TopNotch Products SPUNKY User manual

SPUNKY

ASSEMBLY MANUAL

Please read the tips section at the back of this manual regarding the

use of laser cut parts. The proper removal and preparation of these

parts is important. When laser cut, some materials may exhibit some

charring of the edges. This is especially so on composite materials

such as plywood. When gluing these parts at the laser cut edge it is

important to use the correct adhesive. It is recommended that you

use only medium or thick Cyanoacrylate (CA), Aliphatic resin or

Epoxy on these joints. Use of thin CA may not give you a strong

bond. The thin CA may only penetrate the thin layer of charred ma-

terial before it sets, yielding a weak bond. Thick and medium CA,

Aliphatic Resin and Epoxy will allow time for the adhesive to pen-

etrate the char and bond to the material for a stronger joint.

p

Step 1

Glue a strip of 3/8” triangle stock along

the top edge of both fuselage sides

on the labeled side. Be sure to align

the stock with the recessed edge as

shown. Also add triangle stock to the

bottom fuselage edge for and aft of the

wing opening. Note the markings on the

fuselage, they indicate where to stop the

triangle stock.

p

Step 2

Mark the back side of a piece of triangle

stock as shown and cut it on these lines.

Then ip the triangle stock around and

glue it onto the fuselage aligned with the

notches in the front edge of the fuselage,

see the photo in step 3.

p

Step 3

The fuselage sides should look like this.

The triangle stock at the front of the

fuselage will support the motor mount

when installed. Note that the triangle

stock is aligned with the notches, not the

end of the fuselage.

p

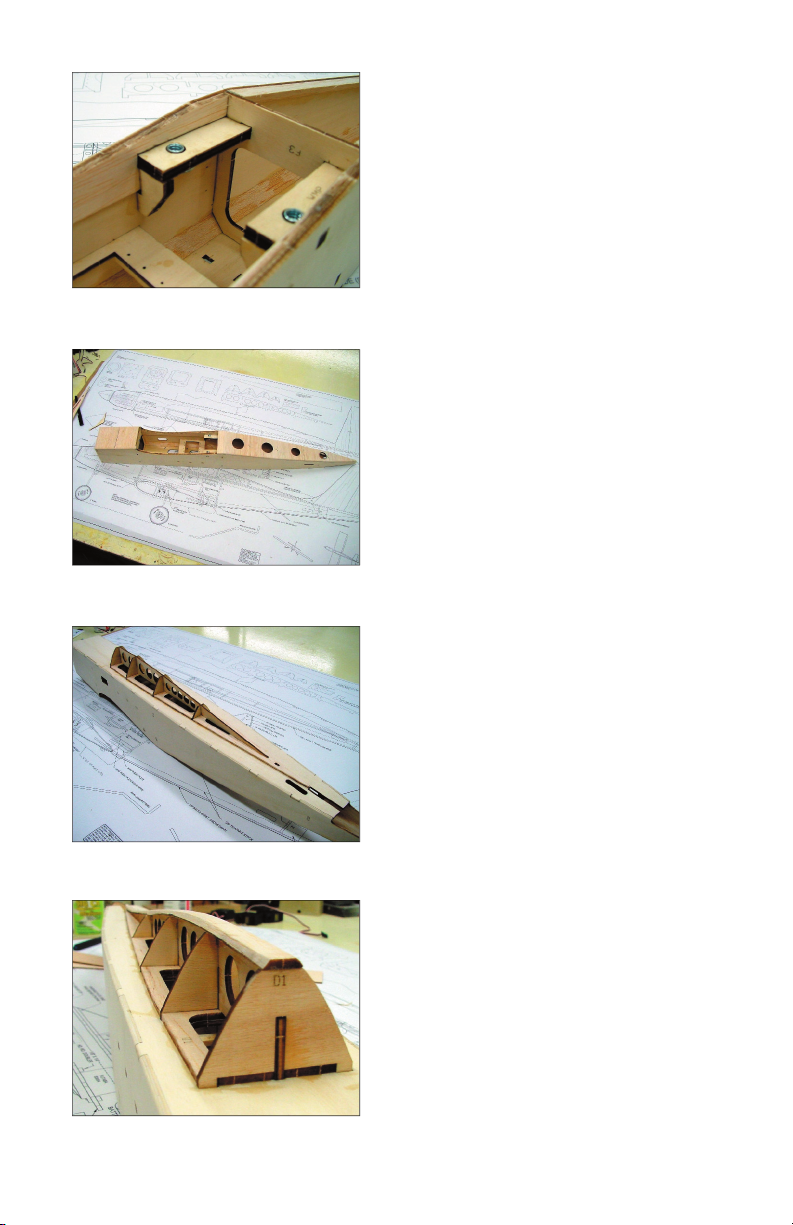

Step 4

Assemble F-2 and F-2A as shown, use

a 1/4” drill bit shank to assure the dowel

holes line up with each other and the

two parts are aligned along the opening

in the center. Do not use a wood dowel

to do this as it may become permanently

glued. Also glue two pieces of 1/8” x

1/4” spruce to the top of the servo plate

along the screw holes, this will provide a better grip for the servo mounting

screws.

