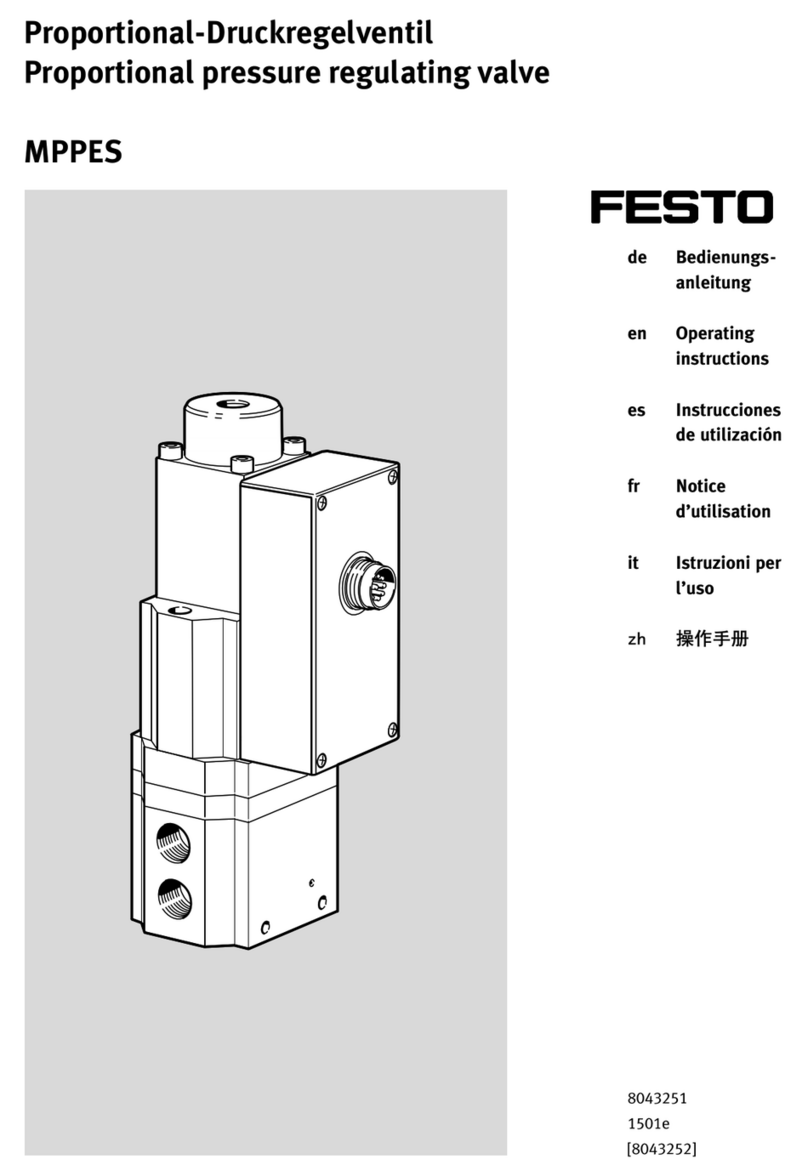

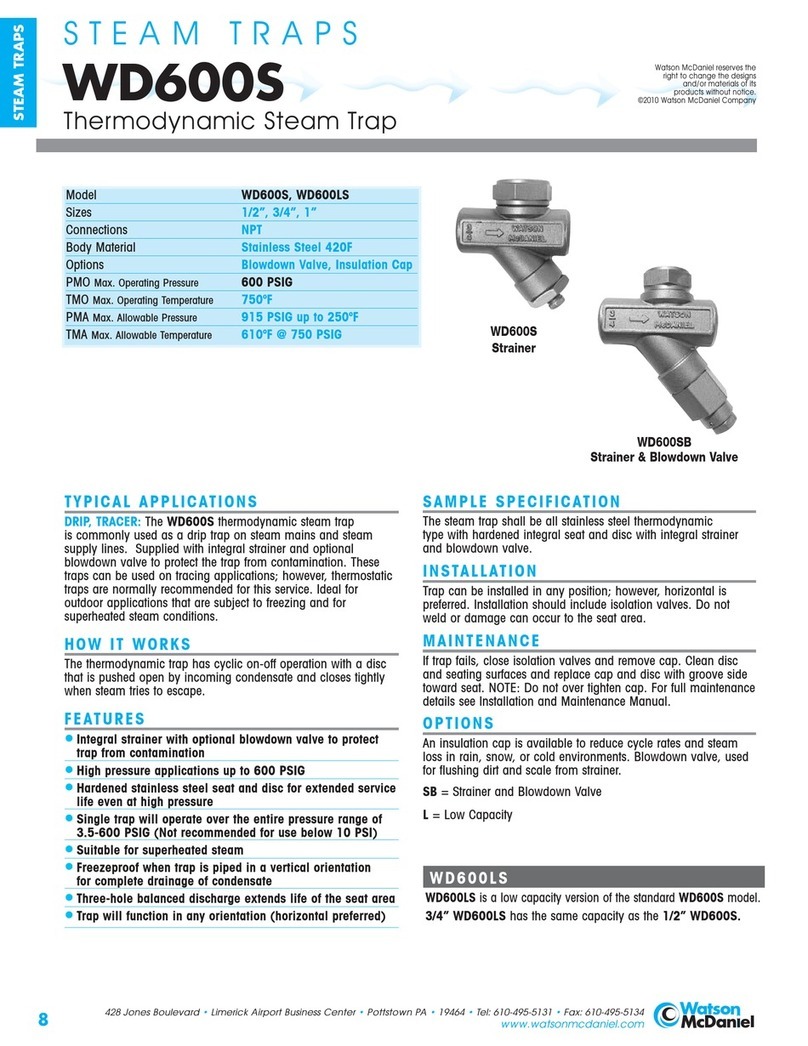

SERIES455-SCREWED

DIAPHRAGMASSY

DIAPHRAGM*

DIAPHRAGMWASHER

DIAPHRAGMCASE NUTS

&BOLTS

PACKINGASSY

PACKING*

PACKINGNUT

SPRING

BOTTOMPLUG

VALVE BODY

MAINVALVEASSY

MAINVALVE

MAINVALVESEAT

PILOTVALVE&STEM

PILOTVALVESTEMNUT

