TOPMAQ LST3700 Assembly instructions

REV032218 LST3700

37TON LOG SPLITTER

Instruction & Assembly

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

- 2 -

Table of Contents

General Warnings and Rules…………………………………………………….3

Hazard Signal Word Definitions………………………………………………….4

Controls and Features Identification……………………………………..…..….5

Assembly Instructions………………………………………………………..…...7

Operation Instructions…………………………………………………………..11

Maintenance and Storage………………………………………………………15

Troubleshooting………………………………………………………………….16

Specification……………………………………………………………………17

Parts Drawing & Parts List …………………………………………………...18

R

E

Operator

maintena

n

maintain

t

Operatio

n

Do n

o

Do n

o

Alwa

y

Repl

a

Alwa

y

Do n

o

Avoid

Alwa

y

Do n

o

Alwa

y

To av

Alwa

y

Alwa

y

.

Crush a

n

Alwa

y

Alwa

y

Alwa

y

splitt

e

.

The wa

r

possibl

e

commo

n

supplie

d

Assembl

y

This prod

u

weight an

assembly

missing o

E

AD and U

N

must read

n

ce and sto

r

t

he log split

t

n

Warning

s

o

t at any tim

e

o

t allow chil

d

y

s inspect t

h

a

ce or repai

r

y

s check an

d

o

t exceed e

q

large holes

y

s operate t

h

o

t operate t

h

y

s tow at re

d

oid person

a

y

s refer to t

h

y

s secure a

n

n

d Cut Haz

a

y

s keep han

d

y

s clear and

y

swear saf

e

e

r.

r

nings, ca

u

e

condition

s

n

sense a

n

d

by the op

e

y

Is Requi

re

u

ct requires

d/or size of

. INSPECT

r damaged.

N

DERSTAN

D

and unde

r

age instruc

t

er could re

s

s

e

carry pas

s

d

ren to play

h

e log splitte

r

damaged

o

d

tighten ha

r

q

uipment m

a

and ditche

s

h

e log splitt

e

h

e log splitte

d

uce speed

a

l injury and

/

h

e vehicle o

w

n

d lock the l

o

a

rds

d

s and feet

keep work

a

e

ty gear, e

y

u

tions, and

s

or situati

o

n

d caution

a

e

rator.

re

d

assembly

b

the log split

ALL COM

P

GENE

R

D

this man

u

rstand all

s

tions befor

e

s

ult in serio

u

s

engers, sit

on, stand u

p

r before usi

n

o

r worn part

s

r

dware and

a

ximum loa

d

s

when towi

n

e

r on clear

a

r at night, o

n

in rough ter

r

/

or equipme

w

ner’s man

u

o

g splitter t

o

clear from

m

a

rea clean

a

y

e protectio

n

instruction

s

o

ns that m

a

a

re factors

b

efore use.

S

ter, it is rec

o

P

ONENTS c

l

- 3 -

R

AL WA

R

u

al comple

t

s

afety and

e

operating t

h

u

s injury to t

h

or stand on

p

on or clim

b

n

g to assur

e

s

immediat

e

assembled

d

capacity o

f

n

g the equi

p

a

nd level gr

o

n

ly during d

a

r

ain, along

c

nt damage

D

u

al for prop

e

o

the vehicl

e

m

oving part

s

a

nd free of

d

n

, gloves a

n

WARNIN

G

s

outlined

a

y occur.

I

which can

S

ee “Asse

m

o

mmended

t

l

osely upon

R

NINGS

t

ely before

warning in

h

is equipm

e

h

e operator

the log spli

t

b

on the log

e

it is in goo

d

e

ly.

parts befor

e

f

37 tons.

p

ment.

o

und.

a

ylight hou

r

c

reeks, ditc

h

D

O NOT E

X

e

r towing.

e

hitch befor

e

s

while oper

a

d

ebris when

n

d work bo

o

G

in this inst

r

I

t must be

not be bui

l

m

bly” sectio

n

t

hat anothe

r

receipt to

m

using 37 T

o

formation,

o

e

nt. Failure

t

or bystand

e

t

ter.

splitter.

d

working c

o

e

operation.

r

s.

h

es and on

h

X

CEED 45

M

e

towing.

a

ting the eq

operating.

o

ts when o

p

r

uction ma

n

understoo

d

l

t into this

n

for instruct

r

adult be pr

e

m

ake sure n

o

o

n Log Spl

i

o

perating i

n

t

o properly

o

e

rs.

o

ndition.

h

illsides.

M

PH (72KP

H

uipment.

p

erating th

e

n

ual cann

o

d

by the op

product an

ions. Becau

e

sent to as

s

o

compone

n

i

tte

r

.

n

structions,

o

perate and

H

)

e

log

t cover all

erator that

d must be

se of the

s

ist with the

n

ts are

ABOU

This hydr

a

work to b

e

done fast

.

and main

t

Technical

H

a

T YOU

R

a

ulic log spl

e

done, you

.

