Toolshop 243-1145 User manual

SAVE THIS MANUAL

You will need this manual for safety instructions, operating procedures and warranty.

Put it and the original sales receipt in a safe dry place for future reference.

Operator’s Manual

243-1145

SOLDERING GUN

2

IMPORTANT SAFETY INSTRUCTIONS

WARNING: When using electric tools, machines or equipment, basic safety

precautions should always be followed to reduce the risk of re, electric

shock, and personal injury.

!

READ ALL INSTRUCTIONS BEFORE USING THIS TOOL

1. KEEP WORK AREA CLEAN. Cluttered areas can cause injuries.

2. CONSIDER WORK AREA ENVIRONMENT. Don’t use power tools in damp,

wet, or poorly lit locations. Don’t expose tools to the rain. Keep the work area

well lit. Don’t use tools in the presence of ammable gases or liquids.

3. KEEP CHILDREN AND BYSTANDERS AWAY. All children should be kept

away from the work area. Don’t let them handle machines, tools or extension

cords.

Bystanders can be a distraction and can be injured.

4. GROUNDED TOOLS must be plugged into an outlet that is properly

installed and grounded. Grounding provides a low-resistance path to carry

electricity to the ground away from the operator, should the tool malfunction elec--

trically. Do not remove the grounding prong from the plug or alter the plug in

any way. If in doubt as to whether the outlet is properly grounded according

to code, check with a qualied electrician.

5. OBSERVE PROPER PRECAUTIONS REGARDING DOUBLE INSULA-

TION. This tool is double insulated. It is equipped with a polarized plug.

One blade is wider than the other, so it will t into a polarized outlet only one

way. If you have difculty inserting the plug, try reversing it. If it still doesn’t

t , do not alter the plug; have a qualied electrician install a polarized outlet.

6. GUARD AGAINST ELECTRIC SHOCK. Prevent body contact with grounded

surfaces: pipes, radiators, ranges, and refrigerator enclosures. When your

body is grounded the risk of electric shock increases. When working wher-

ever “live” electrical wires may be encountered, try to ascertain whether

there is a danger of shock. DO NOT TOUCH ANY METAL PARTS

OF THE TOOL while using it. Hold the tool only by the plastic grip to prevent

electric shock if you contact a live wire.

7. DO NOT MISUSE THE CORD. Never carry your tools by the cord or pull on

the cord to unplug it. Protect the cord from potential sources of damage:

heat, oil & solvents, sharp edges, or moving parts. Replace damaged cords

immediately.

8. WHEN WORKING OUTDOORS, USE AN OUTDOOR-RATED EXTENSION

CORD. An extension cord rated for outdoor use must be marked “W-A” or

“W”.

9. DO NOT EXPOSE ELECTRICAL POWER TOOLS TO MOISTURE. Rain or

wet conditions can cause water to enter the tool and lead to electric shock.

10. ENSURE THE EXTENSION CORD YOU USE IS OF SUFFICIENT GAUGE

FOR ITS LENGTH.

Recommended Minimum Wire Gauge for Extension Cords

Amps

from

Tool Nameplate

25’ length 50’ length 75’ length 100’ length 150’ length 200’ length

0-5 amps 16 ga. 16 ga. 16 ga. 14 ga. 12 ga. 12 ga.

5.1-8 amps 16 ga. 16 ga. 14 ga. 12 ga. 10 ga. Do Not Use

8.1-12 amps 14 ga. 14 ga. 12 ga. 10 ga. Do Not Use Do Not Use

12.1-15 amps 12 ga. 12 ga. 10 ga. 10 ga. Do Not Use Do Not Use

15.1-20 amps 10 ga. 10 ga. 10 ga. Do Not Use Do Not Use Do Not Use

11. STORE IDLE EQUIPMENT. Store equipment in a dry area to inhibit rust.

Equipment also should be in a high location or locked up to keep out of

reach of children.

12. DON’T FORCE THE TOOL. It will do the job better and more safely at the

rate for which it was intended.

13. USE THE RIGHT TOOL. Don’t force a small tool or attachment to do the

work of a larger industrial tool. Don’t use a tool for a purpose for which it was

not intended.

14. DRESS PROPERLY. Don’t wear loose clothing or jewelry; they can be

caught in moving parts. Protective, non-electrically conductive gloves, protective

eyewear and non-skid footwear are recommended. Wear protective hair

covering to contain long hair and keep yourself from harm.

3

IMPORTANT SAFETY INSTRUCTIONS

SAFETY PRECAUTIONS FOR SOLDERING GUN

SPECIFICATIONS

Solder Flux

Roll of Solder

Soldering Tips

Caution: To provide continued protection against risk of electric shock,

connect to properly grounded outlets only.

