2

TABLE OF CONTENTS

INTRODUCTION ..................................................... 2

Scale Competition ................................................ 3

Academy of Model Aeronautics............................ 3

IMAA..................................................................... 3

SAFETY PRECAUTIONS ....................................... 3

DECISIONS YOU MUST MAKE.............................. 4

Engine Recommendations ................................... 4

Retractable Landing Gear..................................... 4

Radio Equipment .................................................. 4

ADDITIONAL ITEMS REQUIRED .......................... 5

Hardware and Accessories................................... 5

Adhesives and Building Supplies..........................5

Optional Supplies and Tools ................................. 5

Covering Tools ...................................................... 5

KIT INSPECTION.................................................... 6

ORDERING REPLACEMENT PARTS .................... 6

PREPARATION ....................................................... 9

ASSEMBLE THE WING PANELS ........................... 9

Hinge the Flaps and Ailerons ...............................9

Mount the Engines.............................................. 10

Hook Up the Throttle and Install the Fuel Tank...11

Mount the Main Landing Gear ............................ 12

Retract Installation........................................... 12

Fixed Gear Installation..................................... 13

Mount the Fiberglass Nacelle Covers................. 13

Mount the Main Landing Gear Doors

(Retracts Only) ................................................ 14

Hook Up the Main Landing Gear Doors .............16

Mount the Cowl................................................... 19

Mount the Replica Engines................................. 22

Hook Up the Flaps and Ailerons......................... 23

ASSEMBLE THE TAIL .......................................... 24

Hinge the Elevators and Rudders....................... 24

Hook Up the Rudders and Elevators ..................25

Mount the Nose Gear .........................................26

Hook Up the Nose Gear Door

(Retract Only) .................................................. 29

FINAL ASSEMBLY ............................................... 30

Assemble the Cockpit .........................................30

Hook Up the Air System .....................................31

