2

KTM SERIES POWDER DISCHARGE SYSTEM (PDS) BALL VALVES

OPERATING AND SAFETY INSTRUCTION

2.3 Cautions for disassembly and assembly

of the valve

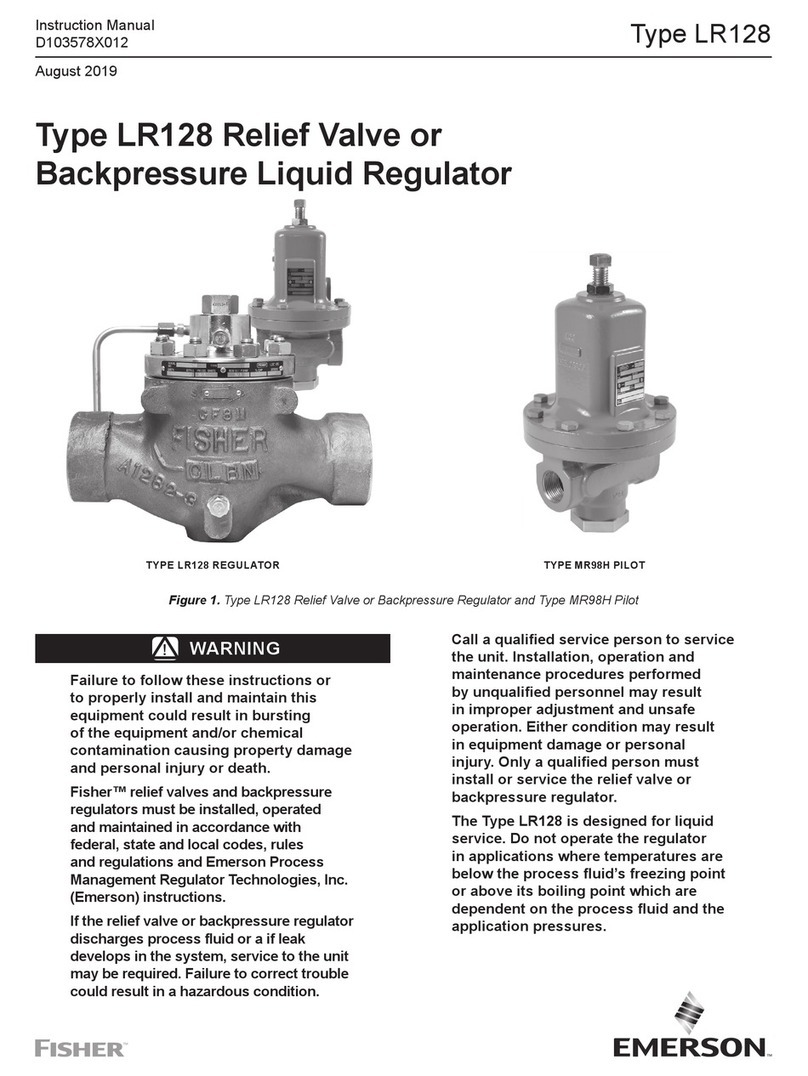

For the valve structure, see the drawing of

delivery.

When disassembling and assembling the valve,

be careful for the following matters.

a. Since fluid (gas or liquid) pressure may be

left as it is inside the cavity of the valve body,

discharge the pressure by open the drain

plug, or open or close the valve to discharge

the pressure from the cavity. After making

sure there is no pressure inside the cavity

any longer, disassemble the valve.

b. If fluid for use in the valve is physically

harmful, or strongly inflammable, clean

the valve and pipes adequately so that no

fluid remains inside the cavity of the valve

body. After making sure there remains no

fluid used inside, disassemble the valve.

In this case, too, it is effective to repeat

opening and closing the valve a number of

times before disassembling and assembling

the valve.

c. Handle the spherical surface of the ball and

each seal with care not to dent or flaw them.

d. In order to protect the spherical surface

of the ball and the seat from being dented

or flaw, fully close the valve before

disassembling or assembling it.

e. When assembling the valve, replace all the

gaskets, stem bearing and thrust bearing

with new ones.

2.4 Disassembly

The following provides a procedure for

disassembling the valve required for

maintenance and checkup, or troubleshooting

of the valve.

1. Removal of the actuator (pneumatic torque

cylinder).

See drawing AE0106-7437

a. Shut off operational pneumatic pressure

and operational electric power supply,

and remove the pneumatic piping and

electric wiring from the ac-tuator.

b. Remove all of the attachments that

may threaten to be damaged by the

disassembly.

c. Mark both yoke (2) and valve (1) with tally.

d. Unfasten Hex Socket Head Bolt (7) from

connector and remove con-nector (3)

from the valve stem.

e. Unfasten anchor nuts to remove both

actuator (4) and yoke (2) together from

valve (1).