15. USE EYE PROTECTION. Use a full-face mask if the work you’re doing

produces metal lings, dust or wood chips. Goggles are acceptable in other

situations. Wear a clean dust mask if the work involves creating a lot of ne

or coarse dust.

16. SECURE WORK. Use clamps or a vise to hold the work, this frees both

hands to operate the tool.

17. DON’T OVERREACH. Keep proper footing and balance at all times. Do not

reach over or across machines that are running.

18. MAINTAIN TOOLS. Keep tools sharp and clean for better and safer

performance. Follow instructions for lubricating and changing accessories.

For safe performance. Keep handles dry, clean and free from oil and grease.

19. AVOID UNINTENTIONAL STARTING. Be sure the switch is in the OFF posi-

tion before plugging in.

20. ALWAYS CHECK AND MAKE SURE TO REMOVE ANY ADJUSTING KEYS

OR WRENCHES before turning the tool on. Left attached, these parts can y

off a moving part and result in injury.

21. DO NOT USE THE TOOL IF IT CANNOT BE SWITCHED ON OR OFF.

Have your tool repaired before using it.

22. DISCONNNECT THE PLUG FROM THE POWER SOURCE BEFORE MAKING

ANY ADJUSTMENTS.

Changing attachments or accessories can be dangerous

if the tool could accidentally start.

23. STAY ALERT. Watch what you are doing & use common sense. Don’t operate

any tool when you are tired.

24. CHECK FOR DAMAGED PARTS. Before using this tool, any part that is

damaged should be carefully checked to determine that it will operate prop-

erly and perform its intended function. Check for alignment of moving parts,

binding of moving parts, breakage of parts, mountings, and other conditions

that may affect its operation. Inspect screws and tighten any ones that are

loose. Any part that is damaged should be properly repaired or replaced by

an authorized service center unless otherwise indicated elsewhere in the in-

struction manual. Have defective switches replaced by an authorized service

center. Don’t use the tool if switch does not turn it on and off properly.

25. REPLACEMENT PARTS. When servicing, use only identical replacement

parts.

26. SERVICE AND REPAIRS should be made by qualied repair technicians at

an authorized repair center. Improperly repaired tools could cause serious

shock or injury.

Do not immerse the

Soldering Gun in water.

Voltage: 120 volts AC, 60Hz.

=

Input power: 100W=

Included

=

=

=

4

TING PROCEDURES

FUNCTION DESCRIPTION

1.Trigger Switch

2.

3. LLight

4. Handle

OPERATING PROCEDURES

1

Soldering Tip 2

3

4

Preparing the Soldering Tip

1. Using a screwdriver, check that the Soldering Tip Nuts are not loose.

Do not overtighten as you may strip the threads.

2. Set the Soldering Gun on the workbench, and plug the Line Cord into an electrical

outlet.

3. Press on the Trigger Switch until the Soldering Tip heats up.

4. Apply a sufficient amount of rosin-core solder to melt over the entire tip of the

Soldering Gun.

Preparing the Metal to be Soldered

1. If wires are to be soldered, thoroughly clean or scrape the wires so that only the

clean copper is showing. Carefully splice the wires to prepare for solder.

2. If other metals are to be soldered, thoroughly clean or scrape the metal surfaces. It

may be necessary to apply acid flux (not supplied) to those metal surfaces before

soldering.

Soldering

1. Press on the Trigger Switch until the Soldering Tip heats up.

2. Brush on solder flux, as needed, to the workpiece. Place the Soldering Tip to the

joint, wiring splice, or metal to be soldered.

3. Apply solder to the wire splice or metal to be soldered, not the Soldering Tip.

When the splice or metal is hot enough, it will melt the solder causing it to flow

within the splice or between the metal surfaces.

4. When the solder has flowed over the entire wire splice or metal surface, remove the

Soldering Tip and release the Trigger Switch.

If you are new to soldering, you may find it helpful to practice soldering first on scrap

wires and splices.

5

ADJUSTMENTS

MAINTENANCE

Note: Maintenance requiring disassembly of this tool should only be performed while

the product is disconnected from the electrical supply circuit and give sufficient

1. When you are finished soldering, heat up the Soldering Tip (1) again and apply a

small amount of rosin-core solder to coat the tip. Wipe off with a rag.

This will leave the tip clean and ready for use again.

2. If the Soldering Tip cracks or becomes eroded, the Soldering Tip needs to be

replaced. In this condition, it will not heat or perform properly.

Accessories

Replacing the Soldering Tip

1. To replace the Soldering Tip, place the Screwdriver over each nut and remove

by turning counterclockwise.

2. Push the nuts toward the Soldering Tip end, exposing the opposite ends of the

Soldering Tip.

3. Guide the old Soldering Tip out of the Transformer Assembly mounting posts .

Refer to the Assembly Drawing on the next page.