Complete the Radio Installation.......................... 32

Mount the Inboard Wing Panels..........................33

Mount the Outboard Wing Panels....................... 34

SCALE FEATURES .......................................... 3535

Mount the Nose-Gunner Canopy........................ 37

Install the Nose-Gunner Cabin ...........................38

Mount the Top Turret & Machine Guns................ 38

Finish the Tail-Gunner Cabin .............................. 39

Mount Side Gun Packs & Waist Gun Windows...40

Mount the ADF “Football” Antenna ..................... 41

Mount the Propeller Hubs................................... 41

Apply the Decals................................................. 41

GET THE MODEL READY TO FLY ....................... 41

Balance the Model (C.G.) ................................... 42

Balance the Model Laterally ...............................42

PREFLIGHT .......................................................... 42

Check the Control Directions.............................. 43

Set the Control Throws ....................................... 43

Identify Your Model ............................................. 43

Charge the Batteries........................................... 43

Balance Propellers ............................................. 43

Ground Check..................................................... 43

Range Check...................................................... 44

ENGINE SAFETY PRECAUTIONS....................... 44

AMA SAFETY CODE (Excerpts) ......................... 44

CHECK LIST......................................................... 45

FLYING.................................................................. 45

Mount the Wings................................................. 45

Takeoff ................................................................ 46

Flight................................................................... 46

B-25 Engine-Out Flying Procedures................... 46

Single Engine-Out Procedures ........................... 46

Landing............................................................... 47

SERVO EXTENSION CHARTS............................. 48

ENGINE MOUNT TEMPLATES ............................ 51

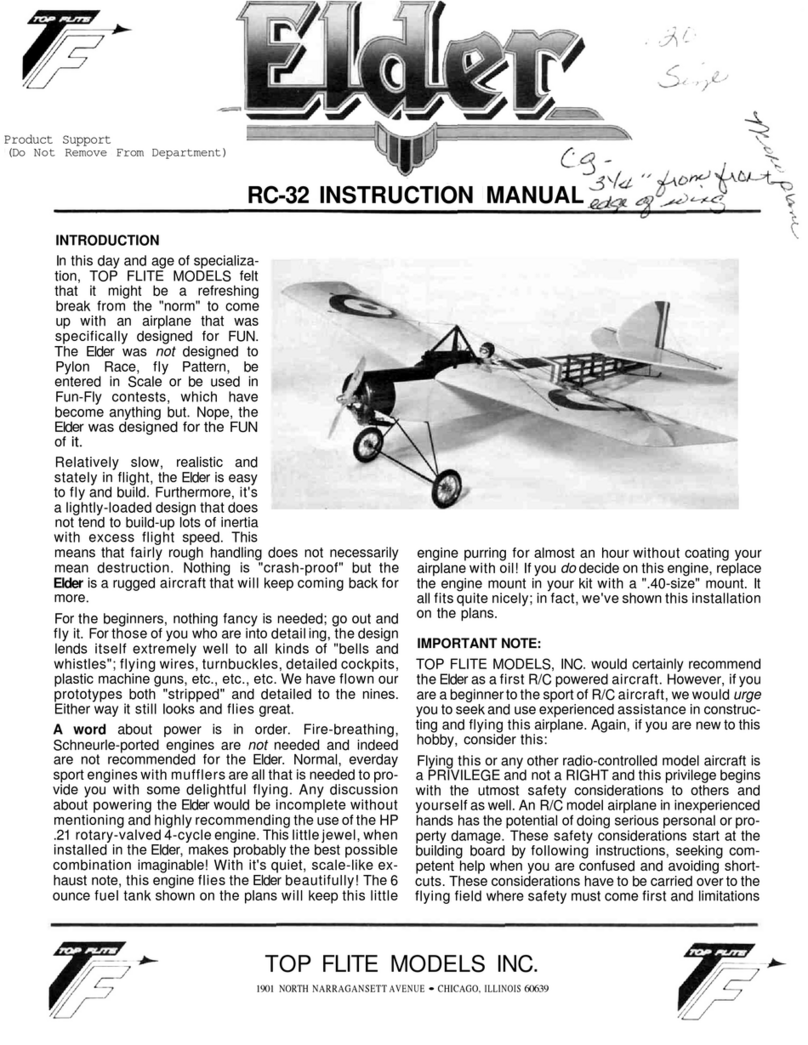

INTRODUCTION

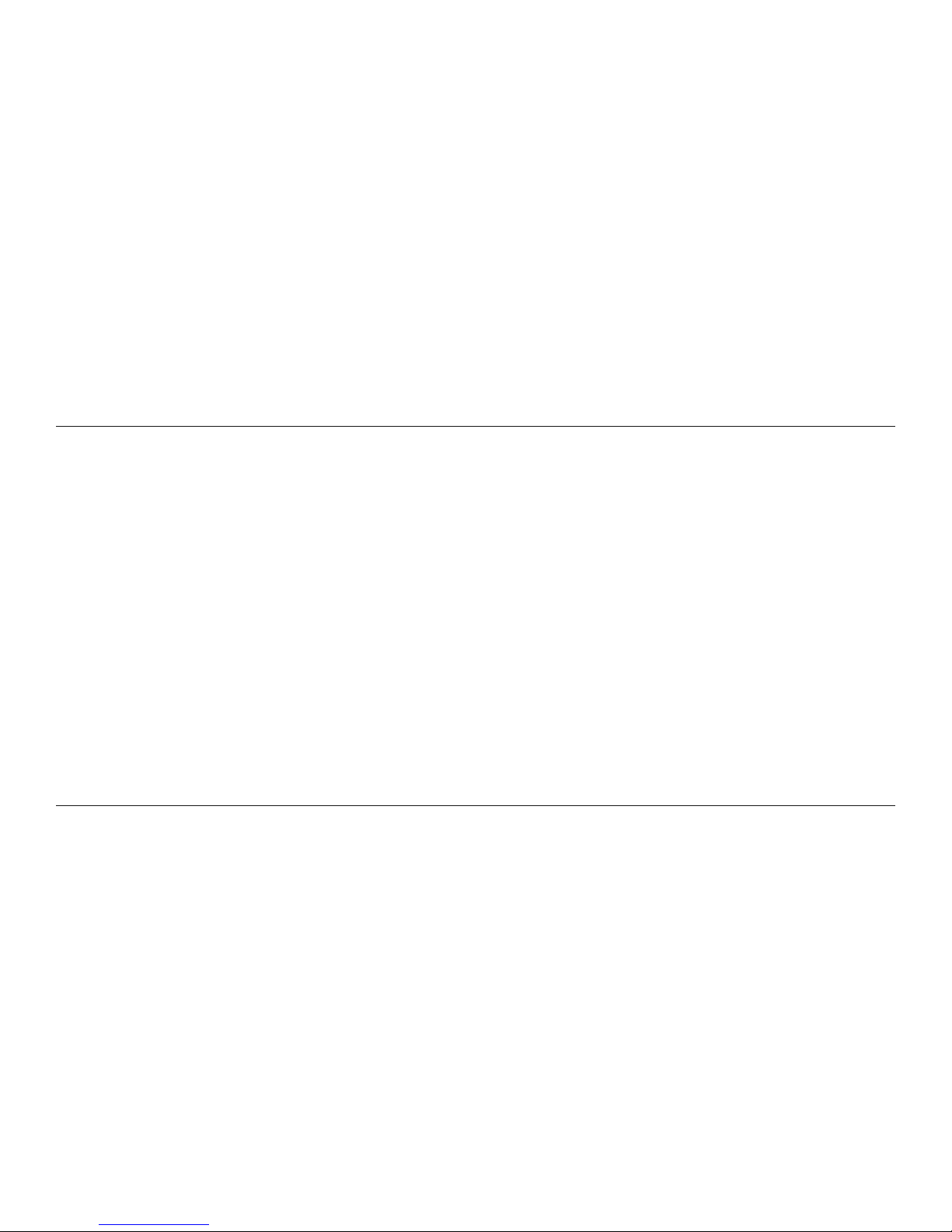

Thank you for purchasing the Top Flite Gold Edition

1/9th-scale B-25J Mitchell ARF. While no ARF model

will provide the level of detail necessary to take

