Tonon Forty VTP Parts list manual

INSTRUCTIONS FOR INSTALLATION, USE AND MAINTANCE

VTP/ VTS/ VTI

CA’ D’ORO fan coil heaters

ITALIANO

ENGLISH

DEUTSCH

INSTALLATORE / INSTALLATION / INSTALLACIÓN

FRANÇAISEESPAÑOL

ITALIANO

ENGLISH

DEUTSCH

UTENTE / CUSTOMER / KUNDENBERATER / USAGER / UTENTE

FRANÇAISEESPAÑOL

1.0 CARATTERISTICHE DELL’APPARECCHIATURA p. 5

1.1 DESCRIZIONE DELL’ ”UNITÀ” p. 5

1.2 DESCRIZIONE DEI COMPONENTI STRUTTURA PORTANTE p. 5

1.3 VERSIONI DISPONIBILI p. 5

2.0 NORME PER UNA CORRETTA INSTALLAZIONE p. 5

2.1 IMBALLO E TRASPORTO p. 5

2.2 INSTALLAZIONE DEI VARI MODELLI p. 5

3.0 COLLEGAMENTI IDRAULICI p. 6

4.0 COLLEGAMENTI ELETTRICI p. 6

5.0 INVERSIONE ATTACCHI BATTERIA p. 7

1.0 AVVIAMENTO p. 28

2.0 ACCESSORI DI REGOLAZIONE p. 28

3.0 USO DEL VENTILCONVETTORE p. 28

4.0 MANUTENZIONE p. 28

5.0 INDIVIDUAZIONE DEI GUASTI p. 28

1.0 FEATURES OF THE HEATER p. 8

1.1 DESCRIPTION OF THE HEATER p. 8

1.2 DESCRIPTION OF THE COMPONENTS p. 8

1.3 AVAILABLE TYPES p. 8

2.0 INSTRUCTIONS FOR CORRECT INSTALLATION p. 8

2.1 PACKAGING AND TRANSPORT p. 8

2.2 INSTALLING THE VARIOUS MODELS p. 8

3.0 HYDRAULIC CONNECTIONS p. 9

4.0 ELECTRIC CONNECTIONS p. 9

5.0 INVERTING THE BATTERY ATTACHMENTS p. 10

1.0 START VP p. 29

2.0 REGULATION ACCESSORIES p. 29

3.0 USING THE FAN-COIL HEATER p. 29

4.0 MAINTENANCE p. 29

5.0 FAULT FINDING p. 29

1.0 GERÄTEEIGENSCHAFTEN p. 11

1.1 BESCHREIBUNG DER EINHEIT p. 11

1.2 BESCHREIBUNG DER BESTANDTEILE p. 11

1.3 VERFÜGBARE VERSIONEN p. 11

2.0 NORMEN FÜR EINE KORREKTE INSTALLATION p. 11

2.1 VERPACKUNG UND TRANSPORT p. 11

2.2 INSTALLATION DER VERSCHIEDENEN MODELLE p. 11

3.0 WASSERANSCHLUSSE p. 12

4.0 STROMANSCHLUSSE p. 12

5.0 UMKEHRUNG AGGREGATANSCHLUSSE p. 13

1.0 INBETRIEBNAIIME p. 30

2.0 ZUSATZGERÄTE DER REGELUNG p. 30

3.0 GEBRAUCH DES GEBL SEKONVEKTORS p. 30

4.0 INSTANDHALTUNG

p. 14

1.1 DESCRIPTION DE L’UNITE p. 14

1.2

DESCRIPTION DES COMPOSANTES STRUCTURE PORTANTE

p. 14

1.3 MODELES DISPONIBLES p. 14

2.0 NORMES POUR UNE INSTALLATION CORRECTE p. 14

2.1 EMBALLAGE E TRANSPORT p. 14

2.2 INSTALLATION DES DIFFERENTS MODELES p. 14

3.0 BRANCHEMENTS HYDRAULIQUES p. 15

4.0 BRANCHEMENTS ÉLECTRIQUES p. 15

5.0 INVERSION EMBOUTS BATTERI p. 16

1.0 DEMARBAGE p. 31

2.0 ACCESSOIRES DE RÉGULATION p. 31

3.0 EMPLOI DU VENTILO-CONVECTEUR p. 31

4.0 ENTRETIENT p. 31

5.0 LOCAUSATIONDESANOMAUES p. 31

1.0 CARACTERISTICAS DELAPARATO p. 17

1.1 DESCRIPCIÓN DE LA UNIDAD

p. 17

1.3 VERSIONES DISPONIBLES p. 17

2.0 NORMAS PARA UNA CORRECTAINSTALACIÓN p. 17

2.1 EMBALAJE Y TRANSPORTE p. 17

2.2 INSTALACIÓN DE LOS VARIOS MODELOS p. 17

3.0 CONEXIONES HIDRÀULICAS p. 18

4.0 CONEXIONES ELÉCTRICAS p. 18

5.0 INVERSIÓN CONEXIONES BATERíA p. 19

1.0 PUESTAENMARCHA p. 32

2.0 ACCESORIOS DE REGULACIÓN p. 32

3.0 USO DEL VENTILCONVECTOR p. 32

4.0 MANTENIMIENTO p. 32

5.0 DETECCIÓNDELAS AVERIAS p. 32

INDEX_TABLE

ENGLISH

INSTALLATION

ATTENTION:

Every intervention must be done by qualied staff and following

the safety norms in force. Before every intervention on the fan coils,

please, read carefully this manual. The present manual must be kept

for all the machine life for future information. Tonon Forty Spa declines

every responsibility for any installation or for using not listed into this

manual.

1.0 FEATURES OF THE HEATER

1.1 DESCRIPTION OF THE HEATER

The “CA’ D’ORO” fan coil heater is a terminal unitfor room air

conditioning, ventilation, heating in the winter and cooling in the

summer.

1.2 DESCRIPTION OF THE COMPONENTS

BEARING STRUCTURE: made from adequately thick galvanised steel

piate, sound and heat insulated.

HEAT EXCHANGE BATTERY: made with copper tubes mechanically

expanded into aluminium ns, 1/2” F bronze manifolds for water

attachments with air valve (maximum working pressure 10 bar).

FAN UNIT: doublé intake centrifugai fans with 1-2-3 fan wheels, single

phase three-speed eiectric motor with heat protection and condenser

permanently activated.

F1LTER UNIT: made from a micro-perforated propylene panel tted on

a hearing fraine with a protection grid, tted to the intake side, it can be

easily removed for cleaning or washing.

COVER: made from moulded and painted steel piate, resistant to

chemical agents and insulated with anti-condensation materia!, the

delivery grid directions can be changed and the access aps to the

electric and hydraulic controls are made in heat resistant ABS. Colours

are RAL 9010 series, with other colours available on request.

1.3 AVAILABLE TYPES

The following types are available:

VTP = wall tted version

VTS = ceiling tted version

VTI = built-in version for the wall or ceiling

Ali the fan coil heaters have a consent thermostat tted standard

(the motor turns only if the water in the exchanger has reached a

temperature of 35°C).

2.0 INSTRUCTIONS FOR CORRECT INSTALLATION

2.1 PACKAGING AND TRANSPORT

Each single unit is packed in a strong cardboard box protected by polythene

and polystyrol shock buffers.

The unit must be handled with care during transport and movement. No more

than three units must be stored on top of each other in the vertical position

and no more than ve in a horizontal position. Check the packaging is not

damaged and do not use any sharp or cutting instruments to open it. When

the unit has been removed from the box, check that it is not damaged and

corresponds to the model effectively ordered with the relative accessories.

Any sort of problem should be immediately communicated to the constructor.

2.2 INSTALLING THE VARIOUS MODELS

Installation must be done by a qualied technician, before beginning

check that the power supply corresponds to the requirements printed

on the plaque attached to each single unit, which also gives the serial

and model number. If the unit is supplied with feet, these should be tted

internally and externally and the supplementary tray if supplied (VEV -

VEO). Drill the wall for the VTP and VTP/ZC models, drill the ceiling for

the VTS and VTS/ZC models, following the measurements given in the

“dimensions” page. Mount the fan coil heater using the expansion nogs

and through screws in the slots on the edge of the unit, the screws must

have a minimum diameter of 6 mm with a washer under the screw head.

