Top Flite Models Beechcraft User manual

READTHROUGHTHIS MANUAL BEFORE STARTING CONSTRUCTION. IT CONTAINS IMPORTANT INSTRUCTIONS AND WARNINGS CONCERNINGTHE ASSEMBLY AND USE OFTHIS MODEL.

TOPZ0905 for TOPA0905 V1.0

Entire Contents © Copyright 2006

Wingspan: 72.5 in [1840mm]

Wing Area: 1525 sq in [97.6 dm2]

Weight: 17-19 lb [7.7-8.6 kg]

Wing Loading: 26-28 oz/sq ft

[80-90 g/dm2]

Length: 62.5 in [1590mm]

Radio: 6-Channel w/7 servos (minimum)

or

8/9-Channel w/9 servos (w/retracts)

Engines: 1.60 cu in [25 cc] two-stroke,

1.60 cu in [25 cc] four-stroke

WARRANTY.....Top Flite Models guarantees this kit to be free

from defects in both material and workmanship at the date of purchase.This warranty

does not cover any component parts damaged by use or modification.In no case shall

Top Flite’s liability exceed the original cost of the purchased kit. Further, Top Flite

reserves the right to change or modify this warranty without notice.

In that Top Flite has no control over the final assembly or material used for final

assembly, no liability shall be assumed nor accepted for any damage resulting from the

use by the user of the final user-assembled product. By the act of using the user-

assembled product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated with the use of this

product, the buyer is advised to return this kit immediately in new and unused condition

to the place of purchase.

To make a warranty claim send the defective

part or item to Hobby Services at the address:

Include a letter stating your name, return shipping address, as much contact

information as possible (daytime telephone number, fax number, e-mail address), a

detailed description of the problem and a photocopy of the purchase receipt. Upon

receipt of the package the problem will be evaluated as quickly as possible.

Hobby Services

3002 N. Apollo Dr. Suite 1

Champaign IL 61822 USA

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . 2

SAFETY PRECAUTIONS. . . . . . . . . . . . . . . . . . 3

DECISIONSYOU MUST MAKE . . . . . . . . . . . . . 4

Radio Equipment . . . . . . . . . . . . . . . . . . . . . . . . 4

Engine Recommendations . . . . . . . . . . . . . . . . . 4

Retracts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ADDITIONAL ITEMS REQUIRED. . . . . . . . . . . . 4

Required Hardware and Accessories . . . . . . . . . 4

Optional Supplies and Tools . . . . . . . . . . . . . . . . 4

IMPORTANT BUILDING NOTES . . . . . . . . . . . . 4

ORDERING REPLACEMENT PARTS. . . . . . . . . 5

KIT CONTENTS. . . . . . . . . . . . . . . . . . . . . . . . . 6

PREPARATIONS . . . . . . . . . . . . . . . . . . . . . . . . 7

BUILD THE WING . . . . . . . . . . . . . . . . . . . . . . . 7

Install the Flaps/Ailerons. . . . . . . . . . . . . . . . . . . 7

Install the Aileron Servos and Pushrods . . . . . . . 8

Install the Flap Servos and Pushrods . . . . . . . . . 9

Install the Wing Joiners. . . . . . . . . . . . . . . . . . . 10

Attach the Wings to the Fuselage . . . . . . . . . . . 11

Install the Struts . . . . . . . . . . . . . . . . . . . . . . . . 12

BUILD THE FUSELAGE. . . . . . . . . . . . . . . . . . 13

Install the Stabilizers, Elevators and Rudder . . . 13

INSTALLTHE LANDING GEAR . . . . . . . . . . . . 15

Fixed Landing Gear . . . . . . . . . . . . . . . . . . . . . 15

Fixed Tail Wheel . . . . . . . . . . . . . . . . . . . . . . . . 17

Tail Wheel Door Installation. . . . . . . . . . . . . . . . 17

Retractable Landing Gear. . . . . . . . . . . . . . . . . 18

Retractable Tail Wheel . . . . . . . . . . . . . . . . . . . 23

Tail Wheel Door Installation. . . . . . . . . . . . . . . . 24

Install the Retract Hardware . . . . . . . . . . . . . . . 26

Adjusting the Retractable Landing Gear . . . . . . 27

INSTALLTHE ENGINE & THROTTLE SERVO . 28

O.S. 1.60 Two-Stroke Engine. . . . . . . . . . . . . . . 28

O.S. 1.60 Four-Stroke Engine . . . . . . . . . . . . . . 29

Install the Fuel Tank for the

O.S. 1.60 Two-Stroke Engine . . . . . . . . . . . . 29

Install the Fuel Tank for the

O.S. 1.60 Four-Stroke Engine. . . . . . . . . . . . 30

Install the Cowl and Dummy Engine . . . . . . . . . 30

Install the Radio System . . . . . . . . . . . . . . . . . . 32

Finishing Touches. . . . . . . . . . . . . . . . . . . . . . . 35

GET THE MODEL READY TO FLY . . . . . . . . . . 36

Check the Control Directions. . . . . . . . . . . . . . . 36

Set the Control Throws . . . . . . . . . . . . . . . . . . . 36

Balance the Model (C.G.) . . . . . . . . . . . . . . . . . 36

Balance the Model Laterally . . . . . . . . . . . . . . . 37

PREFLIGHT. . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Identify Your Model . . . . . . . . . . . . . . . . . . . . . . 37

Charge the Batteries. . . . . . . . . . . . . . . . . . . . . 37

Balance Propellers . . . . . . . . . . . . . . . . . . . . . . 37

Ground Check . . . . . . . . . . . . . . . . . . . . . . . . . 38

Range Check . . . . . . . . . . . . . . . . . . . . . . . . . . 38

ENGINE SAFETY PRECAUTIONS. . . . . . . . . . 38

AMA SAFETY CODE. . . . . . . . . . . . . . . . . . . . 38

IMAA SAFETY CODE . . . . . . . . . . . . . . . . . . . 39

CHECK LIST . . . . . . . . . . . . . . . . . . . . . . . . . . 40

FLYING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Takeoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Flight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Landing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

1.60 Engine Mount Template. . . . . . . . . . . . . . . 43

INTRODUCTION

With its clean lines, negatively staggered wings, and

retractable landing gear, the natural aesthetic beauty

of the “Staggerwing” has made it an uncontested

classic airplane. Even today the Beechcraft Model 17

Staggerwing is comparable to modern private aircraft.