It is design

e

t

ain. Never

e

specificati

o

D

W

A

C

A

CA

a

zard

R

37 TO

N

itter has a

h

need outd

o

e

d to work i

n

e

xceed the

o

ns on the l

o

D

AN

G

A

RNI

N

A

UTI

O

UTIO

N

Sign

a

N

LOG

S

h

eavy-duty

s

o

or power e

q

n

horizontal

rated capa

c

o

g splitter ar

e

G

ER

N

G

O

N

N

- 4 -

a

l Wo

S

PLITTE

s

teel constr

u

q

uipment yo

position an

d

c

ity of 37 to

n

e

provided i

This is

you to

safety

m

possib

l

DANG

E

situati

o

or seri

o

WARNI

N

situati

o

death

o

CAUTI

O

situati

o

or mod

CAUTI

O

indicat

e

if not a

v

r

d D

e

R

u

ction and 3

7

u can rely

o

d

vertical po

n

s when op

e

n the “Spec

the safet

y

potential

p

m

essages

l

e injury or

E

R indica

t

o

n which, i

f

o

us injury.

N

G indic

a

o

n which,

o

r serious i

n

O

N indic

a

o

n which, if

erate injur

y

O

N used

w

e

s a poten

t

v

oided, ma

e

finiti

o

7

tons of ra

m

o

n, this log s

sition. It is

e

e

rating the l

o

ifications” s

e

y

alert sym

b

p

ersonal in

j

that follo

w

death.

t

es an i

m

f

not avoid

e

a

tes a

p

if not av

o

n

jury.

a

tes a p

not avoid

e

y

.

w

ithout th

e

t

ially haza

r

y result in

p

o

ns

m

force. Wh

plitter will g

e

e

asy to tow,

e

o

g splitter.

e

ction of thi

s

b

ol. It is u

s

j

ury hazar

d

w

this sym

b

m

minently

e

d, will res

p

otentially

o

ided, coul

otentially

e

d, may res

e

safety a

l

r

dous situ

a

p

roperty d

a

en there's

e

t the job

e

asy to use

s

manual.

s

ed to ale

r

d

s. Obey a

l

b

ol to avoi

d

hazardou

s

ult in deat

h

hazardou

s

d result i

n

hazardou

s

ult in mino

l

ert symb

o

a

tion whic

h

a

mage.

r

t

l

l

d

s

h

s

n

s

r

o

l

h

,

- 5 -

Read this owner’s manual before operating the equipment. Familiarize yourself with the location and

function of the controls and features. Save this manual for future reference.

1) 50MM Coupler

2) Hydraulic Cylinder

3) Control Valve

4) 8” Wedge

5) Log Cradle

6) Beam

7) Log Cradle

8) Fill Plug

9) Tires

10) Engine

11) Gear Pump

12) Jockey Wheel

13) Safety Chains

Controls and Features Identification

37 T

O

Set the

all part

s

before

s

TOOL

S

R

u

1

3

L

a

P

h

P

l

Read an

d

equipme

n

O

N LOG

S

shipping cr

a

s

out of the

s

s

tarting to a

s

S

REQUIRE

D

u

bber or W

o

3

mm, 16m

m

a

rge Adjust

a

h

illips Scre

w

l

iers

d

follow all

n

t could re

s

S

PLITT

E

a

te on a sol

s

hipping cra

s

semble th

e

D

o

oden Ham

m

m

, 17mm, 1

8

a

ble Wrenc

h

w

drive

r

E

n

B

e

S

e

H

y

W

o

f

In

If

d

e

instructio

n

s

ult in serio

u

E

R ASSE

id flat surfa

c

te and insp

e

e

log splitter

m

er

8

mm, 19mm

h

n

gine Ship

p

e

fore startin

e

e engine

m

y

draulic Oi

l

W

hen adding

f

hydraulic o

spect all L

o

you have

d

e

livered the

n

s for asse

m

u

s injury to

t

- 6 -

MBLY

c

e and car

e

e

ct the com

p

follow step

s

, 24mm, 27

m

p

ed Witho

u

g engine, fil

m

anual for e

n

l

Tank is S

h

oil verify th

e

il tank if ma

r

o

g Splitter

C

d

amaged c

o

log splitter

a

CAUTIO

N

m

bly and

o

t

he user or

e

fully remov

e

p

onents to

e

s

1 through

8

m

m Wrenc

h

u

t Oil.

l with SAE

1

n

gine oil ca

p

h

ipped Wit

h

e

oil level u

s

r

king is not

s

C

omponen

o

mponents:

a

nd file a cl

a

N

o

peration.

F

bystander

s

e

the lid. U

s

e

nsure ther

e

8

.

h

es

1

0W-30 mot

p

acity.

h

out Oil.

s

ing the Oil f

s

hown fill to

ts.

Contact t

h

a

im.

F

ailure to

p

s

, or cause

e

s

e two peop

e

are no mis

s

or oil.

ilte

r

/Dip Sti

c

the L line.

h

e freight c

o

p

roperly as

s

e

quipment

le and take

s

ing pieces

c

k on the to

p

o

mpany tha

t

s

emble thi

s

damage.

p

t

s

- 7 -

STEP 1: Attach Wheel

1. Attach the wheel (#35) to the hydraulic reservoir axle (#44) using a bearing (#82), flat washer

Ø20 (#54) and tighten the wheel with the hex slotted nut M20 (#37). Lock the hex slotted nut

M20 (#37) in place using the cotter pin Ø4x36 (#73). Install the axle cap (#41) on the end using

rubber hammer.

