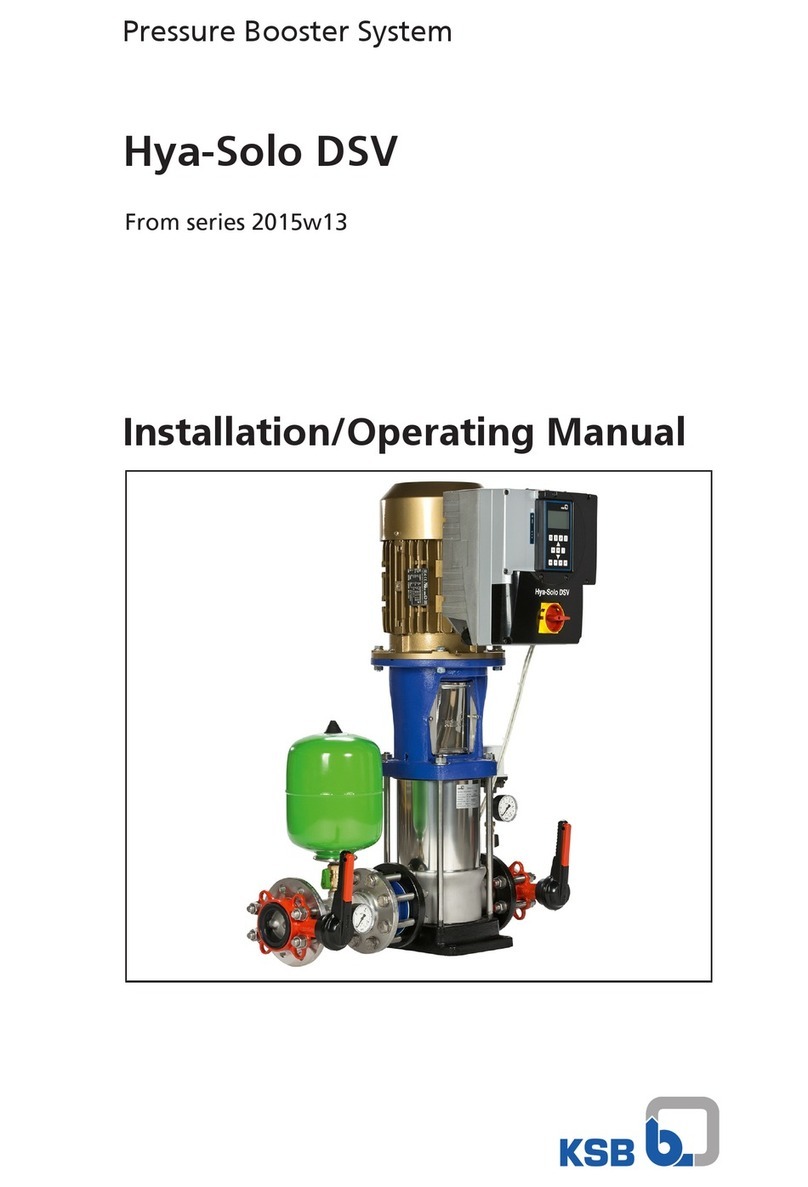

Topline TOP-FLO TF-C Series User manual

TOP-FLO®

Centrifugal Pump Model “TF-C” Series

www.toplineonline.com

Operation

Maintenance

& Parts List

Please read and understand this

manual prior to installing, operating

or maintaining this pump.

SAFETY ...................................................................................1

WARRANTY.............................................................................2

GENERAL INFORMATION......................................................2

Shipping Damage ..............................................................2

Hidden Damage.................................................................2

Warranty Claim ..................................................................2

Ordering/Returning Parts..............................................22

INTRODUCTION ................................................................. 3-4

Description of Components...............................................3

Performance Characteristics .............................................4

Standard Construction.......................................................4

Mechanical Specifications .................................................4

Motor Frame Sizes.............................................................4

INSTALLATION.................................................................... 5-7

Pump Dimensions..............................................................5

Unpacking..........................................................................6

Pump Location...................................................................6

Pump Leveling ...................................................................6

Supply and Discharge Piping/Valves .................................6

Electrical Connections .......................................................7

Flush Seal Option ..............................................................7

Cleaning Pump Prior to First Operation.............................7

OPERATION ........................................................................ 8-9

Cleaning Safety Procedures ..............................................8

Preliminary Test Run ..........................................................8

Operation ...................................................................... 8-9

MAINTENANCE............................................................... 10-20

Stub Shaft Seal................................................................10

Service/Repair .................................................................10

Disassembly for Cleaning and Repair........................ 11-12

Replacing Motor ..............................................................12

Install Adapter/Stub Shaft Adjustment ............................13

Drive Collar Adjustment ...................................................14

Disassembly for “DG” Seal ..............................................15

Reassembly for “DG” Seal (setting the drive collar ... 16-17

Disassembly and Reassembly for “E” Seal ............... 18-20

Routine Maintenance.......................................................20

TROUBLESHOOTING AND CAUSES ..................................21

PARTS ORDERING/SPARE PARTS/PARTS LIST.......... 22-28

Water Cascade Assembly Parts ......................................23

Repair Seal Kits, (All pumps ............................................23

TF-C100……. (With spare parts ......................................24

TF-C114……. (With spare parts ......................................25

TF-C216……. (With spare parts ......................................26

TF-C218……. (With spare parts ......................................27

TF-C328……. (With spare parts ......................................28

TABLE OF CONTENTS

1

TOP-FLO®“TF-C” Series centrifugal pumps have been designed to be safe and

reliable when properly used and maintained.

Operators and maintenance personnel must follow safety measures. Failure

to observe the instructions in this manual could result in personal injury or

machine damage.

• Do Not operate pump beyond the rated conditions for which the pump

was sold.

• Do Not use heat to remove impeller or disassemble pump due to risk of

explosion of trapped liquid.

Warnings, cautions and notes are contained in this manual. To avoid serious injury and/or

possible damage to equipment, pay attention to these messages.

WARNING Hazards or unsafe practices which COULD result in severe personal

injury or death and how to avoid it.

CAUTION Hazards or unsafe practices which COULD result in minor personal

injury or product or property damage.

NOTE Important information pertaining directly to the subject. (Information

to be aware of when completing the task.)

WARNING

ROTATING SHAFT

DO NOT OPERATE WITHOUT

GUARD IN PLACE

Read and understand this manual prior

to installing, operating or maintaining this

pump.

SAFETY

WARNING

Do not operate pump

without CASING/VOLUTE

clamped securely in place.

WARNING

To avoid electrocution, ALL electrical should

be done by a registered Electrician, following

Industry Safety Standards. All power must be

OFF and LOCKED OUT during installation.

WARNING

TO AVOID POSSIBLE SERIOUS

INJURY, SHUT OFF AND DRAIN

PRODUCT FROM PUMP PRIOR TO

DISCONNECTING PIPING.

WARNING

TO AVOID SERIOUS INJURY, DO NOT

INSTALL OR SERVICE PUMP UNLESS ALL

POWER IS OUT AND LOCKED OUT.

CAUTION

Wear gloves to avoid cutting

injuries from sharp pump parts.

2

TOP LINE PUMP WARRANTY

Seller warrants its products to be free from defects in materials and workmanship for a period

of one (1) year from the date of shipment. This warranty shall not apply to products which

require repair or replacement due to normal wear and tear or to products which are subjected

to accident, misuse or improper maintenance. This warranty extends only to the original Buyer.

Products manufactured by others but furnished by Seller are exempted from this warranty and

are limited to the original manufacturer’s warranty.

Seller’s sole obligation under this warranty shall be to repair or replace any products that Seller

determines, in its discretion, to be defective. Seller reserves the right either to inspect the

products in the field or to request their prepaid return to Seller. Seller shall not be responsible

for any transportation charges, duty, taxes, freight, labor or other costs. The cost of removing

and/or installing products which have been repaired or replaced shall be at Buyer’s expense.

Seller expressly disclaims all other warranties, express or implied, including without limitation

any warranty of merchantability of fitness for a particular purpose. The foregoing sets forth

Sellers entire and exclusive liability, and Buyer’s exclusive and sole remedy, for any claim of

damages in connection with the sale of products. In no event shall Seller be liable for any special

consequential incidental or indirect damages (including without limitation attorney’s fees and

expenses), nor shall Seller be liable for any loss of profit or material arising out of or relating to the

sale or operation of the products based on contact, tort (including negligence), strict liability or

otherwise.

GENERAL INFORMATION

SHIPPING DAMAGE

Inspect your shipment immediately. If shipping damage is found, note it on the drivers copy

(packing slip) and request the driver to ask the Inspector to call. You are responsible for

initiating shipping damage claims.