This classiest of classic airplanes transported military

generals and executives throughout the Second

World War and for years afterwards. Top Flite has

returned this vintage airplane to the modeling

community in the form of a “World Class”ARF that we

are sure will bring you hours of great fun.

For the latest technical updates or manual

corrections to the Staggerwing visit the Top Flite web

site at www.top-flite.com. Open the “Airplanes” link,

and then select the Staggerwing ARF. If there is new

technical information or changes to this model a

“tech notice” box will appear in the upper left corner

of the page.

AMA

We urge you to join the AMA (Academy of Model

Aeronautics) and a local R/C club. The AMA is the

governing body of model aviation and membership is

required to fly at AMA clubs.Though joining the AMA

provides many benefits, one of the primary reasons

to join is liability protection. Coverage is not limited to

flying at contests or on the club field. It even applies

to flying at public demonstrations and air shows.

Failure to comply with the Safety Code (excerpts

printed in the back of the manual) may endanger

insurance coverage. Additionally, training programs

and instructors are available at AMA club sites to help

you get started the right way. There are over 2,500

AMA chartered clubs across the country. Contact the

AMA at the address or toll-free phone number below:

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (765) 741-0057

Or via the Internet at:

www.modelaircraft.org

IMPORTANT!!!

Two of the most important things you can do to

preserve the radio-controlled aircraft hobby are to

avoid flying near full-scale aircraft and avoid flying

near or over groups of people.

IMAA

TheTop Flite Staggerwing is an excellent sport-scale

model and is eligible to fly in IMAA events.The IMAA

(International Miniature Aircraft Association) is an

organization that promotes non-competitive flying of

giant-scale models. If you plan to attend an IMAA

event, obtain a copy of the IMAA Safety Code by

contacting the IMAA at the address or telephone

number below, or by logging on to their web site at:

IMAA

205 S. Hilldale Road

Salina, KS 67401

(913) 823-5569

www.fly-imaa.org/imaa/sanction.html.

- 2 -

SCALE COMPETITION

Though the Top Flite Staggerwing is an ARF and

may not have the same level of detail as an “all-out”

scratch-built competition model, it is a scale model

nonetheless and is therefore eligible to compete in

the

Fun Scale

class in AMA competition (we receive

many favorable reports of Top Flite ARFs in scale

competition!).In Fun Scale, the “builder of the model”

rule does not apply. To receive the five points for

scale documentation, the only proof required that a

full-size aircraft of this type in this paint/markings

scheme did exist is a single sheet such as a kit box

cover from a plastic model, a photo, or a profile

painting, etc. If the photo is in black and white, other

written documentation of color must be provided.

Contact the AMA for a rule book with full details.

If you would like photos of full-size Staggerwings for

scale documentation, or if you would like to study the

photos to add more scale details, photo packs are

available from:

Bob’s Aircraft Documentation

3114 Yukon Ave

Costa Mesa, CA 92626

Telephone: (714) 979-8058

Fax: (714) 979-7279

www.bobsairdoc.com

1.Your Staggerwing should not be considered a toy, but

rather a sophisticated, working model that functions very

much like a full-size airplane. Because of its

performance capabilities, the Staggerwing, if not

assembled and operated correctly, could possibly cause

injury to yourself or spectators and damage to property.

2. You must assemble the model according to the

instructions. Do not alter or modify the model, as

doing so may result in an unsafe or unflyable model.

In a few cases the instructions may differ slightly from

the photos.In those instances the written instructions

should be considered as correct.

3.You must take time to build straight,true and strong.

4.You must use an R/C radio system that is in first-

class condition, and a correctly sized engine and

components (fuel tank, wheels, etc.) throughout the

building process.

5. You must correctly install all R/C and other

components so that the model operates correctly on

the ground and in the air.

6. You must check the operation of the model before

every flight to insure that all equipment is operating and

that the model has remained structurally sound.Be sure

to check clevises or other connectors often and replace

them if they show any signs of wear or fatigue.

7. If you are not an experienced pilot or have not

flown this type of model before, we recommend that

you get the assistance of an experienced pilot in your

R/C club for your first flights. If you’re not a member

of a club, your local hobby shop has information

about clubs in your area whose membership

includes experienced pilots.

8. While this kit has been flight tested to exceed

normal use, if the plane will be used for extremely

high stress flying, such as racing, or if an engine

larger than one in the recommended range is used,

the modeler is responsible for taking steps to

reinforce the high stress points and/or substituting

hardware more suitable for the increased stress.

9.WARNING: The cowl, landing gear covers and wing

struts included in this kit are made of fiberglass, the

fibers of which may cause eye, skin and respiratory

tract irritation. Never blow into a part to remove

fiberglass dust, as the dust will blow back into your

eyes.Always wear safety goggles, a particle mask and

rubber gloves when grinding, drilling and sanding

fiberglass parts.Vacuum the parts and the work area

thoroughly after working with fiberglass parts.

Remember: Take your time and follow the

instructions to end up with a well-built model that

is straight and true.

We, as the kit manufacturer, provide you with a top

quality, thoroughly tested kit and instructions, but

ultimately the quality and flyability of your finished

model depends on how you build it; therefore, we

cannot in any way guarantee the performance of

your completed model, and no representations

are expressed or implied as to the performance or

safety of your completed model.

PROTECTYOUR MODEL,

YOURSELF & OTHERS

FOLLOW THESE IMPORTANT

SAFETY PRECAUTIONS

- 3 -

DECISIONSYOU MUST MAKE

This is a partial list of items required to finish the

Staggerwing that may require planning or decision

making before starting to build. Order numbers are

provided in parentheses.

RADIO EQUIPMENT

❏ 6-channel w/7 servos (6- 50oz/in, 1- 30oz/in) or

(with retracts) 8/9-channel w/9 servos (6- 50oz/in,

2- 30oz/in, 1- 90oz/in)

❏ 2 - 6" [150mm] servo extension (HCAM2701 for

Futaba®)

❏ 2 - 12" [300mm] servo extension (HCAM2711

for Futaba)

❏ 2 - Y-harness (HCAM2751 for Futaba)

❏ 1000 mAh battery (minimum)

❏ 6 - 54 oz/in servos (2-tail, 2-flaps, 1-rudder,

1-elevator)

❏ 2 - 30 oz/in servos (1-throttle, 1-retracts)

ENGINE RECOMMENDATIONS

The recommended engine for the Staggerwing is an

O.S.®1.60 two-stroke or four-stroke.

