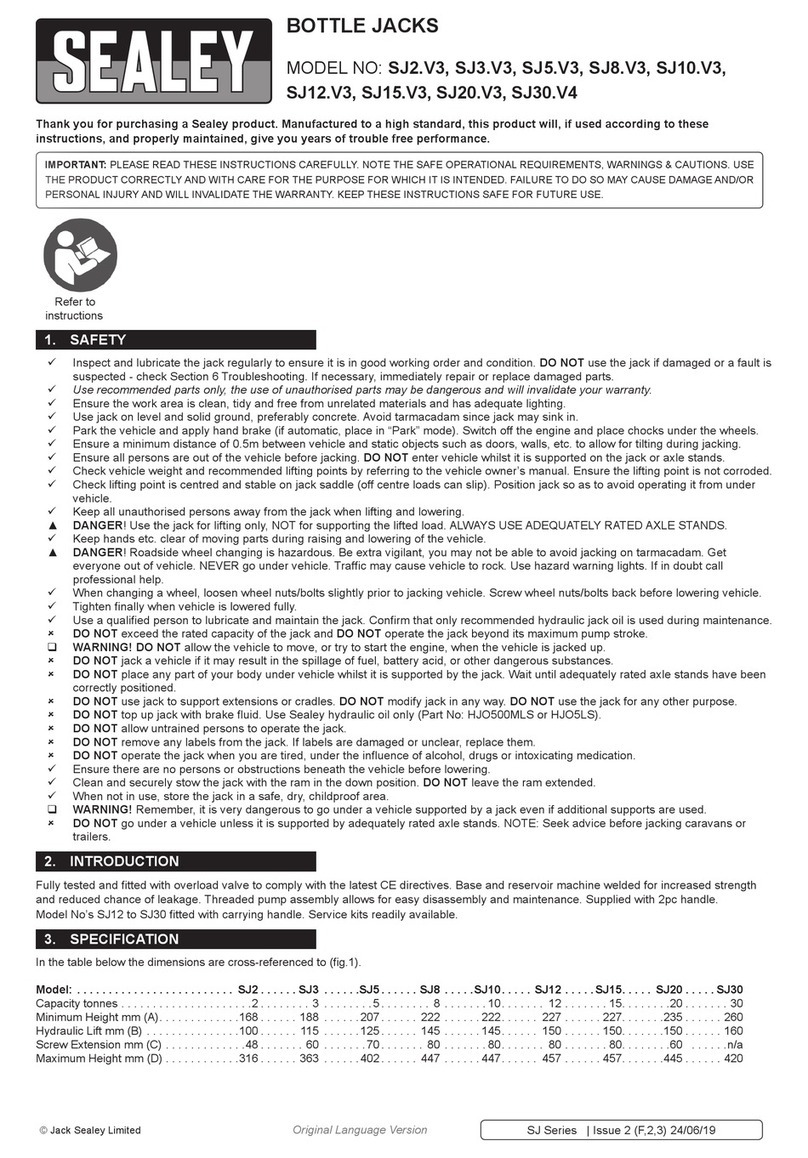

TOOL WAREHOUSE WT83508 User manual

Read carefully and understand all ASSEMBLY AND OPERATION INSTRUCTIONS before operating. Failure

to follow the safety rules and other basic safety precautions may result in serious personal injury.

PROFESSIONAL HYDRAULIC GARAGE JACK-3T

WT83508

2

INTENDED USE

TECHNICAL SPECIFICATIONS

This heavy-duty jack has a single hydraulic pump piston that effortlessly raises the lift arm. Pump piston dust

shields and wiper seals protect the hydraulic system from contaminants. The jack features an overload valve

bypass system to prevent jack damage and user injury. Compact design allows use in conned spaces. Easily

ts under low vehicles. Meets ASME PASE safety standards.

Item Capacity Lifting Range

Min. (Inch)

Lifting Range

Max. (Inch)

Lifting Range

Min. (mm)

Lifting Range

Max. (mm)

T83508 3 TON 3.86 21.06 98 535

GENERAL SAFETY RULES

GENERAL SAFETY RULES

IMPORTANT SAFETY CONSIDERATIONS

WARNING: Read and understand all instructions. Failure to follow all instructions listed below may result

in serious injury.

