Tool-Temp TT-390 Manual

Manual of instruction

Temperature control unit TT-39016/24kW

with Temperature Controller MP-888

05/2017

Version: 05

Manual of instructions TT-390 2/35

General information

This documentation is copyrighted. Unauthorised duplication is prohibited by law. To the best of our

knowledge and belief, the information contained in this documentation is true and correct as of the

date of publication. The contents, however, do not constitute a binding obligation on the part of

TOOL-TEMP AG and are subject to change without notice.

In case of inconsistencies in the English translation, the German version shall prevail.

© Copyright 2017 TOOL-TEMP AG

Contents

1. General Safety Information........................................................................................................... 4

1.1. Safety Symbols.................................................................................................................................................................. 4

1.2. Range of Application.......................................................................................................................................................... 4

1.3. Intended Use..................................................................................................................................................................... 4

1.4. Safety Information.............................................................................................................................................................. 5

1.4.1. General Information.................................................................................................................................................. 5

1.4.2. Process Monitoring................................................................................................................................................... 5

1.4.3. Information for Operators and Personnel.................................................................................................................. 5

1.4.4. Changing the Parameterisation ................................................................................................................................ 6

1.4.5. Residual risks........................................................................................................................................................... 6

1.5. Using this Documentation.................................................................................................................................................. 7

1.5.1. Additional Documentation......................................................................................................................................... 7

2. Overview temperature control unit .............................................................................................. 8

2.1. Front view.......................................................................................................................................................................... 8

2.2. Rear view......................................................................................................................................................................... 10

2.3. Identification of residual risk on the unit ........................................................................................................................... 11

3. Technical Specifications............................................................................................................. 12

4. EC –Declaration of conformity .................................................................................................. 13

5. Installation.................................................................................................................................... 14

5.1. Installing and dimensions of the temperature control unit................................................................................................. 14

5.2. Connections..................................................................................................................................................................... 15

5.3. Power supply................................................................................................................................................................... 16

5.4. Initial operation................................................................................................................................................................ 17

5.4.1. Heat transfer oil...................................................................................................................................................... 18

5.4.1. Pump rotation check............................................................................................................................................... 18

5.4.2. Display of pump pressure....................................................................................................................................... 18

6. Operations.................................................................................................................................... 19

6.1. Overview MP-888............................................................................................................................................................ 19

6.2. Parameter settings MP-888 ............................................................................................................................................. 21

6.3. Setting of the temperature –Heating / Cooling................................................................................................................. 23

6.4. Adjustment of electronic flow control................................................................................................................................ 23

6.5. Temperature measurement INTERNAL (IN) –EXTERNAL (OUT)................................................................................... 23

6.6. Mould drainage –Changing the consumer....................................................................................................................... 24

6.7. Leak prevention operation................................................................................................................................................ 24

7. Safety and monitoring devices................................................................................................... 25

7.1. Pump............................................................................................................................................................................... 25

Manual of instructions TT-390 3/35

7.2. Heating –Temperature monitoring................................................................................................................................... 25

7.3. Level control.................................................................................................................................................................... 25

7.4. Flow control..................................................................................................................................................................... 25

7.5. Temperature deviation control ......................................................................................................................................... 25

7.6. Acoustic indication of faults (horn) ................................................................................................................................... 26

8. Maintenance................................................................................................................................. 27

8.1. Inspection........................................................................................................................................................................ 27

8.2. Cleaning.......................................................................................................................................................................... 27

8.3. Repair.............................................................................................................................................................................. 27

9. Out-of-service / transport............................................................................................................ 28

10. Disposal........................................................................................................................................ 28

11. Failure corrective action ............................................................................................................. 29

12. Components and spare parts..................................................................................................... 31

12.1. Overview components and spare parts (without isolation)................................................................................................ 31

12.2. List components and spare parts..................................................................................................................................... 33

Attachments:

•Electrical diagram MP-888 EL-1712

Manual of instructions TT-390 4/35

1. General Safety Information

1.1. Safety Symbols

DANGER

Denotes imminent danger.

