Toolex 594514 User manual

1

2

I. Applications

Compaction of concrete slabs

Precast sections

Roadways

Warehouse floors

II. Introduction

General Safety Instructions for the Operation of Power Equipment The most important safety device for

This or any tool is the operator. Care and good judgment are the best protection against injury. All

possible hazards cannot be covered here, but we have tried to highlight some of the important

items, individuals should look for and obey caution, warning and danger signs placed on equipment, and

displayed in the workplace. Operators should read and follow safety instructions packed with each

product.

Learn how each machine works. Even if you have previously used similar machines, carefully check out

each machine before you use it.

Get the “feel” of it and know its capabilities, limitations, potential hazard, how it operates, and how it

stops.

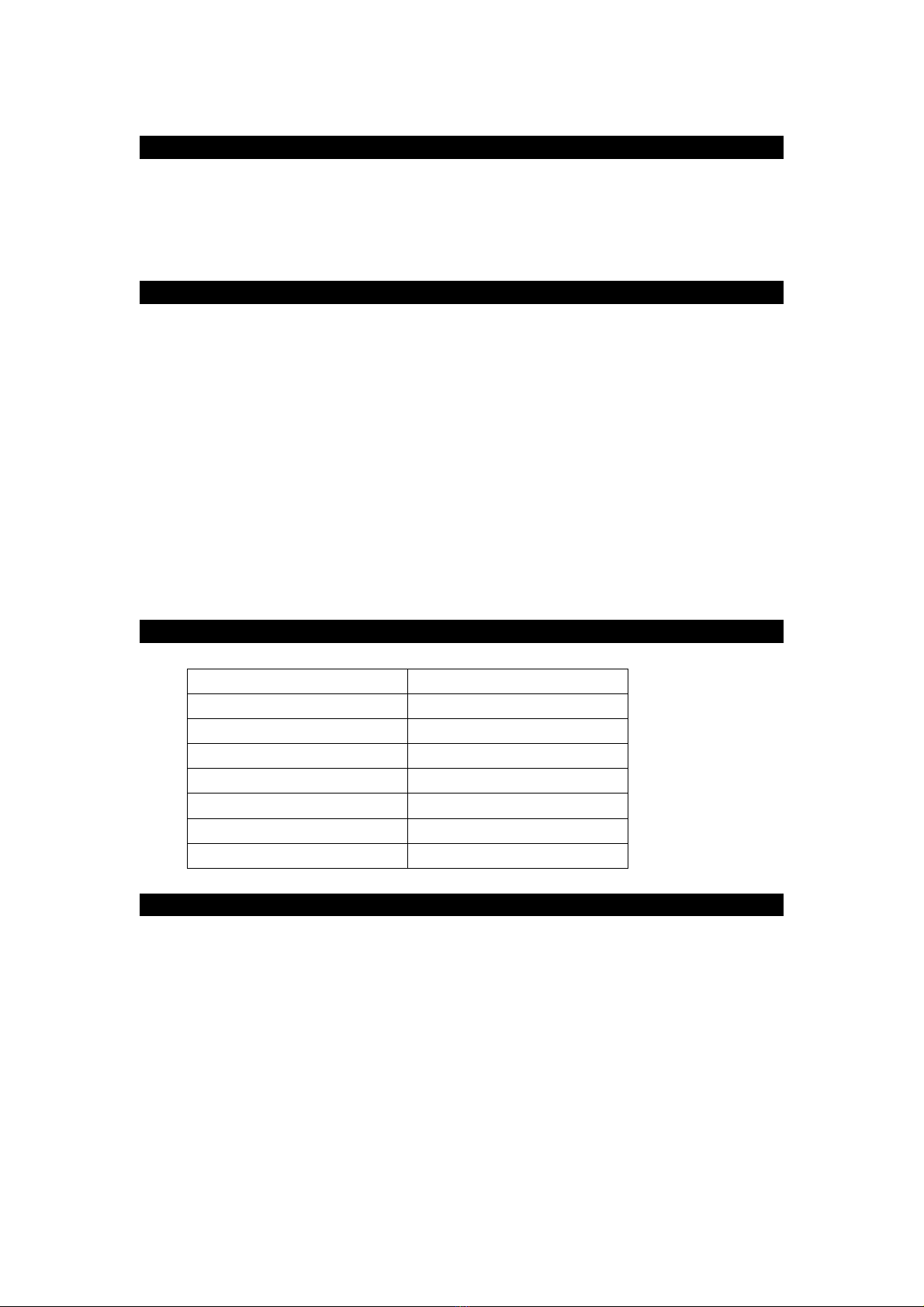

III. Specifications

Model

594514

Size

1200*800*500mm

Blade size

1200mm-4800mm optional

Engine

Air-cooled,4-cycle

Engine Type

Petrol, Honda GX35

Power kw

1.0

Weight kg

15kg

Frequency(1/min)