Note: flat washer Ø20 (#54), hex slotted nut M20 (#37) and cotter pin Ø4x36 (#73) are already

assembled in the log splitter.

2. Attach engine mounting plate (#95) to the hydraulic reservoir using hex lock nut M10 (#83), flat

washer Ø10 (#84) and hex bolt M10x30 (#85).

STEP 2: Attach Tow Bar to the Hydraulic Reservoir

1. Attach the tow bar (#62) to the hydraulic reservoir and secure using two hex bolt M12x100

(#24), flat washer Ø12 (#65) and nylon lock nut M12 (#13).

Assembly Instructions

WARNING: After tightening the slotted nut,

loosen nut 1/4 of a turn so the tire will rotate

freely. Failure to loosen the nut may cause

excessive bearing and tire wear.

- 8 -

STEP 3: Attach the Beam Assembly

1. Attach the beam assembly (#17) to the hydraulic reservoir and secure using the hitch pin (#18)

and R Pin (#21).

STEP 4: Attach Engine and Hydraulic Hose

1. Place four polyurethane blocks (#55) and large flat washer Ø10 (#58) in the mounting plate.

2. Position the engine (#33) over the blocks and washers, secure it to the mounting plate, put the

hex bolt M10x75 (#46) through the bottom of the plate (bolt should go through blocks, flat

washer and engine base). Place a lock washer Ø10 (#90), flat washer Ø10 (#84) and tighten

with nylon lock nut M10 (#83)

3. Attach the clear oil pipe (#53) to the bottom of the gear pump and secure with clamp (#51).

4. Put O ring Ø14x2.5 (#19) on the gear pump outlet connector (#23), attach the hydraulic hose

(#16) to the joint of gear pump (#23).

5. Put O ring Ø17x2.5 (#71) on the connector of hydraulic reservoir, attach the hydraulic hose (#7)

to the connector.

STEP

5

1. A

t

(

#

2. A

t

w

a

(

#

STEP

6

1.

M

2.

R

3.

R

o

4.

C

NOTE: D

u

STEP

7

1.

U

2.

D

3.

R

i

n

4.

S

DO NOT

type and

a

void your

5

: Attac

h

t

tach the lo

g

#

84) and nyl

o

t

tach the fe

n

a

sher Ø8 (

#

#

79) in the

m

6

: Add E

n

M

ake sure t

h

R

emove oil f

i

R

efer to the

il; replace o

C

heck engin

e

u

ring the b

r

7

: Add G

U

se only cle

a

D

O NOT mi

x

R

emove the

n

ch of spac

e

S

crew on th

e

attempt to

c

a

mount of

o

warranty.

h

Log Ta

b

g

tables (#7

7

o

n lock nut

M

n

ders (#34

&

#

36), lock w

a

m

iddle o

f

hy

d

n

gine Oi

h

e log splitt

e

i

ll cap/dipsti

separate o

w

il fill cap/di

p

e

oil level d

a

r

ea

k

-in per

i

asoline

t

a

n, fresh, re

x

oil with fue

fuel cap an

d

e

for fuel ex

p

e

fuel cap a

n

c

rank or sta

r

o

il. Damage

b

les and

7

& #78) to

t

M

10 (#83).

&

#50) to th

e

a

sher Ø8 (#

3

d

raulic rese

r

l

e

r is on a le

v

ck to add oi

w

ner’s engi

n

p

stick.

a

ily and ad

d

i

od check

t

t

o the E

n

gular unlea

d

l.

d

slowly ad

d

p

ansion.

n

d wipe aw

a

r

t the engin

e

to the log

s

- 9 -

Fender

s

t

he beam u

s

e

hydraulic

r

3

2) and nyl

o

r

voir and fe

n

v

el surface.

l.

n

e manual

f

d

as needed

.

t

he engine

o

n

gine

d

ed fuel wit

h

d

fuel to the

t

a

y any spille

d

CAUTIO

N

e

before it

h

s

plitter as a

s

s

ing hex bol

t

r

eservoi

r

usi

o

n lock nut

M

n

der.

o

r the amo

u

.

o

il level oft

e

h

a minimu

m

t

ank. DO

N

d

fuel.

N

h

as been pr

o

result of fai

l

t

M10x30 (

#

ng hex bolt

M

8 (#31). A

t

u

nt needed

e

n.

m

86 octane

N

OT overfill

o

perly filled

l

ure to follo

w

#

85), flat wa

s

M8x25 (#8

9

t

tach rubber

of SAE10

W

rating.

allow appr

o

with the re

c

w

these inst

s

her Ø10

9

), flat

washer

W

-30 engine

o

ximately ¼

c

ommended

ructions will

Log splitt

e

carbon m

to fresh a

Operate l

o

DO NOT

DO NOT

openings

.

DANGE

R

Fuel and

Fire or e

x

Unintenti

o

Only use

DO NOT

Fill tank

a

DO NOT

DO NOT

STEP

8

1.

T

2.

R

3.

A

o

b

4.

C

5.