Failure to heed the information can result in death or grave personal injury

(disability)!

WARNING

Denotes a dangerous situation.

Failure to heed the information can result in death or grave personal injury

(disability)!

CAUTION

Denotes a potentially dangerous situation.

Failure to heed the information can result in property damage as well as

minor or moderate personal injury!

NOTE

Denotes general information, useful advice to users and work

recommendations, which, however, do not have any influence on the safety

and health of personnel.

1.2. Range of Application

This general safety information is generally valid for all temperature control units from TOOL-TEMP.

1.3. Intended Use

The TOOL-TEMP temperature control unit is built according to the current state of the art and the

generally accepted principles of safety engineering. The temperature control unit is intended solely for

the normal use for heating and/or cooling of injection and die casting moulds, extruders, calendars,

mixers and other consumers in areas in which there is no risk of explosion.

Any use beyond this shall be deemed to constitute improper use. The manufacturer is not responsible

for damage resulting from improper use; the user is solely responsible for such risks. The temperature

control unit may not be used under other operating conditions and/or with other media, in deviation

from our specifications, without the prior consent of TOOL-TEMP.

Manual of instructions TT-390 5/35

Use as intended also entails compliance with the operating, servicing and maintenance conditions

stipulated by the manufacturer. The temperature control unit may only be operated, serviced and

maintained by personnel who are familiar with these tasks and have been instructed as to the risks.

1.4. Safety Information

1.4.1.General Information

The TOOL-TEMP temperature control unit is safe to operate, but this device can pose danger to

life and limb if it is used incorrectly or for a purpose other than that intended. It should be noted

that this poses risks to the life and limb of the user or third parties, adverse effects on the

equipment and other material assets belonging to the user, and risks to the efficient operation of

the equipment.

Start-up (i.e., commencement of intended use) is prohibited until it has been determined that the

temperature control unit has been set up and wired in accordance with the Machinery Directive

(2006/42/EC). EN 60204-1 (Safety of Machinery) must also be observed.

These operating instructions must be read carefully before turning on and operating the

temperature control unit. The information regarding the intended use and foreseeable misuse

must be observed. Local safety regulations must also be obeyed.

If the temperature control unit is used in combination with products by other manufacturers, their

notices and safety regulations must also be obeyed.

1.4.2.Process Monitoring

In plants in which a temperature control system malfunction leads to endangerment of the

operating personnel or destruction of the plant, an independent process monitor that shuts down

the plant reliably must be used.

1.4.3.Information for Operators and Personnel

The operator and all persons who are tasked with working on the temperature control unit must

obey the fundamental regulations regarding work safety and accident prevention. The operator

must ensure that only persons who have read and understood these operating instructions,

particularly the chapter on safety, work on the temperature control unit.

WARNING

People with pacemaker should not be allowed to demount or maintain the

magnetically coupled pump!

Any working methods that have a negative effect on the technical safety of the temperature

control unit must not be used. The operator must ensure that the temperature control unit is

operated only in flawless condition. If necessary, the company using the equipment must obligate

the operating personnel to wear protective clothing.

For all tasks having to do with set-up, start-up, operating, modification of operating conditions and

operational modes, maintenance, inspection and repair, any shut-down procedures stated to be

necessary in the operating instructions must be followed.

Manual of instructions TT-390 6/35

1.4.4.Changing the Parameterisation

The parameterisation of the control system may only be carried out by personnel trained by

TOOL-TEMP. In particular, no parameters in the device configuration may be changed without

consulting TOOL-TEMP.

The relevant accident prevention regulations and the generally accepted principles of safety

engineering, occupational medicine and structural engineering must be observed. The national

safety regulations must also be obeyed.

1.4.5.Residual risks

Any unauthorised modifications and changes to the temperature control unit as well as

unauthorised changes to the parameterisation of the control system are prohibited for reasons of

safety.

If the temperature control unit is damaged, it must not remain in use; the defective part must be

replaced or repaired immediately. Only original TOOL-TEMP replacement parts may be used.