1

p

Step 5

Lay one fuselage side at on the bench.

Install F-2, F-3 and the servo plate into

their perspective notches. Assure that

the triangle stock does not interfere with

the parts making good contact with the

fuselage. If so trim it back until contact is

assured. All former labels must face the

front of the fuselage.

p

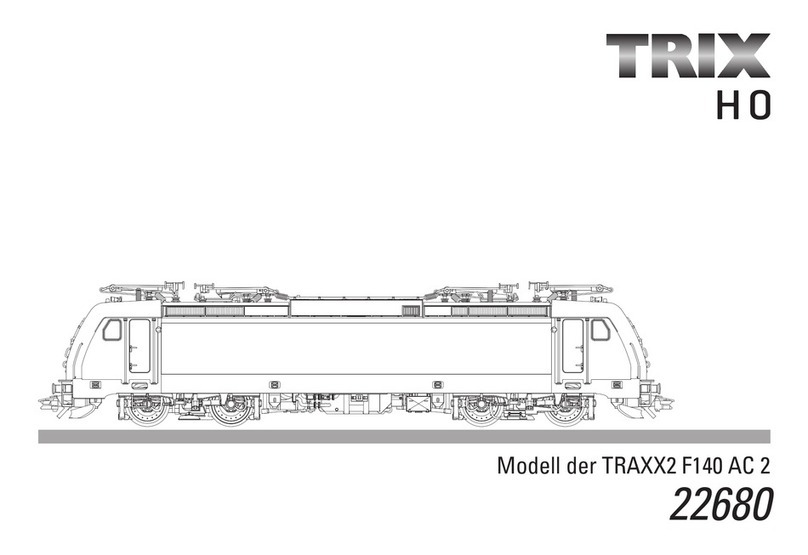

Step 6

When correct t is obtained, glue all

three parts to the bottom fuselage half

using the top fuselage half to apply

pressure. Then ip the assembly over

and glue all three parts to the other side.

Run a bead of medium CA along all

joints for added strength.

p

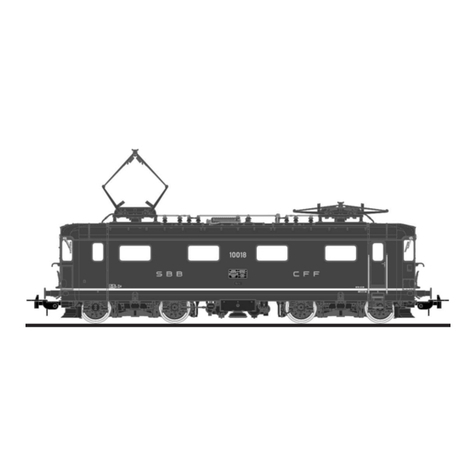

Step 7

Measure 2-1/2” from the fuselage end

and mark the inside of the triangle

stock. Then draw a line from that mark

to intersect with the fuselage side as

shown. Remove the triangle stock

along this line as shown to allow the tail

section to come together. Install F-4 but

do not glue it yet. Carefully align the tail

sections and glue them together.

