Toolshop 241-9826 User manual

1/2” 4.5 AMP HAMMER DRILL

241-9826

SAVE THIS MANUAL

You will need this manual for safety instructions, operating procedures and warranty.

Put it and the original sales receipt in a safe dry place for future reference.

For questions about this product, Please call 1-866-915-8626

Operator’s Manual

IMPORTANT SAFETY INSTRUCTIONS

2

WARNING:When using electric tools, machines or equipment, basic safety

shock, and personal injury. !

READ ALL INSTRUCTIONS BEFORE USING THIS TOOL

1. KEEP WORK AREA CLEAN. Cluttered areas can cause injuries.

2. CONSIDER WORK AREA ENVIRONMENT. Don’t use power tools in damp,

wet, or poorly lit locations. Don’t expose tools to the rain. Keep the work area

3. KEEP CHILDREN AND BYSTANDERS AWAY.

away from the work area. Don’t let them handle machines, tools or extension

cords.

4.

5. OBSERVE PROPER PRECAUTIONS REGARDING DOUBLE INSULA-

TION.

6. GUARD AGAINST ELECTRIC SHOCK.

electric shock if you contact a live wire.

7. DO NOT MISUSE THE CORD.

immediately.

8. WHEN WORKING OUTDOORS, USE AN OUTDOOR-RATED EXTENSION

CORD.

9. ENSURE THE EXTENSION CORD YOU USE IS OF SUFFICIENT GAUGE

FOR ITS LENGTH.

10. STORE IDLE EQUIPMENT.

reach of children.

11. DON’T FORCE THE TOOL. It

rate for which it was intended.

12. USE THE RIGHT TOOL. Don’t force a small tool or attachment to do the

not intended.

13. DRESS PROPERLY.

Recommended Minimum Wire Gauge for Extension Cords

Amps

from

Tool Nameplate

25’ length 50’ length 75’ length 100’ length 150’ length 200’ length

0-5 amps

5.1-8 amps

8.1-12 amps

12.1-15 amps

15.1-20 amps

GROUNDED TOOLS MUST BE PLUGGED INTO AN OUTLET THAT IS

PROPERLY INSTALLED AND GROUNDED.

Bystanders can be a distraction and could be injured.

There should be a low-resistance path to carry

3

IMPORTANT SAFETY INSTRUCTIONS

14. USE EYE PROTECTION.

or coarse dust.

15. SECURE WORK.

16. DON’T OVERREACH.

17. MAINTAIN TOOLS.

18. AVOID UNINTENTIONAL STARTING. Be sure the switch is in the OFF posi

20. DO NOT USE THE TOOL IF IT CANNOT BE SWITCHED ON OR OFF.

21. DISCONNECT THE PLUG FROM THE POWER SOURCE BEFORE MAKING

ANY ADJUSTMENTS.

if the tool accidentally starts.

22. STAY ALERT.

23. CHECK FOR DAMAGED PARTS.

center. Don’t use the tool if switch does not turn it on and o

shock or injury.

ff properly.

24. REPLACEMENT PARTS.

parts.

25. SERVICE AND REPAIRS

19. ALWAYS CHECK AND MAKE SURE TO REMOVE ANY ADJUSTING KEYS OR

WRENCHES BEFORE TURNING THE TOOL ON.

Use clamps or a vise to hold the work, this will free both

hands to operate the tool.

, k

Watch what you are doing and use common sense.

Do not operate any tool when you are tired, or using medication which can

make you drowsy.