Damage due to use of thirdparty parts voids any and all warranty claims.

DANGER

The temperature control unit must be rendered currentless before it is

opened! Press the main switch on the temperature control unit and unplug

mains plug!

Danger due to electrical shock!

Repair leaks in the temperature control circuit (device, connecting lines, consumers, etc.)

immediately.

In temperature control units that use oil as a heat transfer medium, it should be noted that oil is

flammable under certain conditions. For this reason, the temperature control unit must not be

located in the vicinity of heat sources. The thermal insulation in the device must always be kept

clean. Insulation that is soaked with thermal oil poses an increased risk of fire.

Burning thermal oil can be extinguished using a spray foam fire extinguisher, a powder fire

extinguisher (avoid with dust-sensitive plants, control systems, EDP, etc.) or a CO2 fire

extinguisher. The appropriate fire extinguisher must be provided by the operator, taking into

account the equipment located in the room and the mandatory safety regulations.

The temperature control unit may only be operated when all safety systems are completely

installed and intact. The temperature control unit must be protected against sprays and cleaning

agents.

Before detaching connecting lines in the temperature control circuit and depending on the outlet

temperature, allow the temperature control unit to cool down first and then turn it off. Check that

the pump is no longer running.

WARNING

Important - danger of injury in the event of escaping water or oil!

Manual of instructions TT-390 7/35

1.5. Using this Documentation

This documentation contains important information for safe, economical operation and for proper

maintenance of the device.

Compliance with this documentation helps to avoid danger, minimise repair costs and downtime, and

increase the dependability and service life of the unit/system.

NOTE

The operating instructions should be kept near the corresponding unit and

always be accessible to operating and maintenance personnel.

1.5.1.Additional Documentation

The included documentation is completely correct for the basic versions of units. Components

that do not belong to the basic hardware are noted as extra equipment. The corresponding

additional documents are included with special versions of devices. Any additional documents

supplement and/or replace the descriptions contained in this documentation, which are then

either invalid or only conditionally valid.

Manual of instructions TT-390 8/35

2. Overview temperature control unit

2.1. Front view

1

Temperature Controller MP-888

2

ON/OFF-Switch unit (green)

3

ON/OFF-Switch heating (green)

4

ON/OFF-Switch heating (green)

5

ON/OFF-Switch horn (green)

Manual of instructions TT-390 9/35

6

Change-over switch for pump operation mode (green)

Pressure for pressure operation (normal operation)

Vacuum for leakstopper operation and mould drainage

7

Mould drainage (green)

- Cooling the unit below 60°C

- Switch the unit off by the green ON/OFF-Switch

- Pump operation mode switch to „VAC“

- Press the green button „DRAIN“ until consumer is empty

8

Change-over switch for temperature measurement

Internal - Temperature measurement internal (heater)

External - Temperature measurement external with 2-poles socket for

temperature sensor (e.g. at the mould)

9

Control lamp (red)

Thermal relay pump

10

Control lamp temperature monitoring t1 (red)

The maximum temperature of the unit is exceeded. The unit switches off.

11

Control lamp temperature monitoring t2 (red)

The maximum temperature of the unit is exceeded. The power to the heater is switched off, the

unit works and the cooling can be activated.

12

Control lamp temperature monitoring t3 (red)

Temperature deviation control; Difference between desired and actual temperature is too big.

13

Leven control lamp (yellow)

lights + horn Unit switches off, level has to be corrected (refill)

lights + horn Unit switches off, level has to be corrected (drainage)

14

Lamp (yellow)

leakstopper operation and mould drainage

15

Control lamp flow control (red)

16

Working hour meter

17

Horn

18

Main switch

Emergency stop

19

Name plate with following details:

20

Manometer pump pressure

21

Switch cabinet –safety device

22

Side panel

23

Front panel

Manual of instructions TT-390 10/35

2.2. Rear view

24

Service cover

25

Rear panel

26

To mould

¾“BSP female thread

27

From mould

¾“BSP female thread

28

Cooling water inlet with water filter

1“BSP female thread

29

Cooling water outlet with non-return valve

1“BSP female thread

30

Drainage with stop valve

½“BSP female thread

31

Overflow

32

Filler neck

1“BSP male thread

Manual of instructions TT-390 11/35

2.3. Identification of residual risk on the unit

On the temperature control unit following pictograms are mounted to identify the residual risk.