p

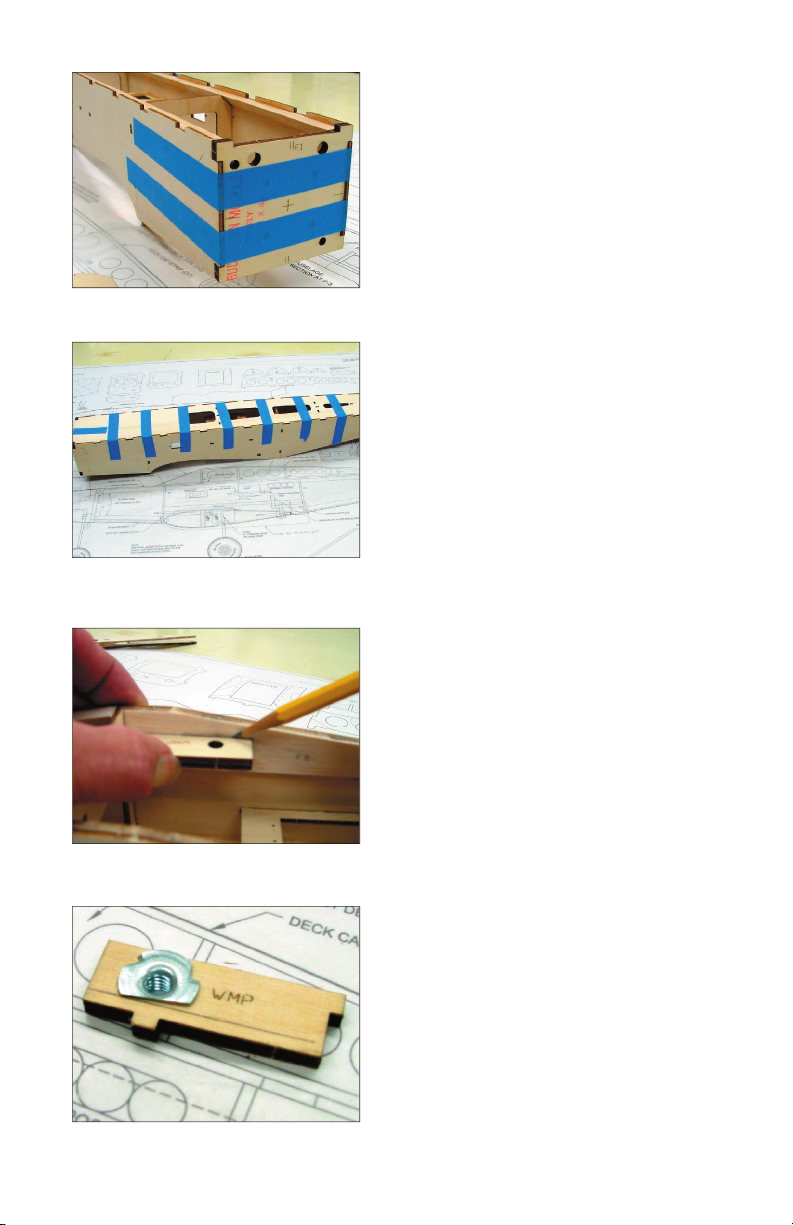

Step 8

Install four #4-40 blind nuts into four of

the 1/16” ply pads and then glue these

assemblies to the back of the rewall in

the motor mount holes. The labeling is

on the front of the rewall.

2

p

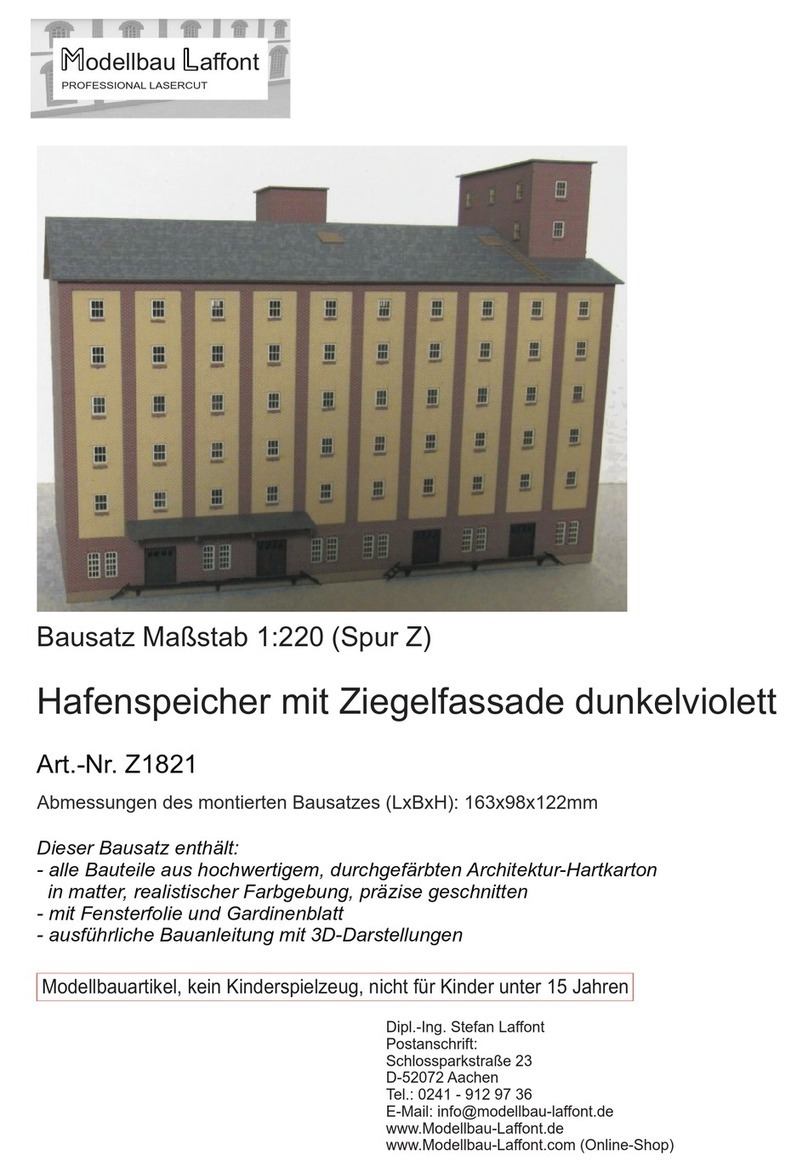

Step 9

Use Epoxy to install the rewall onto the

fuselage. Use masking tape to assure

good contact between all parts. Note

that 1-1/2° of right thrust is built into the

rewall.