❏ For the 2-stroke engine we used the Bisson

Pitts muffler. (BISG4116)

❏ The O.S. 1.60 4-stroke engine can use the O.S.

Flex-pipe. (OSMG2672)

RETRACTS

If you choose to put retracts on your Staggerwing, we

used the following:

❏ Robart #530STAG Retracts (ROBQ0536)

❏ Robart #188VR Air Control Kit Standard with VR

Valve (ROBQ2302)

❏ Robart #169 Pressure Tubing (ROBQ2369)

❏ Robart #121 Scale Retract Tail Wheel (ROBQ2210)

❏ 90 oz-in Servo (such as the Futaba S3305,

FUTM0035 for the tail wheel)

ADDITIONAL ITEMS REQUIRED

ADHESIVES & BUILDING SUPPLIES

This is the list of Adhesives and Building Supplies

that are required to finish the Staggerwing.

❏ 1/2 oz. [15g] Thin Pro™CA (GPMR6001)

❏ 1 oz. [30g] Medium Pro CA+ (GPMR6008)

❏ Pro 30-Minute Epoxy (GPMR6047)

❏ Pro 6-Minute Epoxy (GPMR6045)

❏ R/C Foam Rubber (1/4" [6mm] - HCAQ1000

❏ 3' [900mm] Standard Silicone Fuel

Tubing (GPMQ4131)

❏ Drill Bits: 1/16" [1.6mm], 5/64" [2mm], 3/32"

[2.4mm], 7/64" [2.8mm], 1/8" [3.2mm], 9/64"

[3.6mm], 5/32" [4mm], 3/16" [4.8mm]

❏ 4-40 Tap and Drill Set (GPMR8101)

❏ 8-32 Tap and Drill Set (GPMR8103)

❏ Small T-Pins (100, HCAR5100)

❏ #1 Hobby Knife (HCAR0105)

❏ #11 Blades (5-pack, HCAR0211)

❏ Stick-On Segmented Lead Weights (GPMQ4485)

❏ Silver Solder w/Flux (GPMR8070)

❏ 21ST Century®Sealing Iron (COVR2700)

❏ 4 oz. [113g] Aerosol CA Activator (GPMR634)

❏ CA Applicator Tips (HCAR3780)

❏ Epoxy Brushes (6, GPMR8060)

❏ Mixing Sticks (50, GPMR8055)

❏ Mixing Cups (GPMR8056)

❏ Microballoons (TOPR1090)

❏ ThreadlockerThread Locking Cement (GPMR6060)

OPTIONAL SUPPLIES & TOOLS

Here is a list of optional tools mentioned in the

manual that will help you build the Staggerwing.

❏ Hobbico®Duster™Compressed Air (HCAR5500)

❏ Masking Tape (TOPR8018)

❏ Denatured Alcohol (for epoxy clean up)

❏ Panel Line Pen (TOPQ2510)

❏ Rotary Tool (such as Dremel)

❏ Rotary Tool Reinforced Cut-OffWheel (GPMR8020)

❏ Servo Horn Drill (HCAR0698)

❏ Hobby Heat™Micro Torch (HCAR0750)

❏ AccuThrow™Deflection Gauge (GPMR2405)

❏ Precision Magnetic Prop Balancer (TOPQ5700)

❏ CG Machine™(GPMR2400)

❏ Dead Center™Engine Mount Hole

Locator (GPMR8130)

IMPORTANT BUILDING NOTES

•There are two types of screws used in this kit:

Sheet metal screws are designated by a number

and a length. For example #6 x 3/4" [19mm]

This is a number six screw that is

3/4" [19mm] long.

Machine screws are designated by a number, threads

per inch, and a length.For example 4-40 x 3/4" [19mm]

This is a number four screw that

is 3/4" [19mm] long with forty

threads per inch.

Socket head cap screws are designated by a

number, threads per inch and a length.For example

4-40 x 3/4" [19mm]

This is a number four screw that

is 3/4" [19mm] long with forty

threads per inch

.

•When you see the term “test fit” in the instructions, it

means that you should first position the part on the

assembly without using any glue, then slightly modify

or custom fit the part as necessary for the best fit.

•Whenever the term “glue” is written, you should rely

upon your experience to decide what type of glue to

use. When a specific type of adhesive works best for

that step, the instructions will make a recommendation.

- 4 -

•Whenever just epoxy is specified, you may use

either 30-minute (or 45-minute) epoxy or 6-minute

epoxy. When 30-minute epoxy is specified, it is

highly recommended that you use only 30-minute

(or 45-minute) epoxy, because you will need the

working time and/or the additional strength.

•Photos and sketches are placed before the step they

refer to. Frequently you can study photos in following

steps to get another view of the same parts.

•The Staggerwing is factory-covered with Dark Red

Top Flite MonoKote®film (TOPQ0218 for a six foot

roll).Should repairs ever be required, MonoKote can

be patched with additional MonoKote purchased

separately. MonoKote is packaged in six-foot rolls,

but some hobby shops also sell it by the foot.If only

a small piece of MonoKote is needed for a minor

patch, perhaps a fellow modeler would give you

some. MonoKote is applied with a model airplane

covering iron, but in an emergency a regular iron

could be used. A roll of MonoKote includes full

instructions for application.

METRIC CONVERSIONS

To convert inches to millimeters, multiply inches by 25.4

ORDERING REPLACEMENT PARTS

Replacement parts for theTop Flite Staggerwing are

available using the order numbers in the

Replacement Parts List that follows. The fastest,

most economical service can be provided by your

hobby dealer or mail-order company.

To locate a hobby dealer, visit the Hobbico web site

at www.hobbico.com. Choose “Where to Buy” at the

bottom of the menu on the left side of the page.

Follow the instructions provided on the page to

locate a U.S., Canadian or International dealer.

Parts may also be ordered directly from Hobby

Services by calling (217) 398-0007, or via facsimile

at (217) 398-7721, but full retail prices and shipping

and handling charges will apply. Illinois and Nevada

residents will also be charged sales tax. If ordering

via fax, include a Visa®or MasterCard®number and

expiration date for payment.

