Top Craft TTS-280 User manual

USER MANUAL

TTS-280

TRIANGULAR SANDER

Art.No. DSM6010

www.ferm.com GB-0611-20

UK Subject to change

02 Topcraft

TRIANGULAR SANDER

Read this operators guide carefully, before using the machine. Ensure that you know

how the machine works, and how it should be operated. Maintain the machine in

accordance with the instructions, and make certain that the machine functions

correctly. Keep this operator’s guide and other enclosed documentation with the

machine.

Contents:

1. Technical specifications

2. Safety instructions

3. Use

4. Operation

5. Maintenance

CONTENTS OF THE PACKAGING

The packaging contains:

1 Sander

3 pieces of sandpaper (G60, 80, 120)

1 case

1 Instructions

1 safety section

1 warranty card

Check the machine and accessories for transport damage.

The following symbols are used in these instructions for use:

Denotes risk of personal injury, loss of life or damage to the tool in case of non-

observance of the instructions in this manual.

2. SAFETY INSTRUCTIONS

Voltage 230V~

Frequency 50Hz

Power consumption 280W

No load speed 6000 - 9000 /min

Orbits 12.000 - 18.000 /min

Gewicht 1.2 kg

Lpa (Schalldruck) 70.5 dB(A)

Vibrationswert 5.8 m/s2

1. TECHNICAL SPECIFICATIONS

GB

Topcraft 11

Exploded view

Topcraft 0310 Topcraft

Spareparts list TTS-280

Topcraft no. Description Position

2 Spindle gear 408200

16 Sanding pad 408201

19 Carbon brush (set) 406396

25 Armature gear 408205

38 Switch 408206

Denotes risk of electric shock.

Read instructions carefully

In accordance with essential applicable safety standards of European directives

Class II machine – Double insulation – You don’t need any earthed plug.

Wear a dust mask

Always use ear protection

Faulty and/or discarded electrical or electronic apparatus have to be collected at

the appropriate recycling locations.

Immediately unplug the plug from the mains electricity in the case that the cord

gets damaged and during maintenance

Safety Instructions

ATTENTION!

When using electric machines always observe the safety regulations applicable in your

country to reduce the risk of fire, electric shock and personal injury. Read the following safety

instructions and also the enclosed safety instructions.

Keep these instructions in a safe place!

1. Keep work area clear.

Cluttered areas and benches invite injuries.

2. Consider work area environment.

Do not expose power tools to rain. Do not use power tools in damp or wet locations. Keep

work area well lit. Do not use power tools in presence of flammable liquids or gases.

3. Guard against electric shock.

Prevent body contact with grounded surfaces (e.g. pipes, radiators, refrigerators).

4. Keep visitors away.

Visitors should be kept away from the work area at all times. Do not let visitors handle the

machine at any time.

5. Store unused tools.

When not in use keep tools out of reach of children. Store in a dry and secure location.

6. Do not force tool.

Do not apply undue pressure as this may affect performance and may cause damage to

the machine. Forcing the job also increases the potential for accidents.

GB

Topcraft 09

CE DECLARATION OF CONFORMITY (GB)

We declare under our sole responsibility that

TTS-280 TRIANGULAR SANDER

is in conformity with the following standards or standardized documents:

EN50144-1, EN50144-2-4, EN55014-1, EN-55014-2,EN61000-3-2, EN61000-3-3,

in accordance with the regulations.

98/37EC, 73/23/EEC, 89/336EEC

from 01-10-2006

ZWOLLE NL

J.A. Bakker - van Ingen J. Lodewijk

CEO Ferm BV Quality Manager Ferm Global

It is our policy to continuously improve our products and we therefore reserve the right to

change the product specification without prior notice.

Ferm BV • Lingenstraat 6 • 8028 PM Zwolle • The Netherlands

GB

04 Topcraft

7. Use right tool.

Do not force small tools or attachments to do the job of heavy duty tool. Do not use a tool

for purposes not intended.

8. Dress properly.

Do not wear loose clothing or Jewellery. They can be caught in moving parts. Rubber

gloves and nonskid footwear are recommended when working outdoors. Wear protective

hair covering to contain long hair.

9. Use safety glasses.

Also use face or dust mask when operation is dusty.

10. Connect dust extraction equipment

If devices are provided for the connection of dust extraction and collection facilities

ensure these are connected and properly used.

11. Do not abuse cord.

Never carry tool by cord or yank it to disconnect it from electrical socket. Keep cord from

heat, oil and sharp edges.

12. Secure work.

Use clamps or a vice to hold work. It’s safer than using your hand and it frees both hands to

operate tool.

13. Do not overreach.

Keep proper footing and balance at all times.

14. Maintain tools with care.

Keep tools sharp and clean for better and safer performance. Follow instructions for

lubricating and changing accessories. Inspect tool cords periodically and, if damaged,

have repaired by authorized service facility. Inspect extension cords periodically and

replace if damaged. Keep handles dry, clean and free from oil and grease.

15. Disconnect tools.

When not in use, before servicing and when changing accessories such as blades, bits

and cutters.

