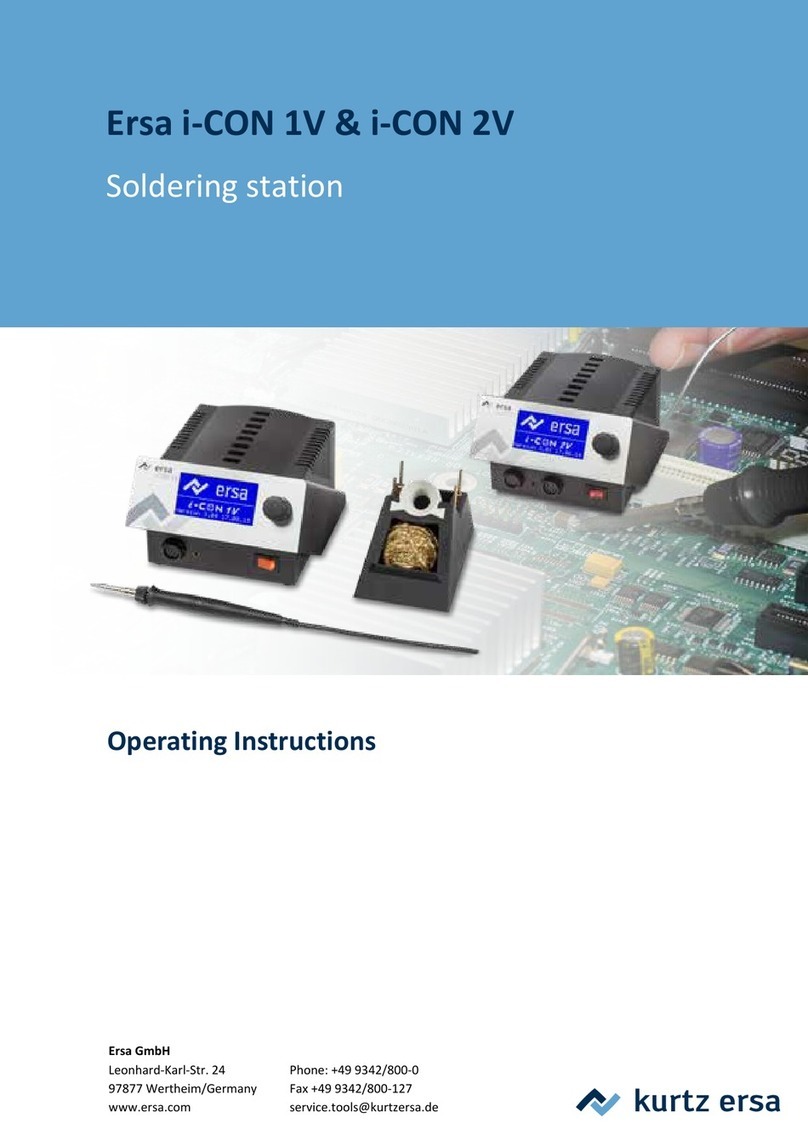

i-CON 1 / 2

3BA00180 • 28.04.2008 • Rev. 1

Contents

1. Introduction .................................................................................................................... 4

1.1 Supply unit ............................................................................................................. 4