S

f

r

6.

W

DO NO

T

causing

oil cap.

High flui

escape

t

Inspect

h

the sys

t

Make su

servicin

g

Make su

Hoses n

e

bodily in

j

e

r engine e

x

onoxide wil

l

ir immediat

e

o

g splitter o

operate the

allow exh

a

.

R

CARBON

fuel vapors

x

plosion can

o

nal startup

regular unl

e

mix oil and

g

a

pproximate

fill fuel tank

light cigaret

8

: Add H

y

T

he log split

t

R

emove the

A

dd 4.3 gall

o

f fluid. Au

t

b

elow 32 de

C

heck the h

y

S

tart engine

r

om the line

s

W

ith the we

d

T

remove t

h

severe bur

n

d pressure

t

hrough a pi

h

ydraulic s

y

t

em is pres

s

re all fitting

s

g

.

re the hydr

a

e

ed to be p

o

j

ury always

x

haust cont

l

cause nau

s

e

ly.

utdoors onl

y

log splitter

a

ust fumes

MONOXID

E

are highly fl

cause sev

e

can result i

n

e

aded gasol

g

asoline to

g

ly ¼” below

indoors or

w

tes or smo

k

y

draulic

t

er needs to

oil cap fro

m

o

ns of hydra

t

omatic tra

grees (all u

y

draulic oil l

e

and use th

e

s

.

d

ge retracte

d

h

e hydrauli

c

n

s. Always

a

and tempe

n-size hole

o

y

stem regul

a

s

urized. S

e

s

are tight a

n

a

ulic hoses

d

o

sitioned w

e

inspect the

ains carbo

n

s

ea, dizzin

e

y

in a well v

e

inside any

b

to enter a

E

, using a l

o

ammable a

n

e

re burns or

n

entangle

m

ine with a

m

g

ether.

the top of t

h

w

hen the e

n

k

e when filli

n

Oil

be on a fla

t

m

the hydrau

ulic oil AW

3

nsmission

nits are tes

t

e

vel.

e

control lev

e

d

, check hy

d

c

oil fill cap

a

llow the lo

g

ratures are

o

pening an

d

a

rly for pos

s

e

ek medical

n

d secure b

d

o not touc

h

e

re they are

hoses befo

r

- 10 -

DANGE

R

n

monoxide,

e

ss, fainting

e

ntilated ar

e

b

uilding, en

c

confined

a

o

g splitter in

d

CAUTIO

N

n

d extremel

death.

m

ent, traum

a

m

inimum 86

h

e tank to a

l

n

gine is run

n

n

g the fuel t

a

t

, level surfa

lic reservoir

.

3

2, AW46 &

fluid shoul

t

ed and hav

e

e

r to extend

d

raulic oil le

v

WARNIN

when the

g

splitter to

created in

d

can punct

u

s

ible leaks.

N

attention i

efore applyi

h

any hot su

clear from

t

r

e operating

R

a colorless

or death. If

e

a.

c

losure or c

o

a

rea throug

h

d

oors CAN

K

N

y explosive

.

a

tic amputat

octane rati

n

l

low for fuel

n

ing or hot.

a

nk.

ce before a

d

.

universal h

y

d be used

w

e

excess oil

and retract

v

el again a

n

G

engine is r

u

cool compl

e

the hydrau

l

u

re skin an

d

N

ever che

c

mmediatel

y

ng pressur

e

rfaces or c

u

t

he engine

a

the log spli

t

, odorless,

p

you start t

o

o

mpartment

.

h

windows,

K

ILL YOU I

.

ion or lacer

a

n

g.

expansion.

d

ding the h

y

y

draulic oil

a

w

hen oper

a

in the ram)

wedge sev

e

n

d fill if nec

e

u

nning o

r

h

e

tely before

l

ic log split

t

d

cause sev

e

c

k for leaks

y

if injured

e

. Relieve

s

u

tting areas.

a

nd cutting

w

t

ter.

poison gas.

o

feel dizzy

o

.

doors, ve

n

N MINUTE

S

a

tion.

y

draulic oil.

a

re all acce

p

a

ting in te

m

.

e

ral times to

e

ssary.

ot. Hot oil

removing t

h

t

ers. Hydra

u

e

re blood p

o

with your

by escapin

s

ystem pre

s

w

edge. To a

v

Breathin

g

o

r weak, ge

t

n

ts or othe

r

S

.

p

table types

m

peratures

remove air

can escap

e

h

ehydrauli

c

u

lic fluid wil

l

o

isoning.

hand whil

e

g fluid.

s

sure befor

e

v

oid seriou

s

g

t

r

e

c

l

e

e

s

Before

o

Failure

t

bystand

e

ALWAY

S

ONLY u

s

NEVER

NEVER

ONLY o

p

NEVER

DO NO

T

serious

b

ALWAY

S

DO NO

T

NEVER

or medi

c

USING

Y

1. D

O

2. C

h

3. In

4. B

e

DO NO

T

DO NO

T

DO NO

T

5. R

e

Serious

Always

c

Before t

o

place.

Always

u

Drive sa

f

Never e

x

Never ri

d

Turn off

t

Block th

e

o

perating o

r

t

o follow t

h

e

rs.