3600

IV. Safety information

Never allow any person to operate the machine without adequate instruction.

Ensure all operators read, understand and follow the operating instructions.

Serious injury could result from improper or careless use of this machine.

1. Mechanical hazards

* DONOT operate the machine unless all protective guards are in place.

* KEEP hands and feet clear of rotating and moving parts as they will cause injury if contacted.

* ENSURE that the motor operation switch is in the OFF position and the spark plug ignition lead is

Disconnected before removing the guards or making adjustments.

* DO NOT leave the machine in operation while it is unattended.

* EXERCISE CARE when operating unit. Exposure to vibration or repetitive work actions may be harmful

to hands and arms.

3

* NEVER stand on the unit while it is operating.

* BE CAREFULL not to come in contact with the muffler when the engine is hot, since it can cause severe

burns.

* ENSURE that repairs to the motor and machine are carried out by COMPETENT personnel.

2. Fire & explosion hazards

* PETROL is extremely flammable and explosive under certain conditions.

* ENSURE that petrol is only stored in an approved storage container.

* DO NOT refuel the motor while it is in operation or hot.

* DO NOT refuel the motor in the vicinity of sparks, a naked flame or a person smoking.

* DO NOT over fill the fuel tank and avoid spilling petrol when refueling. Spilled petrol or petrol vapour

may ignite. If spillage occurs, ensure that the area is dry before starting the motor.

* ENSURE that the fuel tank cap is securely fitted after refueling.

3. Chemical hazard

* DO NOT operate or refuel a petrol motor in a confined area without adequate ventilation.

* CARBON MONOXIDE exhaust gases from internal combustion motor driven units can cause death in

confined spaces.

4. Noise hazards

* EXCESSIVE NOISE can lead to temporary or permanent loss of hearing.

* WEAR an approved hearing protection device to limit noise exposure. As required by Occupational

Health and Safety regulations.

5. Protective clothing

* ALWAYS wear protective clothing and footwear to prevent the skin coming into contact with wet

concrete.

* PROTECTIVE FOOTWARE should be worn to reduce injuries from penetration through the sole,

contact with cutting objects, slipping, contact with wet concrete and electrical hazards.

* GOGGLES for eye protection may also be necessary.

* USE waterproof protection for hands and knees (if kneeling) when concreting .If your clothing becomes

* Wet from concrete contact make sure you change the clothing. Do not walk about waiting for it to dry.

6. Additional hazards

Slip/Trip/Fall is a major cause of serious injury or death. Beware of uneven or slippery work surfaces.

V. Operation

Using the vibrating-beam screed

Once the concrete, with its surcharge, has been spread, start the motor and manually pull the beam

along the slab. Make sure that there is always a continuous surcharge along the entire length of the

leading edge. Generally one steady pass with the screed should be enough to compact and level the

concrete.

Vibration of the concrete is still necessary to bring air bubbles to the surface.

4

Start the motor using the recoil starter.(if the motor is fitted with an on/off switch this must first be turned

to ON before starting.)

ALWAYS maintain good footing so that you do not slip and loose control when starting or operating the

machine.

VI. Maintenance and storage

1. Care and preventive maintenance

Inspect the rubber and vibration mounts for wearing or deterioration.

Clean the aluminum beams regularly to prevent a build up of concrete residue.

2. Service

The housing weight must be greased after every 10 hours of operation. DO not over grease.

Inspect, clean and /or replace the motor air cleaner regularly, particularly when operating in a dusty

Environment.

Inspect, clean and/or replace the spark plug regularly.

Check all fasteners for tightness as the machine is subject to vibration.

To test run the screed support the beams on a resilient support at each end.(eg.use two car tyres.)