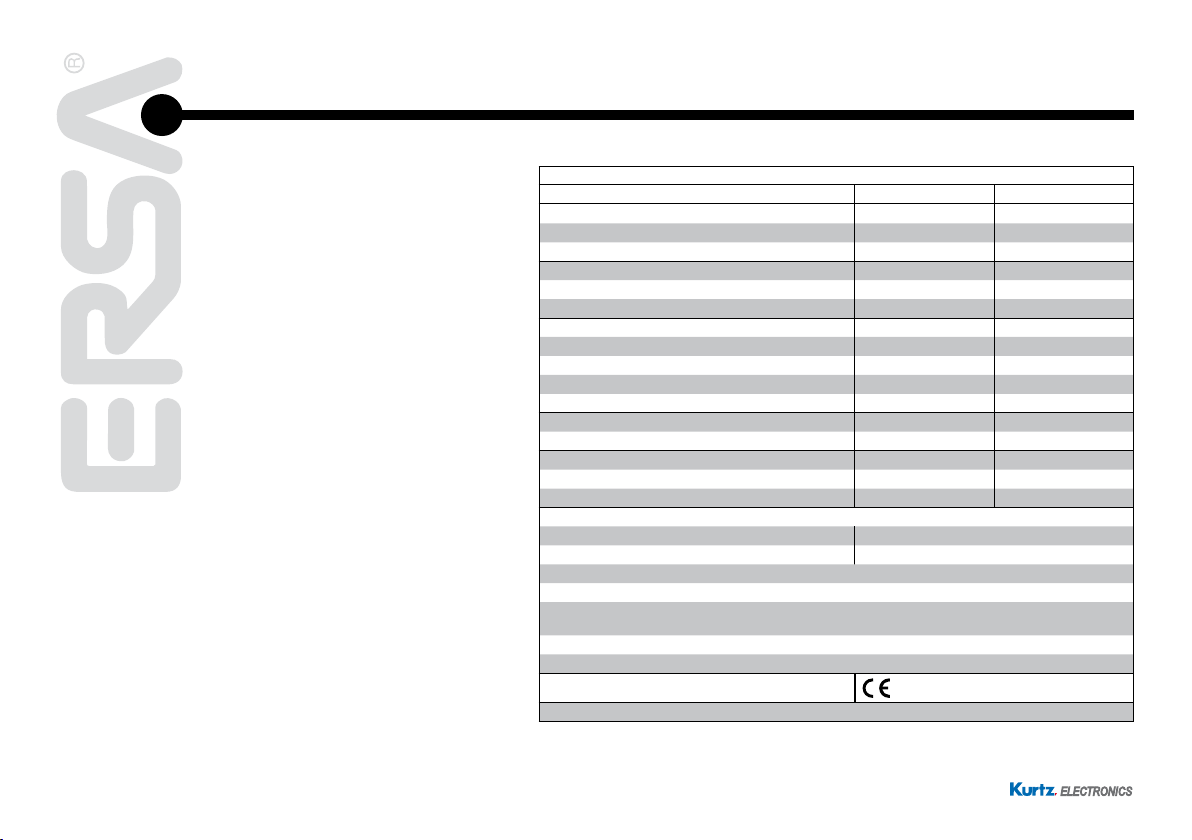

2. Technical data ................................................................................................................ 5

3. For your safety ............................................................................................................... 6

3.1 Pictograph and symbol explanations ..................................................................... 7

3.2 Intended use .......................................................................................................... 8

4. Transport, storage and disposal................................................................................. 11

5. Commissioning ............................................................................................................ 12

5.1 Before starting operation...................................................................................... 12

5.2 Switchingonforthersttime............................................................................... 13

6. Functional description................................................................................................. 14

6.1 Operation ............................................................................................................. 14

6.2 The Work mode ................................................................................................... 15

6.2.1 Software version ..................................................................................... 15

6.3 Parameter mode .................................................................................................. 16

6.3.1 i-Set-Tool................................................................................................. 18

6.3.2 Set temperature ...................................................................................... 19

6.3.3 Calibration temperature .......................................................................... 19

6.3.4 Tip offset ................................................................................................. 20

6.3.5 Calibrating the i-CON 1........................................................................... 20

6.3.6 Calibration temperature .......................................................................... 21

6.3.7 Power Level ............................................................................................ 21

6.3.8 Standby-Time.......................................................................................... 22

6.3.9 Standby-Temperature ............................................................................. 22

6.4 Congurationmode.............................................................................................. 23

6.4.1 Temperature window............................................................................... 24

6.4.2 Process alarm......................................................................................... 24

6.4.3 Password lock......................................................................................... 25

6.4.3.1 Setting the password............................................................. 25

6.4.3.2 Changing the password ........................................................ 27

6.4.3.3 Input of values without deactivating the password................ 27

6.4.3.4 Forgotten password .............................................................. 28