S

use the l

o

s

e the log s

p

modify, alte

attach a ro

p

p

erate the l

o

leave the lo

T

change th

e

b

urns.

S

make sur

e

T

let the bea

operate or l

e

c

ation.

Y

OUR LO

G

O

NOT at a

n

h

eck the hy

d

spect the e

n

e

fore towin

g

T

over inflat

e

T

tow the lo

g

T

exceed th

e

e

fer to the

v

injury or de

a

c

heck the b

a

o

wing a lo

n

u

se safety c

f

ely. Be aw

a

x

ceed the

m

d

e or transp

t

he vehicle

b

e

log splitte

r

r

using the

h

ese instru

c

o

g splitter fo

r

p

litter to spl

i

r or change

p

e, cable or

o

g splitter in

g splitter un

e

splitting p

o

e

the beam

m drop as i

t

e

t anyone

e

G

SPLITT

E

n

y time car

r

d

raulic oil l

e

n

gine and

m

g

the log spl

i

e

tires. Seri

o

g

splitter if t

h

e

maximum

4

v

ehicle own

e

a

th can occ

u

a

ll coupler a

n

g distance

hains, secu

r

a

re of the a

d

m

aximum tra

v

ort cargo o

n

b

efore leavi

n

r

wheels to

p

O

log splitter,

c

tions may

r

its intende

d

i

t wood logs

the log spli

t

other devic

e

daylight.

attended w

h

o

sition with

t

is in the loc

k

t

could crus

h

e

lse operate

,

E

R

r

y passenge

e

vel and vis

u

m

ake sure th

i

tter the tire

s

T

o

us injury c

a

h

e tires are

w

4

5 MPH to

w

e

r’s manual

TO

W

u

r if towing

s

nd wheels t

o

check to m

r

e and lock

t

d

ded length

o

v

el speed o

f

n

the log spl

i

n

g the log s

p

revent uni

n

O

perat

i

- 11 -

WARNI

N

r

eview th

e

result in

p

WARNI

N

d

use.

, length wis

e

t

ter in anyw

a

e

to the con

t

h

ile the eng

i

t

he engine r

u

k

ed positio

n

h

fingers or

,

the log spl

i

rs, sit or st

a

u

ally inspec

t

e engine oil

s

need to b

e

T

IRE WAR

N

a

n result if ti

r

w

orn or will

n

w

ing speed.

for proper s

W

ING WA

s

afety rules

o

make sur

e

ake sure t

h

t

he log split

t

o

f the log s

p

f

45 mph.

i

tter.

plitter unatt

e

n

tended mo

v

i

on In

s

N

G

e

instruction

s

p

roperty da

m

N

G

e

with the g

r

a

y, modific

a

t

rol lever on

i

ne is runni

n

u

nning. Co

n

n

.

cause dam

a

i

tter while u

n

nd on the l

o

t

all hoses a

level is cor

r

e

fully inflat

e

N

ING

r

es explode

n

ot hold air.

afety and t

o

RNING

are not foll

o

e

all hardwa

h

e axle nut

s

t

er to the ve

p

litter.

e

nded.

v

ement.

s

tructi

o

s

below an

m

age or in

j

r

ain.

a

tions will v

o

the log spli

t

n

g.

n

tact with th

e

a

ge to the l

o

n

der the infl

u

o

g splitter.

nd attachm

e

r

ect.

e

d.

o

wing instru

c

o

wed.

re is secur

e

s

and pins

a

hicle hitch

b

o

ns

d all safet

y

j

ury to the

o

id the warr

a

t

ter.

e

muffler ca

o

g splitter.

u

ence of al

c

e

nts for pro

b

c

tions.

e

before tow

i

a

re tight an

d

b

efore movi

n

informatio

n

operato

r

o

a

nty.

n cause

c

ohol, drugs

b

lems.

i

ng.

d

securely i

n

g.

n

.

o

r

,

n

- 12 -

6. The log splitter must have at least seven feet of clearance from combustible material. It needs to

be on a dry and level surface with good footing. Do not work on mud, ice, brush or snow. When

using the log splitter the work zone must be maintained at all times.

NOTE: Serious accidents can happen when other people are allowed inside the work zone.

Keep everyone else outside the work zone while operating the control lever.

7. Always wear safety gear, eye protection, gloves and work boots when operating the log splitter

8. Start the engine and make sure the log splitter is on level ground before operating.

NOTE: The hydraulic oil needs to be above 10°F (-12C°) before starting the engine. Cold

hydraulic oil can damage the hydraulic pump. If outdoor air temperature is below 32°F (0C°)

allow the log splitter to warm up by extending and returning the wedge several times before

splitting wood.

9. Put both support legs in the down position to prevent the log splitter from moving during

operation and block both tires.

10. Set the log splitter in horizontal position.

NOTE: HORIZONTAL position is used for lighter logs that can easily be loaded onto the beam.

Back injury can result from lifting logs onto the log splitter if proper lifting techniques are not

used.