p

Step 10

Test t the fuselage top and then use

an adhesive that will give you time to

pull the top and sides snugly together

and hold it there with masking tape until

cured, such as aliphatic resin. Now glue

F-4 permanently into position.

p

Step 11

Glue on the 1/8” Balsa wing saddle

doublers and then snap the wing mount

plates temporarily into position. Draw

a line along the fuselage side onto the

wing mount plates.

p

Step 12

Trim the anges of two #1/4-20 blind nuts

to the line as shown and install them into

the wing mount plates. Be sure to make

one left and one right. Then Epoxy these

plates into the fuselage sides with the

blind nut anges facing the top of the

fuselage.

3

p

Step 13

Epoxy the wing mount plate braces in

place as shown. Then ip the assembly

over and add a 1-1/4” piece of triangle

stock gusset to the top of each wing

mount plate. You can access this

through the holes in the fuselage top.

p

Step 14

Assemble the 1/8” bottom sheeting for

the tail section and the 1/4” sheeting

for the forward bottom section and glue

in place. Now is the best time to sand

all sides of the basic fuselage smooth.

Sand all corner radius’s at this time as

well.

p

Step 15

Assemble the top deck plate and

formers, D-1 through D-4 and the top

deck keel in place in the fuselage top.

Glue this assembly in place.

p

Step 16

Glue the top deck cap strip on and trim

the edges to the contour of the formers.

Install the 1/16” side sheeting by gluing

along the deck plate at the fuselage top

rst. Then lay it over and glue it along

the cap strip. You can glue it to formers

D-1 through D-4 through the openings in

the top from the bottom of the fuselage.

4

p

Step 17

Trim and sand the top deck to shape as

shown and then add the cockpit oor.

Angle sand the cockpit oor as shown

to accept the windshield later. The basic

fuselage structure is now complete.

p

Step 20

With the wing plan on the building board,

align a straight edge with the leading

edge of the spar and secure it there with

pins. Now butt the 1/4” Square balsa

spar up against it and glue a pinning

tab to the back of the spar. Pin this tab

securely to the building board. Place

one of these tabs at every other bay.