DANGER

The temperature control unit must be rendered currentless before it is

opened! Turn off the main switch on the temperature control unit and

disconnect the power cord from the wall socket!

Danger due to electrical shock!

WARNING

Prohibition for people with pacemaker!

People with pacemaker should not be allowed to demount or maintain the

magnetically coupled pump!

There is a risk of injury to people with pacemaker.

Manual of instructions TT-390 12/35

3. Technical Specifications

TT-390 / 16 kW

TT-390 / 24 kW

Temperature range

Up to 360°C with heat transfer oil TOOL-THERM SH-3

Temperature control

self-optimizing, electronic microprocessor controller MP-888

Heating capacity

with stage switching 8/8

with stage switching 8/16

Pump capacity

motor 1,8 kW

max. 5.5 bar / max. 100 l/min

Cooling capacity

approx. 90 kW at 360°C circulating temperature

Filling amount

15 litres

21 litres

Expansion volume

16 litres

16 litres

Connections

to mould

¾“ BSP female thread

from mould

¾“ BSP female thread

cooling water inlet with water filter

1“BSP female thread

cooling water outlet

1“BSP female thread

Overflow

½“ BSP female thread

Dimensions (L×W×H)

1240 × 480 × 1400 mm, incl. castors

Weight

approx. 205 kg empty

approx. 215 kg empty

Category of protection

IP-44

Electric

In separate switch cabinet, easily accessible from the front

Colour

silver-grey RAL 7001

Heat exchanger

low-maintenance

Noise level (dB)

< 70 dB (distance 3 m)

Manual of instructions TT-390 13/35

4. EC –Declaration of conformity

Manual of instructions TT-390 14/35

5. Installation

Before starting the unit the electrical and hydraulic connections have to be installed. The installation of

the unit has to be done in the order of the following chapters. After the proper installation the unit is

ready to use.

DANGER

The temperature control unit must only be operated with heat transfer oil. Do

not use solvents or other explosive substance such as petrol, toluene, etc. in

the heat transfer oil circuit.

CAUTION

When starting the unit without the prescribed connections the unit can be

damaged.

Water quality (cooling circuit) –do not use water with chlorine addition.

NOTE

Observe the General Safety Information!

Before installing corresponding chapter of the manual should be read!

5.1. Installing and dimensions of the temperature control unit

Manual of instructions TT-390 15/35

The temperature control unit is designed for an ambient temperature of +10 up to 40°C. Sufficient

ventilation must be ensured during set-up. The distance between the temperature control unit and

other facilities must be at least 10cm. The ventilation opening must be free.

•Check the unit of completeness and possible damages.

•The unit has to be installed in a suitable location on even ground. It must be stand on castors.

•The unit is not protected against splash water and is not suitable for use in hazardous location. The

unit must not be used in the open air.

•The unit must not be transported lying. Lying transport destroy the unit.

WARNING

The temperature control unit can release excess pressure. Danger of injury

in the event of escaping steam/hot oil!

Never start up the unit without the protection cover!

Never use the unit in hazardous location!

Repair leaks immediately!

Observe local laws during set-up!

CAUTION

The temperature control unit may be pressurised!

Only when the pressure gauge shows 0 bar, disconnect hoses!

5.2. Connections

Before installing the connecting lines between temperature control unit and consumer must be

subjected following inspections:

•Verify that channels on the consumers are unobstructed

•Remove fouling, e.g. remove shaving in the lines

•Rust and lime deposits must be removed because the greatly interfere with the heat exchange

between consumer and heat transfer medium and increase the pressure drop in the consumer.

