Toolshop 241-9934 Installation manual

Heavy-Duty Spade Handle Drill

SAFETY AND OPERATING MANUAL

SKU#241-9934

Customer service number 1-888-686-1484

2

GENERAL POWER TOOL SAFETY WARNINGS

WARNING: Read all safety warnings and instructions. Failure to follow the

warnings and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term power tool in the warning refers to your electric (corded) power tool or

battery-operated (cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence

of flammable liquids, gases or dust. Power tools create sparks which may ignite the

dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions

can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do

not use any adapter plugs with grounded power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with grounded surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased risk of electric shock if your body is

grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power

tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging

the power tool. Keep cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for

outdoor use marked “W-A” or “W”. Use of a cord suitable for outdoor use reduces

the risk of electric shock.

3

USE PROPER EXTENSION CORD. Make sure your extension cord is in good

condition. When using an extension cord, be sure to use one heavy enough to carry

the current your product will draw. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. Table 1 shows the correct size to use

depending on cord length and nameplate ampere rating. If in doubt, use the next

heavier gage. The smaller the gage number, the heavier the cord.

Table 1 Minimum gage for cord

Volts TotallengthofcordinfeetAmpere Rating

120V

25ft.

50ft.

100ft.

150ft.

MoreThan NotMore Than

AWG

0

6

10

6

10

12

18

18

16

16

16

16

16

14

14

14

12

12

12 16 14 12 Not Recommended

f) If operating a power tool in a damp location is unavoidable, use a Ground

Fault Circuit Interupter (GFCI) protected supply. Use of a GFCI reduces the risk of

electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating

a power tool. Do not use a power tool while you are tired or under the influence

of drugs, alcohol or medication. A moment of inattention while operating power

tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-position before

connecting to power source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energizing power tools that

have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A

wrench or a key left attached to a rotating part of the power tool may result in

4

personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables

better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing

and gloves away from moving parts. Loose clothes, jewelry or long hair can be caught

in moving parts.

g) If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust collection can

reduce dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool

that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the

power tool before making any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce the risk of starting the power tool

accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired before use. Many accidents are

caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc., in accordance with these

instructions and in the manner intended for the particular type of power tool, taking

into account the working conditions and the work to be performed. Use of the power

tool for operations different from those intended could result in a hazardous situation.

5

h) Use clamps or another practical way to secure and support the workpiece to a stable

platform.

i) Holding the work by hand or against your body leaves it unstable and may lead to loss

of control.

5) Service

a) Have your power tool serviced by a qualified repair person using only

identical replacement parts. This will ensure that the safety of the power tool is

maintained.

b) If the replacement of the supply cord is necessary, this has to be done by the

manufacturer or his agent in order to avoid a safety hazard.

ADDITIONAL SAFETY INSTRUCTIONS FOR YOUR

TOOL

1. Wear ear protectors with hand drills. Exposure to noise can cause hearing loss.

2.Use auxiliary handles supplied with the tool. Loss of control can cause personal

injury.

3. Hold power tools by insulated gripping surfaces when performing an

operation where the cutting tool may contact hidden wiring or its own cord.

Contact with a ‘live’ wire will make exposed metal parts of the tool ‘live’ and shock the

operator.

4. Do not use the drill near water.

5. Do not use the drill as a screwdriver.

6. Remove the plug from the socket before carrying out any adjustment, servicing or

maintenance.

7. Fully unwind extension cords to avoid potential overheating.

8. When an extension cord is required you must ensure it has the correct ampere

rating for your power tool and that it is in a safe electrical condition.

9. Ensure your supply voltage is the same as your tool rating plate voltage.

10. Your tool is double insulated for additional protection against a possible electrical

insulation failure within the tool.

11. Always check walls and ceilings to avoid hidden power cables and pipes.

12. After long working periods, external metal parts and accessories could be hot.

6

13. Wear eye protection when operating this tool.

14. Maintain a firm grip on the handle when you are working. Always use the auxiliary

handles supplied with the tool. Loss of control can cause personal injury.

15. Save these instructions. Refer to them frequently and use them to instruct others

who may use this tool. If someone borrows this tool, make sure they have these

instructions.

WARNING!

