Seamaster II Fuselage Assembly

Locate and prepare the two fuselage sides (FS).

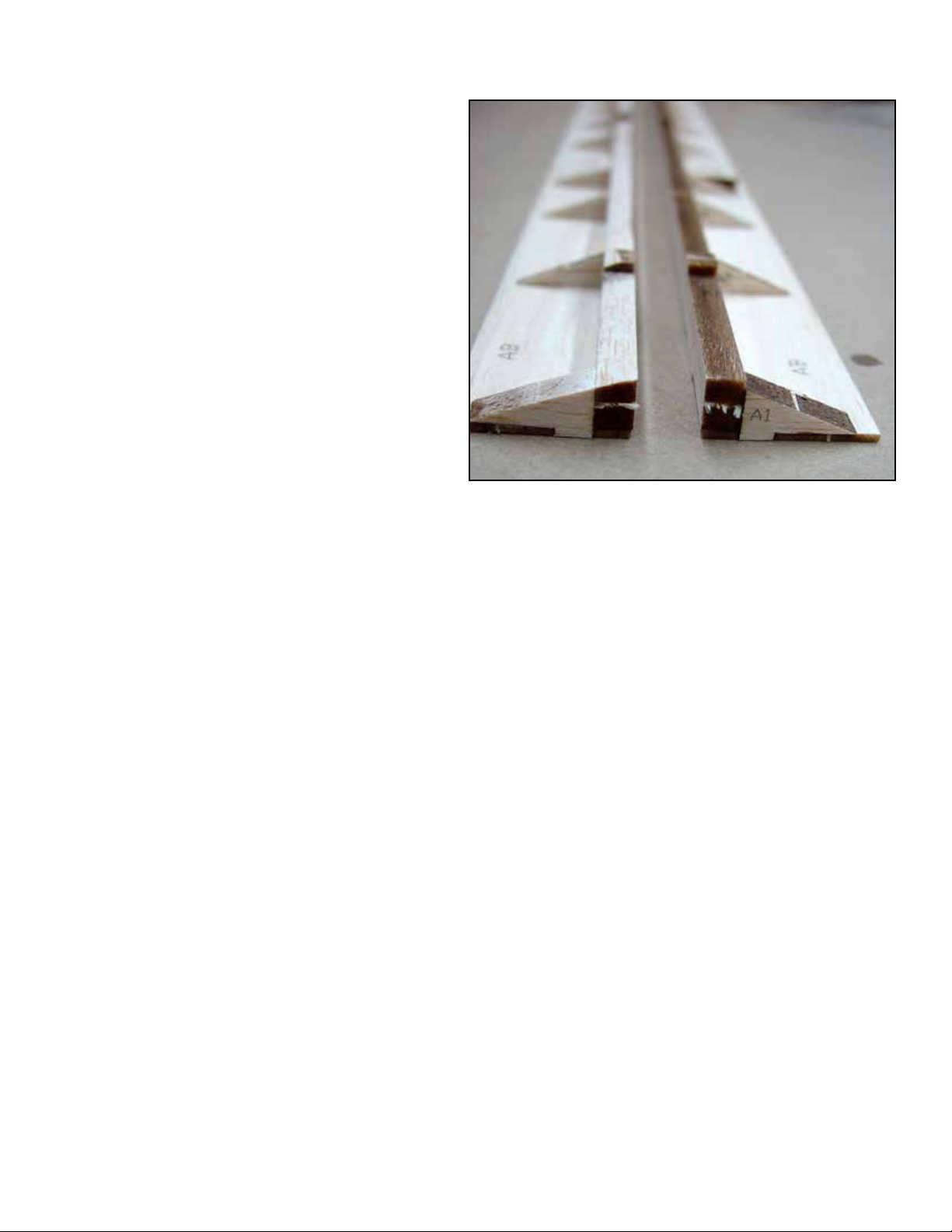

Lay them on the workbench with the tops fac-

ing each other (back to back, see photo).