For the connecting lines (to and from mould, cooling water inlet and outlet, etc.) the following internal

diameters of hoses are recommended:

Thread on the unit

Internal hose-Ø

3/8“

10mm

1/2“

15mm

3/4“

20mm

1“

25mm

DN32

32mm

Quick release couplings will give reduced flow. If the recommended tube size cannot be connected to

the mould, the connection at the mould should be reduced and not the connection on the temperature

control unit. In that way pressure drops can be avoided.

Manual of instructions TT-390 16/35

For the cooling water connections it’s enough to use pressure- and temperature-resistant rubber

hoses. The tap water pressure has to be between 2,0 and 5,0 bar. We recommend to conduct the

water from the unit (cooling water outlet) to an unpressurized outlet.

WARNING

To ensure the operational safety is essential to use pressure- and

temperature-resistant hoses. Pressure-resistant up to 20 bar /

temperature-resistant up to +400°C.

For reason of safety, the cooling must always be connected!

NOTE

Process water filter on the return line reduces contamination in the unit,

which can cause a unit failure (pollution of the solenoid valve).

Mark and take down the maximum temperature for which the connections

are suitable!

5.3. Power supply

Compare supply voltage and frequency with the information on the serial plate. Verify the rating of the

preliminary fuse according to the information in the electrical diagram. Observe local laws during

set-up!

Power cable:

Phases

black / black / black

L1 / L2 / L3

Earth

yellow/green

PE

WARNING

The unit may only be connected by a competent electrician.

Ensure easy access to means for cutting the power supply (mains adapter or

mains connection), the access must be positioned in a distance of 0.6 and

1.9m above the access level.

Do not connect the power supply until the heating medium hoses are

connected!

Manual of instructions TT-390 17/35

5.4. Initial operation

The temperature control unit can only be operated with heat transfer oil. The unit has to be filled

manually through the filler neck for the operation. A guideline for the required filling amount can be

taken from the technical data.

WARNING

Caution „residual water“ (temperature control unit, consumer, hoses) –

water in the oil can lead to dangerous operating conditions. The temperature

control unit can be overflow. Risk of injury by escaping oil-water mixture!

The temperature control unit has to be connected hydraulically and electrically. Possible block valve

must be open.

•Switch on the unit electrically: Turn on the main switch and press the unit ON/OFF-switch

•After switching on the unit the unit can be filled through the filler neck. In the meantime the yellow

lamp lights and the horn sound. If the correct level is reached the pump starts. If the unit switches

down after this, the level has to be corrected as soon as the system has enough heat transfer oil.

NOTE

Too much heat transfer oil reduces the expansion volume! The heat transfer

oil expands during the heating and could be overflow.

WARNING

Warning overflow oil has to be removed immediately!

Oil-soaked isolation has to be replaced immediately, they can ignite.

DANGER

Waste oil has to be disposed as prescribed by law. Never let waste oil come

into the sewage system or soil.

Manual of instructions TT-390 18/35

5.4.1.Heat transfer oil

Temperatures up to +250°C ask for heating transfer oils such as TOOL-THERM SH-3, Shell

Thermia B, BP Transcal N, Essotherm 500 or equivalent products. For operating the temperature

control unit up to temperatures +360°C, must be used TOOL-THERM SH-3. Other similar

products must be individually clarified. Please note: The used heat transfer oil has to be taken

down in a check list. Particularly the maximum operating temperatures according to the

specifications of the heat transfer oil manufacturer has to be taken down.

WARNING

The use of unsuitable oil sorts or water is not permitted and is not regarded

as use as agreed.

5.4.1.Pump rotation check

On top of the unit the direction of rotation can be checked. The unit has been connected to the

main supply, hoses must be mounted and heat transfer medium has been filled. Identify the

sense of rotation of the motor by switching it on shortly. The sense of rotation must be clockwise

as shown by the arrow.

If the sense of rotation is anti-clockwise invert two phases on the electrical connection. This has

to be done by a qualified electrician.