11. L

o

12. M

Wedge

c

Serious

else out

DO NO

T

Only us

e

13. P

u

14. P

u

If a log g

e

and allo

w

If the log

s

and crow

ALWAYS

15. A

l

o

ad a log o

n

ake sure h

a

c

an cut thro

u

accidents

c

of the work

T

wear loos

e

e

the log spl

u

sh control

l

u

sh control

l

e

ts stuck, e

m

w

the splitter

s

till remain

s

bar to rem

o

keep hand

s

l

ways keep

w

n

to the bea

m

a

nds are cle

a

u

gh skin an

d

c

an happen

zone while

e

clothing. It

itter in dayli

g

l

eve

r

FOR

W

l

eve

r

BACK

W

m

bedded or

to strip the

s

stuck, em

b

o

ve the log.

s

clear of th

e

w

ork zone

c

m

against th

e

a

r from the

w

C

R

d

break bon

when othe

r

operating c

o

can get tan

g

g

ht so you

c

W

ARD by on

e

W

ARD by o

will not spli

t

log from th

e

b

edded or w

e

log and w

e

c

lean and fr

e

- 13 -

e

endplate (

w

edge and

c

R

USH WA

R

es. Keep b

o

r

people ar

e

o

ntrol lever.

g

led in mov

c

an see wh

a

e

hand to s

p

ne hand to

r

CAUTIO

N

t

completel

y

e

wedge.

ill not split,

t

e

dge while i

e

e of split w

o

Max Log L

e

c

rush haza

r

R

NING

o

th hands a

w

e

allowed in

s

ing parts of

a

t you are d

o

p

lit the log.

r

eturn wedg

N

y

, push the

c

t

urn the ma

c

t is retracti

n

o

od and de

b

e

ngth-21.65”

r

d areas.

w

ay from w

e

s

ide the wo

log splitter.

o

ing.

e to its origi

c

ontrol lever

c

hine off an

d

n

g.

b

ris.

)

e

dge and b

e

rk zone. K

e

nal position

in the reve

r

d

use a sled

e

am slide.

e

ep everyon

r

se direction

ge hammer

e

- 14 -

Operation Instructions

MAINT

B

e

th

p

r

A

f

b

a

B

e

R

e

A

f

s

e

P

e

A

n

U

s

N

e

W

h

Hoses

Hydrauli

c

Nuts an

d

Beam

Moving

P

Refer t

o

IMPORT

A

If a part n

parts that

STOR

A

B

e

Li

g

S

t

Impro

p

ENANC

E

e

fore perfor

m

e engine

a

r

essure.

f

ter perform

a

ck in place

e

fore opera

t

e

gularly gr

e

f

ter the wh

e

e

cure.

er

iodically c

n

nually clea

s

e a glossy

e

ver excee

d

h

at

c

Fittings

d

Bolts

P

arts

o

the Engi

n

A

NT:

eeds repla

c

do not me

e

A

GE

e

fore storin

g

g

htly lubric

a

t

ore indoors

p

er mainten

E

m

ing maint

e

a

nd move

t

ing any ma

i

before ope

r

t

ing make s

u

e

ase axle a

n

e

el bearin

g

s

heck all fas

t

n and lightl

y

enamel spr

a

d

load capa

c

Wh

Each Us

e

Each Us

e

Each Us

e

Each Us

e

Each Us

e

n

e Owner

’

c

ement, onl

y

e

t specificati

o

g

make sur

e

a

te all log s

p

or protecte

d

M

a

ance and

s

e

nance, the

t

he control

i

ntenance,

m

r

ating the lo

g

u

re the tires

n

d wheel b

e

have been

g

t

eners and

h

y

lubricate a

a

y paint to t

o

c

ity rating o

f

en

e

e

e

e

e

’

s Manual

y

use parts

t

o

ns may re

s

e

the log spli

p

litter surfac

e

d

area duri

n

a

inten

a

- 15 -

WAR

N

s

torage of t

h

log splitter

m

lever forw

a

m

ake sure

a

g

splitter.

have the R

e

aring area

g

reased ma

k

h

oses for tig

ll moving p

a

o

uch up sc

r

f

37 tons it

w

Inspect h

o

Replace

a

starting th

Inspect fit

t

damaged

Check for

A

pply gre

a

Clear deb

r

for engin

t

hat meet th

s

ult in a saf

e

tter is clean

e

s and mov

i

n

g severe w

e

a

nce a

n

N

ING

h

e log splitt

e

m

ust be pla

c

a

rd and ba

a

ll guards,

s

ECOMME

N

or when n

e

k

e sure the

a

htness and

a

rts or whe

n

r

atched or

w

w

ill damage

t

o

ses for e

x

a

ll worn or

d

e engine.

t

ings for c

r

fittings be

f

loose bolt

s

a

se to bea

r

is from lo

g

e mainte

n

e manufact

u

e

ty hazard

o

and dry for

i

ng parts to

e

athe

r

and

w

n

d Sto

e

r may voi

d

c

ed in main

t

ckwards to

s

hields and

s

N

DED TIRE

e

eded.

a

xle nuts a

n

leaks.

n

needed.

w

orn painted

t

he log split

t

How

x

posed wir

e

d

amaged

h

r

acks and

l

f

ore starti

n

s

, tighten

b

m surface

g

splitter.

n

ance.

u

rer’s speci

f

o

r poor oper

a

years of tr

o

prevent rus

t

w

inter mont

h

rage

d

your warr

a

t

enance mo

d

relieve th

e

s

afety featu

PRESSUR

E

n

d pins are i

n

metal surf

a

t

er.

e

mesh an

h

oses bef

o

l

eaks. Re

p

n

g the engi

b

efore op

e

.

f

ications. R

e

a

tions.

o

uble free s

e

t

.

h

s.

a

nty.

d

e. Turn off

e

hydraulic

res are put

E

.

n

place and

ces.

d leaks.

o

re

p

lace all

ne.

e

rating.

e

placement

e

rvice.