Some dust created by using power tools contains chemicals known to

the State of California to cause cancer and birth defects or other

reproductive harm. Some examples of these chemicals are:

1) lead from lead-based paint

2) crystalline silica from bricks and cement and other masonry products

3) arsenic and chromium from chemically-treated lumber

Your risk to these exposures varies, depending on how often you do this type of work.

To reduce your exposure to these chemicals:

1) work in a well ventilated area

2) work with approved safety equipment, such as those dust masks that are

specifically designed to filter out microscopic particles.

Avoid prolonged contact with dust from power sanding, sawing, grinding,

drilling and other construction activities. Wear protective clothing and wash

exposed areas with soap and water. Allowing dust to get into your mouth, eyes, or

lay on the skin may promote absorption of harmful chemicals

DOUBLE INSULATION

:

::

:

The tool is double insulated. This means that all the external metal parts are electrically

insulated from the main power supply. This is done by placing insulation barriers

between the electrical and mechanical components making it unnecessary for the tool

to be grounded.

IMPORTANT NOTE

Be sure the supply is the same as the voltage given on the rating plate. The tool is

fitted with a two-core cable and plug.

Remove the main plug from socket before carrying out any adjustment or servicing.

7

SYMBOLS

WARNING–To reduce the risk of injury, user must read instruction manual

Double insulation

Warning

Wear ear protection

Wear eye protection

Wear dust mask

8

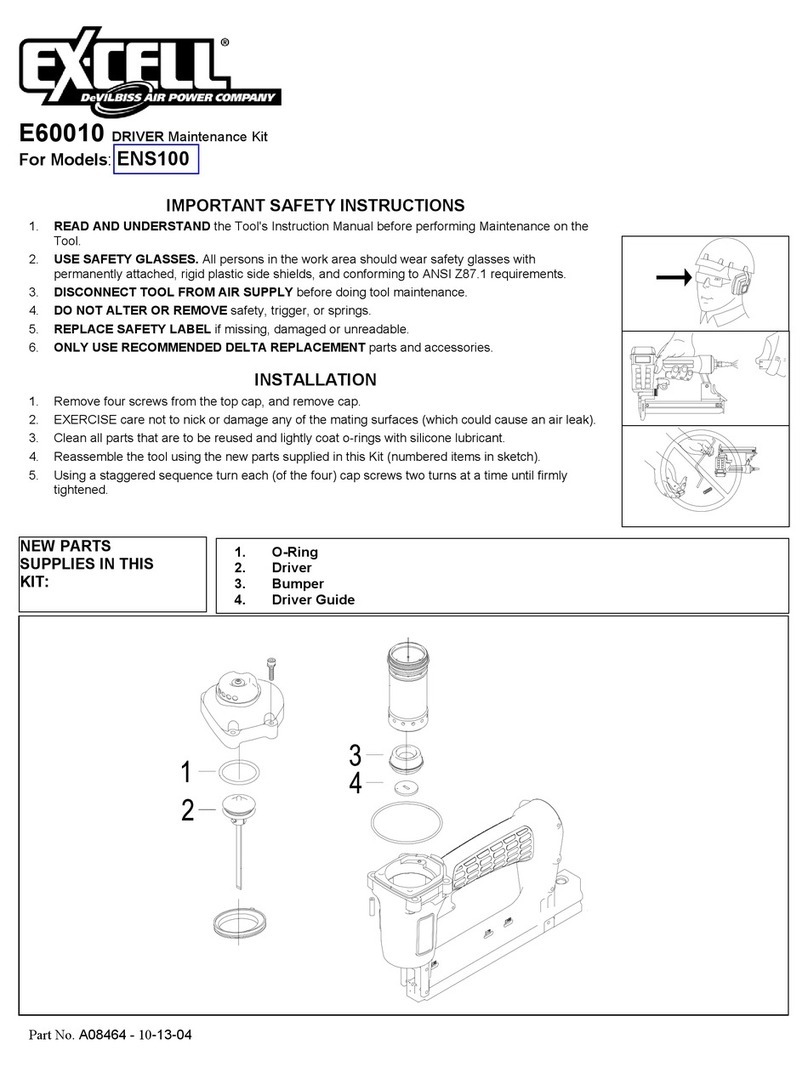

COMPONENT LIST

1. On/off switch with variable speed

2. Lock-on button

3. ‘D’ shape rear handle

4. Rear handle locking knob

5. Main handle

6. Auxiliary handle

7. Variable speed control

8. Forward/reverse selector switch

9. Chuck

10.

