DEM15D335

- 7 -

8. Setting the manufactureʼs serial number (the last 6th – 9th digits)

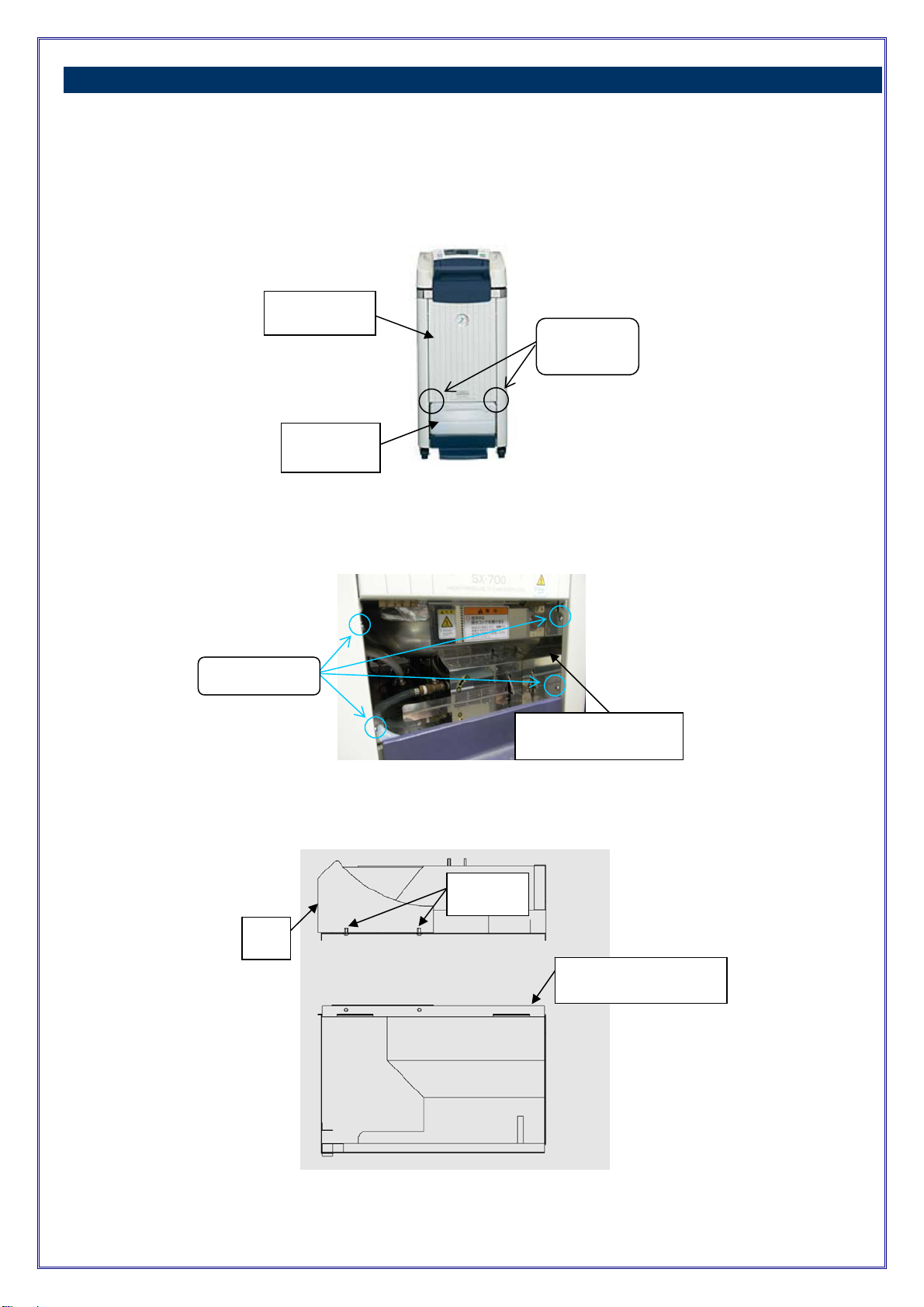

a.) Turn the power switch on while pressing down the FUNCTION , STERILIZE/LIQUID ,and

STERILIZE/NORMAL keys simultaneously to activate the maintenance mode.

b.) Using the temperature setting ▲ and ▼ keys, select the maintenance code [ C17 ]

(change in the 6

th – 9th digits of the serial number) and press the START key.

c.) Using the temperature setting ▲ and ▼ keys, set a three-digit sequential serial number (the

6th – 8th digits of the serial number ) and press the START key.

d.) Using the time setting ▲ and ▼ keys, set a one digit serial number (the 9

th digit of the

serial number ) and press the START key.

When a manufacturerʼs serial number consists of eight digits, having a sequential serial number

of only three digits, the last 9th digit is set to “ – “.

e.) Press the STOP key.