The same procedures are used for xing the VTI and VTI/F models to

the wall or ceiling. The air conditioning ceiling versions mounted on the

ceiling must be installed with special attention paid to the inclination, to

ensure the condensation water is emptied into the horizontal tray, the

outlet pipe must be a 16 mm diameter exible tube and smooth inside. If

the unit is installed in the bathroom, it must be placed in a position where

the switches and controls cannot be touched by anyone in the bath or

shower. The power le ad must have a normal PVC sheath (designation

227 EIC 53) type N07V-K or FROR, measuring 3x1.5 mm (for versions

with heating element, use a lead with the section adequate to the power

intake).The heater must not be placed beneath a power socket.

WARNING!

FOR THE BUILT-IN VERSIONS, THE TEMPLATE IS PREPARED

ON SITE, AND THE DIMENSIONS OF THE AIR INTAKE AND

DELIVERY SECTIONS MUST BE RESPECTED AND ATTENTION

MUST BE PAID THAT THERE IS NO CONTACT BETWEEN THE

MOVING PARTS AND THE POWERED ELECTRIC PARTS.

For the ceiling mounted versions, it is advisable not to mount the

fan-coil heater at more than 2.5-2.8 meters from the oor, to avoid air

recycling during the heating phase.

VTP-VTS MODELS

Remove the cover (1), by unscrewing the two screws (2) on the bottoni

edge and lift it in the direction shown by the arrows, to completely

extract it from the positioning pins (3). During these operations it is

advisable to replace the unit and lter in its packaging.

3

1

2

2

ENGLISH

INSTALLATION

2.3 CONFIGURATIONS

VTI/F

VERTICAL BUILT-IN VERSION WITH FRONTINTAKE

VTI/F

HORIZONTAL BUILT-IN VERSION WITH FRONTINTAKE

VTP

VERTICAL WALL VERSION

VTS

HORIZONTAL CEILING VERSION

VTI

VERTICAL BUILTIN VERSION

VTI

HORIZONTAL BUILTIN VERSION

3.0 HYDRAULIC CONNECTIONS

Connect the heat exchanger using a 1/2” GF attachment to the water

supply, using a spanner and counter-spanner to avoid damage to

the battery connections. The pipes can come from the oor, wall or

ceiling. To bleed any air in the circuit, use a at screwdriver to open the

valve on the top at the side of the attachments. If the fan-coil heater is

also used for air conditioning, connect the condensation outlet to the

collection circuit; if the additional external tray has not been requested,

the cooling water pipes must be insulated against condensation. It is

advisable to make a water trap on the condensation outlet pipe to avoid

intake of evil-smelling air. When the connections are terminated, check

there are no water leaks from the exchanger or tray. The exchangers

are supplied to work with a maximum pressure of 10 bar. The battery

attachments on the tandard unit are on the left but if needed they can be

moved to the tight (refer to the inverting battery attachments chapter). To

instali the valves on the two or four pipe versions, follow the instruetions

given in the technical manual or included in the valve kit.

- IN COOLING FUNCTION (TO AVOID WATER CONDENSING) WE

SUGGEST EV2, EV4.

4.0 ELECTRIC CONNECTIONS

Turn the power of at the mains before beginning the electric connections.

The connections must be made in conformity with current standards in

force following the enclosed wiring diagram with each fan-coil heater. Ali

the fan-coil heaters are supplied with a connection box (standard tting on

the right), which contains ali the regulation components and the grounding

terminal. To reach the components, unscrew the two screws in the cover

next to the lead outlets. Each fan-coil heater must be power ed with single

phase 230 volts (tolerance of-51+10) 50 Hzfrequency. A bipolar motor-ci

cuit switch must be installed upstream from the fan-coil heater.

ENGLISH

INSTALLATION

5.0 - INVERTING THE BATTERY ATTACHMENTS

VTP / AB

VTP / CRE

THE CONNECTION BOX CONTAINS:

Standard wall mounted models with cover

VTP/VB version

- VB controls complete with summer/winter - off selection switch and

3 speed selection switch.

- Consent thermostat (for heating)

- Power terminal board

VTP/AB version

- AB control complete with summer/winter - off selection switch,

3 speed selection switch and room temperature regulation

thermostat.

- Consent thermostat (for heating).

- Power terminal board

VTP/CRE version

- Onboard electronic control

- OFF, E/I and 3 fan speeds

- Automatic/manual speed modes

- Ambient temperature thermostat

- Valve control

- Fan consent sensor

Standard models without cover or ceiling mounted (VTI/VTS)

The box just contains a terminal board for connecting the motor

(simple or three speed), the consent thermostat and the grounding

terminal. Ali the settings for speed, temperature, etc, are done by the

installer. On request TONON S.p.A., can supply the following controls

which can be mounted on the wall: CVM: three speed regulator

and summer/winter selection switch. TAM: electronic thermostat

and summer/winter selection switch. CEM: three speed regulator,

electronic thermostat, summer/winter selection switch and solenoid

valve control CEM/D: electronic thermostat, three speed regulator,

summer/winter heating element and solenoid valve control selection

switch. CRE: Electronic thermostat with manual and automatic speed

switch, manual and automatic summer/winter switch, valve control and

electric heating element. These controls are mounted on the wall using

screws and expansion nogs as described in the instruetions contained

with the controls. If the heating element is installed, it must be powered

separately paying special attention to the absorbed current (refer to the

technical feature plaque on the heater). The heater must always be

grounded.

5.0 INVERTING THE BATTERY ATTACHMENTS

A Dismantle the electric control panel.

BDisconnect the motor lead connector - POS. 9.

C Dismantle the consent thermostat POS. 4 pulling ìt outfrom the

battery ns.

D Loosen the motor base xing screws POS. 10, remove the battery

xing screws POS. 6; hold the battery at both ends and pulì ìt out in

the direction ofthe arrow (taking care not to damage the insulation),

rotate the battery by 180°, replace the attachments on the opposite

side and tighten the screws POS. 10.

EInvert the position of the condensation outlet plug POS. 7 and the

position of the condensation tray POS. 8, if tted.

F Dismantle the motor connection leadfrom the right side andt it to

the housing on the left side.

GReassemble the electric control panel on the opposite side, connect

the electric leads (follow the wiring diagram).

H Piace the consent thermostat (or probe) between the battery ns, in

the opposite position from before; if the room air thermostat istted,

position the bulb (or probe) with the special xings POS. 3.

VTP / VB

MODELLO - MODEL – MUSTER - MODÉLE - MODELO 10 20 30 40 50-60 70-80

Dimensioni d’ingombro, Overall Size, Befestigungslocher, Dimemiom d’enconibrement, Dimensiones

A 660 810 960 1100 1410 1710

B 220 220 220 220 230 230

C 480 480 480 480 525 525

Fori di ssaggio, Fijing holes, AussenmaBe, Trous de mecordement mur, Agujeros de sujecion

D 415 565 715 865 1165 1465

E 200 200 200 200 225 225

F 70 70 70 70 95 95

Attacchi standard, Standard attachments, Standardanschliisseanschluss, attaches standard, Conexiones estandares

G 42 42 42 42 42 42

H 130 130 130 130 155 155

I 238 238 238 238 249 249

L 389 389 389 389 444 444

Attacchi batteria supplementare, Additional battery attachments, Zusatzbatterieabuss, Attaches batt. suppl, Conexiones bat. sup

M 112 112 112 112 112 112

N 149 149 149 149 174 174

O 307 307 307 307 318 318

P 372 372 372 372 427 427

Scarico condensa, Condensation outlet, Kondenswasser, Decìargement condensation, Descarga condensado

Q96 96 96 96 100 100

231 231 231 231 231 243 243

S 202 202 202 202 212 212

Distanza, Dist., Abst., Dist., Dist.