or binding of

, any or mountings, or other conditions

that may affect safe

,

4

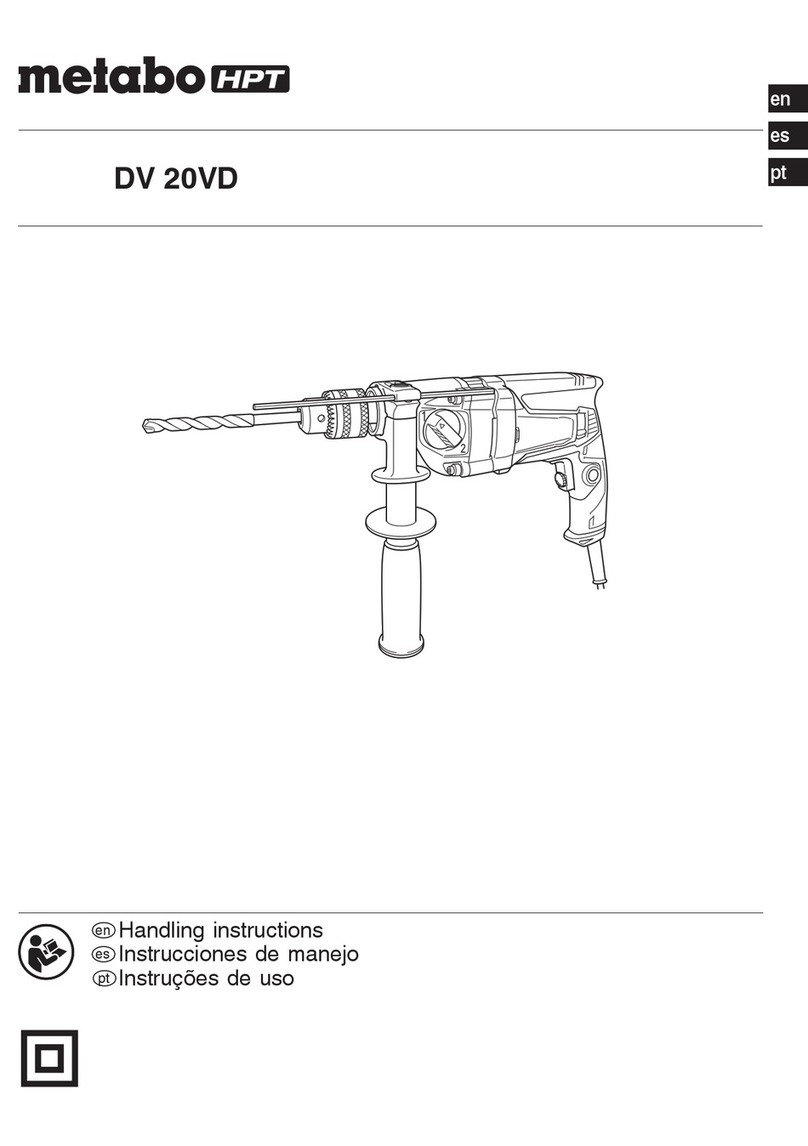

1. Depth gauge rod

2. Depth gauge clamp

3. Chuck

4. Side handle

5. Chuck key

6. Lock-on button

7. Speed control dial

8. Variable speed trigger switch

9. Forward/Reverse switch

10. Drilling and impact mode selector switch

OPERATING PROCEDURES

Operating the chuck

1. Be sure the drill is disconnected from power source.

2. Open the chuck, using the chuck key, until it accepts the drill bit or accessory

shaft, up to 13mm (1/2”) in diameter.

3. Close the chuck and tighten it using the chuck key

4. Remove the chuck key before using the drill.

Side handle

1. Loosen the grip on the Side Handle and slide Side Handle clamp over and

behind the Chuck until it is set against housing.

2. Rotate the Side Handle until it is in desired orientation.

3. Rotate Side Handle grip clockwise to secure the clamp.

Install the depth gauge

1. Loosen the Side Handle.

2. Slide the Depth Gauge into the gauge hole.

3. Set Depth Gauge to required depth.

4. Retighten grip to fasten Depth Gauge into place.

FUNCTIONAL DESCRIPTION

Running the hammer drill

1. Plug the tool into a power source.

2. Hold the tool firmly. The farther you despress the trigger the faster the speed. The

maximum speed is adjustable by rotating the speed adjustment wheel on the

trigger.

3. To maintain a certain speed after you have set your speed dial(located on the trigger)

engage the lock-on button on the left side of the handle when squeezing the trigger switch.

4. To disengage the lock-on button, squeeze the trigger again.

1

210

3

4

5

6

78

9

SPECIFICATIONS

■Voltage: 120 volts AC, 60Hz.

■Current rating: 4.5 Amp

■No load speed: 0-2,800 RPM

No load impacts: 0-40,000 BPM

■1/2'' keyed chuck

5

Forward-Reverse

To change the chuck rotation direction, press the Forward-Reverse switch.

For clockwise (forward) rotation, push it from the right side.

For counterclockwise (reverse) rotation, push it from the left side.

Regular drilling and Hammer drilling mode

To change the drill from regular drilling to the hammer drilling, wait until the drill has

stopped turning, and slide the drilling and impact mode selector switch to the left,

the side with the hammer drill mode symbol. This will cause the drill to use

percussion as well as turning action. This percussion causes the tip of the drill bit to

break up the material it contacts, while the turning action removes the debris created

from the contact point at the drill tip. The percussion varies from 0 to 40,000 beats per

minute. Be aware that the force of the impact tends to diminish as the number of

beats per minute increases.

Do not move the drilling and impact mode selector switch while the drill is turning.

WARNING: Turn off your drill at once, unplug and inspect it for serious problems if:

Moving parts get stuck

Speed drops to an abnormally low level

The motor housing gets hot

Sparks or odors emit from the casing

Metal Drilling

NOTE: rofstibmuinatitrostibleetsdeepshgihesu,ecnamrofrepmumixamroF

metal or steel drilling.

1. Move the drilling and impact mode selector switch to the regular drilling mode.

2. Use a center punch to mark the hole location on the workpiece.

3. Begin drilling at a very low speed to prevent the bit from slipping off the starting

point.

4. Maintain a speed and pressure which allows drilling without overheating the bit.

Applying too much pressure may overheat the drill, wear out the bearing, bend

or burn bits, produce off-center or irregular shaped holes.

5. When drilling large holes in metal it is highly recommended to drill with a small

bit at first, and finish with a larger bit. It is also recommended to use a cutting

lubricant to improve drilling action and increase bit life.

Wood Drilling

NOTE: For maximum performance, use high speed steel bits for wood drilling.

1. Move the drilling and impact mode selector switch to the regular drilling mode.

2. Secure the workpiece to prevent it from turning when drilling which may cause

injury.