5

p

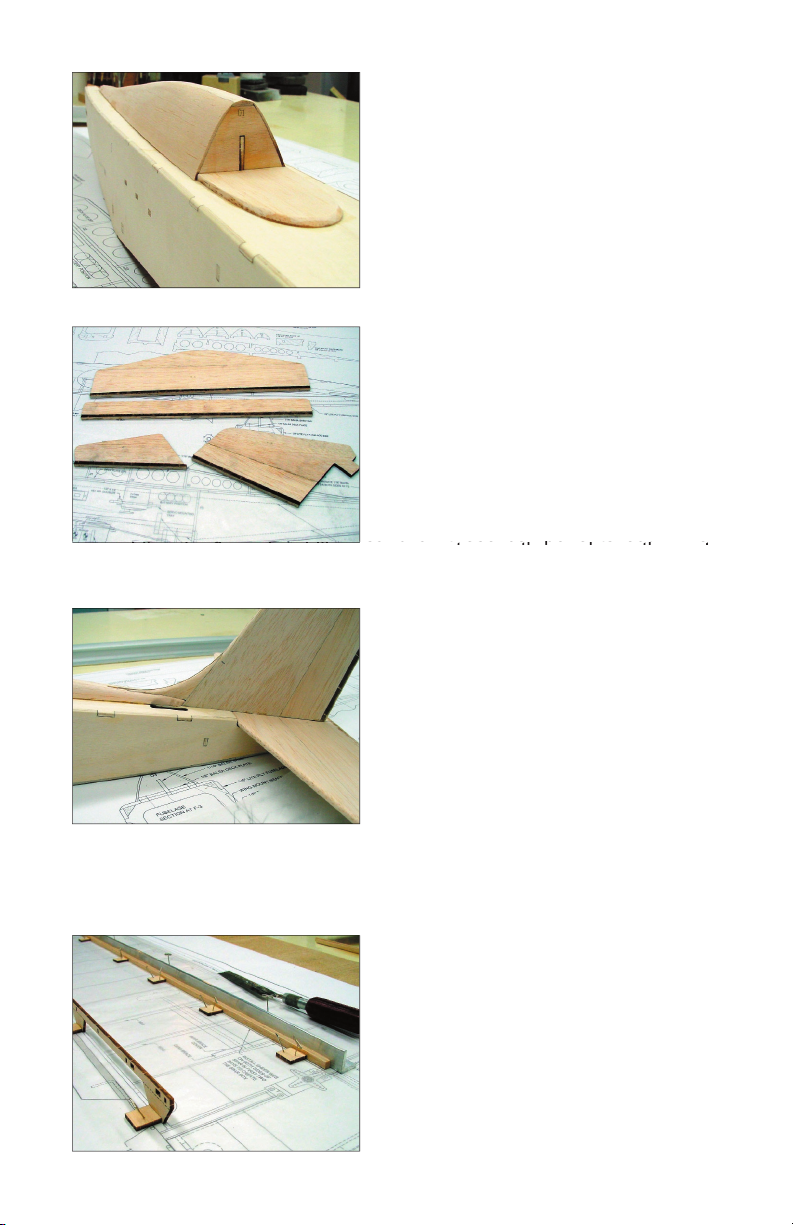

Step 18

Glue the stabilizer sections A & B and

the stabilizer trailing edge together. Glue

the elevator and elevator trailing edge

together. Glue the vertical n sections

A & B together and then glue on the

vertical n trailing edge. Glue the rudder

and rudder leading edge together and

sand all these components out. When

assembling the n and stabilizer components, use the marks on the parts

sand all these components out. When

assembling the n and stabilizer components, use the marks on the parts

sand all these components out. When

assembling the n and stabilizer components, use the marks on the parts

assembling the n and stabilizer components, use the marks on the parts

assembling the n and stabilizer components, use the marks on the parts

for alignment.

p

Step 19

Use the center line marked on the

stabilizer assembly to align the stabilizer

on the stabilizer saddle. Butt the stabilizer

up against the fuselage top. Check that it

is perfectly horizontal when the fuselage

is setting at on the bench and then glue

it on. Install the vertical n, check that

the trailing edge splits the center line

on the stabilizer and then glue in position. Use a generous application of

adhesive on the stub that butts up against F-4 inside the fuselage. You can

access this joint through the hole in the bottom sheeting.

Add pinning tabs to the break away feet on the false trailing edge and also

pin these rmly to the building board. Note that the 1-1/2° washout is set

by the false trailing edge. Be sure that the break away feet are at to the

building board while assembling.

6

p

Step 21

Assemble W-2, GB and GBC. Assemble

W-3 and W-3B. Assemble one W-4 and

W-4B. To assure a left and a right wing

set, assemble these components for

both wings at the same time. Making

sure to construct mirrored sets. That

way you can not go wrong. Also take

care to align the parts with each other.

p

Step 23

Glue the leading edge in place at W-1

and W-5. Then adjust each rib to seat

in the slots in the leading edge and glue

them. Now glue the ribs to the bottom

spar. When gluing W-1 and W-2, only

glue to the sides of the spar, not the

top.

p

Step 22

Glue sheer web SW-1 to the bottom spar

observe the correct orientation of the

dihedral angle. Align it to the line for W2

on the plan. Install W1 using SW-1 to set

the dihedral angle. Install WBP and the

W2 assembly. Proceed down the false

trailing edge installing the remaining ribs

and glue them to the false trailing edge

only at this time.

p

Step 24

Carefully remove the material between

the top and bottom spar notches at W-

1 and W-2. The spar opening has been

laser cut but a small amount of material

will have to cut to make this opening.

p

Step 25

Install the top spar and use the spacers

provided when gluing to W-1 and W-2.

Apply a bead of medium CA to all wing

joints at this time.

p

Step 26

Add the 3/32” sheer webbing the full

length of the wing at the front of the spar.

Add 3/32” sheer webbing between W-1,

W-2 and between W-2, W-3 to the back

of the spar. This will form the spar box.

p

Step 27

Install the 1/4” wing bolt seat onto the

wing bolt plate. You will also add one

of these to the bottom of the wing later,

do not shape these to the contour of the

wing. They will provide a perfectly at

surface at 90° to the bolt orientation for

seating the wing mounting bolt.

7

p

Step 28

Glue on the laser cut 1/4” trailing edge,

make sure the laser cut hinge slots are

facing aft and the root and tip are oriented

correctly. The root has a larger slot cut

for the aileron linkage installation. Sand

the trailing edge and false trailing edge

to the contour of the wing and then add

the 1/16” balsa trailing edge sheeting.

p

Step 29

Mark the exact center of the top spar and

insert a pin at each end at that location.

Use medium CA to glue the leading

edge sheeting along the entire length of

the top spar using the pins to align it. Do

not apply any glue to the ribs at this time.

We will do that in the next step.

p

Step 30

Remove the wing assembly from the

building board and snap off the pinning

tabs and breakaway feet on the false

trailing edge. Starting at the center of

the wing lay the leading edge sheeting

against the ribs and glue it. Lay the

sheeting at on the leading edge and

glue it in that position. When nished,

trim off the excess sheeting ush with the leading edge. Turn the wing

assembly over and repeat steps 28, and 29. When installing the bottom

leading edge sheeting apply aliphatic resin glue to the each rib from the

spar to the leading edge, but not the leading edge. Use medium CA to glue

the sheeting to the main spar and then proceed by pulling the sheeting

at against the leading edge and gluing with CA as you did on the top

sheeting. When nished the leading edge should look like the photo.