DIAPHRAGMSTEM

STEM

BOTTOMDIAPHRAGMCASE

REGULATINGSPRING

TOPDIAPHRAGMCASE

VALVE BRACKET

BRACKETLOCKNUT

VALVE BONNET

FLOW

SERIES 455-FLANGED TOPDIAPHRAGMCASE

DIAPHRAGMASSY

DIAPHRAGM*

DIAPHRAGMWASHER

DIAPHRAGMCASENUTS

&BOLTS

BOTTOMDIAPHRAGMCASE

REGULATINGSPRING

SPRINGYOKE

PACKINGASSY

PACKING*

PACKINGNUT

PACKINGGLAND

STEMLOCKNUT

STUDS&NUTS

TOP

PLATE

TOP

PLATE

GASKET*

REGULATINGNUTS

DIAPHRAGMSTEMASSY

DIAPHRAGMSTEM

DIAPHRAGMWASHER

MAINVALVEASSY

MAINVALVE

MAINVALVE SEAT

PILOTVALVE &STEM

PILOTVALVESTEMNUT

BOTTOMPLUG

VALVEBODY

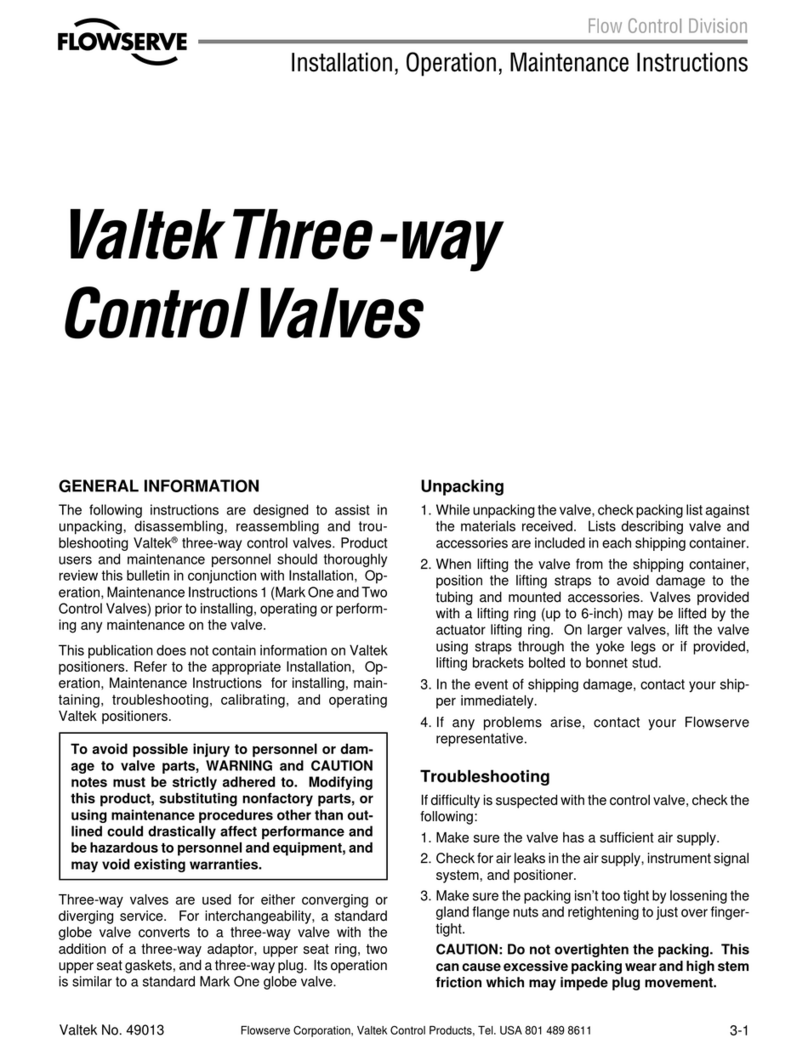

BY-PASS

RELIEF

VALVE

