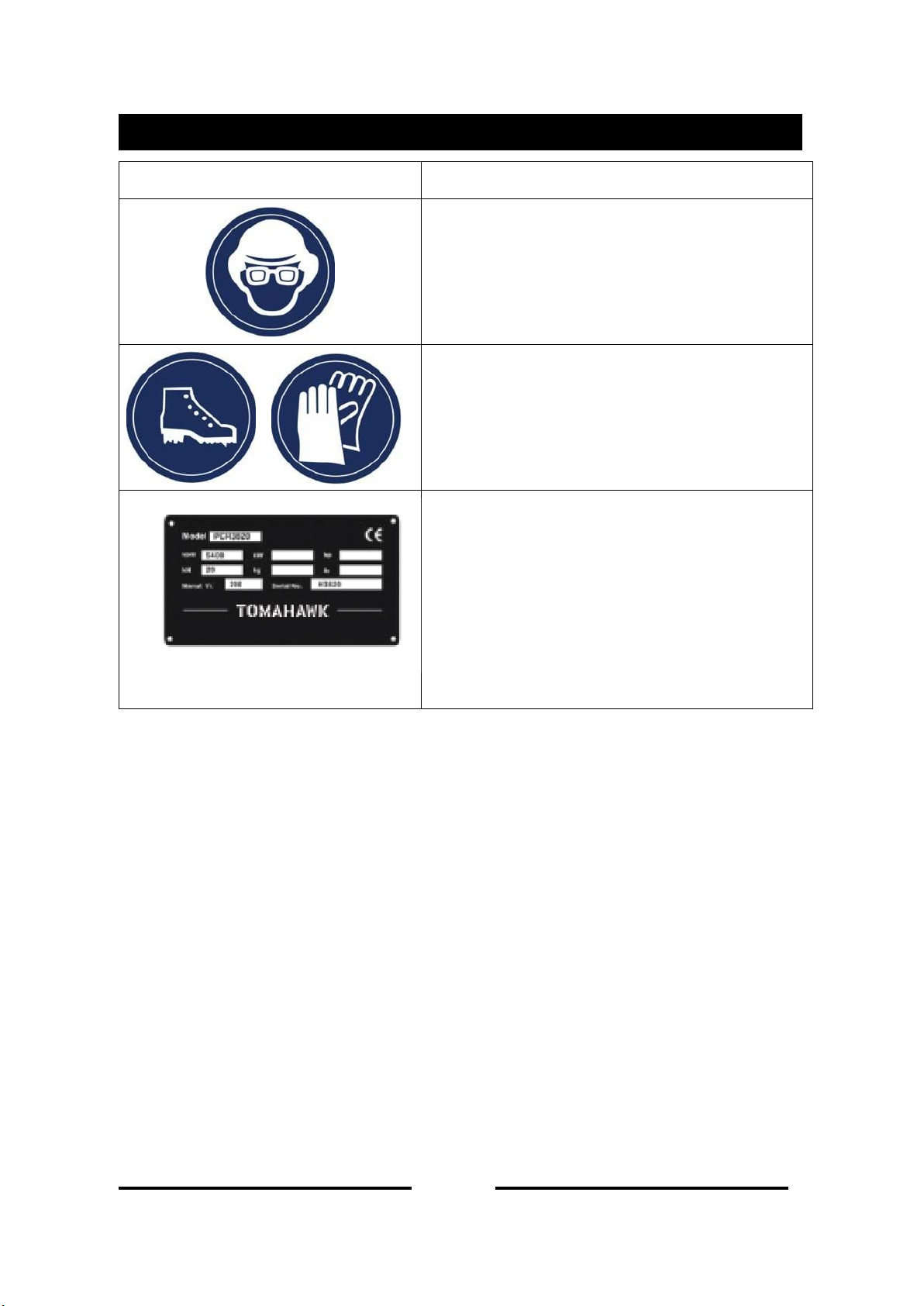

ALWAYS wear appropriate clothing, wear hearing and eye protection when

operating the tool.

DO NOT use the tool near flammable material or in explosive environments. The

exhaust pipe can get very hot during operation. Sparks can be emitted from it,

and these can ignite flammable material.

ALWAYS keep the work area clean and well lit. Cluttered and dark areas invite

accidents.

DO NOT clean or service the machine when it isrunning.

NEVER use the defective parts.

NEVER leave the power tool running unattended.

DO NOT force the power tool. Use the correct power tool for yourapplication.

DO NOT use the power tool if the switch does not turn it on andoff.

DISCONNECT the plug from the power source before making any adjustments,

changing accessories, or storing power tools.

Power tool plugs must match the outlet. Never modify the plug in any way.

DO NOT expose power tools to rain or wet conditions. Water entering a power

tool will increase the risk of electric shock.

DO NOT abuse the cord. Never use the cord for carrying, pulling or unplugging

the power tool. Keep cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric shock.

When operating a power tool outdoors, usean extension cordsuitable for outdoor

use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

If operating a power tool in a damp location is unavoidable, use a residual current

device (RCD) protected supply. Use of an RCDreduces the risk of electric shock.