Chuck key (see fig. C)

Not all the accessories illustrated or described are included in standard delivery.

9

TECHNICAL DATA

Voltage

Rated current

No load speed

Chuck capacity max

Drilling capacity

Wood

Steel

Protection class:

Weight

120 V~60 Hz

9.4A

0-710/min

1/2”

1-1/4"

1/2"

/II

7.5 LBS

ACCESSORIES:

2 auxiliary handle

1 chuck key

2 extra carbon brushes

We recommend that you purchase your accessories from the same store that sold you

the tool. Use good quality accessories marked with a well-known brand name. Choose

the type according to the work you intend to undertake. Refer to the accessory

packaging for further details. Store personnel can assist you and offer advice.

10

OPERATION INSTRUCTIONS

NOTE: Before using the tool, read the instruction book carefully.

ASSEMBLY

1. AUXILIARY HANDLE(See Fig A1

,

,,

,

A2)

For all work with the machine, the auxiliary handle (6) must be mounted.

Screw the auxiliary handle (6) into the head of the machine according to the working

method. There are three positions for you to choose.

(See Fig A1)

Hold both the main handle (5) and the auxiliary handle firmly to operate the machine.

(See Fig A2)

Warning! Do not make any alterations to the auxiliary handle.

Do not continue to use an auxiliary handle if it is damaged.

2. ‘D’ SHAPE REAR HANDLE (See Fig B1,B2)

Screw the ‘D’ shape auxiliary handle (3) into the rear of the machine according to the

working method. Turn the locking knob (4) clockwise to tighten the handle. (See Fig B1)

(See Fig B1)

When not in use, screw the locking knob (4) anti-clockwise to loosen the handle and

put it away.

Hold both the main handle and rear handle firmly to operate the machine. The direction

of the ‘D’ shape handle can be changed to any position you need. (See Fig B2)

A2A1

B1 B2

11

3. MOUNTING BIT IN CHUCK (See Fig C)

When mounting the drill bit, insert bit between the chuck jaws as far as it will go.

Ensure drill bit is in the center of the chuck jaws. Your drill bit is now locked in the

chuck. The bit can be removed by reversing the above procedure.

WARNING: Before installing accessory, remove plug from power

supply. Do not attempt to tighten drill bits (or any other accessory) by

gripping the front part of the chuck and turning the tool on. Damage to the chuck

and personal injury may result.

OPERATION

1. OPERATING THE ON/OFF SWITCH (see Fig D)

On/off switch

Depress the switch to start the tool and release it to stop your tool.

Continuous use

Depress on/off switch (1) then lock-on button (2), release on/off switch first and lock-on

button second. Your switch is now locked on for continuous use. To switch off your tool

just depress and release the on/off switch.

D

C

10

12

2. VARIABLE SPEED CONTROL (SEE E)

The maximum speed can be altered by turning the variable speed control. Turn

clockwise to increase and anti-clockwise to decrease speed.

ON/OFF switch is also a variable speed switch that delivers higher speed and torque

with increased or decreased trigger pressure. Speed is controlled by the amount of

switch trigger depression.

3. FORWARD AND REVERSE ROTATION CONTROL (See Fig F1, F2)

For drilling use forward rotation marked “ ” (lever is moved to the right).

(See F1) Only use reverse rotation marked “ ” (lever is moved to the left) to

release a jammed drill bit. (See F2)

Warning! Never change the direction of rotation when the tool is rotating,

wait until it has stopped.

F1

E

F2

13

WORKING HINTS FOR YOUR DRILL

1. If your power tool becomes too hot set the speed to maximum and run no load

for 2-3 minutes to cool the motor.

2. When drilling in metal, only use HSS drill bits in good condition.

3. Where possible use a pilot hole before drilling a large diameter hole in the metal

material.

MAINTAIN TOOLS WITH CARE

Remove the plug from the socket before carrying out any adjustment, servicing

or maintenance.