16. Remove adjusting keys and wrenches.

Form the habit of checking to see that keys and adjusting wrenches are removed from tool

before turning it on.

17. Avoid unintentional starting.

Do not carry plugged-in tools with finger on switch. Be sure switch is off when plugging in.

18. Outdoor use extension cords.

When tool is used outdoors, use only extension cords intended for use outdoors and so

marked. Always use tool in conjunction with a residual circuit breaker device.

19. Stay alert.

Watch what you are doing. Use common sense. Do not operate tool when you are tired.

20. Check damaged parts.

Before further use of the tool, a guard or other part that is damaged should be carefully

checked to determine that it will operate properly and perform its intended function.

Check for alignment of moving parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect its operation. A guard or other part

that is damaged should be properly repaired or replaced by an authorized service centre

unless otherwise indicated elsewhere in this instructions manual. Have defective

switches replaced by an authorized centre. Do not use tool if switch does not turn on and

off.

21. Warning.

GB

Topcraft 05

The use of any other accessory or attachment other than recommended in this operation

instructions or the catalogue may present a risk of personal injury.

22. Have your tool repaired by an expert.

This appliance is manufactured to very high standards and meets relevant safety

regulations. Repairs should only be done by a suitable qualified electrical engineer or

otherwise.

23. Hearing protection should be worn.

SPECIAL SAFETY INSTRUCTIONS BEFORE USING THE MACHINE:

• Check the following points.

- do the voltage of the appliance correspond with the mains voltage, appliances for a

mains voltage of 230 V can also be connected at a mains voltage of 220 V;

- are the mains lead and the mains plug in a good condition: solid, without any loose

ends or damage;

• Avoid using long extension cables.

• Check the condition of the sandpaper. Is it not worn or are there any cracks. Replace bad

sandpaper.

WHILE USING THE MACHINE

• If you are working with the sander, wear always ear protection and dust mask.

• The machine is not suitable for wet sanding.

• Check that the switch is not in the “ON”-position before connecting the machine to the

mains voltage.

• Always keep away the mains lead from moving parts of the machine.

• Use safety glasses, certain when sanding above your head.

SWITCH OFF THE MACHINE IN CASE OF:

• The machine is overheated.

• Defective mains plug, mains lead or damage to the mains lead.

• Defective switch.

• Smoke or bad smell caused by scorched insulation.

Electrical safety

Always check that the mains voltage corresponds to the voltage on the rating

plate.

The machine is double insulated in accordance with EN50144; therefore no earth

wire is required.

Replacing cables or plugs

Immediately throw away old cables or plugs when they have been replaced by new ones. It is

dangerous to insert the plug of a loose cable in the wall outlet.

Using extension cables

Only use an approved extension cable suitable for the power input of the machine. The

GB

08 Topcraft

Cleaning

Keep the ventilation slots of the machine clean to prevent overheating of the motor. Regularly

clean the machine housing with a soft cloth, preferably after each use. Keep the ventilation

slots free from dust and dirt.

If the dirt does not come off use a soft cloth moistened with soapy water. Never use solvents

such as petrol, alcohol, ammonia water, etc. These solvents may damage the plastic parts.

Lubrication

The machine requires no additional lubrication.

Faults

Should a fault occur, e.g. after wear of a part, please contact the service address on the

warranty card. In the back of this manual you find an exploded view showing the parts that can

be ordered.

Environment

To prevent damage during transport, the appliance is delivered in a solid packaging which

consists largely of reusable material. Therefore please make use of options for recycling the

packaging.

Faulty and/or discarded electrical or electronic apparatus have to be collected at

the appropriate recycling locations.

Guarantee

The guarantee conditions can be found on the separately enclosed guarantee card.

GB

Topcraft 07

REPLACING THE SOLE

Before you are going to replace the sole you have to disconnect the sander and

you have to pull the mains plug out of the power source.

- The sole has to be replaced when the velcro has been worn out.

- Remove the sandpaper of the sole.

- Remove the three screws which the sole is fixed to the sander.

- Install the new sole on thesander.

- Tighten the screws well.

TROUBLESHOOTING

In case the sanding machine does not work well, we give you some possible causes and

solutions.

While maintaining and cleaning the machine pull the plug from the mainssocket.

Never use water or other agressive liquids to clean the machine. Clean the

machine by brushing it with a brush.

The machines have been designed to operate over a long period of time with a minimum of

maintenance. Continuous satisfactory operation depends upon proper machine care and

regular cleaning.

5. MAINTENANCE

• The electromotor gets

hot

• The connected machine

does not work.

• The dust is not extracted:

The air vents in the motor are

filled up with dirt.

The motor is defect.

Interruption in the mains

connection.

Defective mains switch

This can be caused by a full

dust bag.

This can be caused by a filled

up dust extraction.

Clean the cool ventilation

slots.

Have your sanding machine

repaired or checked by your

local dealer.

Check mains connection for

fracture.

Have your sanding machine

repaired or checked by your

local dealer.

Empty your dust bag.

Clean your dust collection

opening.

GB

06 Topcraft

minimum conductor size is 1.5 mm2. When using a cable reel always unwind the reel

completely.