Put this wing half aside and repeat steps 20 through 30 for the remaining

wing half.

8

p

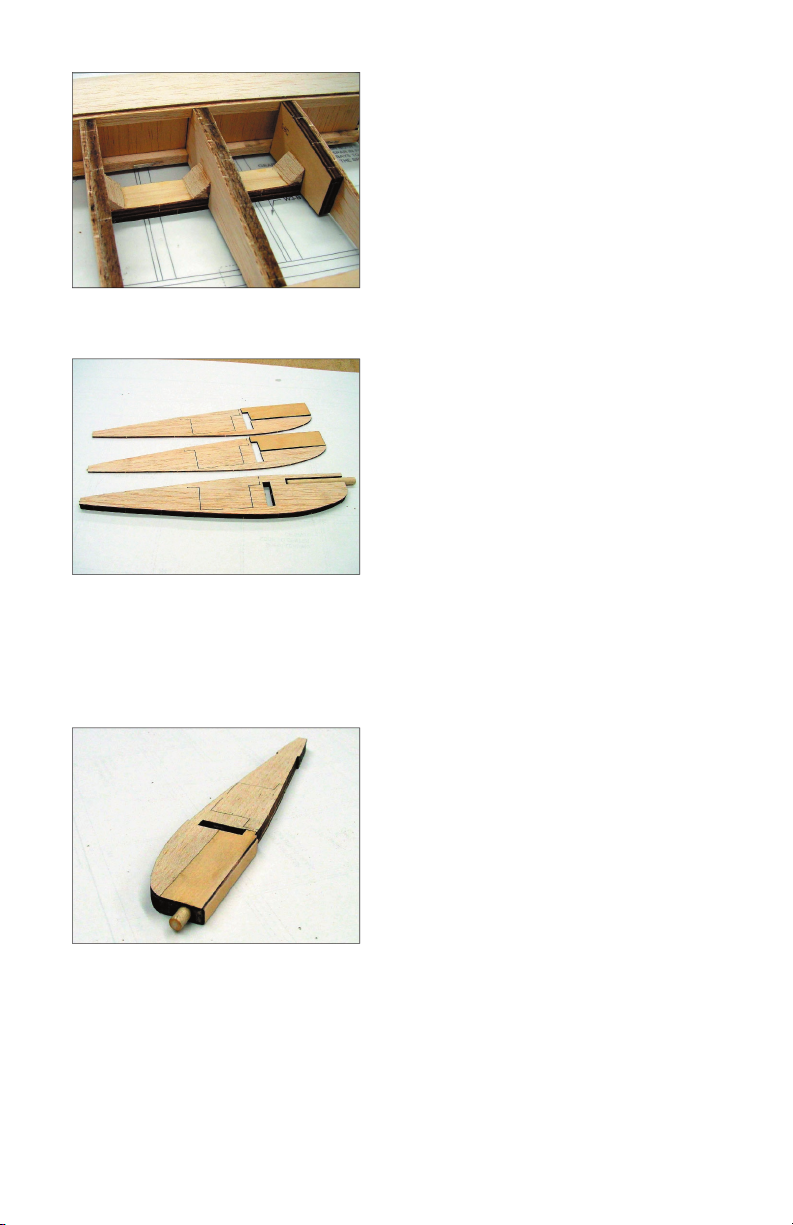

Step 31

Assemble the 1/4” ply main gear mount

and the 1/8” ply main gear mount retainer

plate. The end of the slot in the retainer

plate aligns with the hole in the main

gear plate. Install this assembly into the

notches provided in WGB, W3-B and W-

4-B. The end of the assembly with the

hole in it should be pointing toward the

p

Step 32

When assembling the wing joiner, use a

generous amount of Epoxy to install the

wing dowel and the wing dowel cap. Use

adhesive sparingly around the servo

knockout cuts.

The wing joiner is assembled from six

parts, they are the 1/4” core, two 1/16”

balsa sides, two 1/16” ply sides and a 2-

1/2”x 1/4” dowel. This assembly performs

several functions, in addition to aligning

the wing incidences it provides a secure

elevated mount for the wing dowel and

also serves to support the aileron servo.

A knockout for the aileron servo opening has been cut into all the required

parts. When assembling the wing joiner, do not allow adhesive to get into

the knockout cuts. If you do they will be dif cult to remove. You can use

thin CA to rm up all these parts after the knockout has been removed.

NOTE:

root of the wing. Add some triangle stock gussets to the top of the landing

gear block a shown.