- 16 -

Problem

Cylinder rod will not move SOLUTION: A,D

Slow cylinder rod speed when extending

or retracting SOLUTION: A,B,D,I

Wood will not split or splits extremely

slowly SOLUTION: A,B,D,G,I

Valve will not stay in detent or will not kick

out of detent position SOLUTION:H

Engine bogs down during splitting SOLUTION: This is normal

Engine stalls under low load condition SOLUTION: L

Engine will not start SOLUTION: C,E,F

Engine is difficult to turn over and will not

start when cold SOLUTION:J

Engine runs but cylinder does not move SOLUTION: D,K

Cause Solution

A-Insufficient oil to pump Check oil level in reservoir

B-Air in oil Check oil level in reservoir

C-Low engine oil Check and add engine oil

D-Blocked hydraulic lines Check for restriction

E-“ON”/“OFF” Move to “ON” position

F-Fuel shut off in “OFF” position Move to “ON” position

G-Damaged control valve Return control valve for authorized repair

H-Detent setting incorrect Remove plastic cap on valve and adjust

detent kick out pressure

I-Internally damaged cylinder Return cylinder for authorized repair

J-Cold ambient temperature Cold weather (below 32°) can result in

difficult engine starting. Change toATF.

K-Broken pump / Engine coupler Check and replace coupler

L-Defective pump or engine Contact service center

Troubleshooting

- 17 -

Max. Force ....................................................................................................37Ton

Cycle Time.........................................................................................................15s

Max. Log Length............................................................................ 21.65” (550mm)

Hydraulic Cylinder...................................................4.9” x19.4” (127mm x 493mm)

Max. Pressure..............................................................................26Mpa (3800psi)

Gear Pump...................................................................................17GPM, 2-Stage

Max. Towing Speed.....................................................................45 MPH (72KPH)

Wheel Size................................................................................ 16inches ( 4.8 x 8)

NOTE: For Engine Details Refer to the Engine Owner’s Manual.