4. Straighten out the ends of the old Soldering Tip using pliers, and remove the Nuts.

5. Place the Nuts over the mounting ends of the new Soldering Tip.

6. Using pliers slightly, bend the mounting ends of the new Soldering Tip for added support

from the connectors.

If the bend is too long, the Nuts will not fit over mounting posts.

7. Guide the bent ends into the mounting posts of the Transformer Assembly.

8. Carefully tighten the Nuts over the mounting posts.

Make sure that the Nuts fit squarely over the threads or damage will occur to the

mounting post threads. Do not overtighten.

Replacing the Light Bulb

1. Remove the Light Bulb Lens from the front of the Soldering Gun.

2. Pull out the burnt Light Bulb and replace with a new one of the same voltage and

type (see Specifications).

3. Replace the Light Bulb Lens

time to cool down.

ADJUSTMENTS

PARTS LIST

6

}

1Body 1

2Transformer 1

3Connectors 2

4Screw 2

5Soldering Tip 1

Connector Holder

6 1

Cable Strain Relief

71

Light Bulb

81

Power Cord

9 1

Trigger Switch

10 1

Electrical Connection Cover

11 1

Spring Lever

12 1

13 Connecting Rods 2

7

SCHEMATIC DRAWING

!WARNING Repairs should be made by an authorized repair center. Do not

this power tool . Contact at

for questions regarding this power tool. 1-866-915-8626

open or disassemble

Table of contents

Popular Soldering Gun manuals by other brands

Hakko Electronics

Hakko Electronics 937 instruction manual

VOLTCRAFT

VOLTCRAFT LS 50 operating instructions

jbc

jbc JNASE-A instruction manual

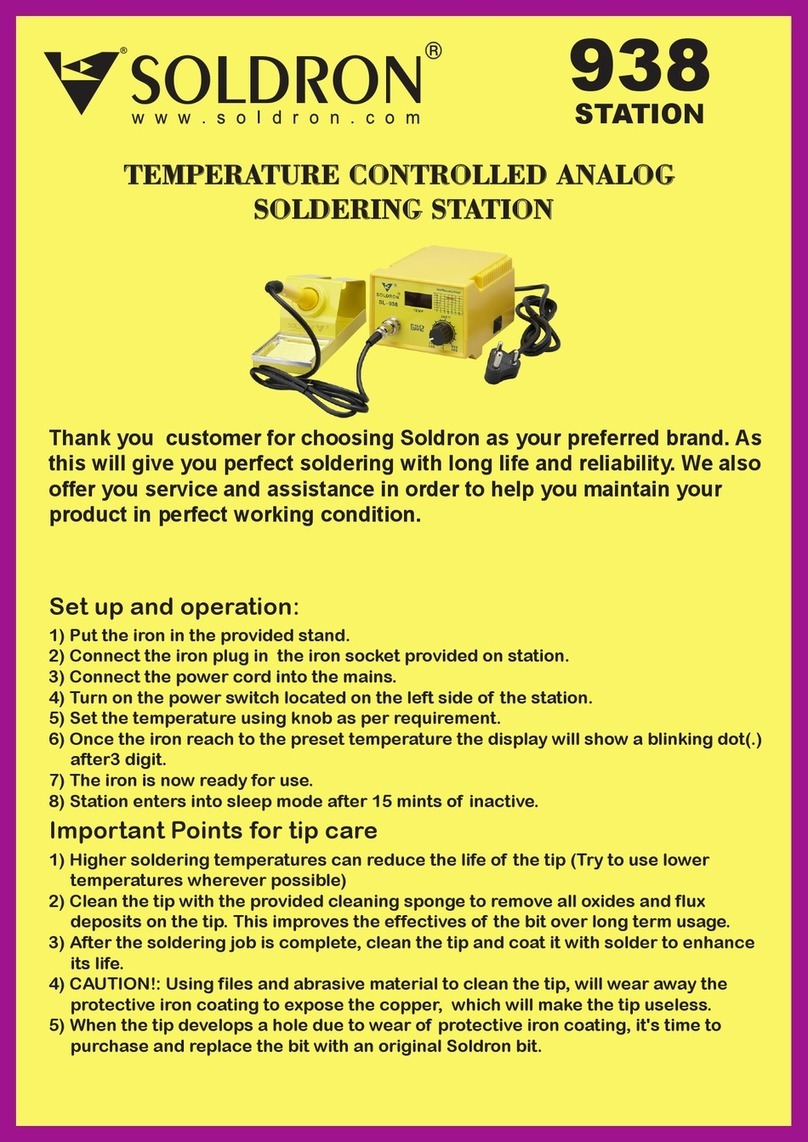

Soldron

Soldron 938 instruction manual

Vishay Precision Group

Vishay Precision Group Micro-Measurements Mark V Operating and maintaining

Parkside

Parkside PLBS 30 A1 Operation and safety notes