5.4.2.Display of pump pressure

The pump pressure is shown on the manometer.

WARNING

The temperature control unit may be pressurised!

Only when the pressure gauge shows 0 bar, disconnect hoses!

Manual of instructions TT-390 19/35

6. Operations

The unit is controlled by the temperature controller MP-888.

The temperature controller MP-888 is a universal controller for all TOOL-TEMP units.

6.1. Overview MP-888

1

Display of set value

2

Display of actual value

3

Flow control (Feature not available)

Display of the current flow in litres/min, English or American gallons/min.

4

Up arrow Raise of set value

5

Down arrow Reduction of set value

6

Program button

7

Flow control (Feature not available)

Flow control active LED green

Alarm flow control LED red

8

LED Cooling

Lights up when the cooling relay is active

9

LED Heating

Lights up when the heating relay is active

10

LED Sensor failure

Lights up when the sensor is intermitted

11

LED Temperature deviation control

Lights up when the difference between set and actual temperature is too high

12

LED Maximum temperature

Lights up when the maximum temperature has been reached

13

LED External temperature control

Lights up when the set value is applied from extern

Manual of instructions TT-390 20/35

1

Possible supply voltages (factory adjusted)

2

Possible temperature sensor (factory adjusted)

3

Version of the controller

4

Temperature sensor connection

21+23 Temperature sensor –note + / -

22 Pt-100 compensation

5

Flow control –encoder signal

6

Connection external set point

26+28 Analog input 4 - 20mA

27+28 Analog input 0 - 10 V

7

Connection actual value - output

29+30 Analog output 0 - 10V

8

Power supply

1 230V AC

2 Neutral

3 PE

9

Flow control (alarm)

10

Temperature monitoring, temperature deviation alarm

11

Cooling (command)

12

Heating (command)