c 1

c 9

c 5

c 4

c 3

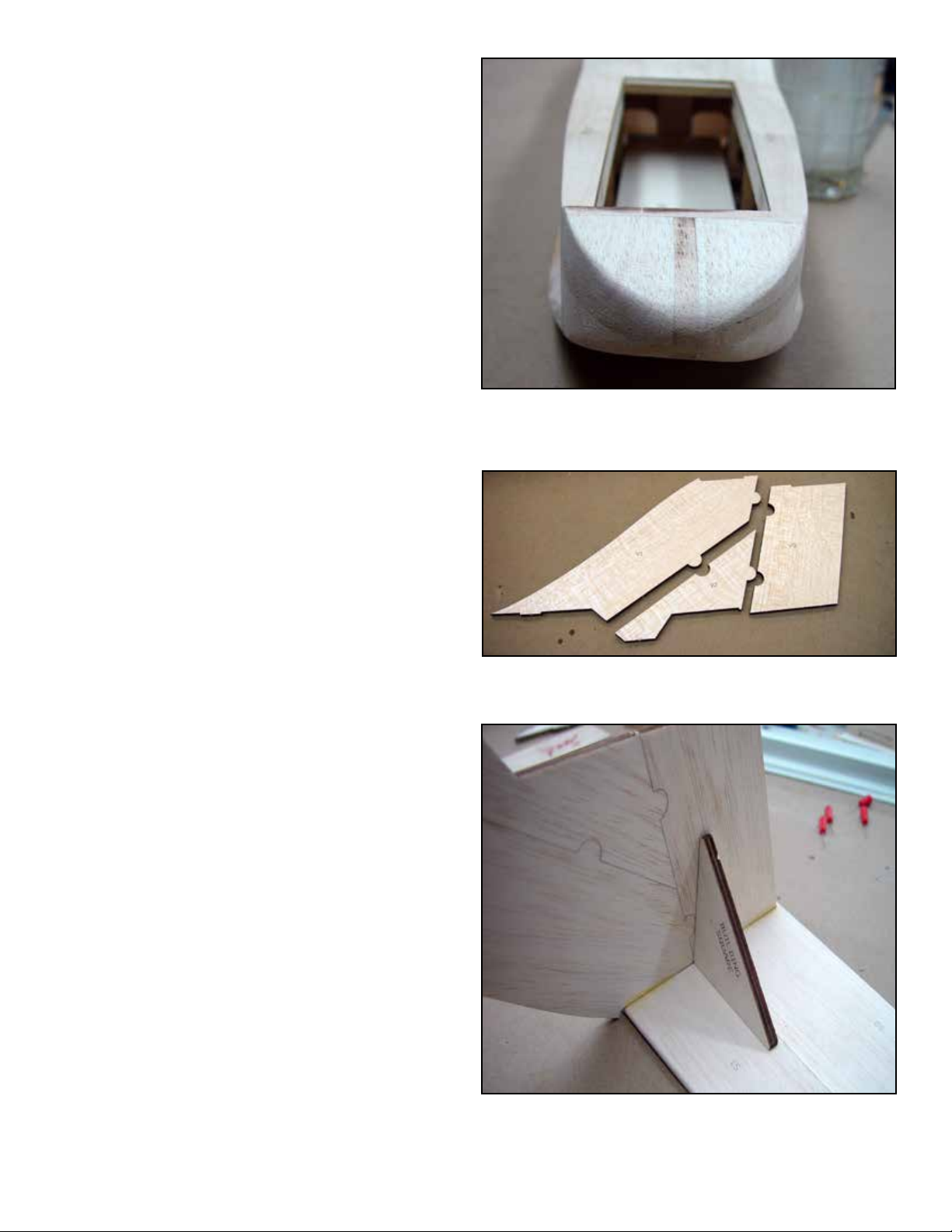

c 2Locate and prepare the wing saddle doublers

(WS).

Use the Registration Pins to install and glue it

to the fuselage sides. Note that you will make

a LEFT and a RIGHT fuselage side. See the

photo.