WARNING: The warnings, cautions, and instructions discussed in this instruction manual cannot

cover all possible conditions or situations that could occur. It must be understood by the operator

that common sense and caution are factors that cannot be built into this product, but must be supplied by

the operator.

CAUTION: Do not allow persons to operate or assemble this jack until they have read this manual and

have developed a thorough understanding of how the jack works.

INSPECTION

DO NOT OPERATE OR REPAIR THIS EQUIPMENT WITHOUT READING THIS MANUAL.

To maintain the Service Jack and user safety, the responsibility of the owner is to read and follow these

instructions.

• Inspect the service jack for proper operation and function.

• Keep instructions readily available for equipment operators.

• Make certain all equipment operators are properly trained; understand how to safely and correctly operate

the unit.

• Allow unit operation only with all parts in place and operating properly.

• Use only genuine replacement parts.

• Service and maintain the unit only with authorized or approved replacement parts; negligence will make the

jack unsafe for use and void the warranty.

• Carefully inspect the unit on a regular basis and perform all maintenance as required.

• Store these instructions in the handle of your jack.

• Keep all decals on the unit clean and visible.

• Inspect the jack carefully before each use. Ensure the jack is not damaged, excessively worn, or missing

parts.

• Do not use the jack unless it is properly lubricated.

• Using a jack that is not in good clean working condition or properly lubricated may cause serious injury.

• Inspect the work area before each use. Make sure it is free and clear of any potential hazards.

3

SAFETY

SAFETY MARKINGS

Always follow safety precautions when installing and operating this jack. Keep all decals on the unit clean and

visible. Before proceeding ensure that you fully understand and comprehend the full contents of this manual.

Failure to operate this equipment as directed may cause injury or death. The distributor is not responsible for

any damages or injury caused by improper use or neglect.

Always use Jack Stands!

DO NOT USE wood blocks or any other non-approved load sustaining devices. The manufacturer only

warrants loads to be sustained by jack stands that meet current ASME standards.

DO NOT USE wood blocks or any other non-approved lifting devices for a means of lifting with the jack and or

load being raised. Failure to head these warnings may cause injury or death.

1. Study, understand, and follow all instructions before operating this device.

2. Do not exceed rated capacity.

3. Use only on hard, level surfaces, with less than 3 degrees of slope.

4. Lifting device only. Immediately after lifting, support the vehicle with appropriate means.

5. Do not move or dolly the vehicle while on the jack.

6. Lift only on areas of the vehicle as specied by the vehicle manufacturer.

7. No alterations shall be made to this product.

8. Only attachments and/or adapters supplied by the manufacturer shall be used.

9. Do not get under or allow anyone under the vehicle until it has been supported by jack stands.

10. Center load on saddle prior to lifting.

11. Use wheel chocks or other blocking device on opposing wheels before using jack.

12. Never use on a lawn mower or lawn tractor.

13. Do not use this jack for any use other than the manufacturer specied usage.

14. Do not rock the vehicle while working on or around equipment.

15. The following are not recommended for supporting on this equipment: Foundations, Homes, Mobile

Homes, Trailers, RV’s, Campers, nor Fifth Wheels, etc...

16. Failure to heed these markings may result in personal injury and/or property damage.

THIS IS A LIFTING DEVICE ONLY!

• This jack is designed only for lifting part of the total vehicle.

• Do not move or dolly the vehicle while on the jack.

• The vehicle must be supported after lifting immediately by appropriately rated jack stands.

• NEVER go under a vehicle that is not supported with appropriately rated jacks stands.

• Use wheel chocks or other blocking device on opposing wheels before using jack stands.

WARNING!

WARNING!