Table of contents

Other Tool-Temp Control Unit manuals

Popular Control Unit manuals by other brands

Nibe

Nibe DEH 310 Installer manual

M-system

M-system R3-NF2 instruction manual

ABB

ABB FSCA-01 Quick installation and start-up guide

Watson McDaniel

Watson McDaniel 455 SERIES Installation & operating instructions

EOS

EOS Emotec D Operation manual and user guide

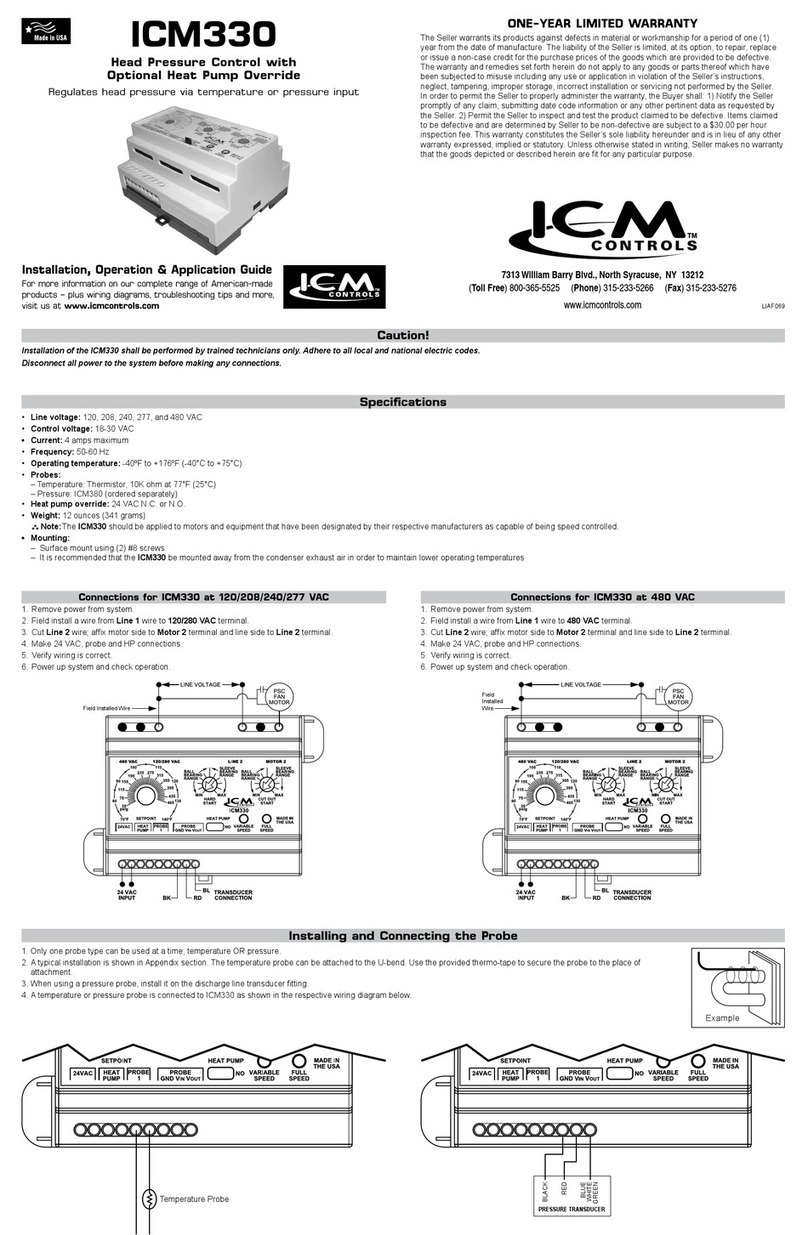

ICM Controls

ICM Controls ICM330 Installation, operation & application guide