9

p

Step 33

Assembly sequence of the wing joiner.

Apply Epoxy in the spar box, on the

spar, to the joiner and ribs forward of the

spar and to the joiner and ribs at least 1”

behind the servo knockout. Make sure

both wing halves align at the trailing

edge and secure in that position with

pins until cured. Long strips of masking

p

Step 34

Install the forward bottom center section

sheeting next. In this photo, the openings

for the landing gear blocks have not

been cut, They are now laser cut into the

bottom forward center section sheeting

and it need only be placed in position

and glued.

p

Step 35

The top and bottom center section

sheeting has been cut slightly oversized

to accommodate variations in positioning

of the leading and trailing edge sheets

by the builder. Butt the back sheet up

against the trailing edge sheeting and

mark where they overlap, trim and

install.

p

Step 36

Trim the retainer tabs on the servo

knockout and remove the material at the

center of the wing joiner. This works best

if you remove the material one layer at

a time. After removal, harden this area

with some thin CA.

tape pulled taught along the leading and trailing edge sheeting work great

for pulling the wing halves together.

10

p

Step 37

Glue the aileron servo tray into position

and brace it with some triangle stock

gussets as shown. NOTE: Not shown

here, install the two sheet support rib

sections to the top of the servo tray

along both sides of the servo opening.

These supports look like the drawing

below.

p

Step 38

Install the top sheeting and then

temporarily install the aileron servo.

The top sheeting has holes cut into it for

the servo and the servo cable exit. You

will need to enlarge the servo hole to

accommodate your servo.

p

Step 39

Assemble the ailerons and aileron

leading edges, sand to shape and then

test install the hinges and the aileron

linkage. The aileron horn bearing will

need to be trimmed some to avoid hitting

the wing bolt plate. Then Epoxy in place.

NOTE: All hinge slots are laser cut but

you will need to increase the depth of

these slots by about 1/8”.

p

Step 40

Aileron installation should be straight

and tight. Allow only a minimum gap

between the wing and the aileron for

smoothest aileron effect. Permanently

attach only after covering.

11

p

Step 41

Du-Bro steel landing gear straps are

used to retain the landing gear leg.

p

Step 42

When opening up the cowl, give the

motor plenty of space for cooling air.

This is a berglass cowl fabricated

for the prototype model. Install the

mounting screws so they screw into

the 1/4” ply rewall and then harden the

holes with CA.