4

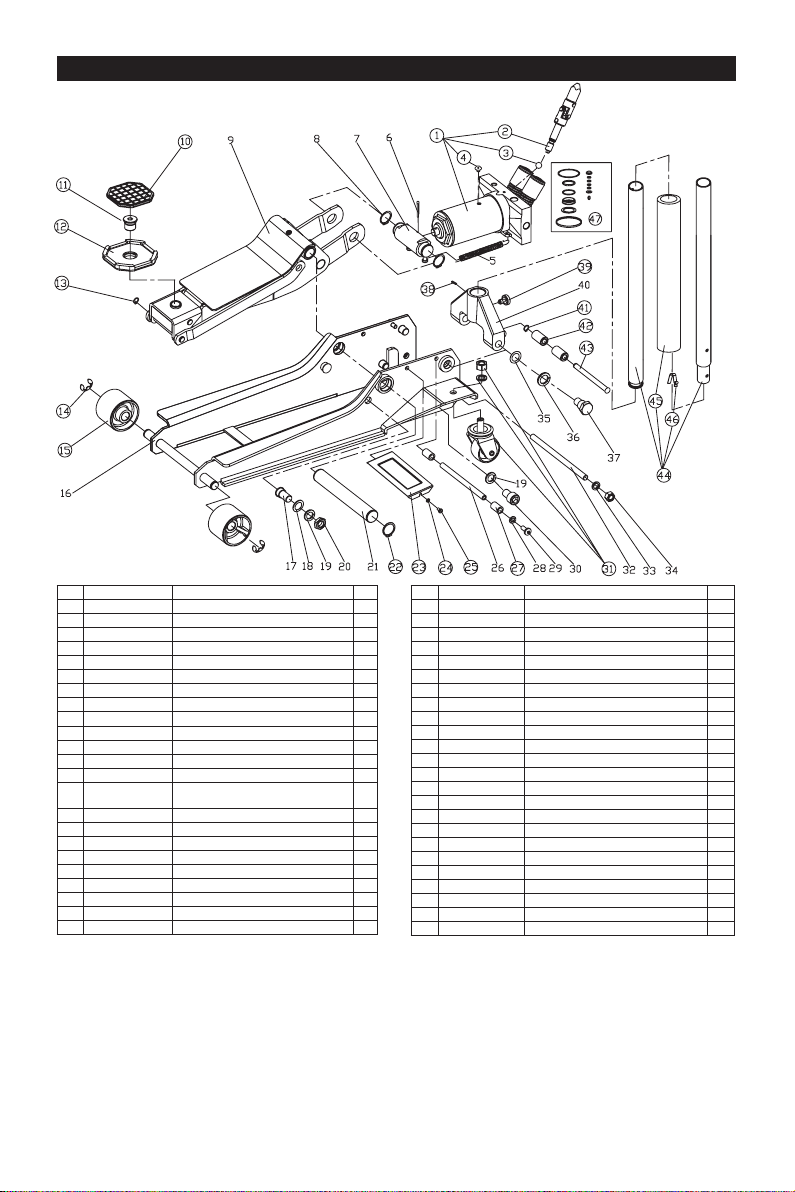

ASSEMBLY DIAGRAM

No. Part Description Qty

1 T83508.3 Power unit assembly 1

2 T83508.3.1(asm) Universal Joint Assembly 1

3 GB308-6 Steel ball Φ6mm 1

4 TF1201C-29 Oil plug 1

5 Return spring 2

6Cotter pin Φ4x40mm 1

7 Coupling connector 1

8C-clip Φ30mm 2

9 Lifting arm assembly 1

10 T83508-1 Saddle pad 1

11 T825011l-4 Pin for saddle 1

12 T83508-2 Saddle 1

13 GB894.1-Φ16 C-clip Φ16mm 1

14 GB896-M15 Side-mount external retaining ring

Φ15mm

2

15 T84004-3 Front wheel 2

16 Frame assembly 1

17 Connecting rod pintle 2