3. Begin drilling at a very low speed to prevent the bit from slipping off the starting

OPERATING PROCEDURES

!

!

!

point. Increase the speed as the drill bit bites into the material.

This tool is designed for drilling into almost any material. For drilling into wood,

metal, and plastics, use it in the regular (non-hammer) setting. For drilling holes

in stone or concrete, use special masonry drill bits and the hammer setting.

Set to Hammer Drill for masonry bits.

(Hammer drilling mode) (Regular drilling mode)

Set to Drill for other bits.

6

4. When drilling through holes, place a block of wood behind the workpiece to

prevent ragged or splintered edges on the back side of the hole.

5. Do not lock the trigger in the “ON” position if the drill may need to be stopped

suddenly.

Masonry Drilling

NOTE: For maximum performance use tungsten carbide-tipped masonry impact

bits when drilling holes in concrete, brick or tile.

1. Move the drilling and impact mode selector switch to the hammer drilling mode.

2. Apply light pressure and medium speed for best results in brick.

3. Apply additional pressure and high speed for hard materials such as concrete.

4. When drilling in tile, practice on a scrap piece to determine the best speed and

pressure.

NOTE: When drilling into tile, a special tile cutting bit may be required.

MAINTENANCE

Keep the tool housing clean and free of oil and grease by using mild soap and a

damp (not wet) cloth.

Inspect the cord regularly and have it replaced by an authorized repair facility if

it is damaged.

Lubrication for this tool is done at the factory and should not be necessary

again under normal use.

An authorized repair center should do any repairs, modification, or mainte-

nance that involves disassembling the tool.

Any damage to the tool should be corrected at an authorized repair center.

OPERATING PROCEDURES

!

!

Keep the vents clear of dust and debris. This will help prevent possible electri -

cal shorts and ensure proper cooling.

7

PARTS LIST

Please refer to Schematic Drawing, page 8

Part Description Qty

1 Screw M5×25 1

2 Chuck 1

3 Spindle 1

4 Woodruff key 1

5Ball Φ5 1

6 Spring 1

7 Bearing 6201 1

8 Ring 1

9 Gear 1

10 Retaining Ring 1

11 Arm 1

12 Function Switch 1

13 Impact Block 1

14 Bearing 1

15 Rotor 1

16 Bearing 1

17 Stator 1

Part Description Qty

18 Brush Holder 2

19 Carbon Brush 2

20 Brush Cap 2

21 Forward/Reverse Button 1

22 Right Housing 1

23 Trigger 1

24 Depth Gauge Knob 1

25 Depth Gauge 1

26 Side Handle 1

27 Side Handle Knob 1

28 Cord Clip 1

29 Left Housing 1

30 Label 2

31 Screw ST 4.2*16 12

32 Chuck Key 1

33 Cord Sheath 1

34 Power Cord 1

SCHEMATIC DRAWING

!

8

WARNING Repairs should be made by an authorized repair center. Do not

this power tool tatcatnoC.

for questions regarding this power tool.

1-866-915-8626

open or disassemble

25

26

33

34

23

24

27

9

TOOL SHOP®

1-YEAR LIMITED WARRANTY:

This

TOOL SHOP®

brand power tool carries a 1-Year Limited Warranty to the

original purchaser. If the tool fails within one (1) year from the date of

purchase, simply bring this tool with your original sales receipt back to your

nearest

MENARDS

®

retail store. At its discretion,

TOOL SHOP®

agrees to

have the tool replaced with the same or similar

TOOL SHOP®

product free of

charge, within the stated warranty period, when returned by the original

purchaser with original sales receipt. Notwithstanding the foregoing, this

limited warranty does not cover any damage that has resulted from abuse or

misuse of the Merchandise. This warranty: (1) excludes expendable parts

including but not limited to blades, belts, bits, light bulbs, and/or batteries;(2)

shall be void if this tool is used for commercial and/or rental purposes;and (3)

does not cover any losses, injuries to persons/property or costs. This

warranty does give you specific legal rights and you may have other rights,

which vary from state to state. Be careful, tools are dangerous if improperly

used or maintained. Seller’s employees are not qualified to advise you on the

use of this Merchandise. Any oral representation(s) made will not be binding

on seller or its employees. The rights under this limited warranty are to the

original purchaser of the Merchandise and may not be transferred to any

subsequent owner. This limited warranty is in lieu of all warranties,

expressed or implied including warranties or merchantability and fitness for a

particular purpose. Seller shall not beliable for any special, incidental, or

consequential damages. The sole exclusive remedy against the seller will be

for the replacement of any defects as provided herein, as long as the seller is

willing or able to replace this product or is willing to refund the purchase price

as provided above. For insurance purposes, seller is not allowed to

demonstrate any of these power tools for you.

For questions / comments, technical assistance or repair parts –

Please call toll free at: 1-866-915-8626

(M-F

9

am – 5pm EST)

SAVE YOUR RECEIPTS. THIS WARRANTY IS VOID WITHOUT THEM.

1/2” 4.5AMP HAMMER DRILL WARRANTY

Table of contents

Other Toolshop Drill manuals