Installing sandpaper

As the sole of your sander is provided with velcro, you can only use sandpaper which can be

fixed in the same way.

• Pull the mains plug out of the power-point

• Have the little gaps in the sandpaper coincide with the little gaps in the sole and push on

the paper for fixing it on the sole.

Applications

The sander can only be used for the subjoined applications.

• Sanding wooden surfaces

• Sanding metal surfaces

• Polishing.

DUST EXTRACTION

The sanding machine is provided with a connection for dust extraction to keep the working

surface clean. This is the opening at the back of the sander. You can connect a vacuum cleaner

onto this opening.

Insert the adapter into the dust extraction opening of the triangular sanding machine. When

doing so, make sure that the adapter projections fall into the recesses of the dust extraction

opening. Turn the adapter 45 degrees clockwise. You may now insert the vacuum cleaner tube

into the adapter. The adapter is equipped with an adapter ring, located in the back of the

adapter. For deviant tube sizes, remove the adapter ring from the adapter.

Press the on/off switch to turn on the machine. To regulate the speed, use the adjusting wheel.

An excessive load when the sanding machine is running at a low speed may cause the motor

to burn out.

SANDING

The foot of the sanding machine makes small circular movements. The result is an even,

smoothly sanded surface without trails. Because of the circular movement, how you hold and

move the sanding machine is of little importance. Additional pressure force on the machine is

rarely necessary.

4. OPERATION

3. USE

GB

Other manuals for TTS-280

1

This manual suits for next models

1

Table of contents

Other Top Craft Power Tools manuals

Popular Power Tools manuals by other brands

Milwaukee

Milwaukee K 540 S Original instructions

Motorgeräte Fischer

Motorgeräte Fischer 500FP20Inox Instructions for use

Greenlee

Greenlee GATOR EK6IDL Service manual

VONROC

VONROC PR501AC Original instructions

KoolGlide

KoolGlide PRO Operating instructions manual

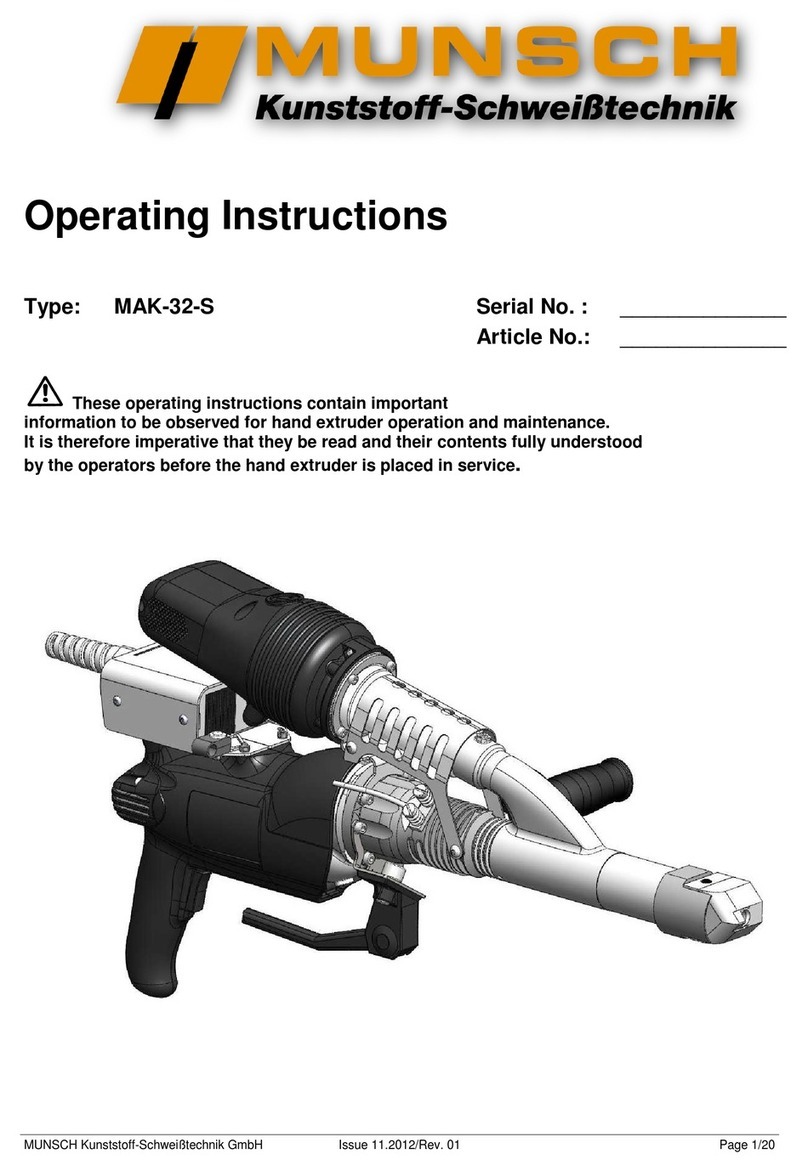

Munsch

Munsch MAK-32-S operating instructions