Mail parts orders and payments by personal check to:

Hobby Services

3002 N Apollo Drive, Suite 1

Champaign IL 61822

Be certain to specify the order number exactly as

listed in the Replacement Parts List. Payment by

credit card or personal check only; no C.O.D.

If additional assistance is required for any reason

contact Product Support at:

(217) 398-8970

productsuppor[email protected]

REPLACEMENT PARTS LIST

Description How to purchase

Missing pieces Contact Product Support

Instruction manual Contact Product Support

Full-size plans Not available

Order # Description

TOPA1680........Top Wing w/Joiner

TOPA1681........Bottom Wing

TOPA1682........Fuselage

TOPA1683........Rudder w/Hinges

TOPA1684........Horizontal Stabilizer

TOPA1685........Landing Gear w/Tailwheel

TOPA1686........Gear Doors & Wheel Covers

w/Actuating Wires

TOPA1687........Cowl

TOPA1688........Cockpit Floor w/ Seat Backs

TOPA1689........Tail Cone

TOPA1690........Horizontal Stabilizer Tubes

TOPA1691........Interplane Wing Strut Mounts

TOPA1692........Interplane Wing Strut

TOPA1693........Wing Mounting Blades

.4mm = 1/64"

.8mm = 1/32"

1.6mm = 1/16"

2.4mm = 3/32"

3.2mm = 1/8"

4mm = 5/32"

4.8mm = 3/16"

6.4mm = 1/4"

9.5mm = 3/8"

12.7mm = 1/2"

15.9mm = 5/8"

19mm = 3/4"

25.4mm = 1"

50.8mm = 2"

76.2mm = 3"

152.4mm = 6"

304.8mm = 12"

381mm = 15"

457.2mm = 18"

533.4mm = 21"

609.6mm = 24"

762mm = 30"

914.4mm = 36"

- 5 -

- 6 -

2

22

11

14 15

17

18

16

19

20

21

10 9

8

76

55

4

3

1

12 13

KIT CONTENTS

1. Fuselage

2. Cowl

3. Tail Cone

4. Rudder

5. Stab with Elevators

6. Elevator Control Wire

7. Tail Wheel Hardware

8. Pilot

9. Fuel Tank

10. Pull-Pull Wire with Hardware

11. Spinner

12. Top Right Wing with Aileron

13. Top Left Wing with Aileron

14. Bottom Right Wing with Flap

15. Bottom Left Wing with Flap

16. Struts

17. Main Wheels

18. Seat Backs

19. Tail Wheel Doors

20. Landing Gear Doors

21. Cockpit Floor

22. Dummy Engine

To convert inches to millimeters, multiply inches by 25.4

- 7 -

PREPARATIONS

❏1. If you have not done so already, remove the

major parts of the kit from the box and inspect for

damage.If any parts are damaged or missing, contact

Product Support at the address or telephone number

listed in the “Kit Contents” section on page 6.

❏2.Remove the tape and separate the ailerons and

flaps from the wing and the elevators from the stab.

Use a covering iron with a covering sock on high heat

to tighten the covering if necessary. Apply pressure

over sheeted areas to thoroughly bond the covering

to the wood.

BUILD THE WING

Install the Flaps/Ailerons

Do the bottom right wing first so your work

matches the photos the first time through.

❏❏❏❏1.Drill a 3/32" [2mm] hole, 1/2" [13mm] deep

in the center of each hinge slot to allow the CA to“wick”

in. Follow-up with a #11 blade to clean out the slots.

Hint: If you have one, use a high-speed rotary tool to

drill the holes.

❏❏❏❏2. Use a sharp #11 blade to cut a strip of

covering from the hinge slots in the wing and aileron.

❏❏❏❏3. Cut sixteen 1" x 1"

[25mm x 25mm] hinges from a

CA hinge strip. Snip off the

corners so they go in easier.

Note:The following steps refer to the installation of the

flaps/ailerons. The bottom wing of the Staggerwing

has flaps.The top wing has ailerons. If you look at the

location of the hinge slots of each you will see the

flaps are hinged off the centerline of the flap and the

aileron is hinged on the centerline.

❏❏❏❏4. Test fit the flap/aileron to the wing with

the hinges. If the hinges don’t remain centered, stick a

pin through the middle of the hinge to hold it in position.

❏❏❏❏5.Remove any pins you may have inserted

into the hinges. Adjust the flap / aileron so there is a

small gap between the LE of the aileron and the wing.

The gap should be small, just enough to see light

through or to slip a piece of paper through.

❏❏❏❏6.Apply six drops of thin CA to the top and

bottom of each hinge. Do not use CA accelerator.

After the CA has fully hardened, test the hinges by

pulling on the aileron.

❏7.Repeat steps 1- 6 for the left wing panel and the

two wing panels for the top wing.

Install the Aileron Servos and Pushrods

❏❏1. Glue two 5/16" x 1/2" x 11/16" [8mm x 13mm x

18mm] hardwood blocks to the servo cover. Position

the blocks so the servo fits between the blocks.

❏❏2. Drill a 1/16" [1.6mm] hole through the servo

cover into the center of the servo mounting blocks.

Install and then remove a #2 x 3/8" [10mm] wood

screw into the holes you drilled. Apply a drop of thin

CA into the holes to harden the threads.Once the glue

has cured, install the screws into the servo cover.

❏❏3. Install a 12" [305mm] servo extension onto

the servo lead. Secure the extension to the lead with

tape, a piece of shrink tube or some other method to

keep them from coming unplugged.

❏❏4. Place the servo onto the servo mounting

blocks. Drill through the servo mounting holes with a

1/16" [1.6mm] drill bit. Remove the servo from the

servo cover. Install and then remove a servo

mounting screw into each of the holes you have

drilled. Apply a drop of thin CA into the holes to

harden the threads. Once the glue has cured, install

the servo onto the servo cover using the hardware

included with your servo. Center the servo and then

install a servo arm as shown.

❏❏5. Inside the servo bay a string is taped.Tie the

string to the servo extension. Pull the string and the

servo lead through the wing.Untie the string from the

lead and insert the lead through the small hole on the

top of the wing at the root.Tape the lead to the wing

to prevent it from falling back into the wing.