9. Setting the Print date and time

a.) Press and hold down the FUNCTION key for approximately two seconds while the ready lamp is

illuminated.

“F0 1” will start flashing in the temperature display.

b.) Press the temperature setting ▲ and ▼ keys until the code of a desired setting item shows in

the display. The time display will show the code of a desired setting item.

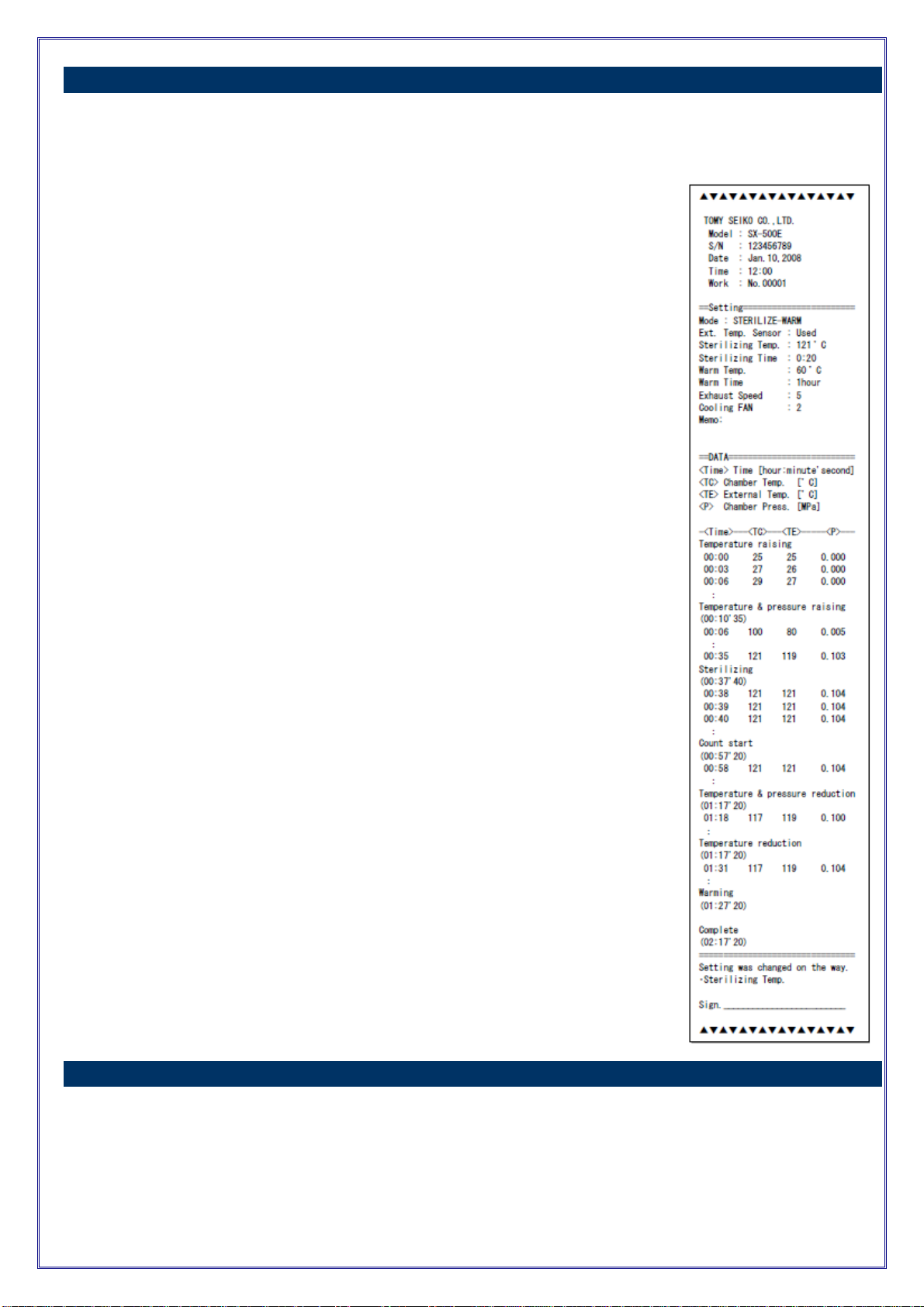

CODE SETTING ITEM SETTING RANGE

F09 YEAR 00-99

F 10 MONTH 01-12

F 1 1 DAY 01-31

F 12 HOUR 00-23

F 13 MINUTE 00-59

* To set the year, enter the last two digits of the year.

c.) Press the START key. The time display will start flashing.

d.) Press the time setting ▲ and ▼ keys until the display

shows a desired set value.

e.) Press the START key again to enter the value.

*When the set value for the minutes is entered, seconds are set as 00.