GEA

GEA VARIVENT X R Series operating instructions

ABB

ABB RELION 650 SERIES Point List Manual

Mitsubishi Electric

Mitsubishi Electric iQ-F Series user manual

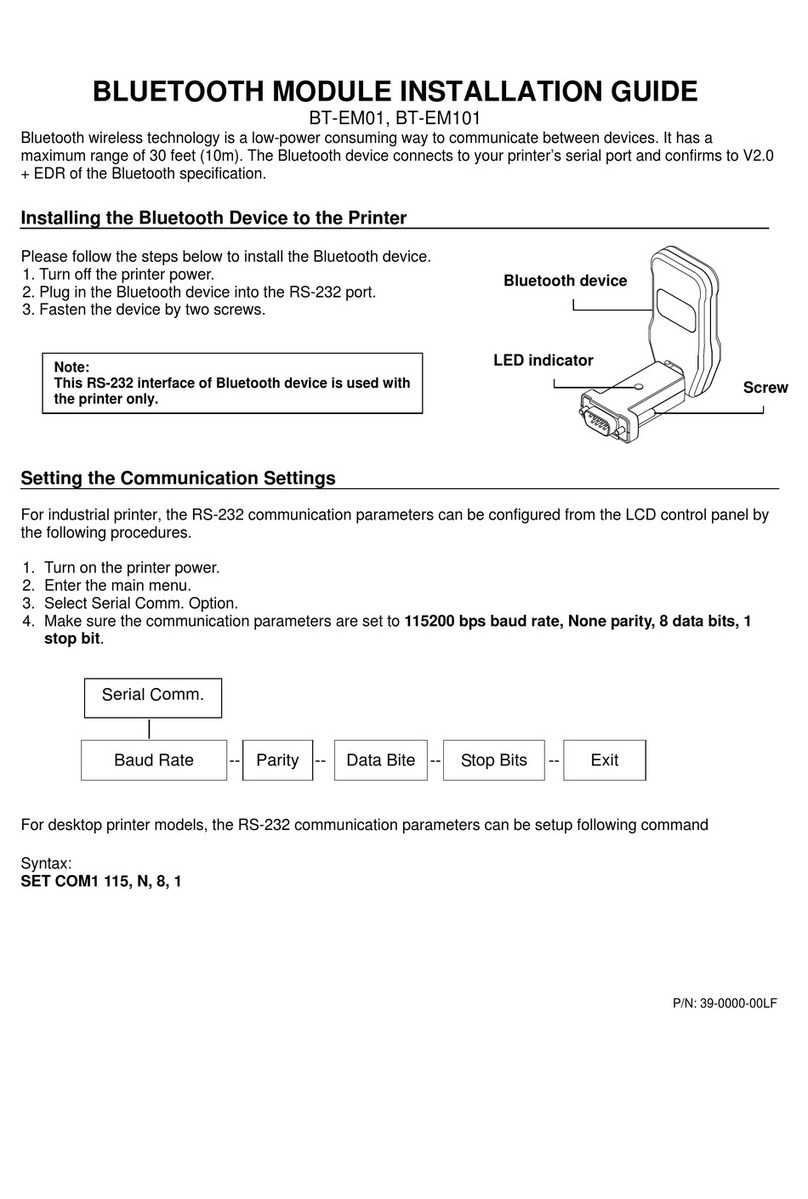

TSC

TSC BT-EM01, BT-EM101 installation guide

DEWESOFT

DEWESOFT Krypton Technical reference manual

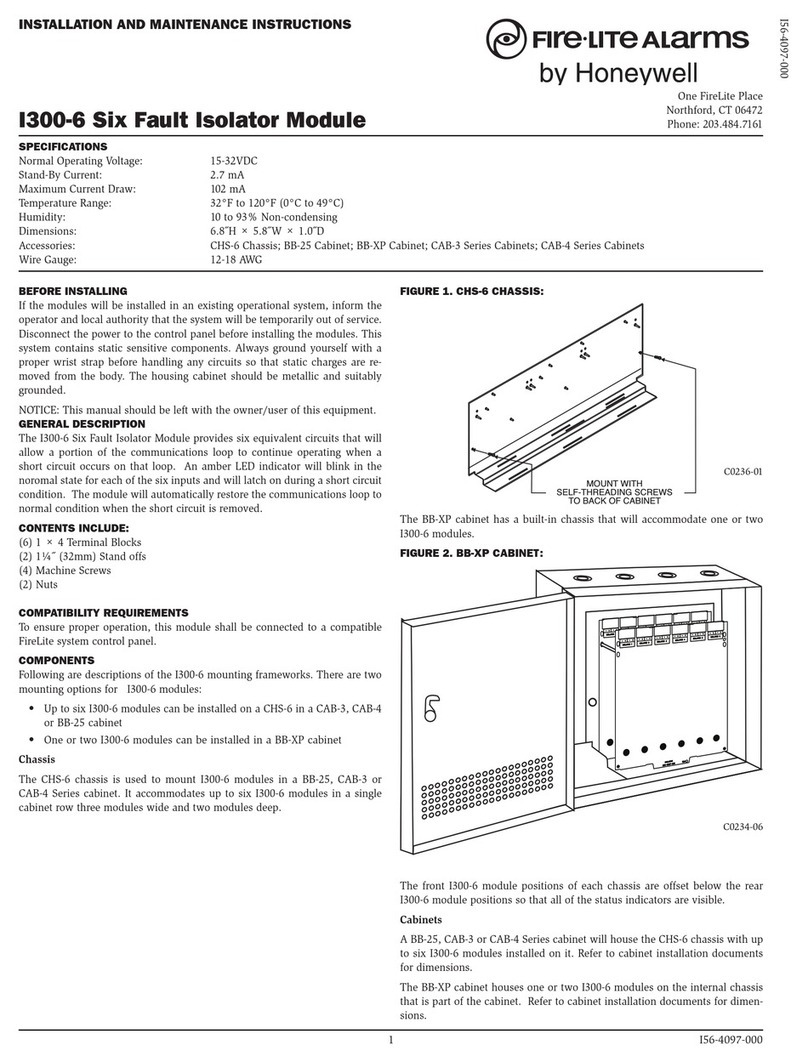

Fire-Lite Alarms

Fire-Lite Alarms I300-6 Installation and maintenance instructions