❏❏6. Place the servo cover onto the wing. The

opening for the servo arm should be pointed

towards the wingtip. Drill a 1/16" [1.6mm] hole

Did you know…At the height of the Great

Depression, aircraft executive Walter H. Beech

and airplane designer T.A.“Ted”Wells joined forces

to collaborate on a project many considered

foolhardy—a large, powerful, and fast biplane built

specifically for the business executive. The Beech

Model 17, popularly known as the “Staggerwing,”

was first flown on November 4, 1932.

- 8 -

through each corner of the cover. Remove the cover.

Then, install and remove a #2 x 3/8" [10mm] screw

into the holes you drilled. Apply a drop of thin CA into

the holes to harden the threads. Once the glue has

hardened, mount the servo cover with #2 x 3/8"

[10mm] screws and #2 flat washers.

❏❏7.Place a nylon control horn in line with the outer

hole in the servo arm. When positioned properly the

control horn will rest on a hardwood plate in the aileron.

Mark the location of the mounting holes onto the

aileron.Drill a 1/16" [1.6mm] hole on the marks, drilling

through the plywood plate

but not

through the top of

the aileron. Insert and remove a #2 x 3/8” [10mm]

screw into each of the holes. Apply a couple drops of

thin CA into the holes to harden the threads. Once the

glue has hardened attach the horn to the aileron with

two #2 x 3/8" [10mm] screws.

❏❏8. Screw a nylon clevis onto a .074 x 6" [152mm]

threaded wire 20 turns.Slide a nylon clevis retainer onto

the clevis.Install the clevis into the second hole from the

end of the control horn.Then, slide the silicone retainer

over the clevis. Drill a 5/64 [2mm] hole in the outer hole

of the servo arm. Center the servo and the aileron.With

a fine tip marker, mark the wire where it aligns with the

outer hole of the servo arm. Make a 90 degree bend on

the mark. Cut the wire so the wire is 3/8” [10mm] in

length after the bend.Insert the wire into the servo arm

and lock it in place with a nylon Faslink.

❏9. Repeat steps 1-8 for the left wing panel.

Install the Flap Servos and Pushrods

❏❏1. Glue two 5/16" x 1/2" x 11/16" [8mm x 13mm x

18mm] hardwood blocks to the servo cover. Position

the blocks so the servo fits between the blocks.

❏❏2. Drill a 1/16" [1.6mm] hole through the servo

cover into the center of the servo mounting blocks.

Install and then remove a #2 x 3/8" [10mm] wood

screw into the holes you drilled. Apply a drop of thin

CA into the holes to harden the threads.Once the glue

has cured, install the screws into the servo cover.

❏❏3.Install a 6" [152mm] servo extension onto the

servo lead. Secure the extension to the lead with

tape, a piece of shrink tube or some other method to

keep them from coming unplugged.

❏❏4. Place the servo onto the servo mounting

blocks. Drill through the servo mounting holes with a

1/16" [1.6mm] drill bit. Remove the servo from the

servo cover. Install and then remove a servo

mounting screw into each of the holes you have

drilled. Apply a drop of thin CA into the holes to

harden the threads. Once the glue has cured, install

the servo onto the servo cover using the hardware

included with your servo. Center the servo and then

offset the servo arm as shown.

❏❏5. Inside the servo bay a string is taped.Tie the

string to the servo extension. Pull the string and the

servo lead through the wing.Untie the string from the

lead and insert the lead through the small hole on the

top of the wing at the root.Tape the lead to the wing

to prevent it from falling back into the wing.

❏❏6. Place the servo cover onto the wing. The

opening for the servo arm should be pointed

towards the wing root on the right wing. (When

installing the left wing the opening will be towards the

wing tip). Drill a 1/16" [1.6mm] hole through each

corner of the cover. Remove the cover. Then, install

and remove a #2 x 3/8" [10mm] screw into the holes

you drilled. Apply a drop of thin CA into the holes to

harden the threads. Once the glue has hardened,

mount the servo cover with #2 x 3/8" [10mm] screws

and #2 flat washers.

- 9 -

FASLINK

2-56 (.074")

PUSHROD WIRE

SERVO

HORN

❏❏7. Place a nylon control horn backwards from

what would be considered the normal mounting

position, in line with the outer hole in the servo arm.

When positioned properly the control horn will rest

on a hardwood plate in the flap. Mark the location of

the mounting holes onto the flap. Drill a 1/16"

[1.6mm] hole on the marks, drilling through the

plywood plate

but not

through the top of the flap.

Insert and remove a #2 x 3/8" [10mm] screw into

each of the holes. Apply a couple drops of thin CA

into the holes to harden the threads. Once the glue

has hardened, attach the horn to the aileron with two

#2 x 3/8" [10mm] screws.

❏❏8. Screw a nylon clevis onto a .074 x 6” [152mm]

threaded wire 20 turns.Slide a nylon clevis retainer onto

the clevis.Install the clevis into the second hole from the

end of the control horn.Then, slide the silicone retainer

over the clevis.Drill a 5/64" [2mm] hole in the outer hole

of the servo arm. Center the servo and the flap. With a

fine tip marker, mark the wire where it aligns with the

outer hole of the servo arm. Make a 90 degree bend on

the mark. Cut the wire so the wire is 3/8" [10mm] in

length after the bend.Insert the wire into the servo arm

and lock it in place with a nylon Faslink.

❏9. Repeat steps 1-8 for the left wing panel.

Install the Wing Joiners

❏❏1. Locate three aluminum wing joiners. Slide

one joiner completely into the joiner pocket of the

lower right wing. The lower wing is the shorter wing

panel with the flaps.

❏❏2.Draw a line on the joiner where it extends out of

the joiner pocket. Roughen the portion of the joiner that

extends into the joiner pocket with 80-grit sandpaper.

❏❏3. Apply 30-minute epoxy to the inside of the

joiner pocket and the roughened end of the

aluminum joiner. Insert the joiner into the joiner

pocket. Be sure to insert the joiner fully into the

pocket. Clean any excess epoxy away from the wing

and joiner with rubbing alcohol.

Did you know…The Model 17s could achieve

a top speed of 201 miles per hour (323 kilometers

per hour), which made it faster than most military

aircraft of the era.Staggerwing’s speed also made

it the darling of the air racers of the 1930s.An early

version of Model 17 won the 1933 Texaco Trophy

Race. In 1935, a British diplomat, Capt. H.L.