120 120 120 120 130 130

DATI DIMENSIONALI, MEASUREMENTS, BESCHAFFENHEIT UND AUSSENMABE, DONNEES CONCERNANT LES DIMENSIONS,

DIMENSIONES

144

100

A

R

S

B

Ø 16

VTS

VTP

VTS/ZC

VTS/ZC

ATTACCHI 1/2”

ATTACHMENTS 1/2” F

ANSCHLUSS 1/2” F

ATTACHES 1/2” F

CONEXIONES 1/2” F

ATTACCHI 1/2”

ATTACHMENTS 1/2” F

ANSCHLUSS 1/2” F

ATTACHES 1/2” F

CONEXIONES 1/2” F

70

100

EF

C

A

B

D

Q

O

G

P

H

M

N

I

L

157.5

87.5

Ø 20

60

144

T

B

R

S

A

Ø 16

EF

T

C

A

B

N

H

M

G

L

I

D

O

P

Q

87.5

157.5

Ø 20

70

MODELLO - MODEL – MUSTER - MODÉLE - MODELO 10 20 30 40 50-60 70-80

Dimensioni d’ingombro, Overall Size, Befestigungslocher, Dimemiom d’enconibrement, Dimensiones

A 562 712 862 1012 1312 1612

B 216 216 216 216 226 226

C 445 445 445 445 490 490

Fori di ssaggio, Fijing holes, AussenmaBe, Trous de mecordement mur, Agujeros de sujecion

D 415 565 715 865 1165 1465

E 200 200 200 200 225 225

F 70 70 70 70 95 95

Attacchi standard, Standard attachments, Standardanschliisseanschluss, attaches standard, Conexiones estandares

G 42 42 42 42 42 42

H 130 130 130 130 155 155

I 238 238 238 238 249 249

L 389 389 389 389 444 444

Attacchi batteria supplementare, Additional battery attachments, Zusatzbatterieabuss, Attaches batt. suppl, Conexiones bat. sup

M 112 112 112 112 112 112

N 149 149 149 149 174 174

O 307 307 307 307 318 318

P 372 372 372 372 427 427

Scarico condensa, Condensation outlet, Kondenswasser, Decìargement condensation, Descarga condensado

Q96 96 96 96 100 100

231 231 231 231 231 243 243

S 202 202 202 202 212 212

ATTACCHI 1/2”

ATTACHMENTS 1/2” F

ANSCHLUSS 1/2” F

ATTACHES 1/2” F

CONEXIONES 1/2” F

ATTACCHI 1/2”

ATTACHMENTS 1/2” F

ANSCHLUSS 1/2” F

ATTACHES 1/2” F

CONEXIONES 1/2” F

DATI DIMENSIONALI, MEASUREMENTS, BESCHAFFENHEIT UND AUSSENMABE, DONNEES CONCERNANT LES DIMENSIONS,

DIMENSIONES

A

B

114 R

S

100

EF

D

68.5 78.5

A

70

60

N

H

M

G

L

I

B

C

O

P

Q

100

Ø 16

Ø 20

VTI

VTI/F

A

B

114

R

S

A

D

68.5 78.5

FE

70

60

B

O

N

H

M

G

L

I

P

C

15

Q

Ø 20

Ø 16

1

2

3

4

5

TM TM

M

123456789

NL

OFF

EST

INV

TDC

230V 50 Hz

FUNZIONAMENTO IN CONDIZIONAMENTO

CONDITIONING

KÙHLEN

FONCTIONNEMENT EN CONDITIONNEMENT

FUNCIONAMIENTO EN LA FASE DE

ACONDICIONAMIENTO

FUNZIONAMENTO IN RISCALDAMENTO

HEATING

HEEEN

FONCTIONNEMENT EN CHAUFFAGE

FUNCIONAMIENTO EN LA FASE DECALEFACCIÓN

Allacciamento elettrico Mod.

VTP/VB - VTP/AB

1 cavo d’alimentazione (min.3x1.5 mmq)

2 SCHEMA ELETRICO VTP/VB

3 SCHEMA ELETRICO VTP/AB

4 Sonda ambiente

5 Valv. per 2 tubi

EV 1 = ELETTROVALVOLA

“RAFFREDDAMENTO”

EV 2 = ELETTROVALVOLA

“RISCALDAMENTO”

Conexión eléctrica Mod.

VTP/VB - VTP-P/AB

1 Camble de alimentación (min.3x1.5)

2 ESQUEMA ELECTRICO VTP/VB

3 ESQUEMA ELECTRICO VTP/AB

4 Sonda ambiente

5 Valv. para 2 tubos

EV 1 = ELECTROVALVULA

“REFRIGERACION”

EV 2 = ELECTROVALVULA

“CALEFACCIÓN”

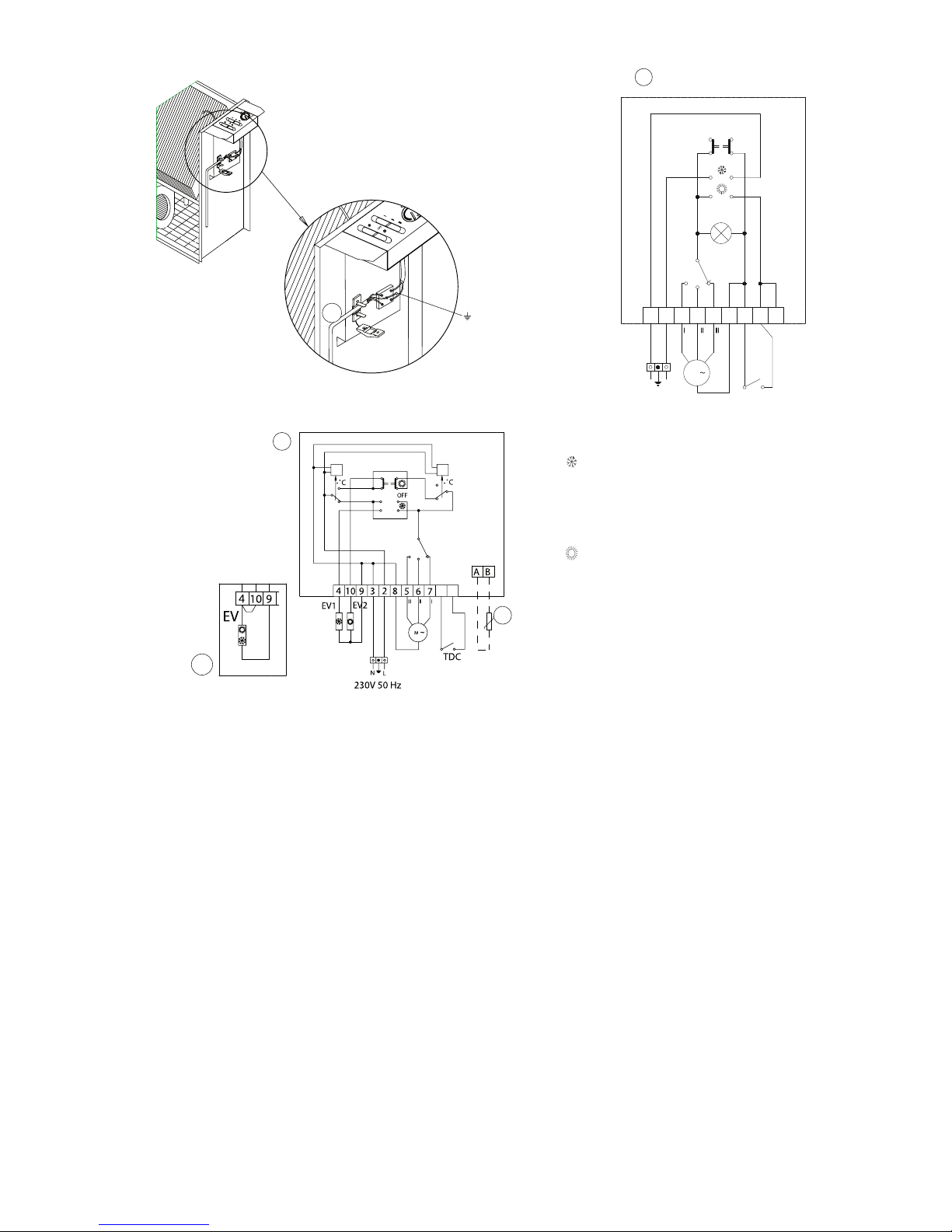

Electric wiring types VTP/VB-VTP/AB

1 supply lead (min. 3x1.5 mm2)

2 WIRING DIAGRAM VTP/VB

3 WIRING DIAGRAM VTP/AB

4 Roomprobe

5 Valve for 2 pipes

EVI = “COOLING” SOLENOID

EV2 = “HEATING” SOLENOID

SCHEMI ELETTRICI, WIRING DIAGRAMS, SCHALTPPLANE, SCHEMAS ELECTRIQUES, ESQUEMAS ELECTRICOS

Branchement électrique Mod.

VTP/VB-VTP/AB

1 Cable d’alimentation (min. 3 x 1.5 mm2)

2 SCHEMA ÉLECTRIQUE VTP/VB

3 SCHEMA ÉLECTRIQUE VTP/AB

4 Sonde environnement

5 Soupape pour 2 tubes

EVI = ELECTROVANNE

“REFROIDISSEMENT”

EV2 = ELE CTROVANNE

“CHAUFFAGE “

Elektrische Anschiusse Mod.