HIDDEN DAMAGE

If during installation, you discover hidden damage caused in shipping, contact the Shipper

immediately and ask for an Inspector to call. Notify your Top Line Distributor of the problem.

WARRANTY CLAIM

Please read the Warranty statement to correctly determine if you have a claim. In warranty

claims you must have a “Returned Goods Authorized” (RGA) from Top Line before any

returns will be accepted. Your Top Line Distributor will help you with a warranty problem.

ORDERING/RETURNING PARTS

See page 24 for complete information on ordering parts. Complete the Distributor/Product

information immediately and keep for later reference.

WARRANTY

3

INTRODUCTION

DESCRIPTION

This manual contains installation, operation, cleaning, repair instructions and parts lists

for the “TF-C” Series Centrifugal Pumps. It also provides a Troubleshooting Causes

chart to help in determining and correcting possible pump problems.

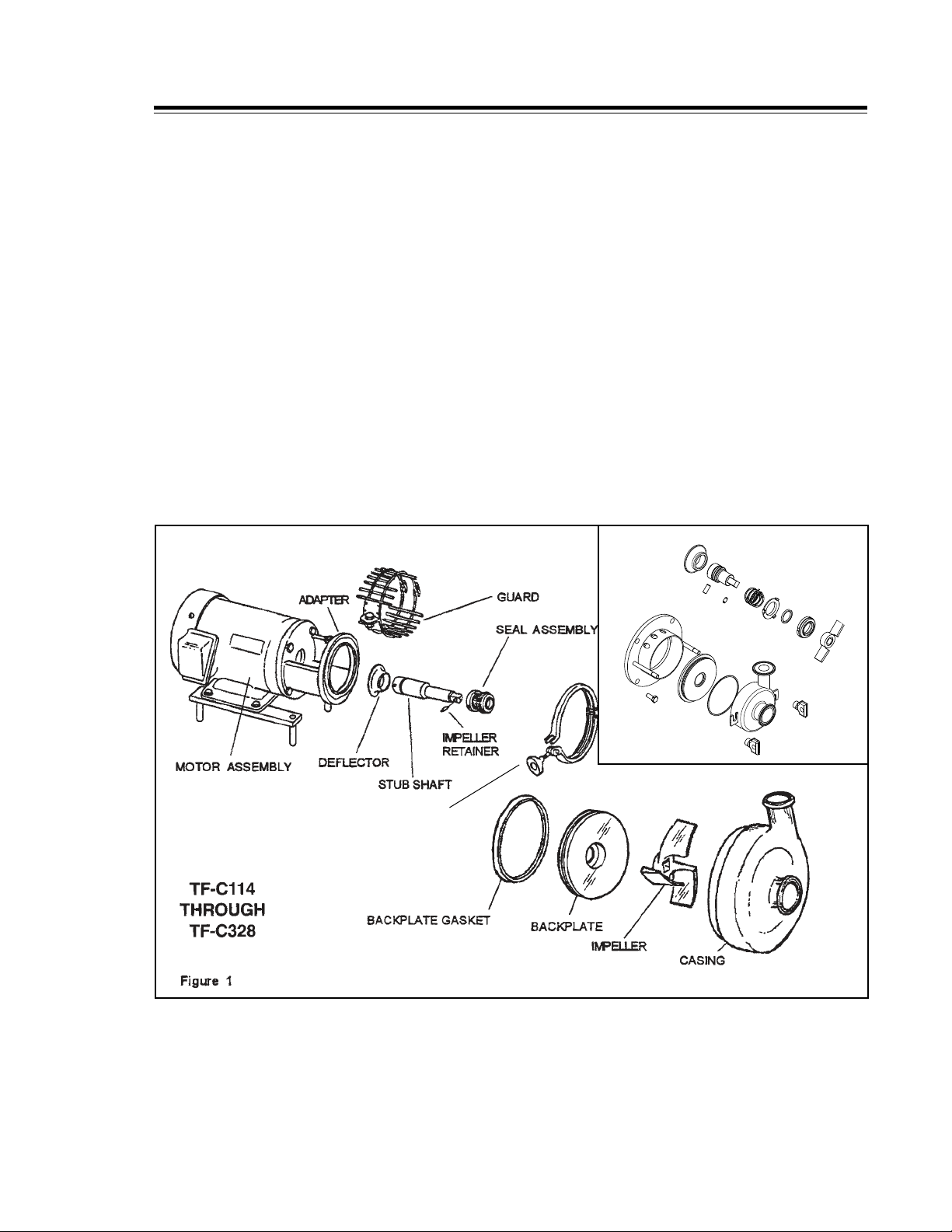

The “TF-C” Series Centrifugal Pumps consist of two sections, the motor assembly, and the

pump components. (Figure 1) The pump is mounted on the drive motor with an adapter, and

is coupled to the motor with a stainless steel stub shaft. The pump impeller mounts on the

stub shaft and is secured with a floating impeller retainer pin.

The casing is joined to the adapter by a clamp, greatly simplifying removal and also

permitting the casing outlet to be rotated to various positions. (The TF-C 100 is secured with

two wing nuts and may only be mounted with the outlet facing straight up.) The mechanical

external balanced seal assures a long wear life. The drive motor is mounted on a frame with

adjustable legs in accordance with sanitary design requirements providing simple installation

and easy leveling of the pump.

40

6D

*80CA

*80A

*80B

*80 2

75K

1

*90

11

71B

71

*24

6A

CLAMP

TF-C100

4

STANDARD CONSTRUCTION:

• Casting, backplate, and impeller are 316L stainless steel with a 32Ra grit polished sanitary

finish.

• Port Connection: Clamp fittings are standard.

• Power: Supplied by a standard foot-mounted C-face motors through 60 horsepower.

• Seal: “Type D” Seal material is carbon rotating on stationary stainless steel backplate.

Water cascading attachment is available option (“F” Seal.) Dual seal is available option

(“E” Seal.)

• Elastomers: Buna, FKM and EPDM.

PERFORMANCE CHARACTERISTICS:

Nominal Capacity: To 780 GPM Viscosity: To 1500 CPS Temperatures: To 212°F (100°C)

Nominal Speeds: To 2900 RPM - 50HZ; To 3500 RPM - 60HZ

MECHANICAL SPECIFICATIONS

PORT SIZE

Inches

IMPELLER DIA.

Inches (mm)

MODEL Inlet Discharge Minimum Maximum

TF-C100 1-1/2

-

1

-

3.0

(76)

3.68

(93)

TF-C114 1-1/2

2

1-1/2

1-1/2

2.5

(63)

4.0

(101)

TF-C216 2

2-1/2

1-1/2

1-1/2

4.0

(101)

6.0

(152)

TF-C218 2

3

1-1/2

1-1/2

6.0

(152)

8.0

(203)

TF-C328 3

4

2

2

5.5

(139)

8.0

(203)

AVAILABLE MOTOR FRAME SIZES FOR PUMP MODELS

TF-C100 56C

143TC-145TC

TF-C114 56C

143TC-145TC

182TC-184TC

TF-C216 56C

143TC-145TC

182TC-184TC

213TC-215TC

254TC-256TC

TF-C218 143TC-145TC

182TC-184TC

213TC-215TC

254TC-256TC

284TC-286TC

TF-C328 182TC-184TC

213TC-215TC

254TC-256TC

284TC-286TC

324TC-326TC

INTRODUCTION

5

INSTALLATION TOP-FLO®CENTRIFUGAL PUMP DIMENSIONS

6

INSTALLATION

UNPACKING EQUIPMENT

Check all parts received and inspect for damages that may have occurred during shipping.

Report any damage to the carrier.

PUMP LOCATION

• Place as close as practical to the liquid

supply. Keep supply piping short and

straight. Keeping the pump supplied with

liquid will prevent damaging from cavitation.

• The pump must be accessible for service

and inspection during operation.

• The motor must be protected from flooding.