Farquhar, successfully flew around the world in a

Model B17R, traveling 21,332 miles (34,331

kilometers) from New York to London, by way of

Siberia, Southeast Asia, the Middle East, North

Africa and back across Europe. Aviatrices Louise

Thaden and Blanche Noyes won the 1936

Bendix Trophy Race in a Model C17R

Staggerwing.Thaden also won the Harmon Trophy

for her achievement. Aviatrix Jackie Cochran set

a women’s speed record of 203.9 mph,

established an altitude record of over 30,000 feet

(9.144 meters), and finished third in the 1937

Bendix Trophy Race, all while flying a special

Model D17W Staggerwing.

- 10 -

- 11 -

❏❏4. Using 30-minute epoxy, glue two nylon anti-

rotation dowels into the holes at the root of the wing.

Glue them in so 1/2" of the dowels extends from

the wing.

❏5. Repeat steps 1-4 for the other wing.

❏6. Test fit a 3/8" x 2-1/2" [10mm x 64mm] wood

dowel into the hole at the leading edge of the top

wing. Push it into the wing, making sure it catches in

the hole further inside of the wing. Once you are

satisfied with the fit, epoxy them in place.Repeat this

for the other wing panel.

❏7. Glue the remaining wing joiner into the joiner

pocket of the top left wing using the same procedure

used for installing them in the bottom wing.

Only glue

the joiner into the left wing!

Glue the remaining

nylon anti-rotation dowel in the hole in the wing root.

Attach the Wings to the Fuselage

❏1. Slide the bottom wing panels into the sides of

the fuselage.Install a 6-32 x 1/4" [6mm] socket head

cap screw into the threaded holes on the bottom of

the fuselage. Push the wing tight to the fuselage.

Then, tighten the screw against the wing joiner.

Did you know…The Model 17’s unusual wing

configuration—the upper wing inversely staggered

behind the lower—and unique shape resulted in a

design that maximized the pilot’s visibility while

minimizing the aircraft’s tendency to stall.The fabric-

covered fuselage was faired with wood formers and

stringers. The Staggerwing’s use of retractable

conventional landing gear, uncommon at that time,

combined with streamlining, reducing the weight of

the materials, and its use of powerful radial engines

ranging from 225 to 710 horsepower produced an

aircraft with impressive performance.

❏2. Slide the two top wings together. On the bottom

of the right wing you will see a threaded hole. Install

a 6-32 socket head cap screw into the hole. Make

sure the wings are tight against each other and then

tighten the screw against the wing joiner.

❏3. Install the top wing onto the top of the fuselage.

Secure the wing to the fuselage with two

1/4-20 x 2" [50mm] nylon wing bolts.

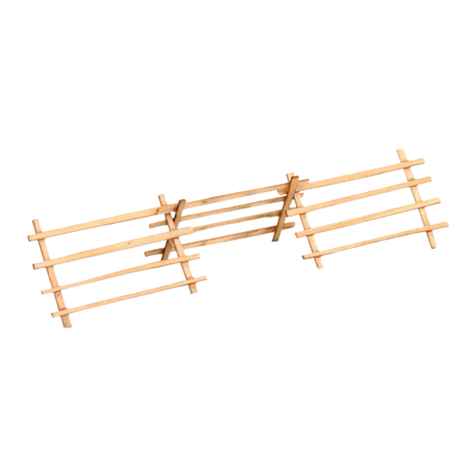

Install the Struts

❏1. On the top of the bottom wing and the bottom of

the top wing locate the pinholes that the manufacturer

made in the MonoKote film. Cut the covering on the

pinholes to reveal the 4-40 blind nuts pre-installed in

the wing. Install a metal bracket in each of the holes

with a 4-40 x 1/2" [13mm] socket head cap screw,

#4 flat washer and #4 lock washer. Do this for both the

left and right wings.

❏2. Slide the struts in place for both the left and right

wings.When positioning them the trailing edge of the

strut should be just in front of the hinge line for the flap.

❏3. When you are satisfied with the positioning of

the struts, mark the location of the holes from the

bracket onto the strut. Drill a pilot hole through the

marks with a 1/16" [1.6mm] drill. Then, drill through

the pilot hole with a 1/8" [3mm] bit.

- 12 -

❏4. Mount the strut to the bracket with a 4-40 x 1/2"

[13mm] Philips head screw, flat washer and 4-40

nylon lock nut. Do this for all four holes. Repeat this

for the other wing.

❏5. Remove the wings before moving on to the

next section.

BUILD THE FUSELAGE

Install the Stabilizers, Elevators

and Rudder

❏1. Slide the two aluminum stab tubes into the

back of the fuselage. The longer of the tubes goes

into the rear-most hole.

❏2.Slide the stabs onto the tubes, making sure that

they slide on and fit tight to the fuselage. When you

are satisfied with the fit, remove the stabs. Then

roughen the fuselage with 80-grit sandpaper where

the stab meets with the fuselage.

❏3. Apply epoxy to the root of each stab and the

fuselage side you roughed up. Slide the stabs onto the

aluminum tubes, pressing them firmly against the stab.

Hold the stabs tight to the fuselage with masking tape.

❏4. Test fit the joiner and the right elevator to the

stab, making sure that the elevator control arm is

inside of the fuselage. Epoxy the wing joiner to the

right elevator.

- 13 -

❏5. Cut nine 1" x 1" [25mm x 25mm] hinges from a

CA hinge strip. Insert three hinges into the elevator.

If the hinges don’t remain centered, stick a pin

through the middle of the hinge to hold it in position.

Slide the hinges into the elevator

❏6. Remove any pins you may have inserted into

the hinges.Adjust the elevator so there is a small gap

between the LE of the elevator and the stab.The gap

should be small, just enough to see light through or

to slip a piece of paper through. Apply six drops of

thin CA to the top and bottom of each hinge. Do not

use CA accelerator. After the CA has fully hardened,

test the hinges by pulling on the elevator.

❏7.Install three hinges into the left elevator.Test fit the

elevator to the stab, making sure you fit the elevator

joiner into the hole in the leading edge of the elevator.

Once you are satisfied with the fit, apply epoxy into the

hole in the leading edge of the left elevator and then

slide the hinges into the stab. Secure the hinges with

thin CA the same as was done with the right elevator.