VTP/VB - VTP/AB

1 Stromkabel (min. 3 x 1.5 mm2)

2 SCHALTPLAN VTP/VB

3SCHALTPLAN VTP/AB

4 Raumsondc

5 Vendi ir 2 rohre

EV1=ELEKTROVENTIL “KUHLUNG”

EV2=ELEKTROVENTIL “HEIZUNG”

MOD. VTP/AB

MOD. VTP/VB

2

1

34

d a

M

1

C3V RES

C

2

1

TAA

L

N

2

1

3

DEI

5

4

6

REL

TDC

C

I

II

III

2

3

5

6

IRE

NL

DTS

e

e

f

x

2

1

34

ad

M

1

C3V

RES

C

2

1

TAA

L

N

2

1

3

DEI

5

4

6

TDC

C

I

II

III

2

3

5

6

IRE

DTSR

e

e

f

Allacciamento elettrico 230V 50Hz

1 cavo d’alimentazione (min. 3 x 1.5 mmq)

Electric wiring types 230V 50Hz

1 supply lead (min. 3 x 1.5 mm2)

Elektrische Anschliisse 230V 50Hz

1 Stromkabel (min. 3 x 1.5 mm2)

Branchement électrique 230V 50Hz

1 Cable d’ alimentation (min. 3 x 1.5 mm1)

Conexión eléctrica 230V 50Hz

1 Cable de alimentación (min. 3 x 1.5 mm2)

SCHEMI ELETTRICI, WIRING DIAGRAMS, SCHALTPPLANE, SCHEMAS ELECTRIQUES, ESQUEMAS ELECTRICOS

CVM + TDC

MOD VTS 10 - 80

MOD VTI 10 - 80

TAM + TDC

MOD VTS 10 - 80

MOD VTI 10 - 80

1

OFF

OFF

C

I

II

M

1

L

N

III

1

2 3 4 5

6

e

230V 50HZ 230V 50HZ

C3V + TAA + TDC + DEI + RES

MOD VTP 10-30

C3V + TAA + TDC + DEI + RES

MOD VTP 40-80

230V 50HZ 230V 50HZ

230V 50HZ

TDC

Collegamento effettuato alla velocità media

Wiredfor medium speed

Bei mittlerer Geschwindigkeit durchgeihrte Verbindung

Branchement effectué à vitesse moyenne

Conexión efe tuada a la media velocidad

C

I

II

M

1

III

1

2 3 4 5

6

TDC

1

2 3 4 5

6

6

8

10

12

14

16 18

20

22

24

26

28

30

NL

e

I

1

2 3 4 5

6

7

8

9

II

III

OFF

C

I

II

M

1

III

1

2 3 4

NL

5

6

TDC

e

SCHEMI ELETTRICI, WIRING DIAGRAMS, SCHALTPPLANE, SCHEMAS ELECTRIQUES, ESQUEMAS ELECTRICOS

CEM

TDC + RES + EV

MOD. VTS 10 - 80

MOD. VTI 10 - 80

CEM + EV + TDC

MOD. VTS 10 - 80

MOD. VTI 10 - 80

230V 50HZ230V 50HZ 230V 50HZ 230V 50HZ

230V 50HZ

CEM CEM/D

CEM/D+TDC

MOD. VTS 10 - 80

MOD. VTI 10 - 80

CEM+TDC+EV1+EV2

MOD. VTS 10 - 80

MOD. VTI 10 - 80

230V 50HZ 230V 50HZ

CEM/D

CEM/D

230V 50HZ 230V 50HZ

Parametri manuale, Parameters of the manual, Parametern des Handbuchs,

Parametres manuel, Parámetros del manual CEM/D:

P02= Selezionare, select, auswählen, sélectionner, seleccionar

P07= 2

Parametri manuale, Parameters of the manual, Parametern des Handbuchs,

Parametres manuel, Parámetros del manual CEM/D:

PO1= 1

PO2= Selezionare, select, auswählen, sélectionner, seleccionar

PO7= 2

Parametri manuale, Parameters of the manual, Parametern des Handbuchs,

Parametres manuel, Parámetros del manual CEM/D:

P02= Selezionare, select, auswählen, sélectionner, seleccionar

P07= 2

CEM/D+TDC+EV1+EV2

MOD. VTS 10 - 80

MOD. VTI 10 - 80

CEM+TDC+EV1

MOD. VTS 10 - 80

MOD. VTI 10 - 80

230V 50HZ

CDM/D

DTSR

RES

REL

230V 50HZ FUNZIONAMENTO IN CONDIZIONAMENTO

CONDITIONING

KÙHLEN

FONCTIONNEMENT

EN CONDITIONNEMENT

FUNCIONAMIENTO EN LA FASE DE

ACONDICIONAMIENTO

FUNZIONAMENTO IN RISCALDAMENTO

HEATING

HEEEN

FONCTIONNEMENT

EN CHAUFFAGE

FUNCIONAMIENTO EN LA

FASE DECALEFACCIÓN

Vericare i parametri, Verify the parameters, Kontrollieren die Parameter, Verier

les paramètres, Comprobar los parámetros:

PO1= 2

PO2= Selezionare, select, auswählen, sélectionner, seleccionar

PO7= 2

P21= 60

CEM/D+TDC+EV1+RES

MOD. VTS 10 - 80

MOD. VTI 10 - 80

C

I

II

III

1

2 3 4 5

6

H O

2

M

1

e

L

N

4

5

6

7

10

11 14

15

16 1817 19 20

auto

auto

CRE

CRE + H2O

MOD. VTS/I 10-80

230V 50Hz

EV

H O

2

C

I

II

III

1

2 3 4 5

6

v1 v1

M

1

e

L

N

4

5

6

7

10

11 14

15

16 1817 19 20

auto

auto

CRE

CRE+H2O+EV

MOD. VTS/I 10-80

230V 50Hz

H O

2EV1

EV2

C

I

II

III

1

2 3 4 5

6

v1 cv2

M

1

e

L

N

4

5

6

7

10

11 14

15

16 1817 19 20

auto

auto

CRE

CRE+H2O+EV1+EV2

MOD. VTS/I 10-80

230V 50Hz

SCHEMI ELETTRICI, WIRING DIAGRAMS, SCHALTPPLANE, SCHEMAS ELECTRIQUES, ESQUEMAS ELECTRICOS

C3V= commutatore 3 velocità

TDC= termostato di consenso

TAA= termostato aria ambiente

DEI= deviatore estate - inverno

TAM= termostato amb. a muro

CVM= commutatore a vel. a

muro

CEM= Comando remoto

Estate/Inverno

- Termostato ambiente

- Commutatore tre velocità

- Comando valvole

CEM/D= Estate/Inverno

commutatore manuale e

automatica

- Termostato ambiente

- Comando valvole

- Commutatore tre velocità

manuale e automatica

DTSR= doppio termostato di

sicurezza resistenza elettrica

RES= resistenza elettrica

IRE= interruttore res. elettrica

REL= relé resistenza per mod.

40 - 80

EV1= elettrovalvola

“raffreddamento”

EV2= elettrovalvola

“riscaldamento”

L= linea

N= neutro

= terra

e= condizionamento

c= bianco (comune motore)

I= rosso (min)

II= blu (med)

III= nero

e= giallo - verde (terra)

f= alimentazione

---= limite cablaggio interno

SOLO PER GRANDEZZE 60-80

C= bianco (comune)

I= blu (min)

II= nero (med)

III= marrone (max)

Air = sonda ambiente remota

H2O = sonda acqua

EV = Elettrovalvola

raffrescamento -

riscaldamento per impianto a

2 tubi

EV1= Elettrovalvola

raffrescamento

per impianto a 4 tubi

EV2 = Elettrovalvola

riscaldamento

per impianto a 4 tubi

C3V= 3 Geschwindigksiten-

regler

TDC= Zustimmungsthermostat

TAA= Raumluftthermostat

DEI= Umleiter Sommer- Winter

TAM= RaumthennostatWand-

montiert

CVM= 3 Geschwindigkeitenregler

Wandmontiert

Raumregler Mod. CEM .

Sommer/Winter

- Raumthermostat

- 3-Stufen-Wahlschalter

- Ventilsteuerung.

Raumregler Mod. CEM-D.

Sommer/Winter manuelle und

automatische Umschaltung

- Raumthermostat

- Ventilsteuerung

- manueller und

automatischer 3-Stufen-

Wahlschalter

- Steuerung elektr. Widerstand.