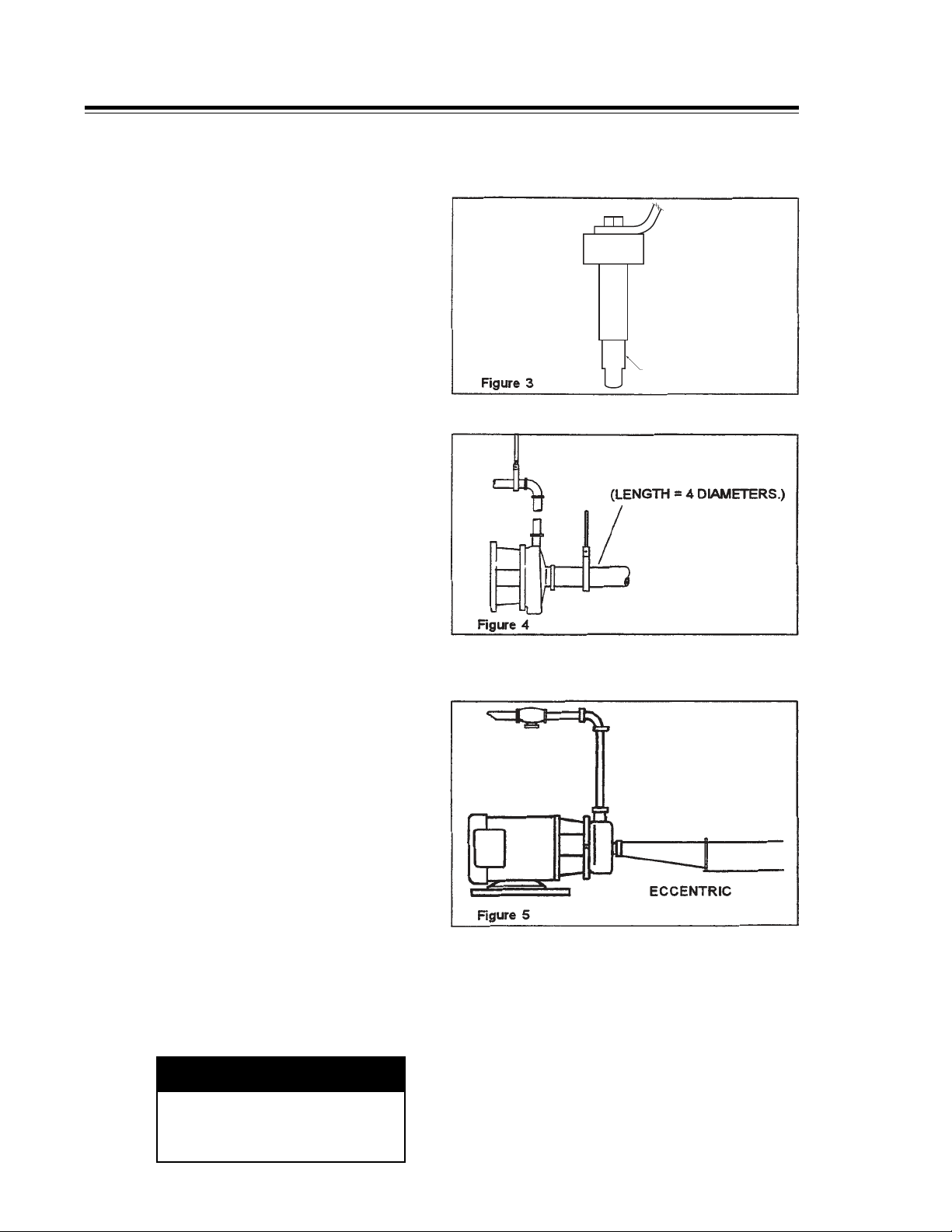

PUMP LEVELING

• Level the pump by rotating the adjustable

legs. (Figure 3)

SUPPLY AND DISCHARGE PIPING/VALVES

• Use line size equal to, or larger than

connection sizes on pump, especially the

inlet supply line.

• Keep the supply line short and straight. Use

as few elbows, valves, or other types of

restrictions as possible. Avoid up and down

rises which will trap air.

• Be certain all joints in the suction lines are

well sealed to prevent air leaks.

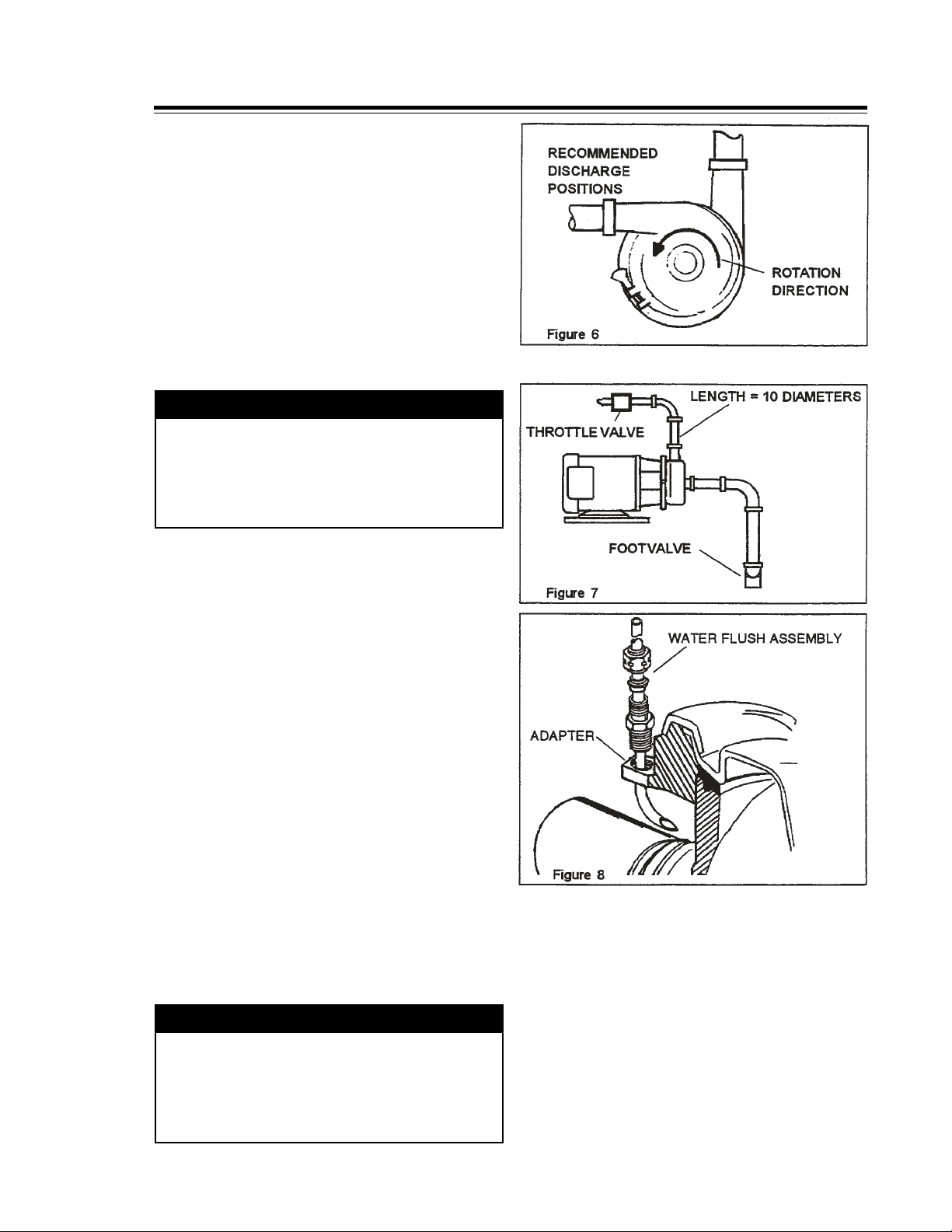

• Maintain a straight length of pipe at least 4

diameters long at the pump inlet. (Figure 4)

• The pump casing may be rotated with

the discharge connection pointing in any

direction. The best pump performance will

be with the outlet up, to the left, or positions

in between. These positions insure the

casing is flooded and prevents problems

due to air in the system. (Figure 6)

• Support the supply and discharge piping

near the pump so no strain is put on the

pump casing.

• If an expansion joint is used, install a pipe

anchor between it and the pump.

• If a reducer is connected to the inlet, use

an eccentric type (Figure 5) to prevent

problems due to trapped air.

ADJUSTABLE LEGS

CAUTION

Wear gloves to avoid cutting

injuries from sharp pump and

piping parts.

• Line slope will depend on application

requirements. The best pump operation

is with supply line sloped slightly upward

toward pump to prevent trapped air. If the

system must drain into the pump casing,

keep downward slope to a minimum or

priming problems may occur.

• Install shutoff valves to isolate pump from

supply and discharge lines to allow pump

service without draining the system.

ADJUSTABLE LEGS

ADJUSTABLE LEGS

7

installed above the supply liquid level. Install

INSTALLATION

• This pump is not self-priming. The pump is

installed above the supply liquid level. Install

a foot valve or other system check valve to

keep casing flooded for priming. (Figure 7)

• A throttling valve may be required to control

the pump flow rate to prevent motor

overload. Always install the throttling valve

in the discharge piping, never in the supply

piping, and at least 10 diameters from the

pump outlet (Figure 7)

ELECTRICAL CONNECTIONS

WARNING

To avoid electrocution, ALL electrical

installation should be done by a registered

electrician, following Industry Safety

Standards. All power must be OFF and

LOCKED OUT during installation.

• Read the manufacturer’s motor instructions

before making installation. Follow the

manufacturer’s lubrication schedules.