❏8. Glue the rudder control horn into the rudder

with epoxy. When gluing it into the rudder be sure to

glue the end of the wire

without the threads

into the

rudder. Allow the glue to completely harden before

moving on to the next step.

❏9. Install three hinges into the rudder the same as

was done with the elevator.Insert the end of the rudder

control horn into the hole in the top of the fuselage.

Thread the nylon clevis link onto the threaded end of

the rudder control wire. Guide the hinges into the

vertical fin.Once satisfied with the fit, apply six drops of

thin CA to the top and bottom of each hinge.

- 14 -

INSTALL THE LANDING GEAR

The following instructions are for the installation of the

fixed landing gear.If you will be installing the retractable

landing gear skip ahead to the instructions for the

retractable landing gear. Should you later decide to

change over to the retractable landing gear, the

mounting holes match so the gear is interchangeable.

Fixed Landing Gear

❏❏1. Locate the components of the landing gear

blocks.Assemble them as shown using eight #4 x 3/8"

[10mm] screws on each landing gear block.

❏❏2. Place the assembly into the opening in the

fuselage

. Note that the hole for the landing gear wire

should be towards the inside of the fuselage.

Drill a

5/32" [4mm] hole through each of the mounting holes

and into the landing gear rails.Mount the block to the

landing gear rails with four #6 x 1/2" [13mm] screws

and a #6 lock washer.

❏❏3.Test fit the landing gear wire into the hole in the

landing gear block.When positioned properly the wire

should fit into the slot. If the wire does not fully seat,

grind away some of the nylon with a Dremel tool to

allow the radius of the wire to fully seat into the block.

❏❏4. Insert the landing gear wire into the landing

gear block. Using #2 x 3/8" [910mm] screws, attach

two nylon landing gear straps to the landing gear

block as shown.

❏❏5. Mark a line parallel to the mold line at the

bottom of the landing gear door. Mark the line 1/8"

[3mm] from the mold line. Cut on the line you have

drawn with a razor saw.

❏❏6. Measure 3/4" [19mm] from the mold line

and draw a line. Roughen the area shown with 80

grit sandpaper.

- 15 -

- 16 -

❏❏7. Locate the landing gear door wood mounting

bracket. Place it on the landing gear wire as shown.

Drill a 1/16" [1.6mm] hole for each of the landing gear

strap mounting holes. Install three flat nylon landing

gear straps with #2 x 3/8" [10mm] sheet metal screws.

❏❏8. Apply 6-minute epoxy to the part of the door

that you roughened up. Place the door onto the wood

mounting bracket, positioning the door so the axle is

in the center of the door and the bottom of the door is

approximately 3/4" from the bottom of the fuselage.

Hold the door in position while the glue hardens.

❏❏9. File a flat spot on the end of the axle. Install

a 5mm wheel collar and set screw onto the axle.

❏❏10. Slide a wheel onto the axle followed by the

wheel collar. Tighten the set screw against the flat

spot you made.Open the lower portion of the landing

gear door as shown. Apply a couple of drops of thin

CA to the hinge to keep the door fixed in place.

Note: Read step 11 and 12 before proceeding with

them. The installation of a cover to close the wheel

well is optional.The door will reduce the overall drag

but is not required for good flight performance.

❏❏11. From the 1/4" x 1/4" x 12" [6mm x 6mm x

300mm] balsa stick, cut pieces 3/4" [19mm] in length.

Glue them in the wheel well 1/16" [1.6mm] below the

bottom of the fuselage.

❏❏12. Glue the plywood wheel cover to the balsa

blocks and the fuselage.

❏13. Repeat steps 1-12 for the left landing gear.

Fixed Tail Wheel

❏1.Using the hardware in the tail wheel bag, assemble

the tail wheel components as shown.Be sure to apply

thread locker to the set screws during assembly.

❏2. Insert the tail wheel mounting bracket into the

fuselage, aligning the holes in the mounting bracket

with the holes in the wood mounting plate inside of the

fuselage. Mount the tail wheel to the wood mounting

plate with two 4-40 x 1/2" [13mm] socket head cap

screws, #4 flat washers and #4 lock washers.

Tail Wheel Door Installation (Fixed)

The following steps cover the installation of the tail wheel

doors. This is optional and not required for flight

performance. If you fly from a grass field that is very

rough or has long grass, you might wish to omit the

installation of the doors due to the amount of clearance

between the doors and the ground.If you omit the doors

you might also consider replacing the 1-1/4" [32mm] tail

wheel with the 2" [51mm] wheel included in this kit.

❏❏1. Locate the fiberglass tail wheel doors and

four pinned hinges. Place the doors into the opening

aligning the simulated stringers on the fuselage with

the doors to determine which door is the right and left.

❏❏2. On the backside of the door make a mark

1/2" [13mm] in from each end of the door.

❏❏3.Place the hinges on the line and make another

mark at the other end of the hinge to mark the exact

placement of the hinge. Do this for both hinges.

❏❏4. Measure in from the side of the door 1/16"

[1.6mm] and draw a line as shown.

- 17 -

❏❏5. Make a file by cutting a piece of plywood the

width of the hinge. Apply 180-grit sandpaper to the

plywood. Sand the door to make a 1/16" [1.6mm]

groove in the door at the location of each hinge.

❏❏6.Roughen the fiberglass with sandpaper in the

area the hinges will be glued to the doors. After

sanding, clean the area with rubbing alcohol.

❏❏7. Apply a couple of drops of lightweight oil to

the hinge pin to prevent glue from getting into the

hinge. Glue the hinges to the door.

❏❏8. Place the door into the opening in the

fuselage.Mark the area the hinge will be glued to the

fuselage. Sand and clean the areas inside of the

fuselage where the hinges will be glued.Then, epoxy

the doors in place.

❏9. Repeat steps 1-8 for the other door.

❏10. Spread the doors as far open as they will go.

Clean any remaining oil in the hinge pin with rubbing

alcohol. Apply a couple of drops of thin CA into the

hinge to lock the doors open. (Note: If you have any

thoughts of installing a retractable tail wheel in the

future, do not glue the hinges. Leave them free. This

will not interfere with the tail wheel operation.

Retractable Landing Gear

❏❏1. Cut two air lines 24" [610mm] long. Remove

the string taped at the root of the fuselage and tie it

tightly around the two air lines.