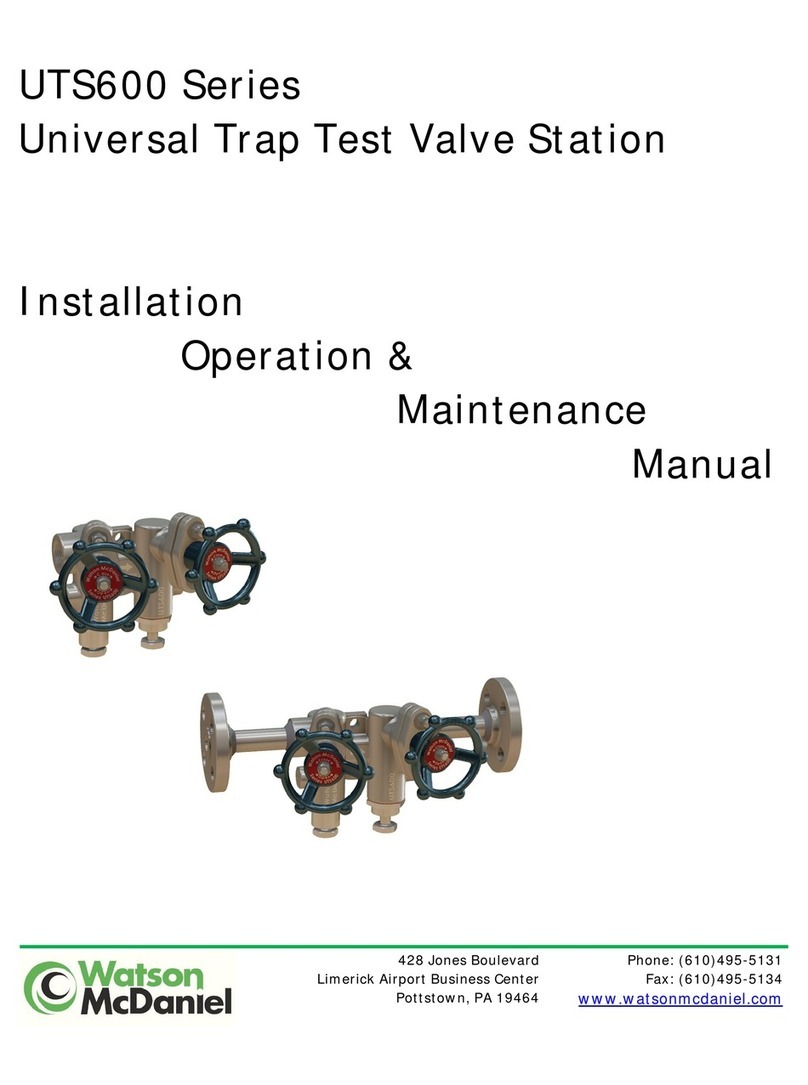

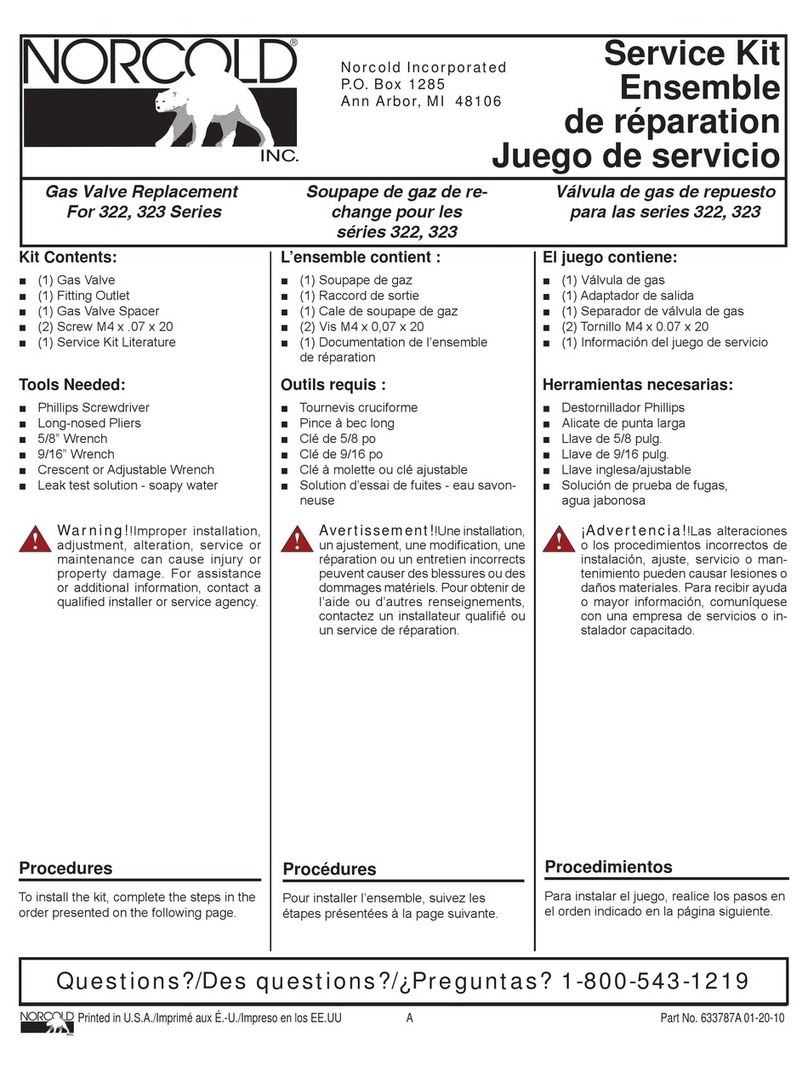

TYPICALINSTALLATION

10 PIPE DIAMETERS MIN.

455

REGULATING

VALVE

LINE

NEEDLE

VALVE

STRAINER

STEAM

SUPPLY

INSTALLATION AND OPERATION

Beforeinstallingthepressureregulatingvalve,besuretoblowoutthe

pipelinetoremoveall dirt,pipescale,pipechips,etc.