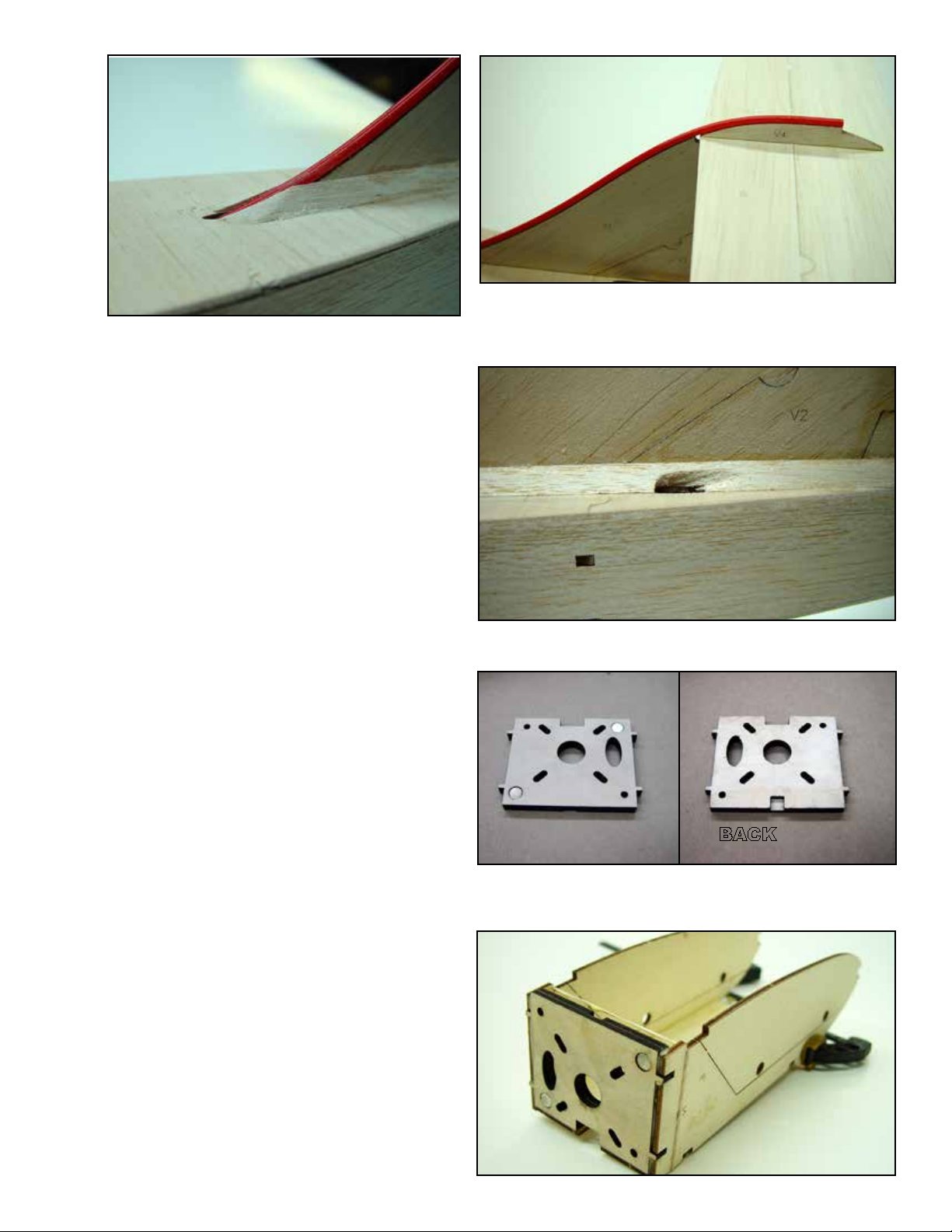

Locate the Fuselage Servo Tray (FST) and two

3/16” x 3/8” x 4” basswood rails. Note that

FST can be congured for standard size servos

(remove the dash cut area) or for micro servos.

Determine which you will be using and cong-

ure it appropriately. Glue the basswood rails to

the edge of the servo opening to provide mate-

rial for the servo screws. Glue them in position.

The left and right fuselage sides are laid out and the wing

saddles are installed using the registration pins.

Now is a good time to mark and drill the pilot

holes for the servo mounting screws.