18 Washer M16 2

19 Spring washer M16 4

20 Nut M16 2

21 Supporting shaft 1

22 GB894.1-Φ28 C-clip Φ28mm 2

23 T83508-8 Cover plate 1

No. Part Description Qty

24 GB859-M6 Spring washer M6 2

25 GB67-M6X10 Machine screw M6X10 2

26 Handle socket shaft 1

27 T84004-7 Rubber sleeve 2

28 Spring washer M8 2

29 Machine screw M8X20mm 2

30 Socket head cap screw M16X25mm 2

31 T84006.5(asm) Rear wheel assembly 2

32 Back shaft 1

33 Spring washer M12 2

34 Nut M12 2

35 Washer M18 2

36 Spring washer M18 2

37 Shoulder bolt M18x65mm 2

38 GB879-Φ3 Spring pinΦ3X14mm 1

39 T83508.2-2 Handle socket screw M10X23.5mm 1

40 Handle socket 1

41 GB894.1-Φ10 C-clip Φ10mm 1

42 T83508.2-3 Contact roller 2

43 T83508.2-4 Pin for roller 1

44 T83508.5 Handle assembly 1

45 T83508-9 Flexible protective pipe 1

46 T83508.5-4 Piece of spring 1

47 T83508.MF Seal kit 1

Popular Jack manuals by other brands

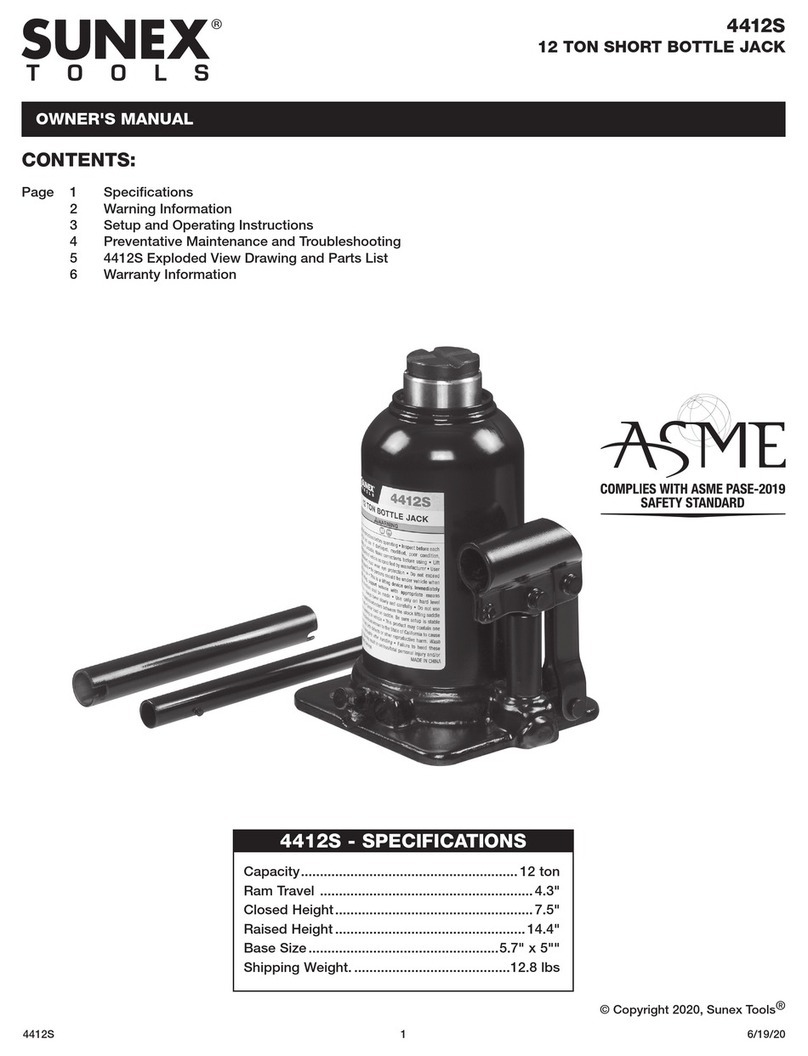

Sunex Tools

Sunex Tools 4412S owner's manual

Yale

Yale YAM operating instructions

Halfords

Halfords ADVANCED TH32505B instruction manual

MGTS

MGTS 2262070-NO6874 Installation Manual and Security Information