3. Cleaning and Storage

Keep the unit clean and free of concrete residue.

Ensure the cooling fins on the motor are kept unobstructed.

VII. Malfunction list

SYMPTOM

POSSIBLE CAUSE

SOLUTION

Vibrates insufficient and

as a result the

concrete floor can

not be leveled

and smoothed in the proper

way.

The centrifugal force of the

vibrator is set too low?

Adjust the eccentric weights or

increase engine speed.

There is Excessive amounts of

concrete along the leading edge

of the blades?

Remove the excessive concrete

from the blade.

The chosen width of the blades

is too large?

Work with a smaller blade

remember maximum width is 20ft.(2

engines)

Screed when used as a

form-to-form screed vibrates

too much and does not travel

smoothly across the rail

supports.

Selected blade and eccentric

weights do not match?

Adjust eccentric weights to match

selected blade width.

Concrete looks “WAVY” as the

screed blade passes over it.

Operator moving too slowly

Walk backwards at a faster pace.

Too much vibration for the

type of concrete

Reduce engine speed and walk

backwards at a faster pace.

Leaving HIGH or LOW spots

during wet screeding.

Concrete too high or low on one

side?

Have workers shape the concrete

close as possible to grade. Maintain

5

about 1 inch of concrete across the

front of the blade at all times.

Blade digs into wet concrete

Is blade positioned correctly?

Each end of the blade must ride on

the same surface. Either each end

of the blade rides on forms or

concrete (wet screed) not both.

Difficult to start,”fuel is

available, but no SPARK at

spark plug”.

Spark plug bridging?

Check gap, insulation or replace

spark plug.

Carbon deposit on spark plug?

Clean or replace spark plug

Short circuit due to deficient

spark plug insulation?

Check spark plug insulation, replace

if worn

Improper spark plug gap

Set to proper gap.

Difficult to start, ”fuel is

available, and SPARK is

present at the spark plug”.

On/OFF switch is shorted?

Check switch wiring, replace switch

Ignition coil defective?

Replace ignition coil

Improper spark gap, points

dirty?

Set correct spark gap and clean

points.

Condenser insulation worn or

short circuiting?

Replace condenser

Spark plug wire broken or short

circuiting?

Replace defective

spark plug wiring.

Difficult to start, ”fuel is

available, spark is present and

compression is normal”

Wrong fuel type?

Flush fuel system, and replace with

correct type of fuel

Water or dust in fuel system?

Flush fuel system

Air cleaner dirty?

Clean or replace air cleaner.

Choke open?

Close Choke

Difficult to start, ”fuel is

available, spark is present and

compression is low”

Suction/exhaust valve stuck or

protruded?

Reseat valves.

Piston ring and/or cylinder

worn?

Replace piston rings and or piston.

Cylinder head and/or spark plug

gasket damaged?

Torque cylinder head bolts and

spark plug

Head gasket and/or spark plug

gasket damaged?

Replace head and spark plug

gaskets.

No fuel present

inside priming

bulb

Fuel not available in fuel tank?

Fill with correct type of fuel.

Fuel filter clogged?

Replace fuel filter

Fuel tank cap breather hole

clogged?

Clean or replace fuel tank cap

Air in fuel line?

Bleed fuel line

6

VIII. Parts list

1. Finishing screed drawing

HGZ12

7

Finishing screed spare part name

No.

Parts No.

Name

Qty

Remarks

1

10001

Blade

1

2

10002

Vibrating Box

1

3

10003

Eccentric Shaft

1

4

10004

Linkage nut

1

5

10005

Cover of Gearbox

1

6

10006

Bearing

1

7

10007

Lock

4

8

10008

Bearing

1

9

10009

Grip Handle

2

10

10010

Throttle Control lever

1

11

10011

Shell of Clutch

1

12

10012

Connecting Shaft

1

13

10013

Connecting housing

1

14

10014

Screw

2

15

10015

Bolts

2

16

10016

Bolts

1

17

10017

Screw

1

18

10018

Support Shaft

1

19

10019

Shock Mount

4

20

10020

Connecting Flex Shaft

1

21

10021

Flameout switch

1

22

10022

Bearing

1

23

10023

Bearing

1

24

10024

Engine

1

25

10025

V-Frame

1

26

10026

Upper Handle

2

8

Table of contents