Your power tool requires no additional lubrication or maintenance. There are no user

serviceable parts in your power tool. Never use water or chemical cleaners to clean

your power tool. Wipe clean with a dry cloth. Always store your power tool in a dry

place. Keep the motor ventilation slots clean. Keep all working controls free of dust.

If the supply cord is damaged, it must be replaced by the manufacturer, its service

agent or similarly qualified persons in order to avoid a hazard.

TROUBLESHOOTING

1 If your drill will not operate, check the power at the mains plug.

2 If the drill is not cutting properly, check the drill bit for sharpness, replace drill bit if

worn. Check that the drill is set to forward rotation for normal use.

3 If a fault can not be rectified return the drill to an authorized dealer for repair.

14

Tool Shop Heavy-Duty Spade Handle Drill Warranty

1-YEAR LIMITED WARRANTY:

This TOOL SHOP® brand power tool carries a 1-Year Limited Warranty to the original

purchaser. If the tool fails within one (1) year from the date of purchase, simply bring

this tool with your original sales receipt back to your nearest MENARDS® retail store.

At its discretion, TOOL SHOP® agrees to have the tool replaced with the same or

similar TOOL SHOP® product free of charge, within the stated warranty period, when

returned by the original purchaser with original sales receipt. Notwithstanding the

foregoing, this limited warranty does not cover any damage that has resulted from

abuse or misuse of the Merchandise. This warranty: (1) excludes expendable parts

including but not limited to blades, belts, bits, light bulbs, and/or batteries; (2) shall be

void if this tool is used for commercial and/or rental purposes; and (3) does not cover

any losses, injuries to persons/property or costs. This warranty does give you specific

legal rights and you may have other rights, which vary from state to state. Be careful,

tools are dangerous if improperly used or maintained. Seller’s employees are not

qualified to advise you on the use of this Merchandise. Any oral representation(s)

made will not be binding on seller or its employees. The rights under this limited

warranty are to the original purchaser of the Merchandise and may not be transferred

to any subsequent owner. This limited warranty is in lieu of all warranties, expressed

or implied including warranties or merchantability and fitness for a particular purpose.

Seller shall not be liable for any special, incidental, or consequential damages. The

sole exclusive remedy against the seller will be for the replacement of any defects as

provided herein, as long as the seller is willing or able to replace this product or is

willing to refund the purchase price as provided above. For insurance purposes,

seller is not allowed to demonstrate any of these power tools for you.

For questions / comments, technical assistance or repair parts –

Please call toll free at: 1-888-686-1484 (M-F 8am – 6pm)

SAVE YOUR RECEIPTS. THIS WARRANTY IS VOID WITHOUT THEM.

15

Taladro con mango tipo espada de

alto rendimiento

MANUAL DE SEGURIDAD Y OPERACIÓN

SKU#241-9934

número de atención al cliente: 1-888-686-1484

16

ADVERTENCIAS DE SEGURIDAD GENERALES

PARA LA HERRAMIENTA MOTORIZADA

¡ADVERTENCIA! Lea y comprenda todas las instrucciones. El no seguir

todas las instrucciones a continuación puede ocasionar descargas eléctricas,

incendios y/o heridas graves.

Conserve todas las advertencias e instrucciones para consulta futura.

El término “herramienta eléctrica” que figura en todas las advertencias que aparecen a

continuación hace referencia a la herramienta que funciona con la red de suministro

eléctrico (con cable) o a la herramienta eléctrica accionada a baterías (sin cable).

1) ÁREA DE TRABAJO

a) Mantenga su lugar de trabajo limpio y bien iluminado. Bancos de trabajo

desordenados y lugares oscuros invitan a los accidentes.

b) No utilice herramientas eléctricas en atmósferas explosivas, como por

ejemplo en presencia de líquidos, inflamables, gases o polvo. Las herramientas

eléctricas crean chispas que pueden encender el polvo o los vapores.

c) Mantenga a los espectadores, niños y visitantes a una distancia prudente

cuando esté utilizando una herramienta eléctrica. Las distracciones pueden

hacerle perder el control.