“high-static” at premier scale competitions, you’ll still

be amazed at the level of detail and the number of

scale features included with this model! And we’ve

done our best to balance the level of authenticity and

detail with the requirements for simplicity that an ARF

modeler expects. For example, the main landing gear

doors on the full-size B-25 close both after the gear

has retracted and after it has extended (look at photos

of a B-25 sitting on the tarmac—notice that the gear

doors are closed!). But rather than duplicating the

full-size configuration (which would require a larger

radio with additional channels, air control valves on

every door, additional pushrods, linkages, air lines,

sequencers and considerable time, expense and

skill), and rather than abandoning functioning doors

altogether, we did it the “hard way” back in the shop by

taking time to figure out how to incorporate operating,

scale-appearing landing gear doors that the average

ARF builder could both afford and assemble. The

Top Flite B-25 ARF features operating, spring-loaded

doors that use mechanical levers to open and close,

thus eliminating all the aforementioned paraphernalia

that would be required.

And while other scale details including the nose-

gunner interior, cockpit interior, tail-gunner canopy

and machine guns are not exact replicas, these scale

features still “get the point across” with their presence

and stand-off accuracy. With all this detail also comes

the time commitment to put it all together, but in the

end we know it will all be worthwhile when you’re

executing slow fly-bys straight down the runway with

the flaps and gear extended and everybody else at

the field standing by watching.

The“Gold” B-25 is also a user-friendly model for breaking

down for transport and set up. Most modelers will simply

remove the outboard wing panels allowing the model to

fit easily into a mini van. If it’s still too big, the inboard

wing panels and vertical and horizontal stabilizers can

also be easily removed with the sturdy building stand

supporting the model during the process.

For the latest technical updates or manual corrections

to this model visit the Top Flite web site at www.top-

flite.com. Open the “GOLD EDITION ARFS” link on

the left side of the page and click on image of the B-25

that appears. If there is new technical information or

changes there will be an “Important! TECH NOTICE”

box on the upper left corner of the page. Click on the

Tech Notice box to read the info.