WatsonMcDanielrecommendsa'Y'typestrainerbeplacedinthelineon

theinletsideofthepressureregulatingvalve.Abypasslineandhand

shutoff valvesandgaugesshouldbeinstalledoneithersideofthe

regulatingvalveasshowninsketch.

Install theSeries455 pressureregulatingvalveinastraighthorizontal run

ofpipeawayfrom any meters,tees,elbows,etc.whichwouldcauseflow

turbulenceandeffectregulation.Theflowshouldbeinthedirectionof

thearrowonthebodywiththediaphragm chamberabovethecenterline

ofthepipe.However, ifheadroomisscarce,thesecondbestpositionis

toinstallthevalveinaninvertedorientationwiththediaphragm chamber

belowthecenterlineofthepipe..

WARNING:TheSeries455 valveshouldnotbeinstalledinavertical run

ofpipeastheweightofthepartswill causeincreasedwearand

subsequentlyshortenthelifeofthevalve.

Connectacontrollinefrom thetopofthediaphragm chambertothetop

ofthepipingonthedownstream sideofthevalve.Thecontrollineshould

beinstalledapproximately10 pipediametersdownstream ofthevalveina

straightrun ofpipeawayfrom any flowturbulence.Aneedlevalveshould

beinstalledinthiscontrollineforthepurposeofdampeningtheresponse

ofthevalveifrequired.

Onstart-upchecktosee thattheby-pass valveisclosedandthe

downstream pressuregaugeisreadingzero.Theupstream pressure

gaugeshouldindicatethelinepressure,andthehandvalve

theinletandoutletsideofthepressureregulatingvalveshould

befull openbeforeadjustingdownstream pressure.

TheSeries455 pressureregulatingvalvesarediaphragm

actuated,springloadedandarenormallyopen.Increasingthe

springcompressionresultsinahigherdownstream pressure,

whiledecreasingthespringcompressionreducesthedown

stream pressure.Onstartup,slowlyincreasedownstream

pressure(onsteamwaitforthepipetoheatandexpand)until

thedesiredpressureisreached.

Thisinstructionsheetisintendedasgeneral informationandis

nottobeinterpretedasspecificinformationonany particular

application.If,afterreadingtheaboveinstructions,youare

uncertainastotheproduct's adaptabilityforyourapplication,

pleasecall factoryorauthorizedrepresentativebeforeinstalling

LimerickAirportBusiness Center

Pottstown,PA19464

Fax:(610)495-5134

www.watsonmcdaniel.com

INSTRUCTIONPARTNO.2227900REVISION3

EachWatsonMcDanielCompany Productiswarrantedagainstdefectsinmaterialand workmanshipforoneyearfromdateofshipment.Thiswarranty

extendstothefirstretail purchaseronly. All defectivematerialmustbereturnedtothepersonfrom whom youpurchasedtheProduct, transportationprepaid,

free ofany liensorencumbrances,and iffound tobedefectivewill berepairedfreeofchargeorreplaced,atthewarrantor'sorseller'soption.If thematerial

isreplaced,any replacementwillbeinvoicedintheusualmannerand afterinspectionofallegeddefectivematerialanadjustmentwillbemadefor

depreciationcausedby purchaser'suse.Innoeventwill WatsonMcDanielCompany beliabletodomorethanrefund theoriginalcontractprice.Incidental

and consequentialdamagesareexcluded,whetherunderthiswarrantyorotherwise.All impliedwarranties,including warrantiesofmerchantability and

fitnessforaparticularpurpose, aredisclaimedand excluded.