DTSR= Doppelter Siche-

rheitsthermostat elektrischer

Widerstand

RES = elektrischer Widerstand

IRE = Schalter elektrischer

Widerstand

REL= Widerstandsrelais far

Mod. 40-80

EVI= Elektroventil “Kuhlung”

EV2= Elektroventil “Heizung”

L= Linie

N= Neutral

= Erde

e= Klimatisierung

e= weiB (einfacher Motor)

I= rat (min)

II= blau (med)

FU= schwarz (max)

e= gelb-griin (Erde)

f= Stromversorgung

--- = Grenze innere Verkablung

NUR FUR DIE GROSSEN

60-80

C= weiB (einfadi)

I= blau (min)

ll= schwarz (med)

lll= brami (max)

Air = Raumsonde

H2O = Zustimmungssonde

EV = Electroventil “Kuhlung

Heizung”

EV1= Electroventil “Kuhlung”

EV2 = Electroventil “Heizung”

C3V= 3 speed selection switch

TDC= coment thermostat

TAA= room air thermostat

DEI= summer-winter selection

switch

TAM= walltted room

thermostat

CVM= walltted 3 speed

selection switch

CEM= model remote control

Summer/Winter

- Room thermostat

- Three-speed switch

- Valve controls

CEM/D= Comando Res.

Elettrica o manual and auto

Summer/Winter switching

- Room thermostat

- Valve control

- manual and auto three-speed

switch

- Heating element Controls

DTSR= doublé thermostat far

heating element safety

RES= heating element

IRE= heating element switch

REL= heating element relayfar

types 40-80

EVI= “cooling” solenoidi

EV2= “heating” solenoid

L= power line

N= neutra!

= earth

e= cooling

e= white (common motor)

I = red (min.)

II= blue(med)

III = biade (max.)

e= yellow-green (earth)

f= power

---= limitfor internai wiringù

JUSTFOR THE 60-80 SIZES

C= white (common)

I = blue (min.)

II = black(med.)

Ill= brown (max.)

Air = Remote air probe

H2O = Water probe

EV = Cooling and Heating

solenoid

(2 pipes system)

EV1 = cooling solenoid (4 pipes

system)

EV2 = Heating solenoid (4

pipes system)

C3V= commutateur 3 vitesses

TDC= thermostat de

consentement

TAA= thermostat air ambiati!

DEI= déviateur été-hiver

TAM= thermostat ambiarti àxer

sur le mur

CVM= commutateur 3 vitesses

àxer sur le mur

CEM= Commandes remotés

Eté / Hiver

- Thermostat d’ambiance

- Commutateur trois vitesses

- Commande soupapes

CEM/D= Été / Hiver

commutation manuelle et

automatique

- Thermostat d’ambiance

- Commande soupapes

commutateur trois vitesses

manuelle et automatique

- Commande Rés. électrque

DTSR= doublé thermostat de

sécurité

résistance électrique

RES= résistance électrique

IRE= interrupteur rés. électrique

REL= relais résistance pour

mod. 40-80

EVI= électrovanne

«refroidissement»

EVI= électrovanne «chauffage»

L= tigne

N= neutre

= terre

e= conditionnement

e= blanc (moteur commuti)

I = rouge (min.)

II = bleu (moy.)

Ill= noir (max.)

e= ialine - vert (terre)

f= alvmentation

--- = limite càblage interne

SEULEMENTPOURLES

MODELES 60-80

C= blanc (commun)

I = bleu (min.)

II = noir (moy.)

Ill= marron (max.)

Air = Sonde environnement

H2O = Sonde consentement

EV = Electrovanne

“Refroidissement

Chauffage”

EV1 = Electrovanne

“Refroidissement”

EV2 = Electrovanne

“Chauffage”

C3V= conmutador 3

velocidades

TDC= termostato de asenso

TAA= termostato aire ambiente

DEI= desviador verano

- invierno

TAM= termostato amb. murai

CVM= conmutador 3 vel. murai

mandos a distancia CEM.

Estate/Inverno

- Termostato ambiente

- Conmutador de tres

velocidades

- Mando valvulas

Mandos a distancia CEM-D.

Verano/Invierno . conmutacion

manual y automatica

- Termostato ambiente

- Mando valvulas

Conmutador de tres

velocidades manual y

automatica

- Mando Res. Electrica

DTSR= doble termostato de

seguridad resistencia eléctrica

RES= resistencia eléctrica

IRE= interruptor res. eléctrica

REL= relè resistencia para

mod. 40-80

EV1= electrovàlvula

“refrigeración”

EV2= electrovàlvula

“calefacción”

L= linea

N= neutro

= ticrra

e= acondicionamiento

e= bianco (comùn motor)

I= rojo (min)

II= azul (med)

HI= negro (max)

e= amarillo - verde (tierra)

f= alimcntación

--- = limite cableado interior

SOLO PARA DIM. 60-80

C= bianco (comùn)

l= azul (min)

II= negro (med)

lll= marron (max)

Air = Sonda ambiente

H2O = Sonda asenso

EV = Electrovalvula

“Refrigeracion

calefaccion”

EV1= Electrovalvula

“Refrigeracion”

EV2 = Electrovalvula

“Calefaccion”

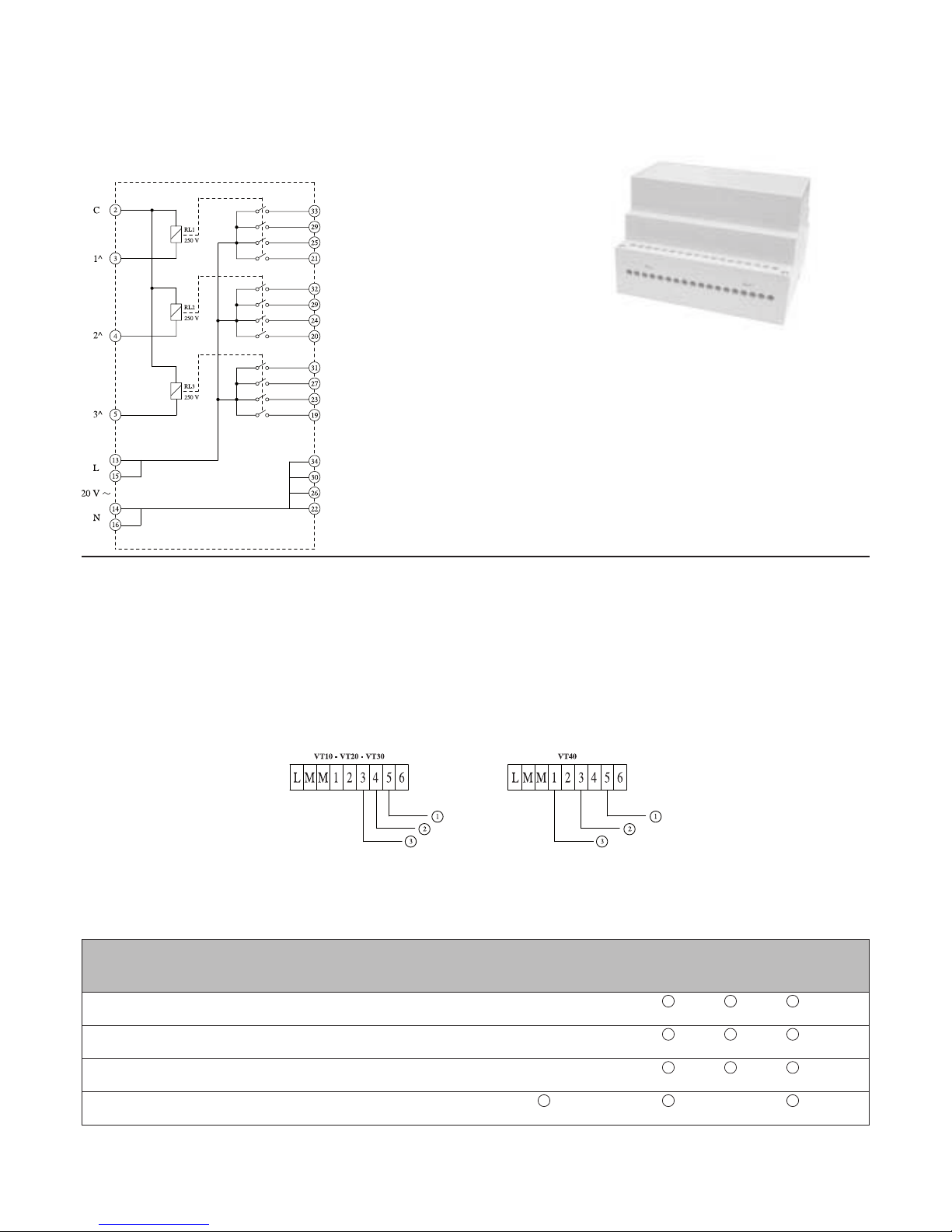

INTERFACCIA DI POTENZA - POWER INTERFACE - LEISTUNGSANSCHLUSS - INTERFACE DE PUISSANCE - ESTERFAZ DE POTENCIA

Attenzione, Attention, Achtung, Attention, Attención:

Utilizzare sempre l’interfaccia di potenza per collegare più ventilconvettori ad un solo comando remoto. Always use the power interface to connect more

fan coils to single remote control. Leistungsanschluss immer zu benutzen um mehre Klimakonvektoren zu ein einzigen Fernbedienung zu verbinden. Il

faut utiliser toujours l’interface de puissance pour commander plusieurs (jusqu’à 4) ventilo-convecteurs avec un seule commande a distance.