p

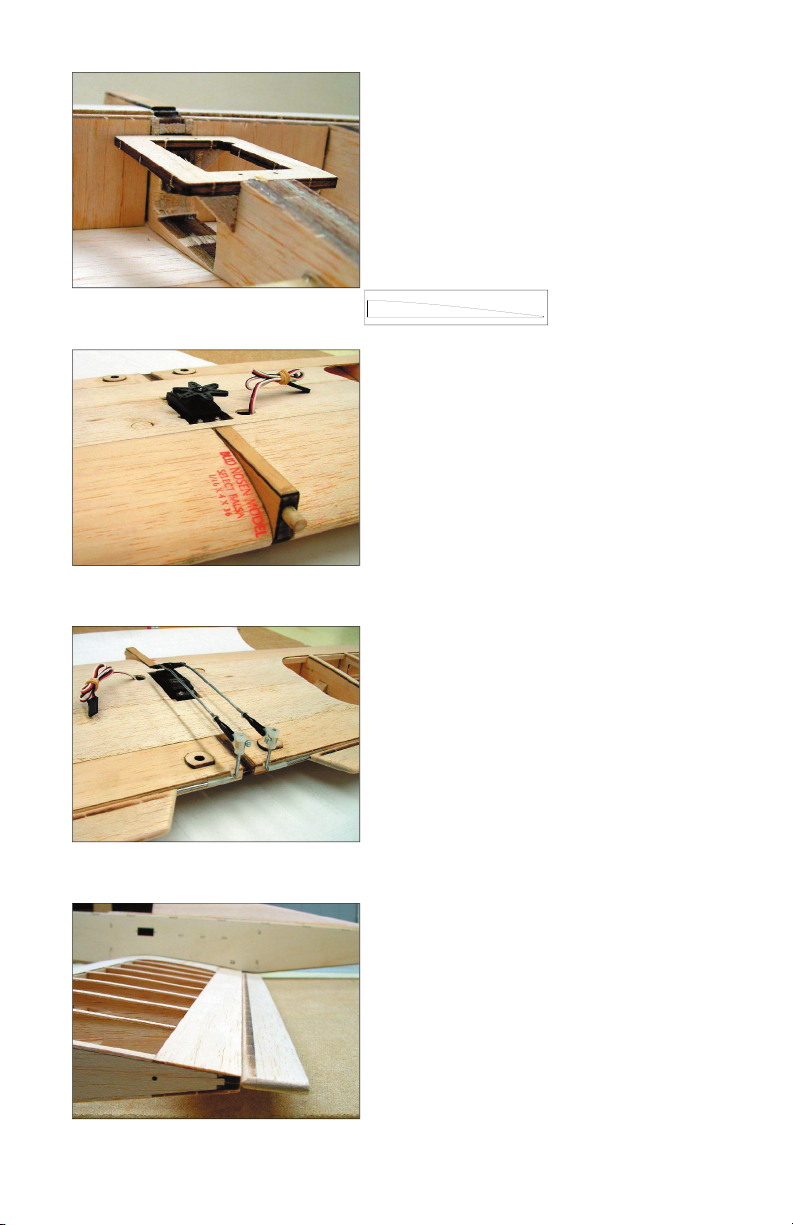

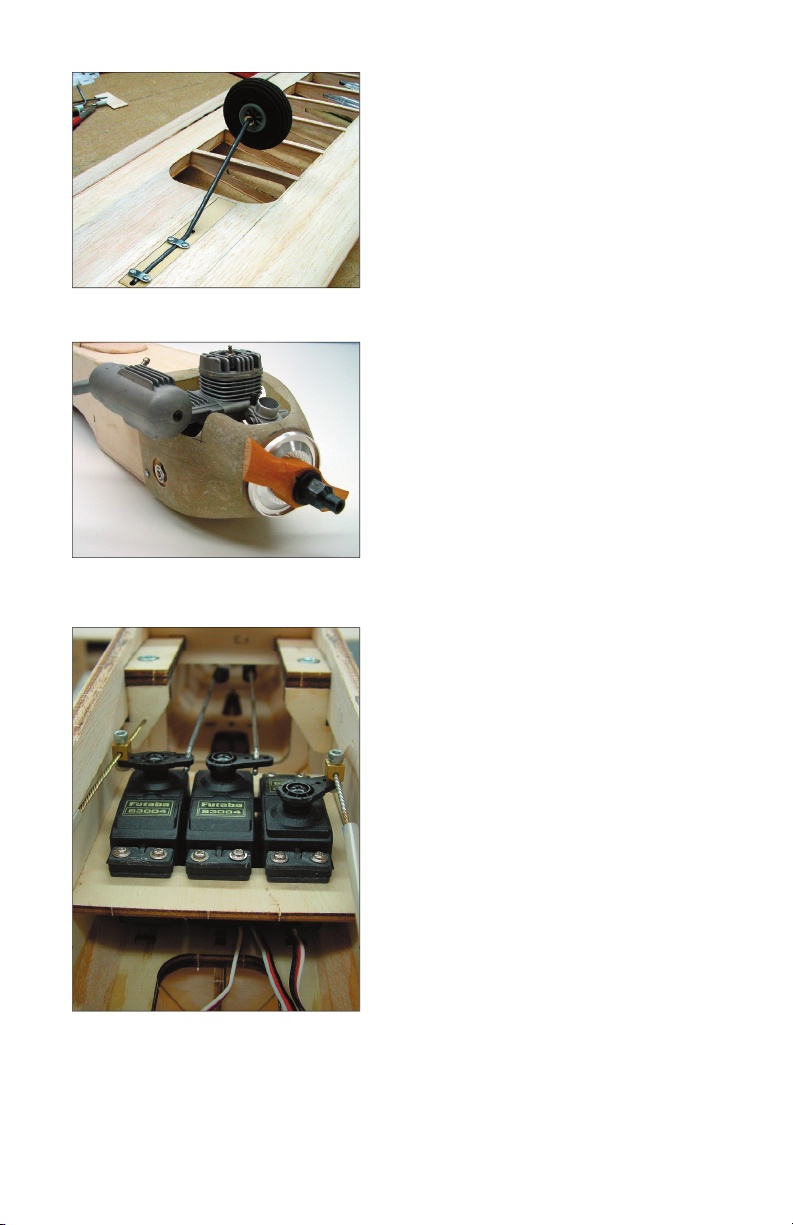

Step 43

Installation of the servo’s. Note that the

center push rods utilize a Z-bend to

maintain a low pro le to allow space for

the aileron servo. Make sure all linkages

are snug with no play. Note that a small

amount of material was removed from

the fuselage doubler to allow clearance

for the throttle linkage connector block.

Temporarily install all linkages, the motor

and the fuel system before covering. You

may have to remove a small amount of

material at the corner of the rewall for

muf er clearance depending on your

choice of motor.

12

Other TopNotch Products Toy manuals

TopNotch Products

TopNotch Products MINI SUPREME User manual

TopNotch Products

TopNotch Products Seamaster II User manual

TopNotch Products

TopNotch Products Mooney M-18 User manual

TopNotch Products

TopNotch Products Li'l Pup User manual

TopNotch Products

TopNotch Products Maverick User manual

TopNotch Products

TopNotch Products BUSH HAWK XP User manual