2) SEGURIDAD ELÉCTRICA

a) Los enchufes de las herramientas eléctricas deben coincidir con el

tomacorriente. No modifique de algún modo el enchufe. No utilice enchufes

adaptadores con herramientas eléctricas conectadas a tierra. Si no se modifican

los enchufes y se utilizan los tomacorrientes adecuados, se reducirá el riesgo de una

descarga eléctrica.

b) Evite el contacto del cuerpo con las superficies conectadas a tierra tales

17

como tuberías, radiadores, estufas de cocina y refrigeradores. Existe mayor

riesgo de que se produzcan descargas eléctricas si su cuerpo está conectado a tierra.

c) No exponga las herramientas eléctricas a la lluvia ni a los ambientes húmedos.

La entrada de agua en una herramienta eléctrica aumenta el riesgo de que se

produzcan descargas eléctricas.

d) No abuse del cable. Nunca use el cable para transportar las herramientas ni para

sacar el enchufe de un tomacorriente. Mantenga el cable alejado del calor, el aceite,

los bordes afilados o las piezas móviles. Los cables dañados aumentan el riesgo de

que se produzcan descargas eléctricas.

e) Cuando utilice una herramienta eléctrica en exteriores, utilice un cable de

extensión apto para uso exterior. La utilización de un cable de extensión reducirá el

riesgo de una descarga eléctrica.

CABLES DE EXTENSIÓN. Utilice cables de extensión apropiados. Cerciórese de que

su cable prolongador esté en buenas condiciones. Asegúrese de utilizar un

prolongador lo suficientemente resistente como para soportar la corriente que requiere

su producto. Un cable pequeño causará una caída de corriente en la línea de voltaje,

dando por resultado recalentamiento y pérdida de potencia. La Tabla 1 muestra el

calibre correcto a utilizar, dependiendo de la longitud del cable y del amperaje indicado

en la placa de identificación. En caso de duda, utilice el tamaño mayor siguiente.

Cuanto menor es el calibre, mayor es la capacidad del cable.

Tabla 1. Calibre mínimo para el cable

Voltios Longitud total del cable en piesAmperios Capacidad

120 V

25 pies

50 pies 100

pies

150

pies

Mayor de

No mayor

de

Calibre AWG

0 6 18 16 16 14

6 10 18 16 14 12

10 12

16 16 14 12

12 16

14 12 No se

recomienda

f) Si no se puede evitar la utilización de una herramienta motorizada en una

18

ubicación húmeda, utilice un suministro de alimentación protegido por un

interruptor de circuito accionado por corriente de pérdida a tierra (GFCI). El uso de

un GFCI reduce el riesgo de descarga eléctrica.

3) SEGURIDAD PERSONAL

a) Manténgase alerta, fíjese en lo que está haciendo y use el sentido común

cuando utilice una herramienta eléctrica. No use la herramienta cuando esté

cansado o se encuentre bajo la influencia de drogas, alcohol o medicamentos.

Un momento de distracción al utilizar herramientas eléctricas puede dar lugar a

lesiones personales graves.

b) Utilice equipo de seguridad. Use siempre protección ocular. La utilización del

equipo de seguridad como mascara antipolvo, zapatos de seguridad antideslizantaes,

casco o protección auditiva para condiciones adecuadas reducirá el riego de lesiones

personales.

c) Evite el arranque accidental. Asegúrese de que el interruptor esté en la

posición de trabado o de apagado antes de instalar el paquete de baterías.

Transportar herramientas con el dedo en el interruptor o instalar el paquete de batería

cuando el interruptor está encendido invitan a los accidentes.

d) Retire las llaves o claves de ajuste antes de encender la herramienta. Una llave

o clave de ajuste dejada en una parte giratoria de la herramienta puede causar una

lesión personal.

e) No intente alcanzar demasiado lejos. Mantenga un apoyo de los pies y un

equilibrio adecuados en todo momento. El apoyo de los pies y el equilibrio

adecuados permiten un mejor control de la herramienta en situaciones inesperadas.

f) Vístase apropiadamente. No se ponga ropa holgada ni joyas. Mantenga su

cabello, ropa y guantes alejados de las piezas móviles. La ropa holgada, las joyas

o el pelo largo pueden quedar atrapados en las piezas móviles.

g) Si se proporcionan dispositivos para la extracción y recolección de polvo,

asegúrese que estos estén conectados y utilizados correctamente. El uso de

estos dispositivos puede reducir peligros relacionados con el polvo.