Utilizar siempre la interfaz de potencia para conectar varios fan coils a un solo mando a distancia.

Schema elettrico - Wiring diagram

Elcktrischcr Schaltplan - Schèma électrìque

Esquema elettrico

1^ VELOCITÀ

1st SPEED

1. GESCHWINDIGKEIT

1AVTTESSE

1AVELOCIDAD

2^ VELOCITÀ

2st SPEED

2. GESCHWINDIGKEIT

2^ VITESSE

2^ VELOCIDAD

3^ VELOCITÀ

3st SPEED

3. GESCHWINDIGKEIT

3^ VITESSE

3^ VELOCIDAD

COMUNE

COMMON

GEMEINSAM

COMMUNE

COMÚN

Descrizione:

- Possibilità di collegare no a

4 Ventilconvettore con un solo

comando remoto.

- Potenza max assorbita di ogni

Ventilconvettore 1/10 hp

Description:

- Up to 4 fan-coils can be connecte

withjusta single remote control.

- Max. Absorbed power by each fan

coil is1/10 hp

bcschrcibung:

- Moglicher anschluss von bis zu

4 klimakonvektoren mit nur einer

einzigen fernbedienung.

- max. Aufgenommene leistung von

jedem klimakonvektoren 1/10 hp

Description:

- Possibilite de brancher jusqu’a 4

Ventilo-convecteurs avec une seule

commandea distance.

- Puissance maxi absorbee de chaque

Ventilo-convecteurs 1/10 hp

Descripción:

- Posibilidad de conectar hasta 4

Ventilconvectores con un ùnico

mando remoto.

- Potencia max. Absorbida por cada

Ventilconvectores 1/10 hp

I ventilconvettori modello

VT 10-20-30-40 , sono dotati di

variazione della ventilazione,

mediante auto-

trasformatore a 6 posizioni.

Le posizioni certicate

EUROVENT sono:

VT10 - VT20 - VT30 - VT40

Morsettiera autotrasformatore

(vedi g.)

© - Min. (rosso)

© - Med. (blu)

© - Max. (nero)

The VT 10-20-30-40 version

fan-coil heaters have a fan

regulator using a 6 position

auto-transformer.

The certied

EUROVENTpositions are:

VT10 - VT20 - VT30 - VT40

Auto-transformer terminal

board

(follow thè pict.)

© - Min. (red)

© - Med. (blue)

© - Max. (black)

Die Geblasekonvektormodelle

VT 10-20-30-40 sind mit einer

Lüftungsregelung durch

Spartransformator mit 6

Stellungen ausgestattet.

Die von EUROVENT

zertizierten

Positionen sind:

VT10 - VT20 - VT30 - VT40

KlemmleisteSpartransformator

(siehe g.)

© - Min. (rot)

© - Mitt. (blau)

© - Max. (schwarz)

Les ventilo-convecteurs

VT 10-20-30-40 sont pourvus

de variation de la ventilation,

grâce à l’autotransformateur

à 6 positions.

Les positions certiées sont

les suivantes:

VT10 - YT20 - VT30 - VT40

Plaque à bornes

autotransformateur (voir le g.)

© - Min. (rouge)

© - May. (bleu)

© - Maxi (noir)

Los ventilconvectores modelo

VT 10-20-30-40 estan dotados

de variación de la ventilación,

mediante auto-transformador

de 6 posiciones.

Las posiciones certicadas

EUROVENT son:

VT10 - VT20 - VT30 - VT40

Tablero de bornes

autotransformador (ver g.)

© - Min. (rojo)

© - Med. (azul)

© - Max. (negro)

PORTATA ARIA RIFERITA ALLE VARIE POSIZIONI DEI COLLEGAMENTI ALL’AUTOTRASFORMATORE (mc/h) - AIRFLOW REFERRED

TO THE VARIOUS CONNECTION POSITIONS TO THE AUTO-TRANSFORMER (mjh) - LUFTDURCHSATZ FÜR DIE VERSCHIEDENEN

POSITIONEN DER ANSCHLÜSSE AN DEN SPARTRANSFORMATOR (m3/h) - DEBIT AIR SE RAPPORTANT AUX DIVERSES POSITIONS DES

BRANCHEMENTSA L’AUTOTRANSFORMATEUR (mc/h) - CAUDAL DE AIRE REFERIDO A LAS VARIAS POSICIONES DE LAS CONEXIONES AL

AUTOTRANSFORMADOR (m3/h)

AUTOTRASFORMATORE - AUTO-TRANSFORMER

AUTO-TRANSFORMER AUTOTRANSFORMATEUR

AUTOTRANSFORMADOR

Pos. 1 Pos. 2 Pos. 3 Pos. 4 Pos. 5 Pos. 6

Mod. VT 10 333 296 252 200 147 128

Mod. VT 20 388 348 304 254 194 184

Mod. VT 30 584 505 430 353 254 232

Mod. VT 40 716 570 490 423 300 283

3 2 1

3 2 1

3 2 1

2 13

ENGLISH

CUSTOMER

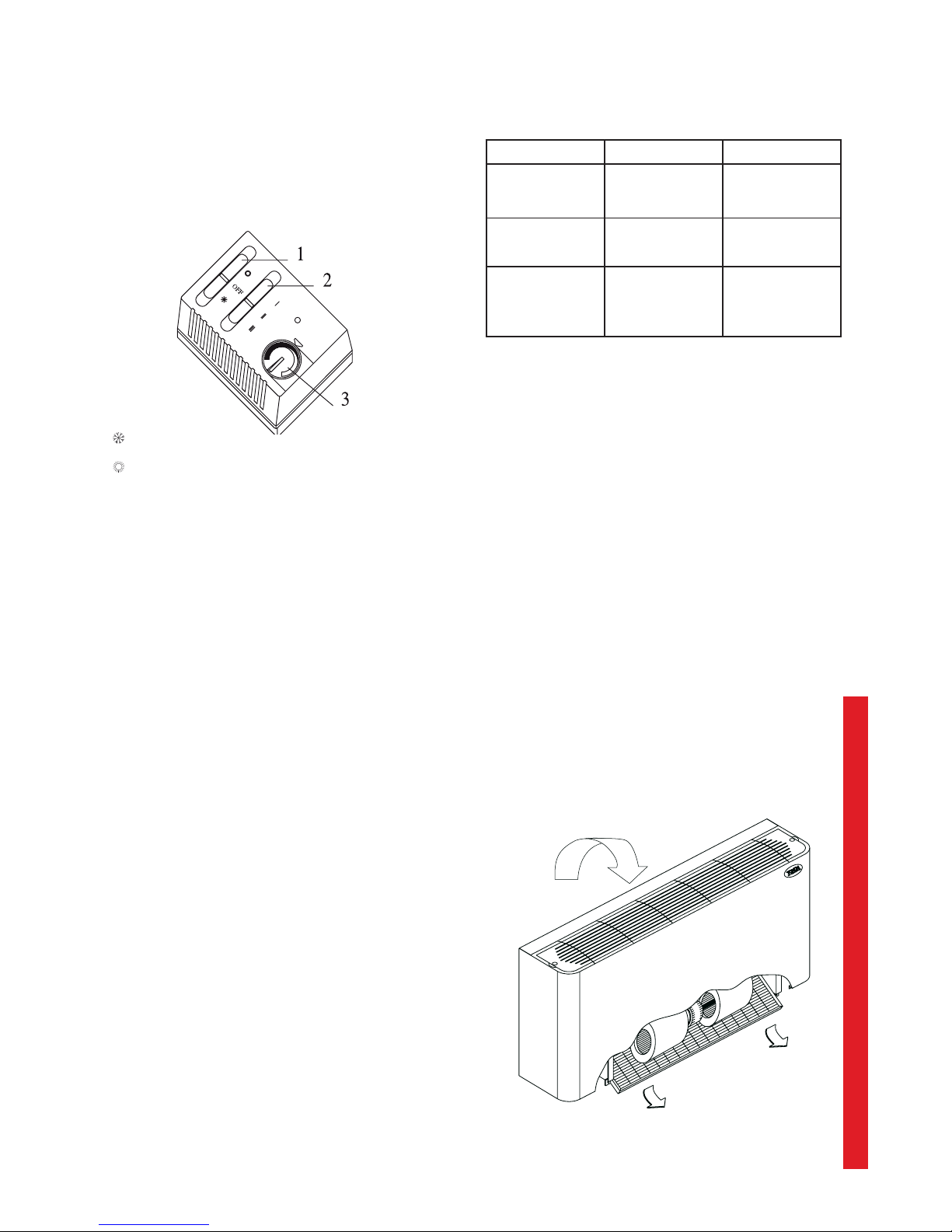

1.0 START UP

Control that the cover andlter are correctly assemblea and that the

electric connectìons have been mode in conformity with the enclosed

diagrams. Turn the heater on and check the controis to ensure the

fan-coil heater and accessories work properly.