• Check the motor nameplate to be sure

the motor is compatible with the electrical

supply and all wiring, switches, starters,

and overload protection are correctly sized.

• Check pump rotation following electrical

installation. Correct rotation is counter

clockwise when facing pump inlet

connection. (Figure 5)

FLUSH SEAL OPTION

When this option is ordered, a fitting

assembly is supplied for directing a flow

of water onto the backplate/seal area. The

water supply should be cool and filtered. If

the product solidifies at cool temperatures,

use warm or hot water. The connection size

is 1/4 inch O.D. tubing and the required flow

is approximately 5 U.S. gallons per hour.

(Figure 8)

WARNING

TO AVOID SERIOUS INJURY, DO NOT

INSTALL OR SERVICE PUMP UNLESS

ALL POWER IS OFF AND LOCKED OUT.

CLEANING PUMP PRIOR TO FIRST

OPERATION

CLEAN PUMP AND PIPING

Disassemble pump and clean all product

contact parts and seals prior to first operation.

Follow instructions in the “Cleaning Safety

Procedures” and “Disassembly for Cleaning

and Repair” section (pages 9 and 12).

The pump should be thoroughly cleaned of any

materials which may have accumulated during

installation.

8

CLEANING SAFETY AND TEST RUN

AMMETER TEST

Operate pump under process conditions and

check motor amp draw versus nameplate full

load rating. If amp draw exceeds motor rating,

a system change or pump change is required.

If process conditions and/or liquid changes,

(higher viscosity, higher specific gravity)

recheck motor amp draw.

Contact your authorized TOP LINE distributor

for assistance.

WARNING

TO AVOID ELECTROCUTION, ONLY

A QUALIFIED ELECTRICIAN SHOULD

INSTALL THE AMMETER.

OPERATION

• Any system throttling valves, or similar

devices used to control flow rate must

be installed in the discharge line, not the

supply line. Restriction in the supply line

may cause cavitation and pump damage.

• “Water hammer” in the system can

damage the pump and other system

components. Water hammer often occurs

when valves in the system are suddenly

closed causing lines to move violently and

with a loud noise. When this condition is

present, find and eliminate the source of

the water hammer. One way to eliminate

water hammer is to slow down the

actuation speed of the valve.

• Do not expose the pump to freezing

temperatures with liquid in the casing.

Frozen liquid in the casing will damage

the pump. Drain casing before exposing

to freezing temperatures.

DISASSEMBLY, CLEANING/REPAIR

OPERATION

CLEANING SAFETY PROCEDURES

Manual Cleaning:

1. Do not use toxic and/or flammable solvents.

2. Lock out electrical power and shut off all air

prior to cleaning equipment.

3. Keep electrical panel covers closed and

power off when washing equipment.

WARNING

To prevent an accidental start-up

the power source should be locked

out using your lock and key.

4. Clean up spills as soon as possible.

5. Never attempt to clean the equipment while

it is operating.

6. Wear proper protective apparel.

Cleaning-In-Place

1. Make certain that all connections in the

cleaning circuit are properly applied and tight

to avoid contact with hot water or cleaning

solutions.

2. When the cleaning cycle is controlled from

a remote or automated cleaning center,

follow all established safety procedures for

servicing the system.

PRELIMINARY TEST RUN

See OPERATION on page 10 to set pump up

for a test run.

CHECK FOR POSSIBLE MOTOR

OVERLOAD CONDITION

Certain combinations will overload the motor

when operated with open, unrestricted

discharge, which results in a high flow rate.

Additional discharge restriction may be required

to lower the flow rate and lower the horsepower

requirements. DO NOT add restrictions to the

supply line. If the pump was incorrectly sized, a

smaller impeller or a higher horsepower motor

may be required.

If uncertain about pump selection and

application, temporarily install an ammeter in

the electrical service to check the amp draw.

It is not necessary to disassemble the pump for

cleaning if used in a CIP Installation (Clean-In-Place).

However, periodically take pump apart, thoroughly

inspect, clean and reassemble.

(See MAINTENANCE - DISASSEMBLY)

9

8. Slowly open the discharge valve until

desired flow is obtained. Observe pressure

gauges and if pressure is not attained

quickly, stop pump and prime again.

STOP PUMP

9. To stop the pump, shut off the power to

the pump motor. Liquid in the system can

flow freely through the pump. The pump

does not act as a shut off valve. Shut off

supply and discharge lines.

OPERATION

WARNING

Skin and eye protection are required

when handling hazardous or toxic fluids.

CAUTION

If pump is being drained, take necessary

precautions to avoid personal injury.

NOTE: Disposal of drainage must be in

conformance with environmental regulation.

Pumps must have been correctly installed as

described in the “INSTALLATION” section.

SEAL FLUSH

1. If the pump has the flush seal option, start

the flow of flush water (approximately 5 US

gallons per hour recommended rate).

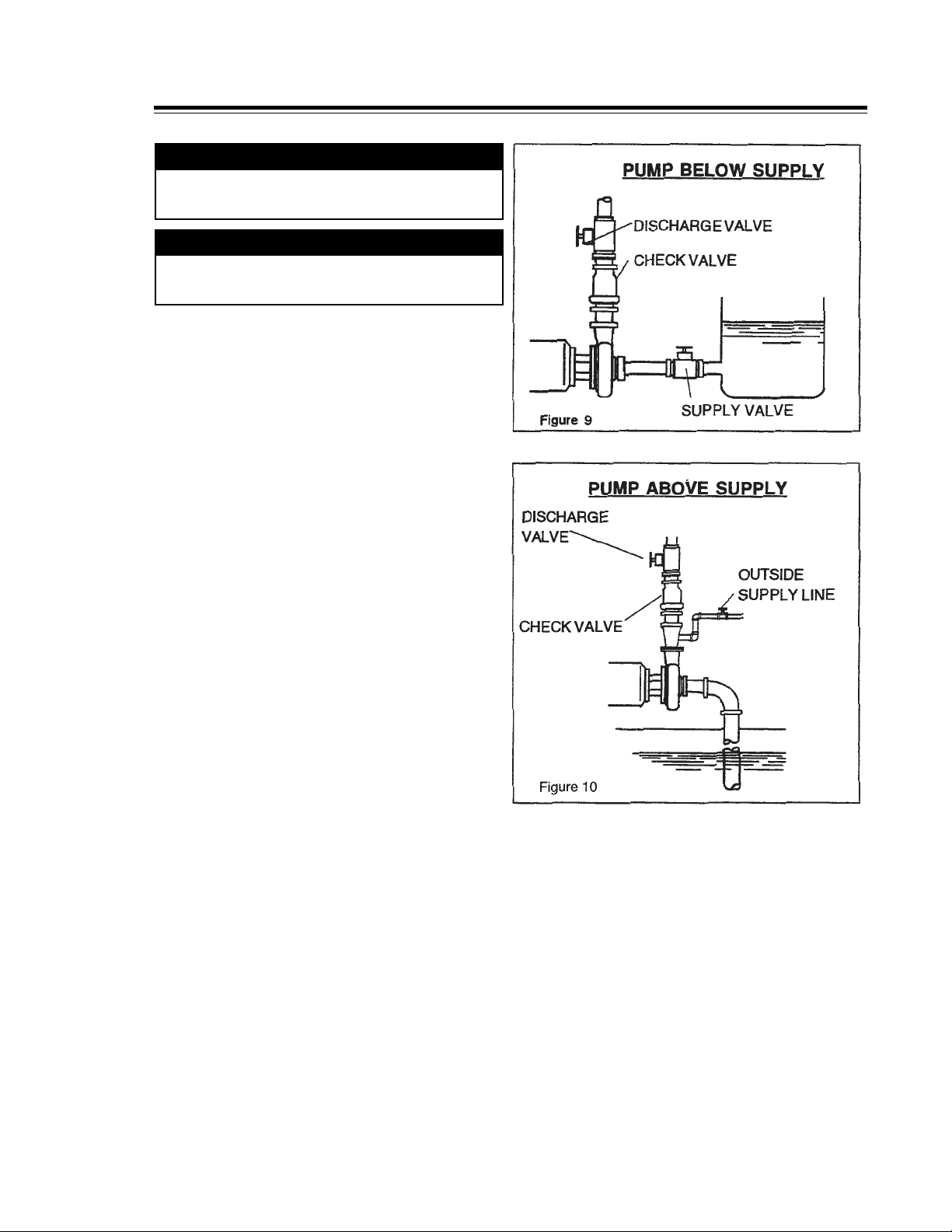

PRIME PUMP

2. Flood the pump casing with liquid BEFORE

starting pump to avoid damage to the pump

parts. Fill the supply tank with liquid and

open supply line valve (suction). Any air

trapped in the supply line or casing should

be vented. (Figure 9)

PRIMING WITH OUTSIDE SOURCE

The pump will not self prime if the liquid

supply is below the pump level. (Figure 10)

3. Close the discharge valve and open the air

vents.