❏❏2. Inside of the fuselage at the wheel well you

will find the other end of the string taped in place.Pull

the string into the wheel well, pulling the airlines

through the fuselage. Insert each of the lines onto

the air inlets on the landing gear.

- 18 -

❏❏3.Partially insert the landing gear into the wing.

Make a mark where the airline will contact the

landing gear rail.

❏❏4. Using a high speed motor tool or a small

round file make a groove in the landing gear rail just

big enough to allow the air line to clear the landing

gear rail without pinching the airline.

❏❏5. Position the landing gear onto the landing

gear rails. The air cylinder will exit the side of the

fuselage as shown. When positioning the landing

gear be sure you do not kink either of the air lines.

❏❏6.Drill a 7/64" [2.8mm] hole into the landing gear

rails for each of the mounting holes.Screw the landing

gear to the rails with four #6 x 1/2" [13mm] screws.

❏❏7. Compress the landing gear strut completely.

While it is compressed, look at the positioning of the

back strut. Under compression the end of the back

strut should be at the end of molded channel. If the

landing gear back strut is too long, cut the end of the

strut so it will fit.

- 19 -

❏❏8. Place the back strut of the landing gear into

the slot molded in the fuselage. Place a flat landing

gear strap over the end of the strut.Mark the location

of the holes for the nylon strap. Then, drill a 1/16"

[1.6mm] hole through each of them, drilling into the

wood mounted under the skin of the fuselage.

Secure the strap with two #2 x 3/8" [10mm] screws.

❏❏9. Remove the screws that hold the axle and

the rear strut to the main landing gear.Install a wheel

onto the axle and the nylon collar over the back strut.

Screw the axle and rear strut back to the landing

gear. Be sure the back strut is under the nylon

landing gear strap and the nylon collar is positioned

over the recess molded into the wheel well. Push the

landing gear into the wheel well.

❏❏10.Place the landing gear door over the landing

gear, making sure it is centered in the wheel well.

Once satisfied with its position tape the door in place.

❏❏11. Draw a line on the door that is in line with

the angle of the back strut.

❏❏12. Measure from the tip of the door 1" [25mm]

and then draw a crossing line.

❏❏13.At the intersection of the two lines drill a 1/8"

[3mm] hole through the door.

❏❏14. Insert a 4-40 x 1/4" [6mm] socket head cap

screw and a #4 flat washer into the gear door.Thread

the screw into the nylon collar.

Do not

over tighten

the screw causing the hole in the collar to strip. The

screw does not have to be overly tight and the screw

will not be tight against the back strut.

- 20 -

This manual suits for next models

1

Table of contents

Other Top Flite Models Toy manuals

Top Flite Models

Top Flite Models Cessna 182 Skylane User manual

Top Flite Models

Top Flite Models Spitfire User manual

Top Flite Models

Top Flite Models RC-33 Elder 40 User manual

Top Flite Models

Top Flite Models SPITFIRE Mk IX User manual

Top Flite Models

Top Flite Models AT-6 Texan User manual

Top Flite Models

Top Flite Models PHASOAR 035 RC-38 User manual

Top Flite Models

Top Flite Models ORION User instructions

Top Flite Models

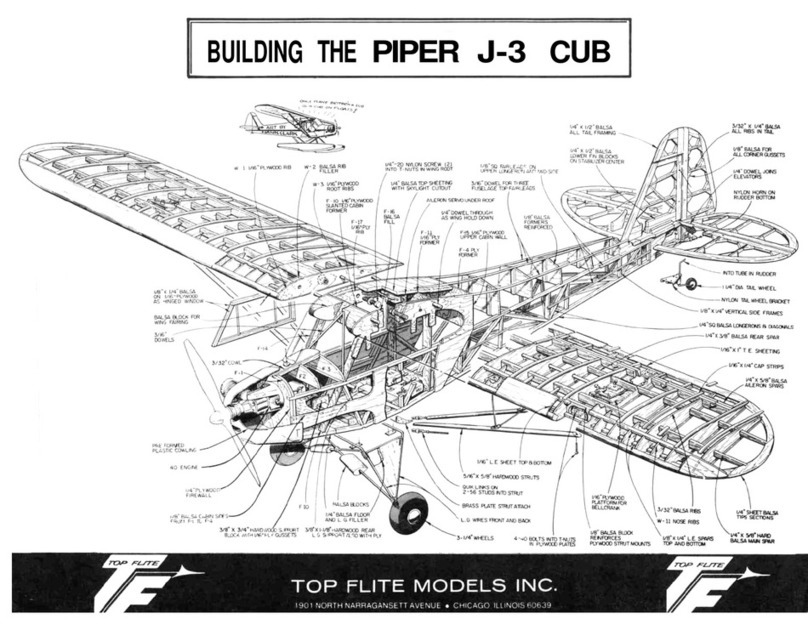

Top Flite Models Piper J-3 Cub User manual

Top Flite Models

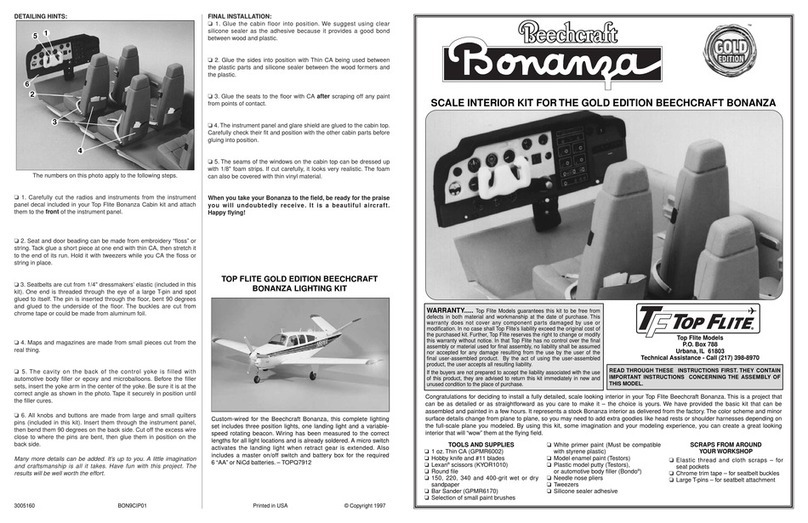

Top Flite Models GOLD EDITION Beechcraft Bonanza User manual

Top Flite Models

Top Flite Models P-39 AIRACOBRA User manual