1 - Summer-winter-off selection switch.

2 - Fan regulation.

3 - Room temperature regulation

(VTP/AB versions).

AIR CONDITIONING

HEATING

2.0 REGULATION ACCESSORIES

Ensure that the accessories have been correctly assemblea and that

the electric conectìons have been mode as given in the instructions

included with the kit.

* READ THE INSTRUCTION MANU AL CAREFULLY BEFORE

MAKING ANY SETTINGS OR C A R R Y I N G O U T THE

MAINTENANCE WORK.

*IF THE FAN-COILHEATER ISDISSEMBLEDAND REASSEMBLED

THE INSTRUCTION MANU AL MUST BE SCRUPULOUSLY

FOLLOWED.

* PAY SPECIAL ATTENTION TO HOW THE HEATER IS USED

WHERE “ATTENTION” OR “DANGER” ARE WRITTEN, TO

AVOID DAMAGE TO THE HEATER, PEOPLE AND PROPERTY.

* TONON S.P.A. DECLINES ALLRESPONSIBILITY FOR DAMAGED

CAUSED BYINCORRECT USE OF THE FAN-COIL HEATER AND

BY FAILURE TO FOLLOW THE INSTRUCTIONS GIVEN IN THIS

MANUAL.

3.0 USING THE FAN-COIL HEATER

Ensure that the air-intake zone isfree and there is nothing covering

the delivery grid (do not use it to dry washing, or piace anything on top

ot) otherwise the heater will not work correctly.

4.0 MAINTENANCE

Correct periodic maintenance means safe top quality performance.

Before beginning any sort of maintenance:

- Turn the power offto the fan-coil heater

- Ensure that the solenoid or holder do not allow water to circuiate in

the exchanger.

- Use protective gloves

Once a month or after heavy use, clean the lter using a vacuum

cleaner or wash it with neutral detergent. If the lter is stili not clean

request a new one from our service centre. How to remove the lter

(see the gure):

- Unscrew the xing screws.

- Pulì the lter downwards towards the oor (or the wall in horizontal

versions).

Once a year or after a long time without being used, clean the battery

with a compressed airjet and check that the condensation outlets are

not blocked.

Do notpour water onto the heater. The electric motor does not require

maintenance.

If the heater is not used and the outside temperature falls below

0°C, empty the exchanger by opening the screws below the bottom

attachment and add mono ethylene glycol to the water to lower the

freezing temperature to the required level.

5.0 FAULT FINDING

FAULT CAUSE REMEDY

No air comes out The motor does not turn

The consent thermostat

does not dose

Check the power supply

Increase the intake

water temperature

Little air comes out Blocked lter or battery

Airow blocked

Clean the lter and

battery Unblock the

airow

Poor heating/cooling Air in the hydraulic circuit

Little water in the circuit

Intake water temperature

low/high

Bleed the hydraulic

circuit Check the boiler

or cooler Check the

boiler or cooler

* FOR ANY PROBLEMS THAT ARE NOTCOVERED BY THE

INSTRUCTION MANUAL, CONTACT THE TONON S.P.A. SERVICE

CENTRE.

ATTENTION

In case ofre water must not be used - only powder or COi

extinguishers.

SPARE PARTS

Use only originai spare parts.

WARRANTY

The warranty is valid for 3 years (except the electric parts which are

coveredfor 1 year). The warranty is valid from the date the heater is

installed. The warranty is no longer valid if repairs or alterations are

mode by unauthorised persons, or due to faults that are not caused

by originai faults of the components or its construction.

DO NOT COVER

CARATTERISTICHE TECNICHE VENTILCOVETTORE CA’ D’ORO - TECHNICAL FEATURES OF CA’ D’ORO FAN COIL HEATES - TECHNISCHE

EIGENSCHAFTEN KLIMAKONVEKTOR CA’ D’ORO - CARACTERISTIQUES TECHNIQUES VENTILO-CONVECTEUR CA’ D’ORO - DATOS

TECNICOS VENTILCONVECTOR CA’ D’ORO

Modello - Type - Modell - Modéle - Modelo 10 20 30 40 50 60 70 80

Potenza termica - Heating capacity - Heizleistung - Puissance termique - Potencia calorica (1) E

Acqua ingresso 70°C, ∆T 10K - Intake water temperature 70°C, ∆T 10K - Temp. Wasservorlauf

70°C, ∆T 10K - Temp. entrée eau 70°C, ∆T 10K - Temp. entrada agua 70°C, ∆T 10K

W max

W med

W min

2910

2430

1900

3770

3260

2640

5250

4490

3460

8870

6540

4330

12100

9870

8190

14300

12100

9870

17100

15300

13000

19200

17100

15300

Portata acqua max - Water ow - Wassermenge - Debit d’eau - Caudal agua

l/h

254 329 459 776 1056 1246 1498 1677

Perdite di carico acqua - Pressuredrop - Druckverlust - Perte de charge - Perdita de carga

Kpa

3.08 6.92 4.34 13.1 6.9 7.08 12.2 14.9

Potenza termica - Heating capacity - Heizleistung - Puissance termique - Potencia calorica (2) E

Acqua ingresso 50°C - Intake water temperature 50°C - Temp.

Wasservorlauf 50°C - Temp. entrée

eau 50°CK - Temp. entrada agua 50°C

W max

W med

W min

1690

1420

1120

2030

1770

1470

2930

2530

1960

5240

3880

2600

6590

5430

4480

7500

5880

4840

9860

8800

7770

10700

9580

8550

Perdite di carico acqua - Pressuredrop - Druckverlust - Perte de charge - Perdita de carga

Kpa

2.47 5.04 4.59 12.3 6.02 8.9 15.4 19.4

Potenza termica IR - Heating capacity - Heizleistung - Puissance termique - Petencia calorica (4) E

Batteria di scambio aggiuntiva an un rango - Additional one rank exchange battery - Leiter

ZusatzAustascherBatterie d’échange addìtionelle à un rang-1 - Battería de intercambio adjunta de un rango

Acqua ingresso 70°C, ∆T 10K - Intake water temperature 70°C, ∆T 10K - Temp. Wasservorlauf 70°C, ∆T 10K

Temp. entrée eau 70°C, ∆T 10K - Temp. entrada agua 70°C, ∆T 10K

W max

W med

W min

1420

1210

980

1910

1680

1390

2700

2350

1600

4080

3210

2260

5580

4570

3890

6070

5580

4570

7440

6920

6050

8150

7440

6920

Portata acqua max - Water ow - Wassermenge - Debit d’eau - Caudal agua

l/h

124 167 236 357 476 530 651 713

Perdite di carico acqua - Pressuredrop - Druckverlust - Perte de charge - Perdita de carga E

Kpa

3.00 6.07 12.3 27.8 21 23.3 42.1 46.7

Potenza frigorifera totale - Total cooling capacity - Kühlleistung Total (3) E

Puissance frigorique totale - Potencia frigorica total

W max

W med

W min

1110

960

780

1560

1380

1130

2200

1880

1470

4210

3240

2250

4690

3570

2910

5790

4030

3030

7940

7210

6650

8500

7710

7000

Potenza frigorifera sensibile - Sensible cooling capacity - Kühlleistung Sensibel (3) E