4. Open the valve in the outside supply line

until the liquid flows from the vent valves.

5. Close the vent valves and the supply line.

Use a type of check valve system to keep

the supply line and pump casing flooded

with liquid. Otherwise, the pump must be

primed before each operation. (See Figure 7)

6. Start the pump motor.

PUMP CHECK

7. Check to see that liquid is flowing and all

piping connections and seals are leak free.

The pump must be operated against a

closed discharge for a short time. However,

continued operation will heat liquid in casing

to boiling and lead to pump damage.

10

STUB SHAFT SEAL

The shaft design utilizes a drive collar as

shown in Figure 11 to assure proper loca-

tion of the seal assembly. The TF-C100 does

not require a drive collar. The drive collar is

incorporated in the design of the stub shaft.

The drive collar must be properly located on

the shaft, following procedures outlined on

page 15.

This type of seal should be replaced when

the face is worn away, or when leakage is

noted (Figure 12)

To remove the seal, disconnect the suction

and discharge piping. Then, remove the

casing, impeller, and backplate. Protect the

sealing face of the backplate from nicks and

scratches.

NOTE: When the carbon seal is replaced,

the position of the drive collar should be

checked and reset if necessary, per the

dimensions given on page 15.

Inspection during cleaning will determine

if the carbon seal needs replaced. No

additional drive collar adjustment is

necessary unless the seal is replaced.

(Figure 12)

SERVICE/REPAIR

Periodically inspect all parts of the pump

to prevent malfunctions caused by worn or

broken parts.

MAINTENANCE SEAL SERVICE

11

d assembly with a

Loosen clamp wing nut and swing clamp

Inspect clamp saddles and the casing for

eplace if necessary.

etaining pin in the center of the stub

shaft. This will allow the impeller to pull off

Remove the backplate gasket and inspect

e must be taken to protect the

sealing face and edges of the backplate

Remove the carbon seal, o-ring, seal cup,

om the stub shaft by pulling

carbon seal for signs of abrasions, cuts,

or other wear that could cause leakage.

the extension end of the seal is less than

MAINTENANCE

CAUTION

Wear gloves to avoid cutting injuries

from sharp pump parts.

1. Shut off product flow to the pump and

relieve any product pressure.

2. Shut off and lock out power to the

pump.

3. Disconnect the suction and discharge

pipe fittings.

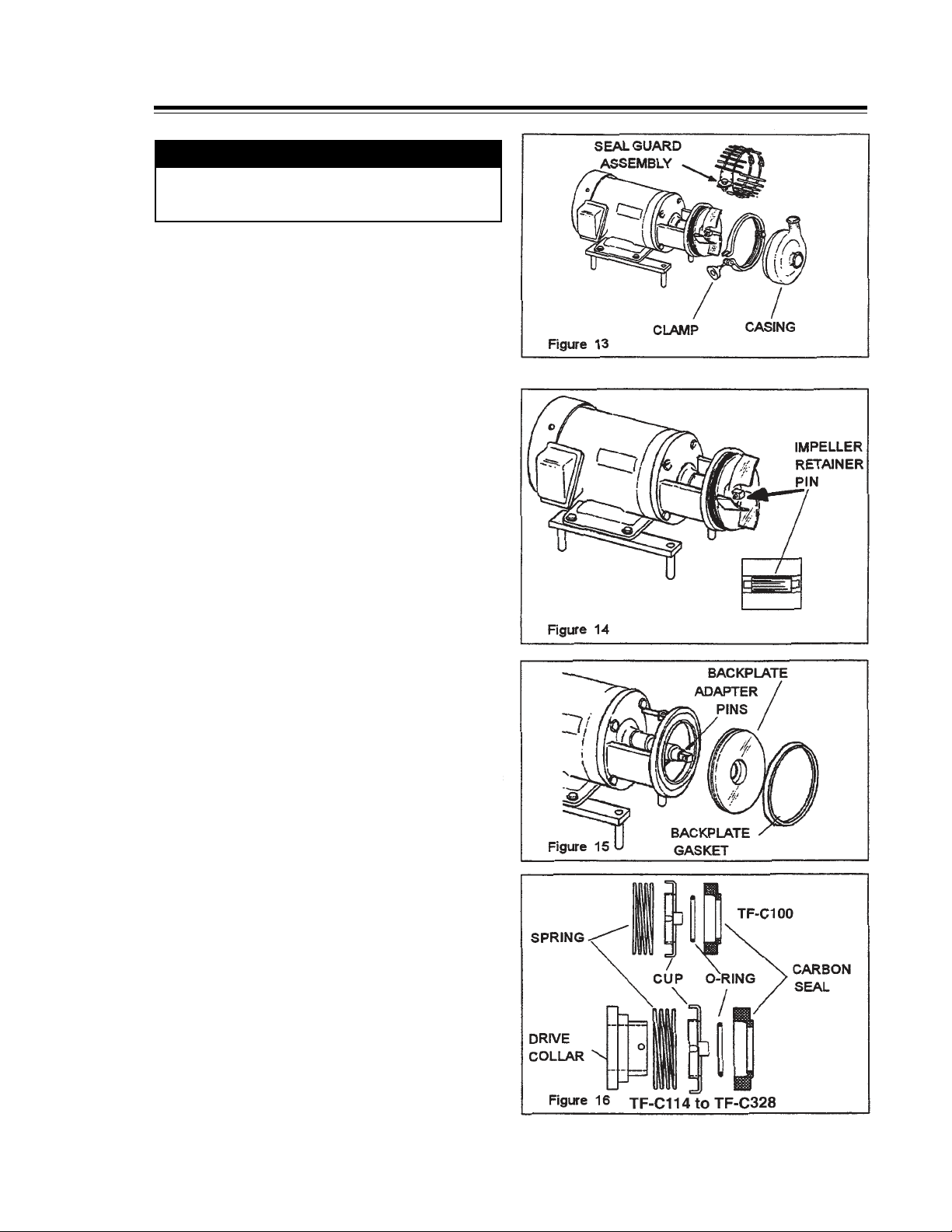

4. Remove the seal guard assembly with a

wrench. (Figure 13)

5. Loosen clamp wing nut and swing clamp

open. On the TF-C100, remove casing

wing nuts.

6. Inspect clamp saddles and the casing for

damage or wear and replace if necessary.

(Figure 13)

7. Push back on the impeller and position

the retaining pin in the center of the stub

shaft. This will allow the impeller to pull off

the stub shaft. (Figure 14)

8. Rotate the backplate to disengage the

backplate pins from the adapter pins.

Remove the backplate with gasket

attached, by pulling straight off the

adapter. (Figure 15)

9. Remove the backplate gasket and inspect

it for wear and sealing failure.

NOTE: Care must be taken to protect the

sealing face and edges of the backplate

from nicks and scratches.

10. Remove the carbon seal, o-ring, seal cup,

and spring from the stub shaft by pulling

them straight off the shaft. (Figure 16)

11. Carefully inspect the o-ring and the

carbon seal for signs of abrasions, cuts,

or other wear that could cause leakage.

(Figure 16)

NOTE: Replace the carbon seal when

the extension end of the seal is less than

1/32”. (Figure 12)

12. After cleaning, inspect the seal, o-ring,

and gasket and replace if necessary.