4) USO Y CUIDADO DE LA HERRAMIENTA

19

a) No fuerce la herramienta. Emplee la herramienta correcta para la aplicación

que desea. La herramienta correcta hará el trabajo mejor y con más seguridad a la

capacidad nominal para la que está diseñada.

b) No utilice la herramienta si el interruptor no la enciende o apaga. Toda

herramienta que no se pueda controlar con el interruptor es peligrosa y debe ser

reparada.

c) Desconecte la batería de la herramienta o ponga el interruptor en la posición

de trabado o de apagado antes de hacer cualquier ajuste, cambio de accesorios

o guardar la herramienta. Estas medidas de seguridad preventivas reducen el

riesgo de encender la herramienta accidentalmente.

d) Guarde las herramientas que no esté usando fuera del alcance de los niños y

otras personas no capacitadas. Las herramientas son peligrosas en las manos de

los usuarios no capacitados.

e) Mantenga las herramientas con cuidado. Compruebe la desalineación o el

atasco de las piezas móviles, la ruptura de piezas y cualquier otra situación que

pueda afectar el funcionamiento de las herramientas. Si la herramienta está

dañada, hágala arreglar antes de usarla. Muchos accidentes son causados por

herramientas mantenidas deficientemente.

f) Conserve las herramientas de corte afiladas y limpias. Las herramientas

mantenidas adecuadamente, con bordes de corte afilados, tienen menos

probabilidades de atascarse y son más fáciles de controlar.

g) Utilice la herramienta eléctrica, accesorios, brocas de la herramienta, etc. de

acuerdo con estas instrucciones y de la manera adecuada para el tipo de

herramienta eléctrica, teniendo en cuenta las condiciones de trabajo y el trabajo

que se realizará. La utilización de la herramienta eléctrica para operaciones diferentes

de aquellas para las que se encuentra diseñada podría dar lugar a una situación

peligrosa.

h) Fijar la pieza sobre la mesa estable con clip o medios alternativos.

i) Fijar la pieza de mano o la apoyar contra el cuerpo llevará a cabo la operación

inestable, podrá estar fuera de control.

5) REPARACIÓN

20

a) La herramienta debe ser reparada por una persona calificada de servicio

técnico y se deben utilizar partes de reemplazo idénticas. Esto asegurará el

mantenimiento de la seguridad de la herramienta eléctrica.

b) Si es necesario reemplazar el cable de alimentación, el fabricante o su agente

deberá ser el encargado de este reemplazo a fin de evitar peligros que atenten

contra la seguridad.

INFORMACIÓN DE SEGURIDAD ADICIONAL DE LA

HERRAMIENTA

1. Utilice protección auditiva durante el uso de taladros de mano. La exposición

al ruido puede causar pérdida del oído.

2. Use siempre el mango auxiliar proporcionado con la herramienta. La pérdida

de control podría provocar lesiones personales.

3. Sujete la herramienta por las superficies de agarre aisladas cuando realice

una operación en la que la herramienta de corte pueda entrar en contacto con

cables ocultos o con su propio cable. El contacto con un cable que tenga

corriente hará que ésta pase a las partes metálicas descubiertas de la

herramienta y que el operador reciba descargas eléctricas.

4. No utilice el taladro cerca de agua.

5. El aparato no debe utilizarse como destornillador.

6. Extraiga el enchufe de la toma eléctrica antes de llevar a cabo cualquier reparación

o ajuste.

7. Desenrolle completamente las extensiones de tambor de cable para evitar posibles

excesos de temperatura.

8. Si necesita un cable prolongador, asegúrese de que tiene el amperaje correcto para

su herramienta y que se encuentra en condiciones eléctricas seguras.

9. Asegúrese de que el voltaje de la fuente de alimentación coincide con los datos de

la placa de valores nominales.

10. Su herramienta posee un doble aislamiento para aumentar la protección frente a

un posible fallo de aislamiento.

11. Revise siempre las paredes y techos para evitar cables y tuberías eléctricas

ocultas.

Table of contents

Languages:

Other Toolshop Drill manuals