Puissance frigorique sensible - Potencia frigorica sensible

W max

W med

W min

960

810

640

1120

1070

860

1820

1520

1160

3040

2270

1520

3870

3080

2390

4860

3870

3080

5950

5340

4570

6620

5950

5340

Portata acqua max - Water ow - Wassermenge - Debit d’eau - Caudal agua

l/h

191 268 378 723 797 996 1365 1440

Perdite di carico acqua - Pressuredrop - Druckverlust - Perte de charge - Perdita de carga E

Kpa

1.59 5.93 5.41 14.7 9.60 10.3 17.9 21.5

Portata aria - Air ow - Luftmenge - Debit d’air - Caudal aire

mc/h max

mc/h med

mc/h min

252

200

147

304

254

194

430

353

254

716

490

300

920

720

573

1130

920

720

1320

1150

946

1520

1320

1150

Pressione sonora - Sound pressure level - Geräuschpegel - Pression sonore - Nivel sonoro

dB (A) max

dB (A) med

dB (A) min

38.5

34.5

28.5

38.5

34.5

27.5

41.5

35.5

27.85

45.5

37.5

26.5

48.5

40.5

34.5

54.5

48.5

41.5

52.5

48.5

43.5

57.5

53.5

49.5

Potenza sonora - Sound output - Schalleistung - Puissance sonore - Potencia sonora E

dB (A) max

dB (A) med

dB (A) min

47

43

37

47

43

36

50

45

36

56

46

35

57

49

43

63

57

50

61

57

52

66

62

58

Alimentazione elettrica - Power supply - Stromversorgung - Alimentation életrique - Alimentacion elèctrica

230V/1/50 Hz

Potenza max ventilatore - Max fan capacity - Max Ventilatorleistung E

Puissance maximale ventilateur - Potencia max ventilador

W

49 32 65 90 108 143 172 217

Corrente max assorbita - Max absorbed current - Max aufgenommener Storm - Puissance

maximum absorbée - Corriente max absorbida

A

0.21 0.14 0.28 0.39 0.47 00.63 0.75 0.94

Resistenza elettrica (a richiesta) - Heating element (on request) - Elektrischer Winderstand (auf

Anfrage) - Rèsistance électrique (en option) - Resistencia elèctrica (bajo pedido)

W

750 1000 1500 2000 2500 2500 3000 3000

Contenuto acqua batteria 3R (di serire) - 3 row water content - Wasserinhalt Austauscher 3R

(serie) - Contenance en eau batterie 3R - Contenido de agua de la batería 3R

1

0.6 0.9 1.3 1.9 2.8 2.8 3.6 3.6

Contenuto acqua batteria IR (supplementare) - I row water - Wasserinhalt Austauscher IR

(optionelle) - Contenance en eau batterie IR - Contenido de agua de la baterfa IR

1

0.2 0.3 0.4 0.5 0.9 0.9 1.2 1.2

Peso - Weight - Gewicht - Poids - Peso

Kg

14 17 20 23 35 35 47 47

“E”: Prestazioni certicate

EUROVENT

(1) - Riscaldamento:

Temperatura ambiente 20°C

- Temperatura ingresso acqua

70°C - ∆T acqua 10°C

(2) - Riscaldamento “E”:

Temperatura ambiente 20°C

- Temperatura ingresso acqua

50°C - Portata acqua come in

raffreddamento alla vel. Max.

(3) - Raffreddamento:

Temperatura aria esterna

27°C b.s. - 19°C b.u.

Temperatura acqua ingresso

7°C - Uscita 12°C

(4) - Valori riferiti alla batteria

aggiuntiva “IR” per impianti

a “4 Tubi”, tutti gli altri valori

sono riferiti alla versione base

con batteria “3R” per impianti

a “2 Tubi”

“E”: EUROVENT

Performance certicate

(1) - Heating: room

temperature 20°C, untake

water temperature 70°C. ∆T

water 10°C

(2) - Heating (E): room temp.

20°C, intake water temp.

50°C, water ow the same as

cooling, all max. speed.

(3) - Cooling: room temp.

27°C dry bulb. 19°C damp

bulb. water Temp. intake 7°C

- outlet 12°C.

(4) - The values refer to the

extra “IR” battery for the “4

tube” systems, all the other

values refer to the basic

version whit the “3R” battery

for “2 tube” systems.

“E”: zertizierte Leistungen

EUROVENT

(1) - Heizung:

Raumtemp.20°C - Temp.

Wasservorlauf 70°C - ∆T

Wasser 10°C

(2) - Heizung “E”: Raumtemp.

20°C - Temp. Wasservorlauf

50°C - Wasserdchuss wie

beim Kühlen auf max. 2

Geschw.

(3) - Kühlung: Temp.

Raumluft 27°C mit feuchter

Thermometerkugel, 19°C mit

troknen Thermometerkugel,

Wassertemp. Vorlauf 7°C

- Ablauf 12°C

(4) - Die Werte beziehen sich

auf den Zusatzaustauscher

“IR” für “4-Leiter-Systeme”,

alle anderen Werte beziehen

sich auf die basisversion mit

Austauscher “3R” für “2-Leiter-

Systeme”

“E”: Prestations certifées

EUROVENT

(1) - Réchauffement: temp.

ambiante 20°C, temp. entrée

eau 70°C. ∆T eau 10°C

(2) - Réchauffement (E): temp.

ambiante

20°C , temp. entrée eau 50°C,

débit eau comme dans la

phase de refroidissement

vitesse max.

(3) - Refroidissement: temp.

air ambiant 27°C bulbe sec.

19°C bulbe humide, temp. eau

entrée 7°C - sortie 12°C

(4) - Valeurs référées à

la batteriesupplémentaire

“IR” pour installations à “4

TUBES”, toules les autres

valeurs se rèfèrent à la

version base batterie “3R”

pour installation à “2 TUBES”.

“E”: Rendimientos

certicados EUROVENT

(1) - Calefacción: Temp:

ambiente 20°C - Temp.

entrada agua 70°C - ∆T agua

10°C

(2) - Calefacción “E”: Temp:

ambiente 20°C - Temp.

entrada agua 50°C - Caudal

agua corno eln refrigeración la

vel. max

(3) - Refrigeración: Temp. aire

ambiente

27°C b.s. - 19°C b.h., Temp.

agua entrada 7°C - salida

12°C

(4) - Valores referidos a la

baterfa adicional “IR” para

installaciones a “4 TUBOS”,

todos los otros valores se

referien a la version base

con baterfa “3R” para

installaciones a “2 TUBOS”

UNITA BASE - BASIC UNIT - BASISEINHEIT - UNITE BASE - UNIDAD BASE

COMPONENTI PRINCIPAL

1 Batteria di scambio

2 Batteria supplementare IR

(a richiesta)

3 Struttura portante

4 Gruppo ventilante

5 Pannello comandi

6 Mobile di copertura

7 Sezione ltrante

8 Sportello sx

9 Sportello dx

10 Griglia diffusore

11 Vaschetta esterna (a richie-

sta)

12 Termostato di consenso

13 Targhetta caratteristiche

MAIN COMPONENTS

1 Exchange battery

2 Single rara, additional

battery (on request)

3 Bearìng structure

4 Fan unii

5 Control panel

6 Cover

7 Filterunit

8 Uhap

9 R/hap

10 Diffuser grid

11 Outside tray (on request)

12 Consent thermostat

13 Technical feature plaque

COMPONENTES PRINCIPALES

1 Bateria de intercambio

2 Bateria suplementaria IR (a

petición)

3 Estructura portante

4 Grupo ventilador

5 Panel de mandos

6 Mueble de copertura

7 Sección ltrante

8 Puerta izquierda

9 Puerta derecha

10 Rejilla de difusión

11 Bandeja externa (a petición)

12 Termostato de asenso

13 Placa de caracteristicas

HAUPTBESTANDTEILE

1 Warmeaustauscher

2 Zusatzaustauscher IR

(auf Anfrage)

3 Tragende Struktur

4 Geblase

5 Bedienblende

6 Abdeckgehause

7 Filter

8 Klappe links

9 Klappe rechts

10 Verteilergitter

11 ÀuBere Wanne (auf Anfrage)

12 Freigabe-Thermostat

13 Typenschild

COMPOSANTES PRINCIPALES

1 Batterie d’échange

2 Batterie supplémentaire R

(en option)

3 tructure portante

4 Groupe de ventilation

5 Panneau de commande

6 Meublé de couverture

7 Groupe deltration

8 Porte gche

9 Porte dte

10 Grille diffuseur

11 Cuve externe (en option)

12

Thermostat de consentement

13 Plaquette caractéristiques

--/VB

--/AB

--/CRE

This manual suits for next models

2

Table of contents

Other Tonon Forty Heater manuals