DISASSEMBLY FOR CLEANING AND REPAIR

12

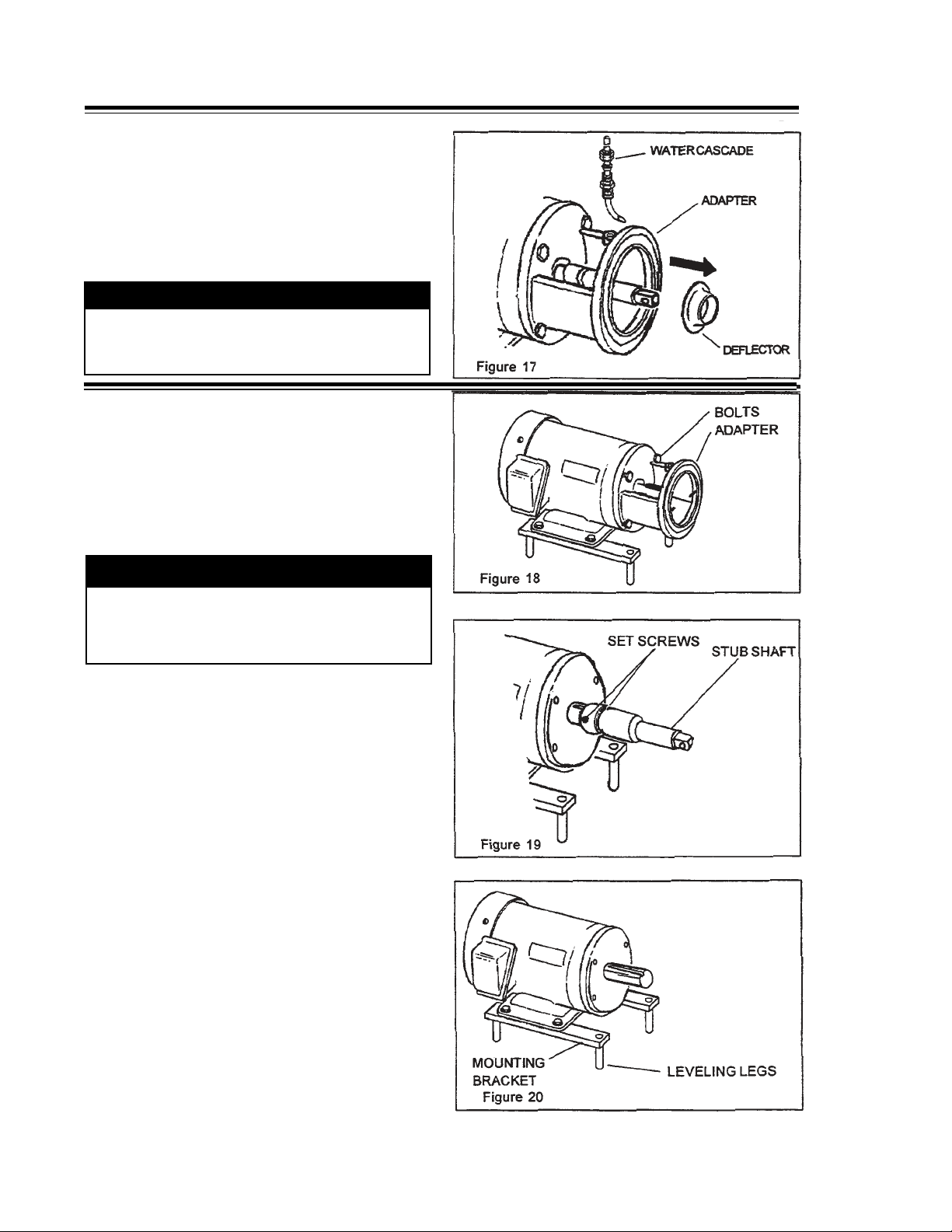

REPLACING MOTOR

To replace or service the motor, disassemble

the pump as outlined in DISASSEMBLY steps

1 through 11.

1. Remove the bolts that secure the adapter

to the motor frame and remove the

adapter. (Figure 18)

CAUTION

The stub shaft has four sharp diagonal

grooves in the end. Wear gloves to

prevent injuries to hands.

2. Loosen the two (2) set screws securing

the stub-shaft to the motor shaft.

Carefully remove the stub-shaft. The

stub-shaft is a tight fit, but can be

removed by applying pressure around

the periphery of the shaft with a pry-bar.

(Figure 19)

NOTE: Examine the shaft sealing surfaces for

nicks or scratches which can cause excessive

o-ring wear or leaking.

3. Remove the bolts securing the motor to

the mounting brackets. Bolt the new motor

to the mounting brackets. (Figure 20)

NOTE: Motor maintenance, repair, and wiring

are not covered in this manual. For specific

information contact the motor manufacturer.

If required, level the motor by rotating the

adjustable legs individually. (Figure 3 & 20)

WATER CASCADE - REPLACING MOTORS

MAINTENANCE

13. Remove the water cascade attachment

from the adapter, if included. Remove

the rubber shaft deflector by pulling it

straight off the stub shaft. Examine it for

tearing, loose fit, or other defects that

would allow liquid leakage into the motor

along the shaft. (Figure 17)

WARNING

TO AVOID SERIOUS INJURY, DO NOT

INSTALL OR SERVICE PUMP UNLESS ALL

POWER IS OFF AND LOCKED OUT.

13

n until the impeller pin

1. Mount the adapter to the motor with the

drain cavity at the bottom. Insert the four

bolts to secure the adapter to the motor.

(Figure 21)

2. Install half key in the motor shaft.

3. Place the stub-shaft assembly onto the

motor shaft. Do not tighten the shaft set

screws.

4. Install the backplate on the adapter and

rotate until the backplate pins engage the

adapter pins, assuring solid contact of the

backplate to the adapter. (Figure 21)

5. Rotate the stub shaft until the impeller

retaining hole is in a horizontal position.

Insert the impeller retainer pin, and center

it in the stub-shaft. Slide the impeller on

the shaft. Hold the impeller tight against

the shoulder in the shaft and rotate the

shaft one-quarter turn until the impeller pin

engages with the impeller. (Figure 22)

STUB SHAFT ADJUSTMENT

1. Push the stub-shaft/impeller assembly

toward the motor until the impeller strikes

the front face of the backplate.

2. Move the stub-shaft away from the

motor shaft to allow 1/16-inch maximum

clearance between the rear face of the

impeller and the front (inside) face of the

backplate. (See Figure 22)

3. Tighten the two set screws on the stub-

shaft.

4. Remove the impeller retainer pin, impeller,

and the backplate.

5. Slide the deflector (large diameter end

first) onto the shaft until it seats in the

shaft groove. (Figure 23)

NOTE: If the deflector cannot be forced on

with the fingers, use a blunt tool to tap it

evenly into place.

MAINTENANCE INSTALL ADAPTER-STUB SHAFT ADJUSTMENT

14

T

e drive

2. Assemble the spring, seal cup, o-ring, and

ease, the seal faces will be

. Make

impeller pin, center it in the shaft end, and

es the

d and tighten

in place. Assemble the suction line and the

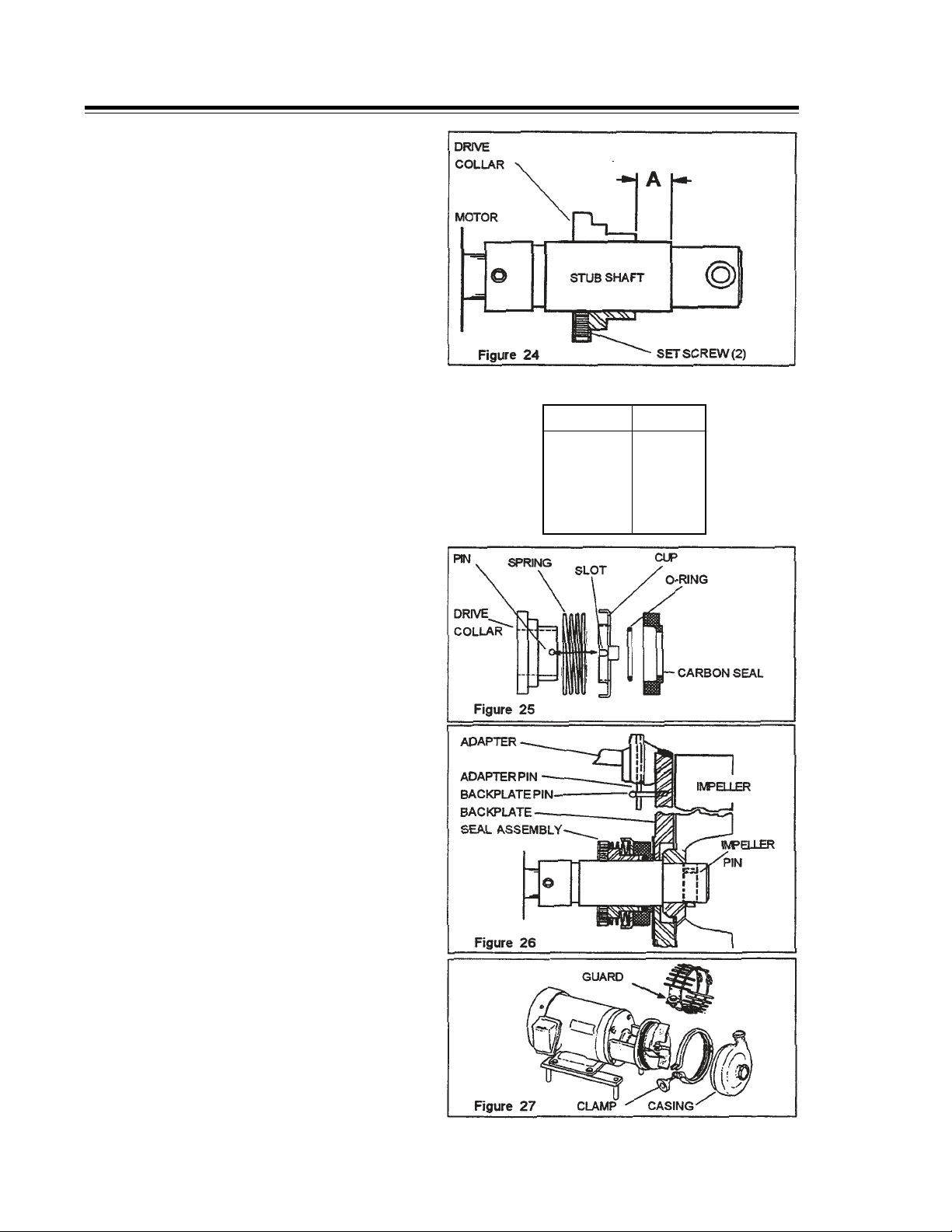

SEAL CHART for figure 24

MODEL A

TF-C114 9/16”