Specifications

- 18 -

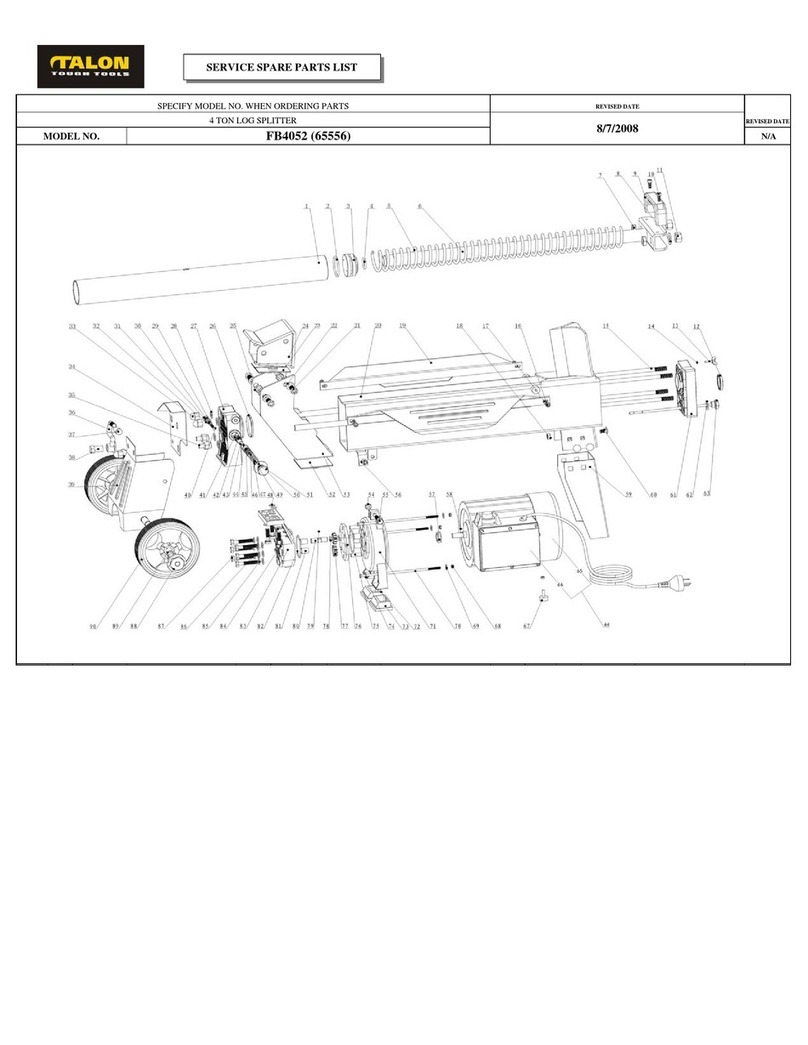

Parts Drawing & Parts List

- 19 -

Ref# Drawing No. Description Qty

1 9306-12000-DX Lock Washer Ø12 10

2 9121-06010-FH Inner Hex Cone Point Set Screw M6x10 1

3 LST37-07000 Cylinder 1

4 LST37-00007 Hydraulic Hose(valve-cylinder) 1

5 LSP25-00005-DX R Pin 2

6 LSP30-00004-DX Cylinder Pin 1

7 LST3000-00003 Hydraulic Hose(valve-connector of reservoir) 1

8 LST37-00002-DX Connector 2

9 LSM30-05000 Control Valve 1

10 LSP25-17000 Combination Connector 1

11 LST37-00016-DX Connector 1

12 LSP25-00006-DX Safety Pin 1

13 9206-12000-DX Nylon Lock Nut M12 5

14 LSE35-04000 Wedge Slide 1

15 9101-14080-DX8.8 Hex Bolt M14x80 1

16 LST3000-00002 Hydraulic Hose(valve-Gear Pump) 1

17 LST3700-01000 Beam 1

18 LSP25-05000 Hitch Pin 1

19 9901-14X2.5 O Ring Ø14x2.5 2

20 LSP25-00010-DX Oil Plug 1

21 LSP25-00012-DX R Pin 1

22 9901-11X2.5 O Ring Ø11x2.5 2

23 LSE35-00002-DX 130°Joint 1

24 9101-12100-DX8.8 Hex Bolt M12x100 4

25 LSP37B-02001 Gear Pump 15/3.0 1

26 LSP25-13000 Fill Plug 1

27 LSP35-02003 Gear Pump Coupling 1

28 LS35-02007 Engine Coupling 1

29 LSP35-02004-DX Engine Axle Sleeve 1

30 LSP35-20005 Gear Pump Stand 1

31 9206-08000-DX Nylon Lock Nut M8 10

32 9306-08000-DX Lock Washer Ø8 14

33 LST3700-10000 Engine 1

34 LST3000-08000 Left Fender 1

35 LST3701-08000 Tire 2

36 9301-08000-DX Flat Washer Ø8 10

37 LSP25-00020-FH Hex Slotted Thin Nut M20 2

Parts Drawin

g

& Parts List

- 20 -

Ref# Drawing No. Description Qty

38 LST37-00012-DX Angle Connector 1

39 LSA22-03001 Slider 2

40 9404-03030-DX Cotter Pin Ø3x30 2

41 LSP25-00009-DX Axle Cap 2

42 LSP30-00006 Rubber Washer 1

43 LSP25-10008-FH Steel Wire Snap Ring for Shaft 1

44 LST3000-03000 Hydraulic Reservoir 1

45 9301-06000-DX Flat Washer Ø6 6

46 9101-10075-DX8.8 Hex Bolt M10x75 4

47 9101-06020-DX8.8 Hex Bolt M6x20 6

48 LSP25-15000-DX Filter Fixed Plate 1

49 LST3000-02000 Cover 1

50 LST3000-09000 Right Fender 1

51 LSP25-00011-DG Clamp 2

52 LSA22-00025 Plate 1

53 LST37M-00002 Clear Oil Pipe 1

54 9301-20000-DX Flat Washer Ø20 2

55 LSP35-00001 Polyurethane Block 4

56 LSP25-00003-DX Spring 2

57 9101-08025-DX8.8 Hex Bolt M8x25 4

58 9302-10000-DX Large Flat Washer Ø10 4

59 LST3000-05000 Support Leg 1

60 9304-62000-FH Circlip for Shaft Ø62 1

61 LSP25-00008-DX Latch Pin 1

62 LST3700-04000 Tow Bar Assembly 1

63 LSP25-11000-DX Chain 2

64 9110-08010-DX Screw M8x10 4

65 9301-12000-DX Flat Washer Ø12 18

66 Z105 50mm Coupler 1

67 LSP25-00022 Oil Filter 1

68 LSP25-00015-DX Thick Washer 2

69 9101-12110-DX8.8 Hex Bolt M12x110 1

70 9306-06000-DX Lock Washer Ø6 6

71 9901-17X2.5 O Ring Ø17x2.5 2

72 9101-08030-DX8.8 Hex Bolt M8x30 4

73 9404-04036-DX Cotter Pin Ø4x36 2

74 9206-14000-DX Nylon Lock Nut M14 1

75 Gear Pump Flat Key 1

Table of contents

Other TOPMAQ Log Splitter manuals

Popular Log Splitter manuals by other brands

Full Boar

Full Boar FBLS-22T instruction manual

Bell

Bell TURBO 8 E Manual for use and maintenance

Tajfun

Tajfun RCA 400 joy operating instructions

Swisher

Swisher L112-182001 owner's manual

Champion Power Equipment

Champion Power Equipment 90720 Owner's Manual and Operating Instructions

Gardeo

Gardeo GFBHT65-22TBSI/C Original instructions