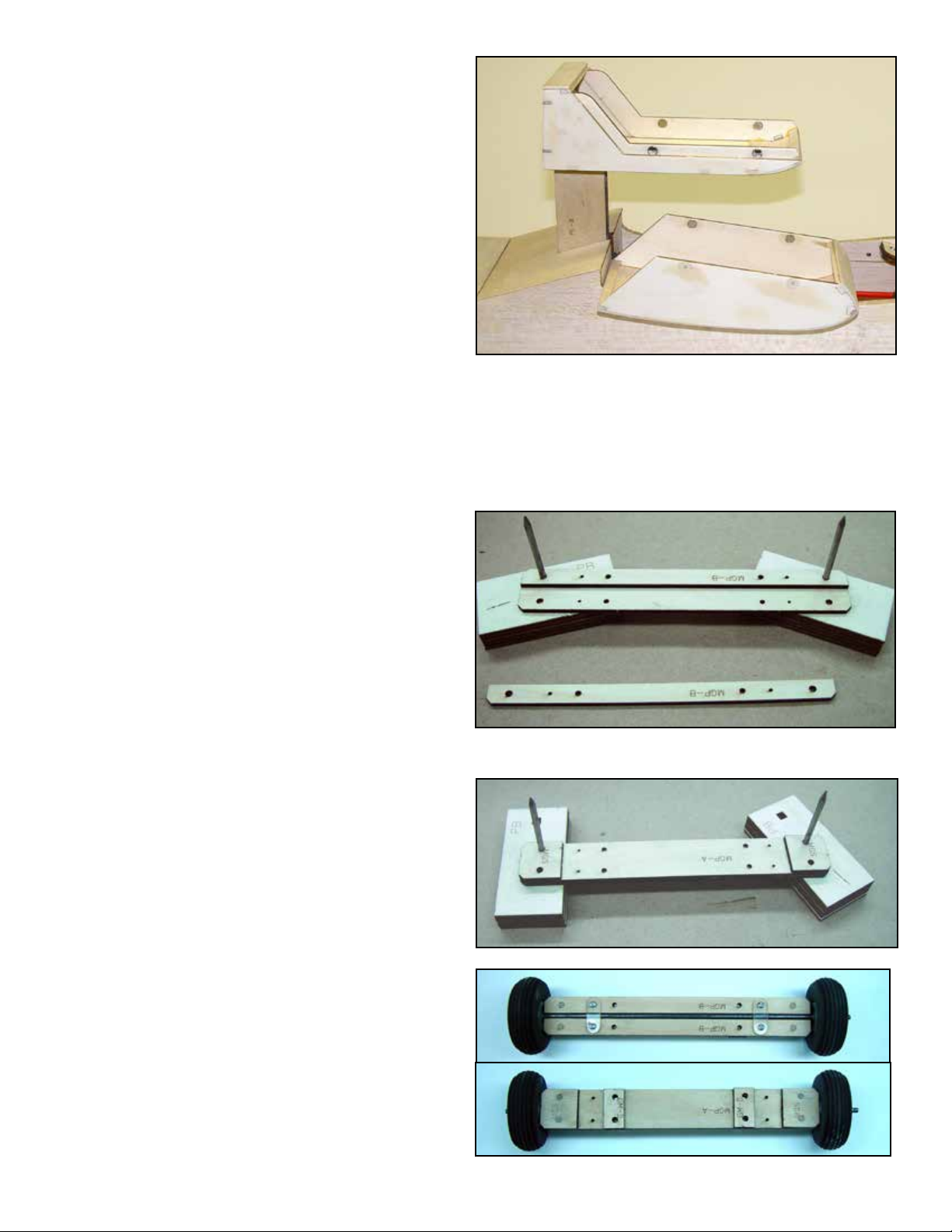

c 6Install and glue the Fuselage Servo Tray assem-

bly to F5 and F6, note that the servo tray screw

rails should be on the bottom.

c 7Glue the F5 and F6 assembly to the RIGHT

fuselage side.

c 8Locate the Wing Mounting Plate and two #10-

32 blind nuts. Press the blind nuts rmly into

the holes provided in WMP.