TF-C216 9/16”

TF-C218 9/16”

TF-C328 9/16”

(Models TF-C114 through TF-C328)

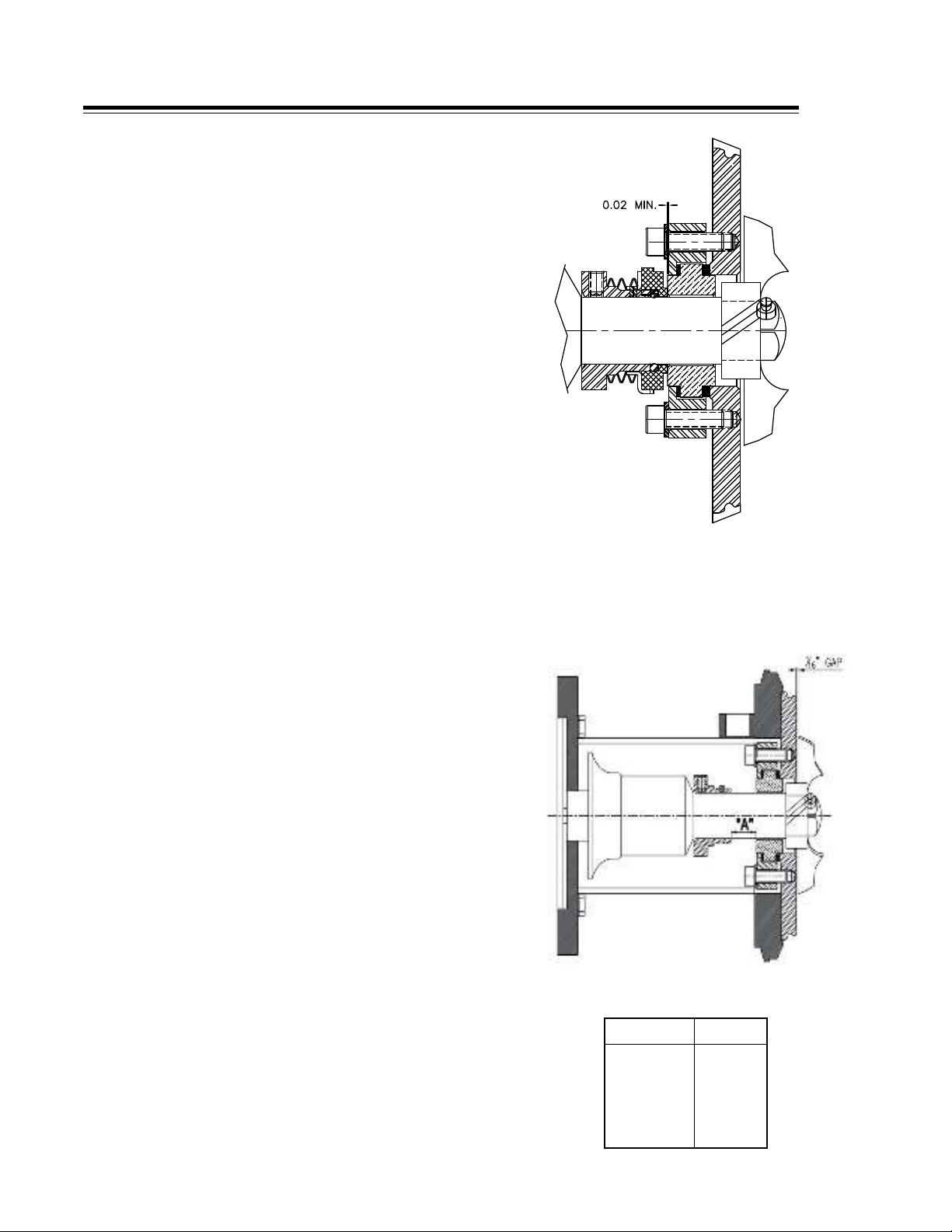

1. Slide the seal drive collar onto the stub

shaft as shown in Figure 24.

Use the “A” dimension in the SEAL CHART

to properly locate the drive collar on the

stub shaft. Tighten the set screws to

secure in place.

NOTE: TF-C100 pump does not require drive

collar.

2. Assemble the spring, seal cup, o-ring, and

carbon seal, and install as a unit. Make

sure the slot in the seal cup aligns with

the pin on the shaft. (Figure 25) Gentle

pressure on the o-ring will overcome

resistance on the shaft.

NOTE: Do not lubricate seals with any

type of oil or grease, the seal faces will be

lubricated by the product being pumped.

3. Assemble the gasket to the backplate.

Install the backplate on the adapter. Make

sure the seal cup slot is engaged with the

pin on the drive collar. (Figure 25)

4. Rotate the backplate until the backplate

pins engage the adapter pins. (Figure 25)

5. Rotate the shaft until the pin hole in the

end is in a horizontal position. Insert the

impeller pin, center it in the shaft end, and

slide the impeller on the shaft.

Hold the impeller tight against the stub

shaft and rotate the shaft one-fourth turn

until the impeller pin drops and secures the

impeller. (Figure 26)

6. Place the casing over the impeller/

backplate, close and tighten the clamp.

(Figure 27)

7. Assemble the cascade water fitting, if

included. Install the seal guard and tighten

in place. Assemble the suction line and the

discharge line to the casing.

NOTE: Check for strain or misalignment

of piping to the casing. Re-adjust the

casing ports and/or entire motor leveling as

necessary.

SEAL CHART for figure 24

MODEL A

TF-C114 9/16”

TF-C216 9/16”

TF-C218 9/16”

TF-C328 9/16”

MAINTENANCE DRIVE COLLAR ADJUSTMENT

15

MAINTENANCE “DG” SEALS

Disassembly

At each step in the disassembly, process parts should be inspected for nicks, cuts,

abrasions, and other wear. Replace parts if necessary. Care should be taken to protect

all sealing surfaces from being damaged during disassembly.

• Disconnect suction and discharge piping from pump casing.

• Remove seal guard and casing.

• Remove the impeller.

• Remove the backplate.

• Remove casing gasket from the backplate.

• Remove the carbon seal, seal cup, and spring from the stub shaft.

• Remove the gland ring, seal seat, and PTFE gaskets by removing the four cap screws.