2. Disassembly of the valve.

See drawing HE0106-7477

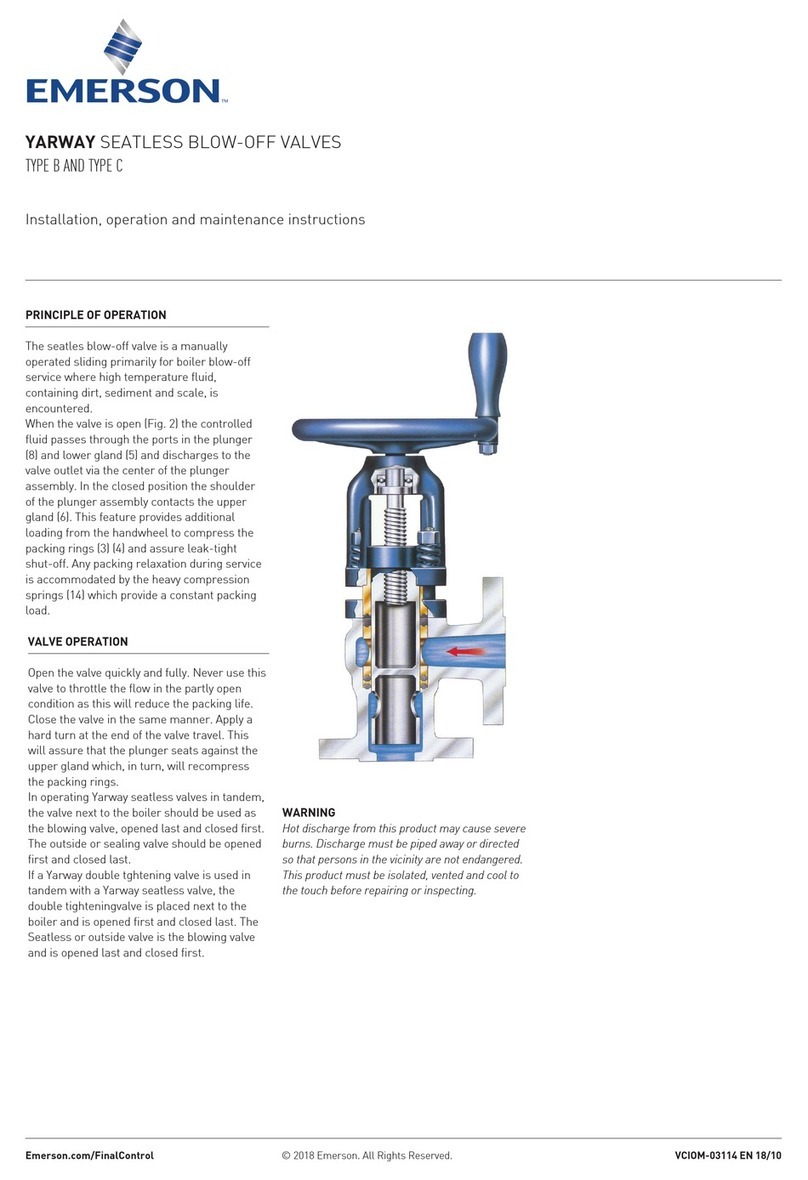

a. Remove key (41) from stem (4), unfasten

nut (32) to remove gland flange (31)

from the valve. Next, unfasten nut (37) to

remove EXT. bonnet (13) from the valve.

(Then, removing the gland packing from

the valve makes the removal work easy.)

b. Extract stem (4) from valve body (1)

(Since there is a female threaded hole

on the top of stem (4), screwing an

eyebolt, or the like in the hole makes

the extraction easy. Moreover, the use

of a jig as shown in Figure 1 makes the

extraction easier.)

c. Unfasten nut (39) to remove lower cover

(14) and shim (44). Next, extract lower

stem (5) from valve body (1).

(Since there is a female threaded hole

on the under surface of lower stem (5),

screwing an eyebolt, or the like in the hole

makes the extraction easy. Moreover, the

use of a jig as shown in Figure 1 makes

the extraction easier.)

d. Unfasten nut (35) to remove body cap

(2) from valve body (1). After that, ball

(3) from valve body (1) with care not to

scratch or flaw the spherical surface of

the ball.

e. Remove seat (6), O-ring (9), spring holder

(7) and spring (8) from the valve body.

Then, be careful for spring (8) set in the

back of spring holder (7) not to be lost.

f. Also, disassemble seat (6) attached to

body cap (2) in the same manner as the

procedure described in step (e) above.

c. Gland seal

The seal for the gland uses a packing made

of reinforced PTFE or Graphite. Since the

gland is the sliding section of the stem,

execute periodic checkup on the gland to

make sure there is no leakage from the

gland seal. In case even slight leakage

occurs from the gland seal, retighten gland

bolts uniformly to make sure the leakage

has been stopped. In case the leakage still

contin-ues, disassemble the valve to check

for the packing, make sure of the pres-ence

or absence of abnormality, and replace the

packing as required.

d. Mating face between the valve body and the

lower cover

The mating face between the valve body and

the lower cover uses a gasket. Make sure

there is no leakage from the mating face.

In case even slight leakage occurs from the

mating face, retighten bolts and nuts for

the mating face. In case the leakage still

continues, disassemble the valve, check for

the gasket to make sure of the presence

or absence of abnormality, and replace the

gasket as required.