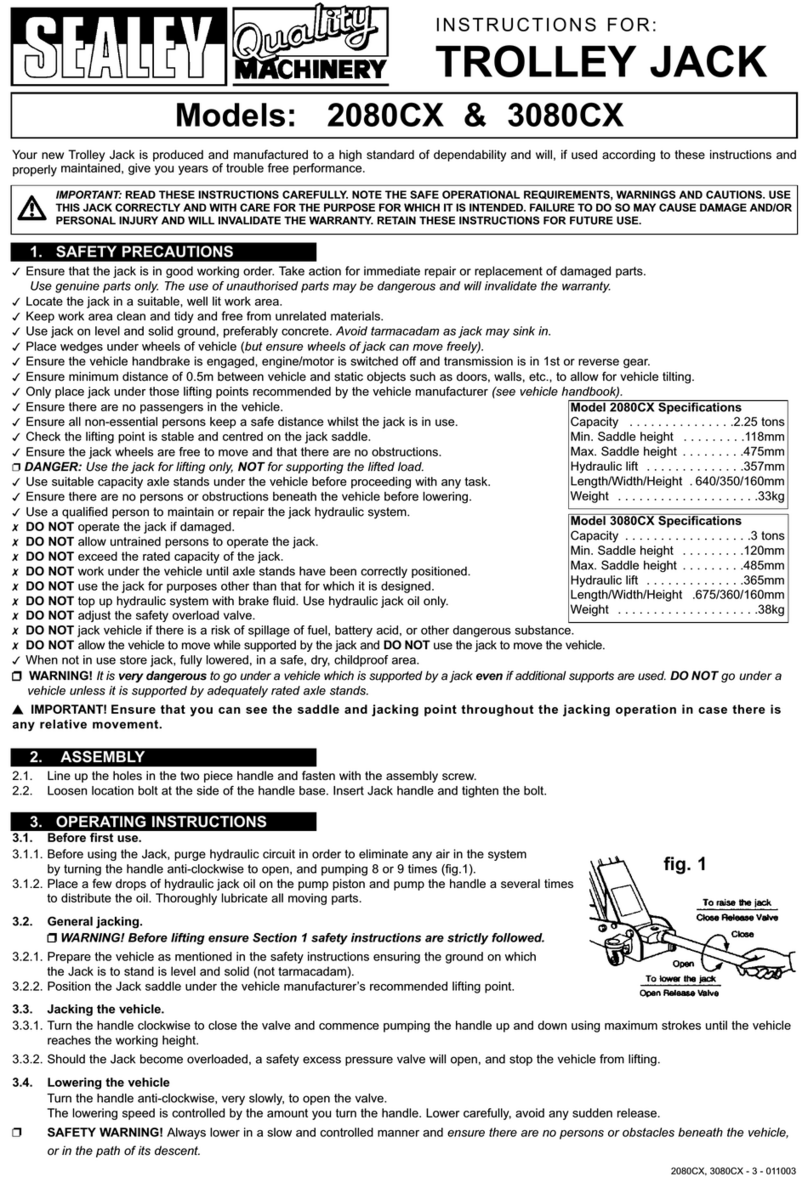

Sealey

Sealey Quality Machinery 2080CX quick start guide

BlueRange

BlueRange BRBJ3T operating instructions

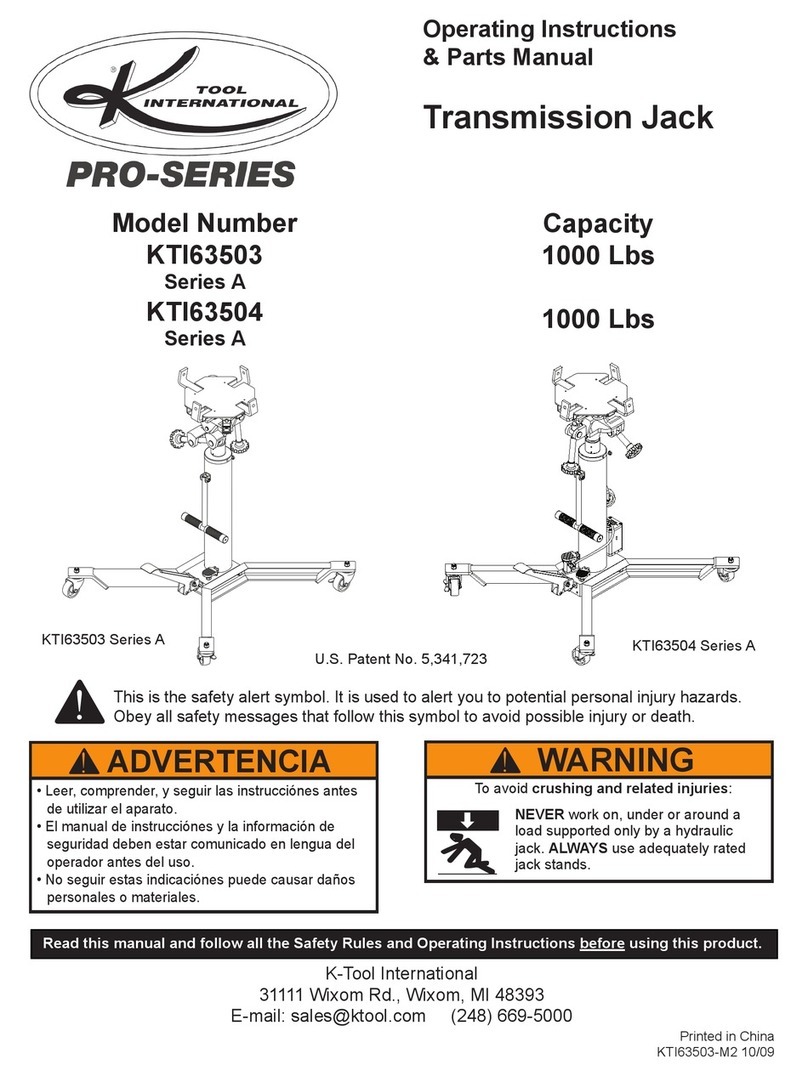

K Tool International

K Tool International PRO Series Operating instructions & parts manual

SW-Stahl

SW-Stahl 20700L instruction manual

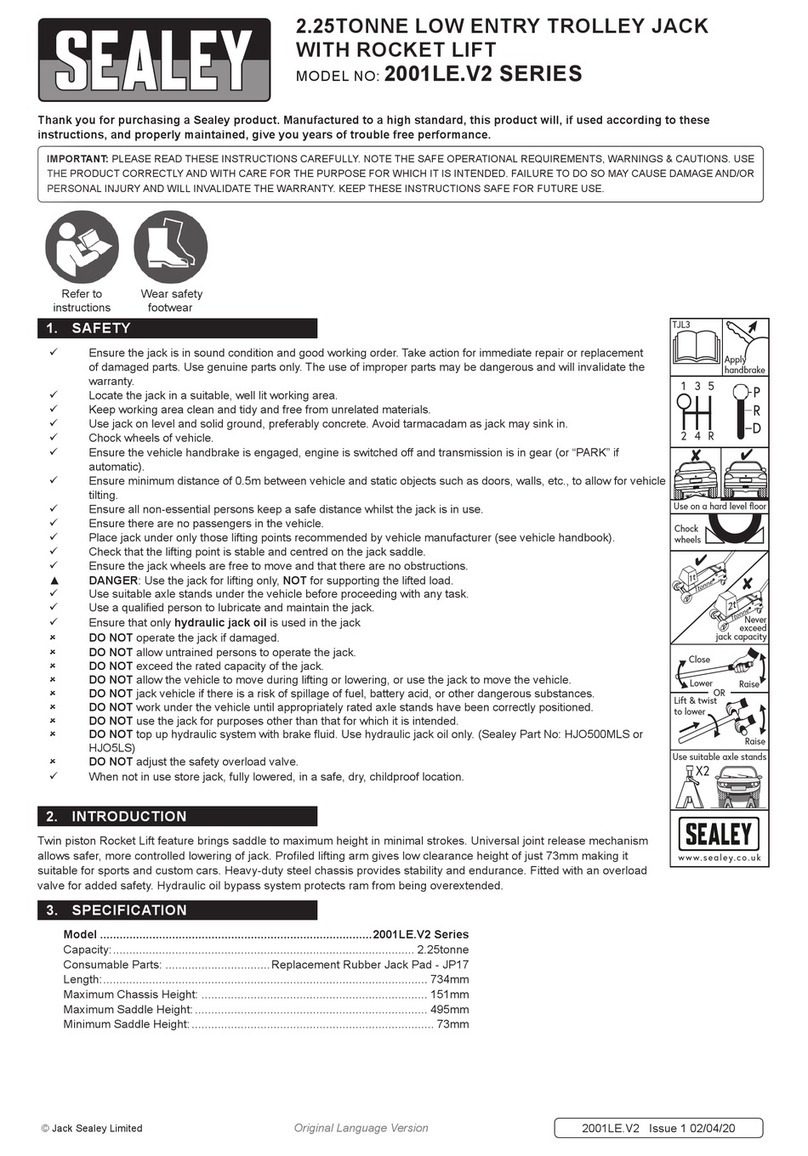

Sealey

Sealey 2001LE.V2 Series quick start guide

PT

PT W1605 owner's manual

Napa

Napa 791-2300 B Operating manual & parts list

Carlyle Tools

Carlyle Tools Napa 791-6600D manual