®

®

* RECOMMENDED SPARE PARTS SEE KITS PAGE 25

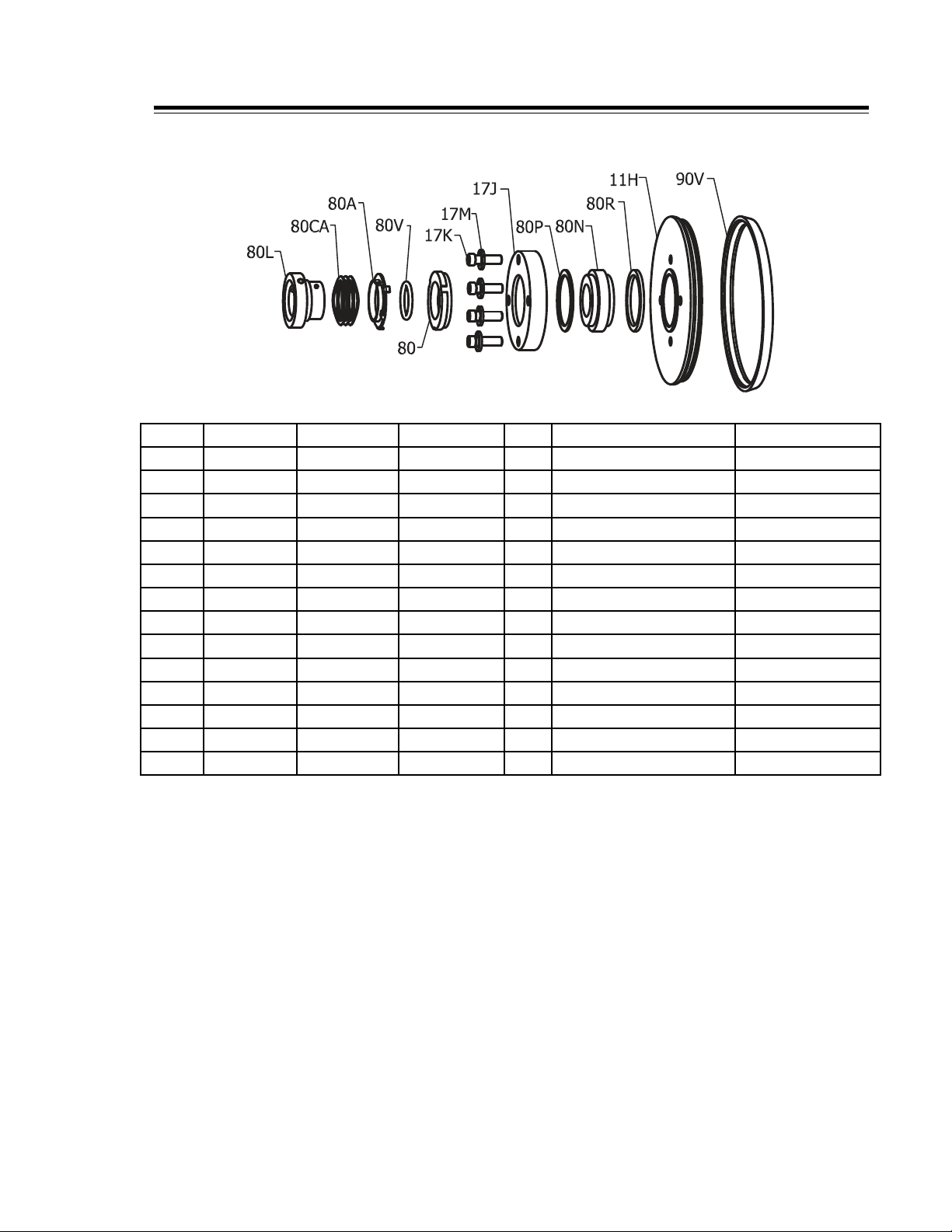

DG-SEAL

KEY C114 C216 C218/C328 QTY. DESCRIPTION MATERIAL

11H 564911H 566911H 568911H 1 BACKPLATE 316L SS

*80R 564980R 566980R 568980R 1 INBOARD GASKET 1/8” PTFE

*80N 564980N-SC 566980N-SC 588980N-SC 1 STATIONARY SEAT SILICONE CARBIDE

*80P 564980P 566980P 568980P 1 OUTBOARD GASKET 1/16” PTFE

17J 564917J 566917J 568917J 1 GLAND RING 304 SS

17K 564917K 568917K 568917K 4 BOLT/SCREW SS

*80 564980 566980 568980 1 ROTATING CARBON SEAL CARBON

*80V 564980V 566980V 568980V 1 O-RING SEAL FKM

80A 564980A 566980A 568980A 1 CUP 304 SS

*80CA 564980CA 566980CA 568980CA 1 SPRING SS

80L 564980L 566980L 568980L 1 DRIVE COLLAR 304 SS

17M WASHER 1/4 WASHER 5/16 WASHER 5/16 4 LOCK WASHER SS

*90V 564990V 566990V 568990V 1 CASING GASKET FKM

*24 564924 566924 568924 1 IMPELLER RETAINER PIN 316L SS

FIGURE 28

* RECOMMENDED SPARE PARTS

16

FIGURE 29

FIGURE 30

MAINTENANCE “DG” SEALS

Reassembly

Setting the Drive Collar - Measuring Method

1. Assemble the PTFE gaskets, seal seat, gland ring,

and secure to the back plate by uniformly tightening

the capscrews.

Note: The PTFE inboard (80R) and outboard (80P)

gaskets are different thicknesses. The thicker gasket

(80R) must always be installed on the impeller side

to prevent contact between the impeller hub and

the stationary seal.

2. Slide the drive collar onto the stub shaft.

3. Install the backplate and the casing gasket.

4. Install the casing and tighten the casing clamp.

5. Scribe a mark on the stub shaft behind the

backplate.

6. Set the drive collar to “A” dimension in the seal

chart and tighten the drive collar setscrew.

(Figure 30)

7. Remove the casing and backplate.

8. Assemble the spring, seal cup, o-ring, and carbon

seal onto the drive collar. The pin on the drive collar

must align with the slot in the cup.

9. Slide the backplate onto the stub shaft. Position

the impeller retaining pin in the center of the stub

shaft hole and install the impeller. Push the impeller

against the stub shaft and rotate the stub shaft

until the impeller retaining pin falls and secure the

impeller.

10.Check the impeller hub and seal face to ensure

there is a clearance between them before installing

the casing.

11.Reset the seal drive collar if required. When the

drive collar is positioned correctly and the seal

components are properly installed, the shaft should

rotate freely by hand.

12.Assemble the casing gasket, casing, and casing

clamp. Use a soft rubber mallet to line up the

casing. Tighten the casing clamp and install the

seal guard.

SEAL CHART

MODEL A

TF-C114 5/16”

TF-C216 5/16”

TF-C218 5/16”

TF-C328 5/16”

17

MAINTENANCE “DG” SEALS

1. Assemble the spring, seal cup, o-ring seal,

and carbon seal onto the drive collar. Care

must be taken so that the spring does not

rest on the tab that is bent back. A portion

of the spring is offset to provide clearance

for this tab. Care must be taken to ensure

the pin on drive drive collar is in line with

slot on cup.

2. Install as a unit on the shaft.

3. Install the backplate and casing.

4. Install and tighten the casing clamp.

5. Slide the drive collar and seal assembly

toward the backplate until the nose of the

drive collar pushes the o-ring and carbon

seal tight against the backplate.

6. Slide the drive collar away from the

backplace 1/32” (.79mm) and secure the

drive collar in this location with the set

screws.

7. When the drive collar is properly

positioned and the seal components are

properly installed, the pump shaft should

rotate freely by hand. If excessive effort

is required to rotate the shaft, check to

be sure that all components are properly

installed and the drive collar is properly

positioned.

Note: Extra care should be taken when assembling “TF-C”

series pumps with type “DG” or “F” seals. Incorrect

stub shaft settings will allow the impeller hub to

contact the inboard face of the stationary seal seat.

Interference of impeller hub and seal seat face will

cause wear of impeller hub and damage the inboard

or secondary seal face of the clamped-in-seat.

Visual inspection is recommended after installation

of the impeller and before installation of casing to

ensure clearance between the impeller hub and

seal face. If no clearance is visible, the pump should

be disassembled and stub shaft moved forward to

provide at least 1/32” (.79mm) clearance between

the impeller hub and seal seat face. Reset seal drive

collar if necessary.

Setting the Drive Collar – By Position for both “D” Seal & “DG” Seal

18

E-SEAL

KEY C114 C216 C218/C328 QTY. DESCRIPTION MATERIAL

17A CSHH1 566917A 568917A 4 BOLT/SCREW SS

17C WASHER 1/4 WASHER 5/16 WASHER 5/16 4 LOCKWASHER SS

17 564917 566917 568917 1 FOLLOWER 316L SS

*17B 564917B 566917B 568917B 1 O-RING FKM

83C 564983C 566983C-1 568983C 1 STUFFING BOX 316L SS

*83E 564983E 566983E 568983E 1 O-RING FKM

*80H 564980H 566980H 568980H 1 SPRING SS

80J 564980J 566980J 568980J 1 DRIVE COLLAR 304 SS

*80G 564980G 566980G 568980G 2 CUP 304 SS

*80V 564980V 566980V 568980V 2 O-RING FKM

*80 564980 566980 568980 2 CARBON SEAL CARBON

83D 564983D CSHH1 568983D 4 BOLT/SCREW 316L SS

11B 564911B 566911B 568911B 1 BACKPLATE 316L SS

*90V 564990V 566990V 568990V 1 CASING GASKET FKM

MAINTENANCE “E” SEALS

“E” water-cooled balanced double seal consists of two carbon seals inside a stuffing box attached to

the backplate. It is designed for applications where a vacuum-tight, cool operating seal is required.

FIGURE 31

FIGURE 31

* RECOMMENDED SPARE PARTS

Disassembly

At each step in the disassembly, process parts should be inspected for nicks,

cuts, abrasions, and other wear. Replace parts if necessary. Care should be

taken to protect all sealing surfaces from being damaged during disassembly.

• Disconnect suction and discharge piping from pump casing.

• Remove seal guard, casing, and impeller.

• Remove the 4 screws (17A) that retain the follower to the stuffing box.

• Remove the backplate and stuffing box.

• Remove the inboard carbon seal, seal cup, and seal spring.

• Remove the drive collar.

• Remove the carbon seal, seal o-ring, cup, and follower.

This manual suits for next models

5

Table of contents

Other Topline Water Pump manuals