Because WMP and F8 interlock it is best to

install them at the same time. First install and

glue WMP into the notches in F8 and then glue

this assembly to the fuselage side. Note that the

anges of the blind nuts should be facing down.

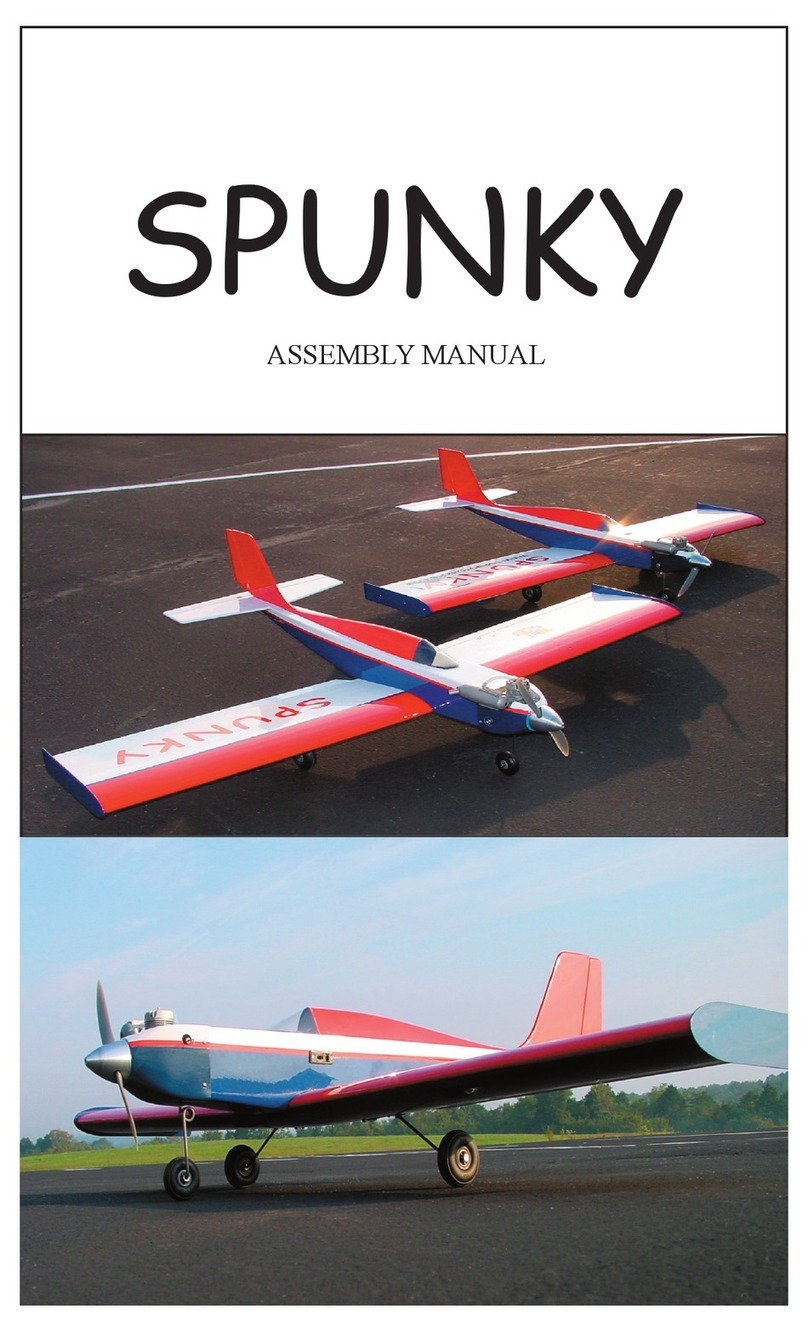

ABOVE: The servo tray can be congured to t standard or mini

servos. Remove the dash cut material for standard servos.

BELOW: F5, F6 and the servo tray assembly.

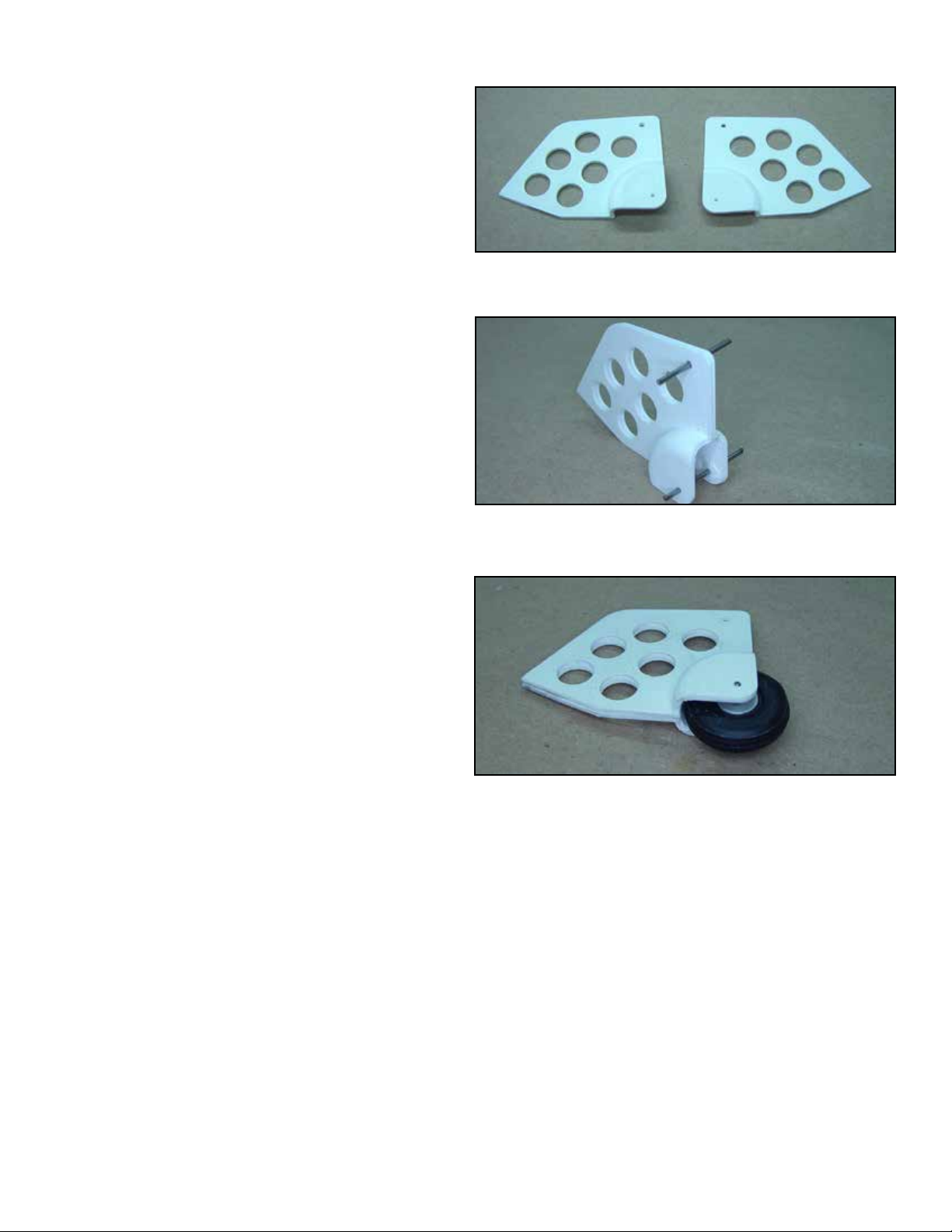

c 10 Test t the le fuselage side to the right fuselage

side assembly. When all notches and tabs are

aligned, apply glue and secure the two halves

together.

Note: Make sure the fuselage assembly is at on the

building bench. Weight the assembly down until the

glue cures to insure a straight fuselage.

c 11 Locate F1, note the dashed line at the bottom,

and sand the bottom to taper from back to front

down to the dashed line. is will conform to

the curve at the bottom of the fuselage side

when installing the fuselage bottom.

Here only half of the bottom of F1 has been beveled to the dashed

line to accommodate the curved bottom sheeting. Leave the tab

until after the sheeting has been attached.

2